One of my all-time favorite movie lines comes from the classic Butch Cassidy and the Sundance Kid. The two outlaws are standing on a high cliff above a raging river, pinned down by the law, with nowhere to go but down. Sundance, the young gunslinger, is clearly reluctant to make the leap. Butch Cassidy, the older, wiser one, is trying to convince him he has to go. Sundance keeps saying no, he can’t jump, there has to be another way. Finally, Cassidy asks him why he won’t jump, and Sundance blurts out, “I can’t swim!” Cassidy pauses, then laughs. “Are you crazy? The fall will probably kill you!”

I like this exchange. It is such a classic setup, and tells us quite a bit about how we deal with risks. Aviation is full of risk. Anyone who tries to say that flying is as safe as sitting in your favorite rocking chair is trying to sell you something. But those risks aren’t always what we think they are. For instance, anyone who carries at least a private pilot’s license has spent countless hours looking for emergency landing sites and practicing power-off approaches to fields, golf courses and roads in case the engine quits. This has to be the single greatest risk of flying in the minds of many: What if that single engine quits?

Well, it’s true that engine failures happen. In years gone by, before the advent of our current crop of four- and six-cylinder air-cooled engines, it happened a lot. But if you read the daily preliminary accident reports from the FAA, you get a better appreciation for what is really happening in the world of aircraft mishaps.

The truth? Bad landings. They happen every day: gear collapses, ground loops, and “failure to remain on the runway on rollout.” Now these aren’t anywhere as dramatic as an engine failure and off-field landing, but they happen often, and usually end up with some bent metal to go along with the pilot’s bruised ego.

Good risk management begins in the design and construction phase. Understanding the risks and safety factors of different systems’ selection criteria is important to estimating the total risk of operation.

Identify, Appreciate

Understanding the real risks in flying is how we can eventually control them. And identifying those risks is the first step toward that understanding. We can spend a great deal of time practicing emergency landings, but if we play the odds, we should probably be spending much more time making routine landings, shooting touch and goes, and improving our ability to simply return the airplane safely to earth. By misidentifying and not understanding our real risks, we put our training emphasis in a place where we might not be doing the most good. (This reminds me of the years I spent in the Volunteer Fire Service. I was an officer and instructor for two decades, and remember well how hard we drilled our firefighters how to safely and effectively fight interior structure fires. This is dangerous work and we spent a lot of time training, figuring that if we could prevent firefighter injuries during this risky activity, we would have a great overall safety record. In fact, if you look at the statistics for on-the-job fatalities in the fire service, the number one killer is heart attacks. Number two is death in motor vehicle accidents while driving to the scene of the fire. Death by fire was a trivial few percent.)

A good preflight is essential to minimizing risk. How else will you know if the airplane is in the condition intended by the builder?

Studying accident reports is the single best way to understand the real risks that we face in Experimental aviation. By knowing what causes accidents, we can better design, build and operate our aircraft to reduce or prevent them. Failure to understand the risks we are facing is like fighting an unknown enemy—a logical problem with no solution. It is not hard to identify a few common causes of accidents—most of them relate to poor decision-making on the part of the builder/pilot, or poor flying skills on the part of the pilot once the aircraft is flying.

We’re Different

Pilots who fly certificated aircraft know that their airplanes have met minimum standard design criteria for safe operation. They have been designed to a common level of reliability and redundancy, and they have flight qualities that fall into some expected norm.

Experimental aviators, on the other hand, might be dealing with design issues that are non-standard and increase risk considerably. For instance, Experimental aircraft are not required to have docile handling qualities proven during certification testing. I have flown Experimental aircraft with remarkably harmonious controls that exhibited superb handling, while others were, to be kind, barely a step above the Wright Flyer (rated today by test pilots as “unflyable”). Aircraft with designs that exhibit quirky handling have a built-in increase in risk unless the pilot is aware of and trained to handle these quirks. Some modern, high-performance designs require faster takeoff and landing speeds, and consequently longer runways. These operational limitations must be taken into account, or risk is significantly increased. Other quirks might relate to stall or spin characteristics, inability to fly in rain without aerodynamic consequences or stability and control variations with loading.

