This month I’m taking a step back from doing the usual aircraft-related project to look at some “off the grid” projects that take advantage of the knowledge, skills and abilities that are gained through the homebuilding process. I call them alternative energy projects (AEPs).

AEPs are just the thing for those days when you’re not able to work on your airplane, but still itching to be in the shop. Maybe you are waiting for parts, or the helpers you need can’t come. Whatever the case, it’s an opportunity for an AEP.

AEPs can be anything, made from anything and as simple or complex as you want. They can be functional or artistic and usually start out from scrap material or surplus parts. While it’s cool to make an AEP out of 100% scrap or surplus, there are, of course, no rules. For example, if your AEP needs a base or a frame or whatever to make it more appropriate to, say, display in the house instead of the shop, then by all means make a special base.

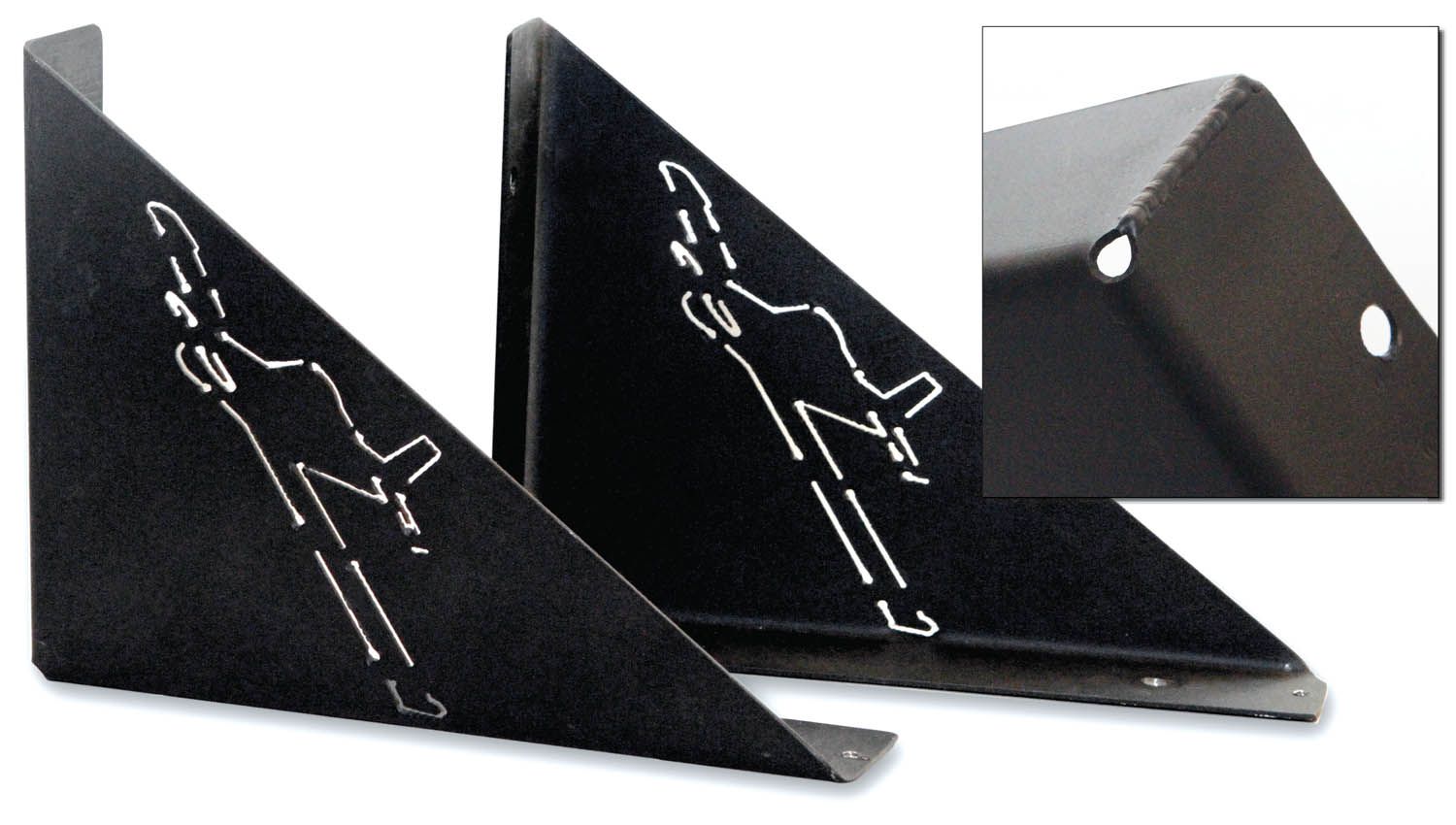

The same goes for drawings. Most AEPs are freestyle projects with no drawing or plans. You just start making them and see how they end up. But if you get into it and decide that a sketch will help, by all means do a sketch. The shelf brackets shown here are a good example. The brackets themselves were made freestyle, but the decorative silhouette took some figuring and playing around with my CAD program (Solid Edge) to make it work.

Shelf brackets are an easy AEP. All you need is some scrap sheet metal and a bender. Make them whatever size you need, small and short for storing small parts or big and long for bulky items. The shelving can be 3/4-inch plywood or 2x6s. Use whatever you have. If using plywood, keep the length reasonable for whatever you intend to store on the shelves. Plywood will sag pretty easily if you overdo it.

I made several sets one afternoon because I needed some shelving to inventory miscellaneous aerosol cans, containers and parts that were in boxes on the floor. I used sheet metal screws to attach them to the corrugated metal siding of the hangar I used to rent. The outline of the airplane was incised using a plasma cutter before bending. The idea, of course, was to add something to make these otherwise simple brackets special. Absent the plasma cutter, I could have added similar artwork any number of ways, from painting the outline to using a sticker or even drilling a bunch of small holes to get the same effect.

