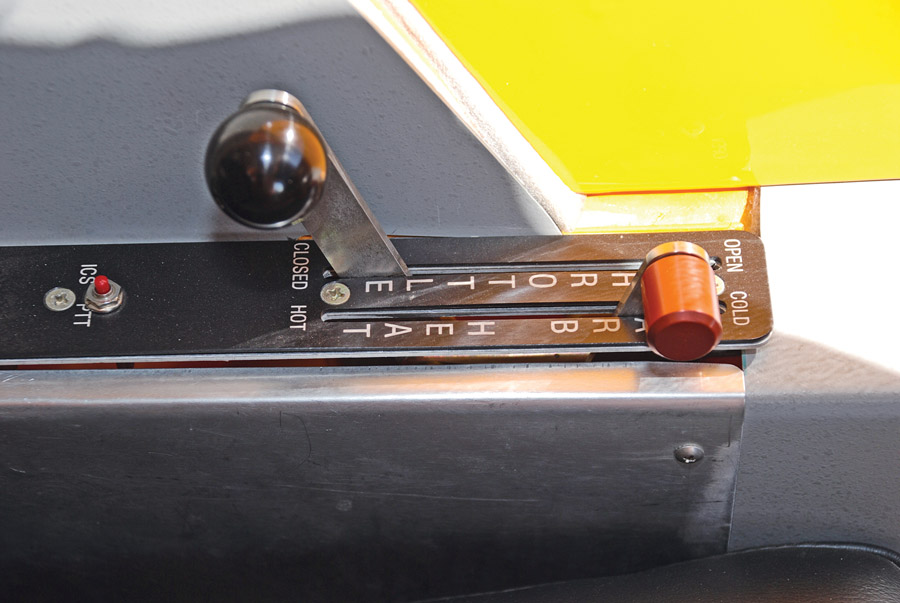

This is a standard layout for engine controls in a plane with side-by-side seating. The colors and styles of these controls are right out of the FAA recommendations for new certificated airplanes. Note the cushion on the throttle and prop controls. The fuel control is clearly marked and in easy reach of the pilot or copilot.

Cockpit controls provide the vital link between pilot and airplane. That link is best served by controls that are familiar and functional, which almost always means conventional. Every control should do what the pilot expects it to do in a manner that is familiar, because when thing get tense, people revert to their training and what is familiar to them. When the engine starts running rough, it is no time to try and remember which unmarked knob works the carburetor heat as opposed to that other little black knob that works the parking brake—or does it release the oil door on the cowl?

Here are some words that describe good controls: conventional, accessible, identifiable, secure, rugged, will hold a setting but easy to change when needed, and cover the full range of motion required.

The throttle in this Legend Cub is conventionally mounted and clearly marked on the left side of the cockpit. Since the engine in this plane has no mixture control, the carburetor heat control has been placed where the mixture would normally go. This is somewhat unconventional but clearly marked. It is a very convenient location for the carburetor heat control, but it would be important to brief any new pilot on this non-standard arrangement at the very least. In a certificated Cub this control is on the panel.

Conventional

I know it’s your plane, and you can do whatever you want, but my experience and the advice of many others says, “Be conventional.” If you don’t do it for your own sake, do it for the next guy who will own your plane someday. Controls should be where most pilots expect them to be and operate in a manner that most pilots would expect. An unconventional design may require something different, but even with an unconventional design, it is best to make as many things standard as possible. The life you save may be your own.

