Racing is popularly marketed as a technological playground, a place where avant-garde hardware triumphs over last year’s effort. Occasionally this is true, but the bulk of racing’s reality is proven, well-developed technology is the way to win. Bringing a limited number of newer technologies to the fight—technologies with proven ability but still with room for development—is the gray area where the racer is most apt to find the elusive winning edge.

An excellent example of this combination of the proven and new is Tom Aberle’s Phantom biplane racer. By any measure it’s been a tremendous success, having been the biplane class runaway benchmark for the last 16 years. Its amazing speed is in large part due to radical propeller design and extensive use of structural carbon fiber, not exactly the norm in biplanes, especially in 2003. But these progressive elements sit atop a bedrock of welded steel tubes, small frontal area, a conventional but high-strung legacy aircraft engine, and solid piloting technique earned by decades circling race pylons.

Additionally, while it isn’t a speed advantage, Phantom is the grassroots aircraft builder’s poster child for eyeball engineering and home-brewed techniques. Where other standout racers—Jon Sharp’s Nemesis hot rods come to mind—seem to have gained their edge by association with major aerospace professionals, Phantom is purely an enthusiast’s triumph. If anything, this underscores the efficacy of its mainly basic approach to speed: Put a really powerful engine and prop in the smallest possible airframe, and slick it up as you can.

Tom Aberle

While Phantom has always been co-owned by Tom Aberle and professional pilot Andrew Buehler, the former is unquestionably the central figure in the Phantom story, a tale that includes many personalities but ultimately revolves around Tom’s drive to dominate in biplane racing. From a general aviation family and always working as an A&P pro centered on light aircraft and especially experimentals, Tom first flew the pylons at Reno all the way back in 1966 and first raced in ’67. Ever since, his extensive air racing experience is purely in the biplane class and includes a series of rag-and-tube Stardusters, Pitts and, notably, Mong Sports in multiple configurations. Many of these were owned by others, some by Tom, and there were multi-year layoffs from racing along the way, but Tom’s orientation was always to designing, building, and flying a dominant biplane gold racer.

Furthermore, Tom’s ideas on what would make a good racer are empirical, learned from decades of building, repairing, and modifying a wide range of experimental and certified aircraft. His schooling was at the Northrop Institute of Technology, followed by a doctorate in the school of hard knocks in the A&P arts.

Getting to Phantom

The airplane that would become Phantom came to Tom as a stripped Mong fuselage in the early 1990s. Andrew Buehler, based in Seattle, had been introduced to Tom as a resource for Andrew’s newly purchased number 26 Mong Sport racer. Shortly thereafter Andrew came across a second Mong that had flown but was disassembled down to the bare fuselage sitting on its gear. Andrew bought it for unspecified future use, sending it to Tom’s shop, Aberle Custom Aircraft, in Fallbrook, California, for storage. The pair talked about what sort of advanced biplane racer could be made from the dormant fuselage, but in the early 1990s it was just talk.

Another customer and talking buddy of Tom’s was Bob Busch. A retired electrical engineer at Northrop Grumman, also based in the Pacific Northwest, Busch brought his lifelong, self-taught airframe engineering talent to bear on discussions of what a major biplane racer would look like.