Design can influence risk in numerous ways. Unfortunately for experimenters, innovation generally is accompanied by increased risk. Fuel systems are a prime, if slightly overused, example. The fuel systems used in the vast majority of certified airplanes are similar and very simple. A tank (or two), fuel valve, auxiliary pump, gascolator, mechanical pump, and carburetor or fuel injector servo. Minimum parts, the fewer to fail. When designers start adding additional tanks, additional pumps, more valves, or unusual cross-feed configurations, the parts count goes up, adding more things that can fail, and, more importantly, the possibility of “unknown unknowns” increases.

It is clear from accident statistics that Experimental aircraft have a higher incidence of fuel-system-related engine failures (especially early in their test programs) than certified aircraft. Again, this is not the primary cause of accidents, so we shouldn’t be necessarily frantic about it, but the fact that it is higher than in the certified world should get our attention. Something is wrong if we have a higher incidence of problems with our own unique designs, which begs the question of whether the potential gain is worth the risk. (But that is another topic altogether.)

A famous and overused case in point is the crash that killed entertainer John Denver. The builder of the aircraft (not Denver) had modified the fuel system to locate the fuel valve in a position that made it extremely difficult for a pilot inexperienced in that aircraft to switch tanks in flight. Was it a “bad” modification? Well, it certainly increased the risk on that particular flight. The point here is not to rant against fuel-system modifications, but rather to point out an increase in risk when you start changing proven designs.

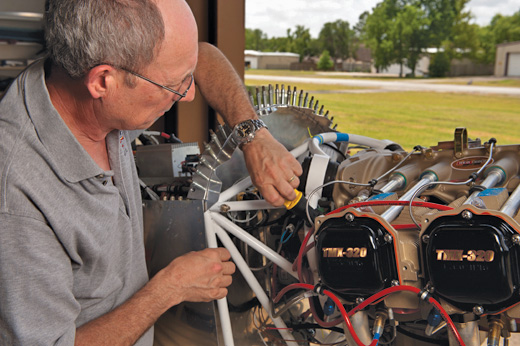

Deciding among today’s many available ignition systems can be tricky. Understanding the maturity, design and redundancy can make the risk trade easier.

Return to Ground

While I pointed out at the beginning of this article that the number one way to get yourself into the daily accident summary is to botch a landing, these accidents are rarely fatal—or even injury-inducing. Most of the time, they merely bend metal and the pilot’s ego. In this respect, the risk to life and limb is fairly small. So what causes fatal accidents? For years we have all heard about VFR flight into IFR conditions and loss of control in IFR flight. These are still big killers in both certified and Experimental aircraft, and they need to be respected. Fortunately, there are significant measures you can take to lower the odds of adding your name to these reports. In-cockpit weather is probably the greatest single operational advance in cross-country safety. The ability for pilots to see all aspects of the weather without having to talk to someone on the ground and interpret what they are hearing cannot be underestimated when it comes to risk mitigation. This does not mean it allows pilots to fly through worse weather than before. It does mean they get an honest and accurate picture of what is going on around them, and can make better decisions.

Fuel injection has advantages in efficiency, but it requires higher-pressure fuel lines and can be more problematic for hot starts. These trade-offs need to go into the overall evaluation of risk.

Another way in which we can combat weather-related losses is through the use of modern instrumentation which is both more reliable and easier to read and interpret than IFR panels of old. EFIS-equipped airplanes do a much better job of presenting data, and Experimental-class autopilots do a remarkable job of reducing a pilot’s workload by flying the airplane while the pilot thinks his or her way through the flight. And while this does not relieve the pilot of the responsibility to be able to hand fly any phase of the mission, failure rates of modern autopilots are extremely low, making the majority of the flights much safer. Designing features in the airplane that are appropriate for the mission of the plane is a great way to use the design and building phase as a means of reducing identified risks.