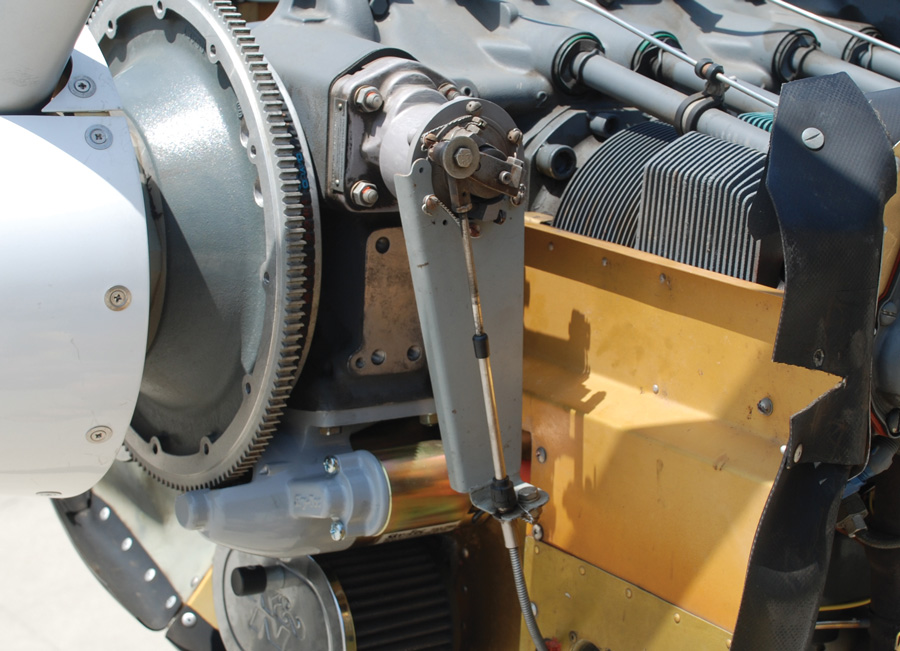

Here is a typical side throttle setup out of an RV-8 that is under construction. These are conventional in every sense, at least for the pilot. It is normal practice in the RV-8 to only extend the throttle to the rear seat where you will often find unconventional control knobs installed by creative builders. Note the friction lock low on the side of the control assembly.

Conventional means that engine controls in planes with side-by-side seating are grouped together in the center of the panel, well clear of the control sticks or yokes. The throttle should be on the left and have a black, smooth knob or handle, with a friction lock being much preferred to a vernier control. The prop control should be to the immediate right of the throttle and should feature a blue, fluted knob or handle. Vernier controls work well for the fine adjustments needed for a prop control. Then to the right of that goes the mixture control, which should be a red serrated knob also with a vernier or friction lock control. Carburetor heat, if required, should be clearly marked and near the throttle for easy application in case of a go-around.

Other similar controls such as cabin heat, parking brake, or other controls of this type should be well marked and well clear of the engine controls to avoid confusion.

In a plane with tandem (front-back) seating, the throttle goes on the left against the side of the cabin. There should be a black knob of some sort that will operate the carburetor or fuel injection servo through its entire range of motion with a little extra travel (cushion) to spare. You should never hit the limit of the throttle travel before you hit the limit of travel of the carburetor or fuel injection servo. If the throttle is part of a cluster of controls, then the throttle should be the leftmost and uppermost of the controls in the cluster. In other words, from left to right you should have the throttle, then the prop control, and then the mixture control, in that order. There should be enough friction to hold the controls in position by themselves. This is typically achieved by a knob that can be tightened or loosened as needed. These are the controls that you would expect to find in an RV-8 as provided by Van’s Aircraft. In that same RV-8 it is typical to provide only a throttle to the rear-seater. This control should be conventional in appearance and function.

Can you deviate from these recommendations? Yes, you can, but you cannot deviate from the requirement to have controls clearly identifiable as to their intended purpose. What about dual throttle controls such as you see in many Zenith airplanes? That’s acceptable if only one side has a friction lock and if both throttles smoothly open and close the carburetors through their full range of motion. I do not consider this an ideal arrangement, but with a center control stick, it is pretty hard to avoid. The basic guidelines are: keep it as simple as possible, keep it as conventional as possible, and make sure the function of every control is crystal clear.

Accessible

Controls should be easy to reach. This especially applies to fuel valves that are more likely than most to be put somewhere that is hard to reach. It should be easy to see which tank has been selected and that the fuel valve is in the correct position. Any location that requires an uncomfortable reach or taking one’s eyes off the instrument panel for more than a second can lead to control problems and vertigo in instrument conditions. The John Denver accident was a vivid demonstration of the perils of unconventional and inaccessible placement of a fuel valve. Google “John Denver accident NTSB report” if you have forgotten about or never heard of this tragedy.

Check to make sure your control stick does not hit or block access to the primary engine controls when operated throughout its full range of motion. Also make sure that controls cannot get stuck or tangled up with each other in flight. This could lead to tragic results.

Identifiable

Most people will use standard controls in standard positions for throttle, prop, and mixture, but those secondary controls—carb heat, alternate air, cabin heat, parking brake—can be confusing if they are all of a similar appearance. If it is not absolutely clear from position and appearance what a control does (and even if it is), they should be labeled clearly with their intended function.

The cabin heat knob in this plane is clearly marked and widely separated from the similar-looking carburetor heat knob. This helps to avoid accidental use of the wrong knob.