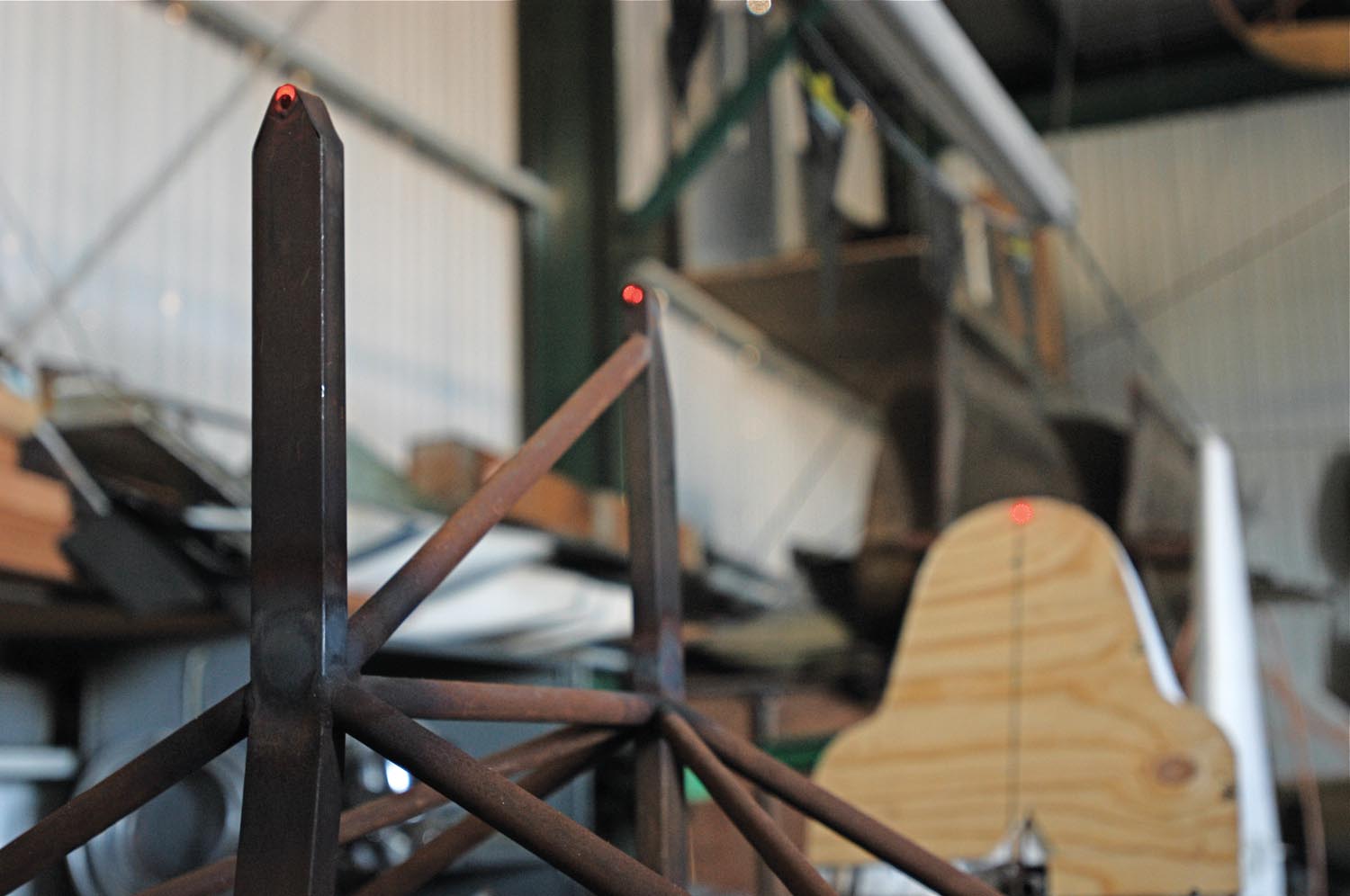

From the early ’90s until January 2003 while Tom was racing other airplanes, very little occurred to Andrew’s spare Mong fuselage. However, as time and motivation allowed, Tom welded the inverted gull structure of the lower wing out to the landing gear. Like everything else on Phantom save the wings, this was all eyeball engineering. No plans were ever drawn or stress analysis calculated.

The pivotal events putting Phantom on the front burner in February of 2003 occurred nearly simultaneously. Tom’s previous racing outlet, Legal Eagle, was no longer available, and a source of very significant funding in the person of Chris Piedmonte, a computer-oriented entrepreneur and air racing enthusiast, became available. Tom showed Chris the rusty Mong fuselage, and Chris had just two questions: “Will it win?” to which Tom answered an enthusiastic “Absolutely!” and “Can it make it to Reno this year?” to which Tom took a breath and said, “It could be done.”

There were just seven months between that conversation and the 2003 air races.

Building Phantom

Obviously, Tom suddenly had a lot on his mind and was immediately chatting up the big new project with all the skilled help in his Aberle Custom Aircraft circle. One of those was Andy Paterson, an accomplished fabricator and driver with extensive formula car racing and building background. Andy’s Paterson Composites and his brother’s Paterson Racing are Aberle tenants at the Fallbrook Air Park, and both were naturally intrigued by the project’s combination of racing and aircraft cultures. After seeing the Mong fuselage truss with its anhedral lower wing stubs, Andy quickly sketched how he saw the finished racer, a vision that extended Tom’s and Bob’s ideas, and so the die was set.