It is interesting to note that while pilots spend a great deal of time thinking about and preparing for “first flights” of their Experimental aircraft, a casual examination of the accident records does not show a preponderance of accidents on first flights, at least among aircraft that are built pretty much to plans. There are engine- and fuel-related issues during the early stages of flight testing, but these are frequently related to Experimental systems designs, Experimental powerplants or other such modifications. Which again, is not to discourage experimentation, but merely to point out that this is a risk elevator, and the pilot needs to be aware.

Powerplant, propeller and fuel mods should always be treated with great respect when it comes time to fly a new machine, and operational contingencies (emergency landing zones and the like) well thought out beforehand. Many pilots, myself included, worry about fire on first flights as we imagine fuel or oil lines working lose, but this has not proven to be the case in the real world—perhaps because we are so terrified of the idea that we take great pains to avoid the possibility.

It’s About Airspeed

It is sadly true that a great many Experimental aviators come to grief in stall/spin accidents in the traffic pattern. While I cannot say from personal study that the incidence is higher than for certified aircraft, I can say that many Experimentals do not have the stall warning systems that are invariably installed on certified aircraft. As annoying as those stall warning horns can be, they do get your attention. Coupled with the fact that many Experimental aircraft have less benign stall characteristics than certified aircraft are required to prove, it’s just easier to get into a low-altitude stall while turning base to final. Good airmanship demands that we stay alert to this possibility and fly with margin above the stall, but many don’t seem to be able to accomplish this task. Good stick-and-rudder skills help, but judgment, foreknowledge of the potential for an accident and situational awareness can help. If we could get rid of weather and low altitude stall/spin accidents, the Experimental aircraft safety record would be significantly improved.

One other real area of risk for the Experimental world is low-level acrobatics. It just seems like people who build their own hot-rod airplanes like to show them off. Here again is an area where risk must be managed entirely by the pilot, through self-discipline and respect for the laws of gravity and aerodynamics—as well as the laws of men. No one is as good as they think they are, and many have proven this by completing their aerobatic maneuvers 6 feet underground. Low-level aerobatics is a high-risk endeavor, easily identified, and almost always fatal if it goes wrong.

Aerobatics are fun and challenging. Done with sufficient altitude, they can be reasonably safe.

Final Notes

Can we make aviation—particularly Experimental aviation—safe? Well, safe is a relative term. I have heard that the only computer safe from viruses is the computer that is never turned on, which isn’t very useful. The same applies to airplanes. The bottom line is that sometimes we simply have to accept some risks. We cannot guarantee that the engine is going to keep running when we are over hostile terrain. We can, however, significantly improve the odds through meticulous maintenance and honesty about its condition. By honestly assessing risks and identifying at least one way to minimize each one, we have made our flying safer.

Improvement is always good. One of my favorite questions to ask pilots preparing for first flight is: “What’s your backup plan?” I want to know what they intend to do if the engine sputters on the takeoff roll, at 50 feet, 200 feet or in the traffic pattern. I want to know what they will do if they smell smoke. I want to know what they are going to do if they hear a loud buzzing or flapping noise. I am not so much interested in exact procedures for each case, but rather I want to know that the pilot has thought about the risk and come up with at least one idea of how to mitigate it. That is the sign of someone who is likely to survive in the world of aviation.

Thousands of textbooks have been written on the subject of identifying risk, accepting risk and mitigating risk. You can look them up, pile them on a table and read until you are too old to qualify for a medical. But that does not ensure that you won’t have an accident. Simply put, real risks must be identified through study of the past. Reasonable precautions should be taken to prevent the failures of the past through careful design and construction. And pilots need to understand and accept the residual risk inherent in the airplane they are about to fly. You can’t control what happens to the rest of the pilot population, but using this three-step process, you can significantly reduce your own chances of showing up in those daily accident reports.