Labels can help with this, but so can position. For example, place the carburetor heat knob near the throttle for easy turn-off in case of a go-around. Make sure the cabin heat control is clearly marked and well away from the carburetor heat knob. The physical separation of the two controls will help avoid inadvertent application of the wrong control. Same for the parking brake. A different shaped knob can also help.

Make the flap switch look like a flap if you can and the gear handle look like a tire. These are typical configurations from the certificated world, and they apply just as much in the Experimental world. In all cases the goal is to avoid the inadvertent application of a control at a critical time.

This control rod end is secured with a castle nut and cotter pin for maximum security. Note the oversized washer that will prevent the nut and bolt from separating from the control arm if the rod end fails.

Secure, Rugged, Reliable

Given the importance of the basic controls, it should be obvious that they need to be secure, rugged, and reliable, but what does that mean? Secure controls must be properly routed to avoid damage and binding throughout their range of travel. They should be held at each end by solid brackets or structure. The engine end of controls need to be secured to brackets that are attached to the engine, rather than the airframe, because they must move with the engine.

Rugged and reliable controls must stand up to frequent use without damage or excessive wear. This will typically mean that control cables will be housed in plastic-coated metal sheaths (or sometimes uncoated). ACS makes many of these cables that can be ordered to a specific length to fit your plane. These cables will typically come with threaded rods on one or both ends to allow them to use Heim rod ends or clevis fork ends to connect to various engine components.

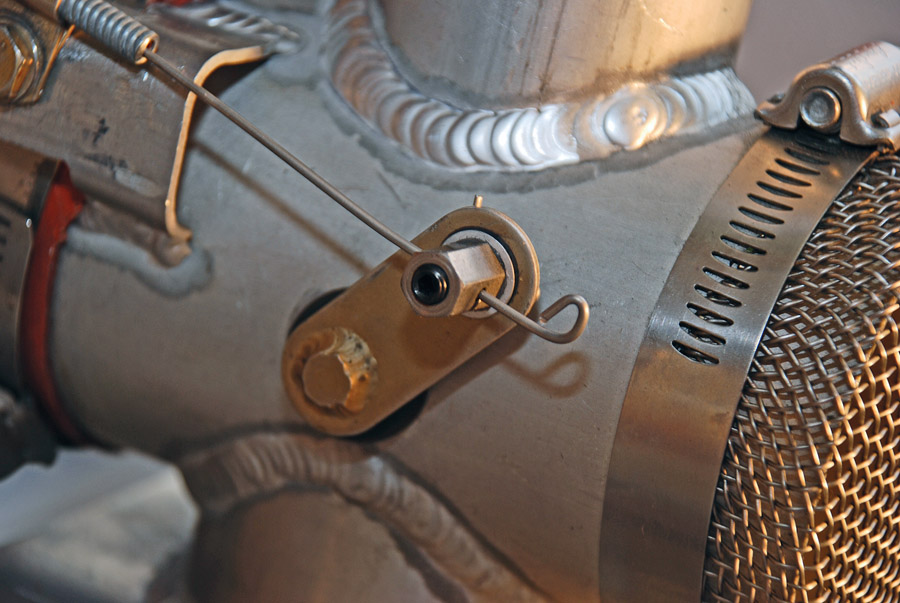

This carburetor heat control uses a bare wire secured with a B-nut. This is fine for secondary controls but is not ideal for the throttle, prop, or mixture controls. Note that the excess wire has been pigtailed to prevent injury.

Reliable controls work as expected every time. They work over the complete range of travel including some cushion to be sure that full range is achieved every time. A control can be said to have cushion if the item being controlled reaches its full travel before the control does. For example, a throttle with cushion will not go all the way to the end of its travel in the cockpit before the carburetor or fuel injection servo is wide open. An eighth of an inch or so is plenty of cushion, but it should never be zero.

A reliable control will also hold its setting until it is changed by the pilot. This is done either with some sort of friction lock, a vernier control that must be screwed in or out, or a cable with a ratchet mechanism built in. All of these methods of holding a control in place are acceptable. The important thing is that the control has a consistent and reliable method of holding in place, but one that can be easily overcome when necessary.

This sturdy bracket works well for this prop governor control. Note how the arm is at roughly a 45-degree angle to the control rod when the governor is at maximum rpm setting. When the control is fully extended, it will then be at about 135 degrees to the control rod.