Knowing there was no way the entire plane could be built in time, in-house at Aberle Custom Aircraft, Tom’s first call was to Robbie Grove at Grove Aircraft Company. He was contracted to build Phantom’s wings. Tom’s second call was to see if Bob Busch could come to Fallbrook to help; though busy, Bob agreed to make the trip as many times as possible to work on the plane. Tom’s third call was a meeting in the Aberle Custom Aircraft hangar, where the core crew got the project overview from Tom and spent a few minutes getting to know each other—if they weren’t already acquainted.

With time so short, it was clearly fortunate the Phantom team had Buehler’s already modified fuselage truss as a starting point. Some of the work was already done, yes, but likely more importantly, the vestigial Mong helped to quicken setting Phantom’s general dimensions, a task finished by Bob Busch. Key of these to Tom is the diminutive firewall, thanks to the Mong’s natively compact nature. “Did you ever see an airplane powered by a 360 Lycoming with that small of a firewall?” he asks rhetorically.

At the other end of the airplane, Andy Paterson thought to eliminate the old-school rag and tube truss in favor of a carbon fiber aft fuselage. The arching shape was simply Andy’s eye joining the cockpit to a maximized streamlined tailwheel with minimum wetted area. Again, no calculations were involved; Andy simply overbuilt the hollow fuselage section to take any possible load. He maintains it is plenty strong without longeron-like reinforcements, but Robbie Grove thought they’d be a good idea, and Tom felt better after talking Andy into adding them.

Building the aft fuselage was via the plug-and-mold process. The Mong fuselage was clamped to the ACA welding bench, the existing steel tube fuselage amputated aft of the cockpit, and a sheet of plywood cut to mock up the new aft fuselage shape. Think of the plywood as a two-dimensional mock-up running along the center of the fuselage. Foam blocks were glued to the plywood, then shaped by Andy to arrive at a three-dimensional shape. The foam was then covered in fiberglass to form a “plug.” The plug then became the male form the female fuselage mold was built around. Finally, the aft fuselage was laid up in the female mold like a race car monocoque using Nomex honeycomb reinforcement inside the carbon fiber layers.

Most amazing about Andy’s aft fuselage is it weighs only 11 pounds! That’s minus the “longerons,” rudder, horizontal stabilizer, and elevators, but still, that’s light, especially considering how rigid it is. Considering Phantom weighs a fairly hefty 738 pounds thanks to the steel-intensive lower wing/landing gear stubs and center pylon, plus the extensive oiling system, it was good to lose some weight in the tail.

Tom found he had to get a little creative when building Phantom’s elevator linkage due to the arched lower fuselage. Running horizontally from the stick to below the pilot’s seat, the elevator linkage then rises vertically behind the pilot, then resumes running aft horizontally to the elevator. Tom calls the resulting Z-like linkage the “quad pod.”

Likewise, the rudder linkage is cables from the pedals to the pilot’s hips where they transfer into a rod. Like the elevator linkage, the complex rudder controls are there to allow breaking Phantom in half behind the cockpit for trailering. That way the complex wing and fuselage interfaces are permanently joined and never disturbed.

Grove Wings

Phantom’s wings were entirely produced by Grove Aircraft and are the second to last set of wings produced there commercially. Ironically, the last set of Grove wings for a commercial client were for Phantom’s competitor, Miss Gianna. A modified Pitts Special, Miss Gianna’s wings are completely different in size, airfoil section, and detail than Phantom’s, but were laid out immediately after Phantom’s wings were completed in the late spring of 2003.

Robbie Grove says Phantom’s wings are basic, “hot wire, blue foam” constructions. Robbie started with airfoils and planforms specified by the Phantom team, then calculated the loads to determine the structure’s specifics. The single-piece upper wing uses a single box spar built up of two vertical webs joined at top and bottom by lighter web caps, while the two lower wings use a main box spar in front and a lighter C-shaped spar aft. The lowers, which are really just the outer panels of the lower wings because of the metal structure in the anhedral section, use 7-inch stubs protruding from the root end as attach points. Each gets two 7/16-inch bolts running parallel to the chord.