Next up is an aircraft-inspired toilet paper holder made by Kevin Kane of Wingnuts Aircraft Service in Southern California. AEPs like this are a good way to advertise your fabrication skills. People can’t help but be impressed! This particular example is installed next to the throne at Daniel Wotring’s Aviator Flight Training facility at Cable airport in Upland, California.

One of my favorite AEPs is a display stand to show off a vintage prototype rolleron from an AIM-9 Sidewinder missile. Rollerons were the secret behind the Sidewinder’s stability. The sawtooth wheel acts as a wind-driven flywheel, whose gyroscopic effect turns the device into an anti-servo control surface. Attached to the trailing edge of the rear stabilizing fins, it automatically prevented the missile from rolling off axis while maneuvering toward a target.

My rolleron display is an example of taking an interesting gadget, in this case a vintage part from a Sidewinder missile, cleaning it up and figuring out how to display it. This rolleron display is one of two that I made. They had been sitting in storage for 60-plus years at my dad’s shop. After Dad died, my brother, who took over the business, was cleaning out the “junk” and asked me if I wanted them. Rather than just setting them on the shelf, I did some research and decided to mount them in such a way that would not only showcase the rollerons statically, but also—with an air hose and ear protection—demonstrate how they function. This example is in my personal collection. The other used to be on display at the Foothill Flying Club office in Upland, California. Presently, its whereabouts are unknown.

Old engine parts make great AEPs. I’ve got some old VW cylinders that (one day) I plan to make into sconces. The mother of all AEPs is, of course, the complete radial engine coffee table, but since that’s more than an afternoon project for most, a more realistic AEP is Paul Dye’s Lycoming cylinder desk lamp. The cylinder is bolted to a wood base that was drilled for the power cord, sanded smooth and varnished. The light switches are mounted on plates in the intake and exhaust ports, and flexible lights are mounted in the valve guides. Super simple. Super cool.

That’s it for now. Time to get back in the shop and make some chips!