Another step you can take to ensure reliability is to fit an oversized washer on the outside of the rod end connection so that if the rod end bearing fails for some reason, the linkage will not come completely apart. Bolts that are secured with castle nuts and cotter pins are preferred on all control connections. A lock nut (all metal in the engine compartment) will work but is not the best practice. The problem is that lock nuts lose their locking property with use. A cotter pin and castle nut is simple, reliable, and easily verifiable as secure. That makes for a pretty good combination when your life depends on it.

If you have a control cable that connects to the engine with a bare wire rather than a threaded rod, you will need a B-nut to secure the end of the cable. This arrangement is not ideal for primary controls such as throttle and prop controls, but it works well enough for things like carburetor and cabin heat. Be sure to pigtail any projecting wire end to avoid sticking yourself later when you are working on the engine.

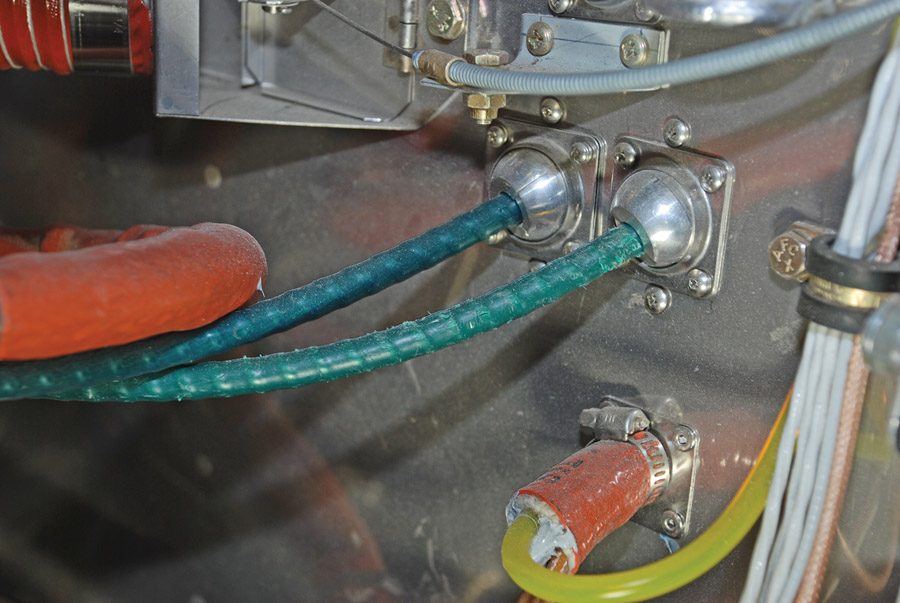

Eyeball fittings do a great job of sealing control cables as they pass through the firewall. These are available from Aircraft Spruce and other aviation vendors.

Routing

In many kits the routing is predetermined, especially if you use the kit manufacturer’s premade cables that are already cut to length based on that routing. In other cases, you will have to decide how to get from the cockpit to the carburetor, for example. As you try to snake a control cable to its destination, the main considerations will be keeping the cable as straight (or at least free of any sharp turns) as possible, getting around things you can’t move out of the way, and keeping clear of the exhaust system that can produce damaging heat. Even with a premade cable and bracket setup, it will be necessary to be aware of heat exposure and protect the cable with firesleeve or a similar product.

This throttle control must run near the exhaust system in this RV-8 by design. To make sure it retains its integrity, it is wrapped in firesleeve where it is exposed to excessive heat.

When designing brackets for the cables, assuming none were included, it is best to try and get the cable straight before securing it to the bracket. This will allow freer movement and take stress off the mounting bracket. Also try to position the cable so that the travel does not get close to going over center at either end of the travel. Ideally the cable should make a 45-degree angle with the arm being moved at one end of the travel and a 135-degree angle when at the other end of its travel, assuming a 90-degree full range of motion.

When penetrating the firewall, be sure to provide a good, flame-proof seal by means of eyeball fittings or a similar method. It is important to keep carbon dioxide, and potential flames in case of fire, out of the cockpit. Of course, all firewall penetrations should be properly sealed with a 2000-degree-rated sealant where leakage is possible.

Conclusion

It is worth repeating: Best practices dictate that controls should be conventional and clearly identifiable. They should also operate smoothly throughout their required range of motion with some cushion at either end to ensure they achieve full travel. No matter what else you get right, you haven’t really done a good job if you compromise on these basic things.