Robbie points out that Phantom’s upper and lower wings are shaped differently from each other in planform, almost as if they came from two different airplanes, and that the lower wings, especially, have an extremely narrow chord at the tips. This is mainly due to the thickness of the lower wing anhedral section where it takes landing gear loads. To maintain the thickness ratio, it ended up with a tiny chord tip.

Biplane racers can have small wings because they have two of them, and Phantom’s are some of the smallest wings around, considerably smaller than Formula One wings, for example. The upper spans 20 feet.

Ailerons are on the lower wings only, with Robbie’s preferred very high aspect ratio to lower stick forces at speed. To avoid flutter Robbie says he always carefully balances control surfaces on the hinge line, then builds them absolutely as stiff as possible. “I’ve built about 30 wings in my life,” says Robbie, “and I build the ailerons all the same, with mass balance about 15 percent outboard of the center of the aileron and always out of carbon fiber. Always lighter and stiffer.”

Of course, overall the wings are strong, light, and stiff, so much so Robbie says Phantom has two cantilever wings, and the interplane struts are there just for the rules. In fact, they use just a single bolt top and bottom and have no resistance to bending, nor are there any wires.

Mounting the lower wings posed no issues, but the upper wing center pylon wasn’t fully developed when the upper wing first went on. Tom said he finished the job by “replicating the Brooklyn Bridge” at the center pylon, adding triangulation and mass until the upper wing remained rigid when bumped out at the tip.

Ly-Con/Paterson Power

While it takes everything—aerodynamics, reliability, competent piloting, etc.—to win races, it’s clear Phantom packs a wallop under the cowling, and that power is efficiently transferred to the atmosphere via an exceptional propeller.

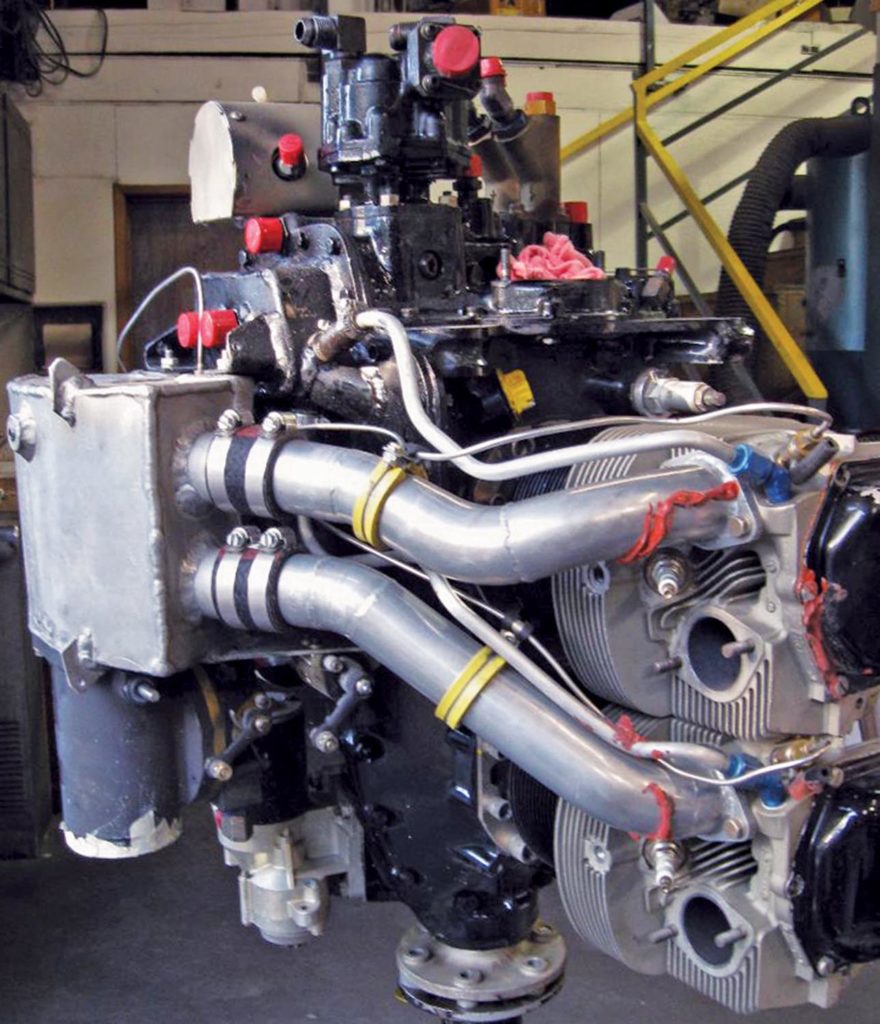

That wallop comes mainly from Visalia, California, a common origination for small-displacement Reno air racing horsepower thanks to Ly-Con Aircraft Engine’s interest in Formula One, Biplane, and Sport air racing. In his typical fashion, Ly-Con principle Ken Tunnell was modest and laconic at first when reviewing Phantom’s engine with us. “It’s just an old narrow deck O-360 parallel valve,” as he put it. Yep, and Picasso was just a painter.

Tom had acquired most of an O-360 Lycoming in parts form over the years, including a brand new crankshaft, and as an established Ly-Con customer, Tom knew Ly-Con would be where the engine would be built and tested. But he also had Stewart Paterson’s extensive automotive motorsports experience on the Phantom team, so Tom had Stewart and Ly-Con’s power-making specialist at the time, Steve Mehalek, put their heads together. The result was a laundry list of speed and durability tricks from both sources.

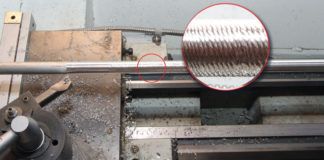

Stewart started by laboriously hand smoothing the internal case surfaces to reduce oil retention and windage. He also knife-edged the crankshaft and hand detailed the reciprocating assembly. Ly-Con then machined the case to accept one of their Babbit crankshaft thrust washers common on their aerobatic engines out of fear of galling the case. Dry-sump oiling was achieved using a custom Stewart-design oil pan, an obscure Lycoming scavenge pump for aerobatic engines that Ly-Con had in their parts pile, plus an external tank from the automotive aftermarket, and enough custom plumbing to join it all together. An immense oil cooler of indeterminate origin purchased from National Aircraft Salvage, along with an electric oil pre-heater bonded to the oil tank, complete the system.

Ly-Con supplied their NFS pistons, coated and tall enough to generate a definitely racy 12.5:1 compression (later raised to 14.5:1 during an upgrade in 2010). Piston rings are gapless Total Seal units, and the intake valve guides were shortened and given oil seals. The new Lycoming cylinders were ported and bored 0.010 inch over.

Ly-Con supplied a custom profiled roller camshaft, their NFS wide-foot lifters, and an accurate, multi-angle valve job.

With light input from Mehalek, the intake plenum and runners were engineered by Stewart and built at Aberle Custom Aircraft by Stewart, and welded up by Tom. Stewart says he wishes the entire intake was a little larger, but it’s as large as space permits. It’s plenty trick inside, featuring airflow directors, hand-formed bell-mouthed runner ends, and the like. Fuel delivery is via Airflow Performance gear using an FM-200 servo, lines, and injectors.

Stewart also designed a set of 4-into-1 headers for Phantom, and they were built at ACA and run on Ly-Con’s dyno, but never on the airplane. They added around eight horsepower but also some frontal area to the cowling, plus Tom was concerned about under-cowl heat and is a fan of short, individual-stack exhaust, so the headers were abandoned.

Tom’s description of Phantom’s fuel system is “convoluted,” the result of at first briefly thinking he might sport fly Phantom or at least fly it to and from the races. That thinking gave a target capacity of 20 gallons (14 gallons is required by the racing rules), so Tom elected for a main tank forward of the cockpit, plus one auxiliary tank in the leading edge of the anhedral portions of each lower wing, for a total of 19.4 gallons.

Actually the main tank is two tanks because one large tank would not fit in and out of the fuselage access point. One of these tanks fits up into the wing pylon somewhat, and the other is below it. Fuel is added to all tanks via a single point inside the pylon. Tom built all the tanks at his ACA shop, noting, “I like welding aluminum.”

A series of valves Lindbergh would have understood allows burning fuel out of the top two-piece main tank, or to dump fuel from the main to the anhedral aux tanks and burn all of it out of there. As Tom soon decided, “I want an airport under me when I’m flying that airplane,” he’s never used the two lower wing tanks.

Naturally the core engine was assembled and dynoed at Ly-Con, but pinpointing its power output is difficult because suitable propellers to load the engine at its 3600 racing rpm were unavailable. Therefore the engine has never been dynoed at such high speed and, furthermore, there is no ram inlet on the dyno. Extrapolating the dyno data suggests Phantom has a fat 300 hp at near-sea-level density altitudes, and with a touch over 2 inches Hg of ram pressure in the inlet while racing, Phantom does a good job of retaining such manifold pressure at typical Reno density altitudes—and let’s remember the biplanes always run in the cool morning air. Fuel flows around 26 gph also support an approximately 300 hp power figure while racing.

Lipps Propeller

When Phantom debuted at the 2003 air races, propeller issues robbed its reliability, but not before a 222 mph qualifying speed was posted. Tom had a conventional composite prop fitted, but it was mislabeled and was thus over-torqued. This crushed the prop hub, which then came loose. A loaned replacement prop delaminated at the tips, and that was the end of 2003.

However, post-Reno the now much missed Jack Cox wrote up Phantom in his Sportsman Pilot magazine, which was read by a somewhat obscure propeller designer, Paul Lipps. He approached Tom with an unusually shaped two-blade prop to try. Figuring the experimental prop with its huge twist and paddle-like inner section tapering to a tiny tip was at least as odd looking as his race plane, Tom decided to give it a try. And just like that, Phantom was 18 mph faster.

Next Lipps supplied a three-blade prop that was a tick faster but slow to accelerate at takeoff. Then Lipps said a four-blade would be better, and it turned out to be the key to putting Phantom consistently into the 260-mph lap speeds at Reno. Unquestionably, the Lipps propellers have been key in turning Phantom’s excellent power into equally impressive thrust.

Flying Phantom

After a lifetime of pitchy little race planes, Tom was ready for something more stable as well as faster when he built Phantom, but he didn’t get it. Much of this is simply what you get with a short-coupled, light, responsive airplane with a wide speed range. Tom insists on no less than 30 degrees of movement on the elevator and rudder because that much is needed for big saves, but that leads to very authoritative controls in normal flight. Some sort of non-linear control response—as given by fly-by-wire systems—would be a huge help, but as Tom says, “I’m not smart enough to figure out how to do that with mechanical controls.”

So Phantom takes a light touch, with short, nearly non-existent throws. “It is accurate [to say] that I don’t move the elevator after I’ve moved the tail off the ground. That’s my perception of it. Maybe I do, but not by command,” notes Tom. “It needs hardly any rudder. There is a fight, a continual battle between the pylon and vertical fin. You cannot get neutral; well, you can get neutral for a second, then some little change and it goes away. You have to settle for a little bit of rudder-in in the turn, or a little rudder out of the turn.

“If you have rudder in the turn and get an upset then you have to get rid of rudder-in and get rudder-out to recover. You are going to get more than you want. A little is tough to get at 250 mph!”

Of course, Tom makes it look easy around the pylons, running his preferred low, tight, and not-climbing-in-the-turns line whenever possible. Andrew has done an admirable job acclimating to Phantom’s pro-level handling, tightening and lowering his lines as he gains experience (which includes three National Championships in the airplane).

If the high-speed characteristics are mainly just touchy, those narrow wing tips are subtle dangers at low speeds because they are very unforgiving of cross-controlling and will stall with extremely serious consequences at the first hint of yaw. Landing approaches should be fully coordinated all the way to the ground; Tom uses 90 mph on the approach and tries to milk off a little bit at the very end. “It’s a matter of getting level at 90 mph or less and stuffing the mains on.” Of course there’s no manhandling Phantom onto the runway, but once the mains have been gently wheeled-on, the stick needs to go forward. Phantom is, “fine on the runway, [there’s] not a mean bone in its body. It likes to go straight.”

Phantom’s 15-year run at Reno can only be described as dominating, but now it’s time for someone else to win with it. Tom has retired from racing due to health, and Andrew Buehler can only devote so much time to the sport, so Phantom is for sale. Andrew is scheduled to fly Phantom in the 2019 races in September, which will be an excellent last chance to see it in action by its originators.

Just before this article went to press, Tom Aberle passed away from cancer. KITPLANES extends its condolences to the Aberle family and the Phantom team.

I read about every second word and a lot of those I don’t understand (Is a “main” a flap?), but this is a great piece of writing. You practically are in there rocketing around the course, a hair’s breadth short of catastrophic mid-air what’s-it. And loving it.