I’ve been analyzing homebuilt accident statistics for almost 25 years. I’ve been documenting the results in KITPLANES® for nearly that long. But sometimes I wonder if some readers hide their magazines so their spouses don’t see the grim results of crashed homebuilts featured in each article.

Fear not: no crash pictures in this article—and we’ll concentrate on the good news about homebuilt safety.

Accident Rate

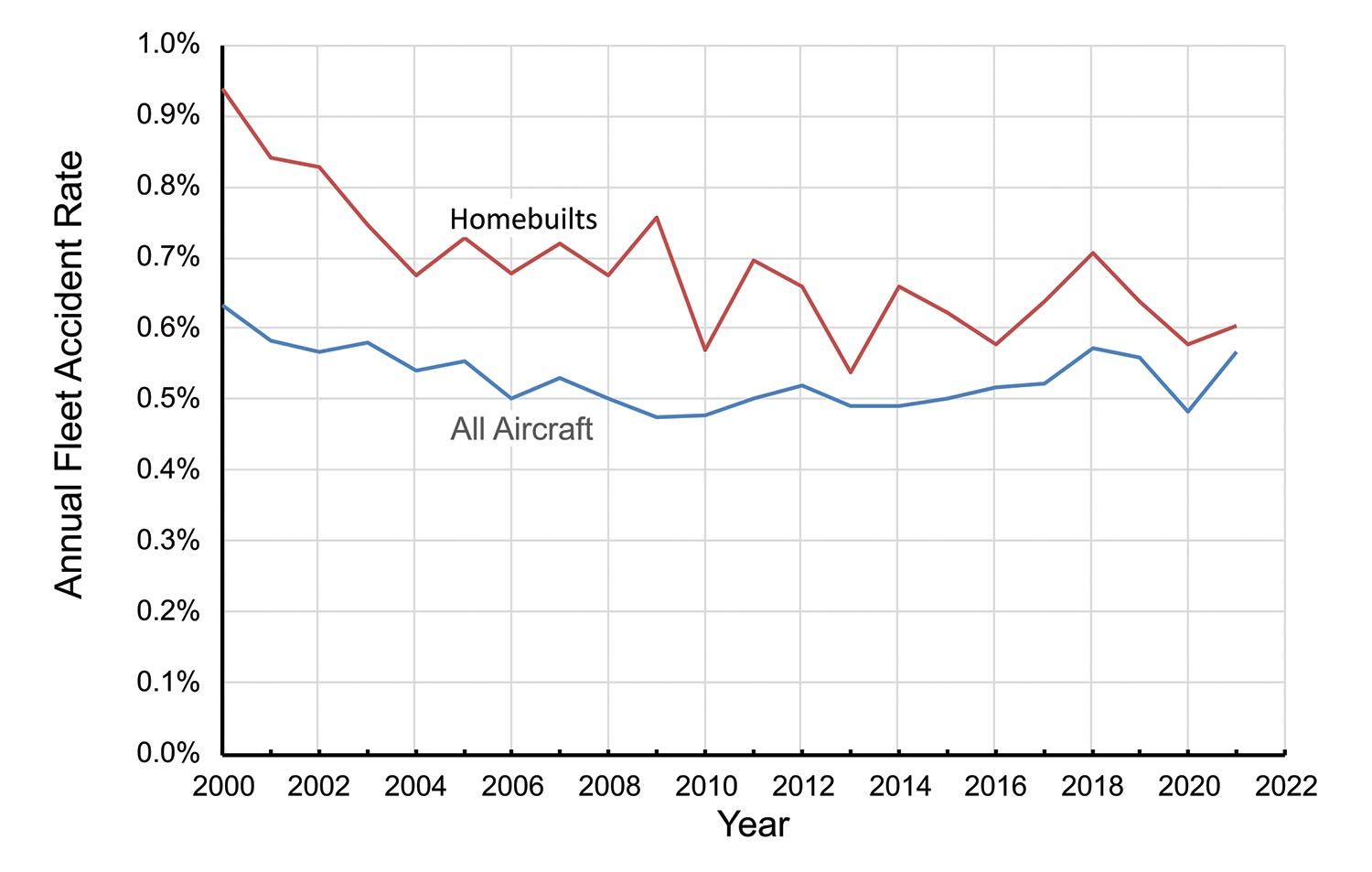

Figure 1 gives the first bit of good news. It tracks the fleet accident rate for both the overall U.S. fleet and U.S.-registered Experimental/Amateur-Built (E/A-B) aircraft from the year 2000 to 2021.

“Fleet accident rate” is just the number of accidents in a given year divided by the number of registered aircraft that year. Note how the rate for the overall aircraft in the U.S. fleet has remained fairly constant over the 22-year period. In comparison, see how the homebuilt fleet rate has improved.

In 2000, it was 0.94%. In other words almost 1% of homebuilts crashed in a given year. But by 2021, it had dropped to about 0.6%. That’s a decrease of over one-third.

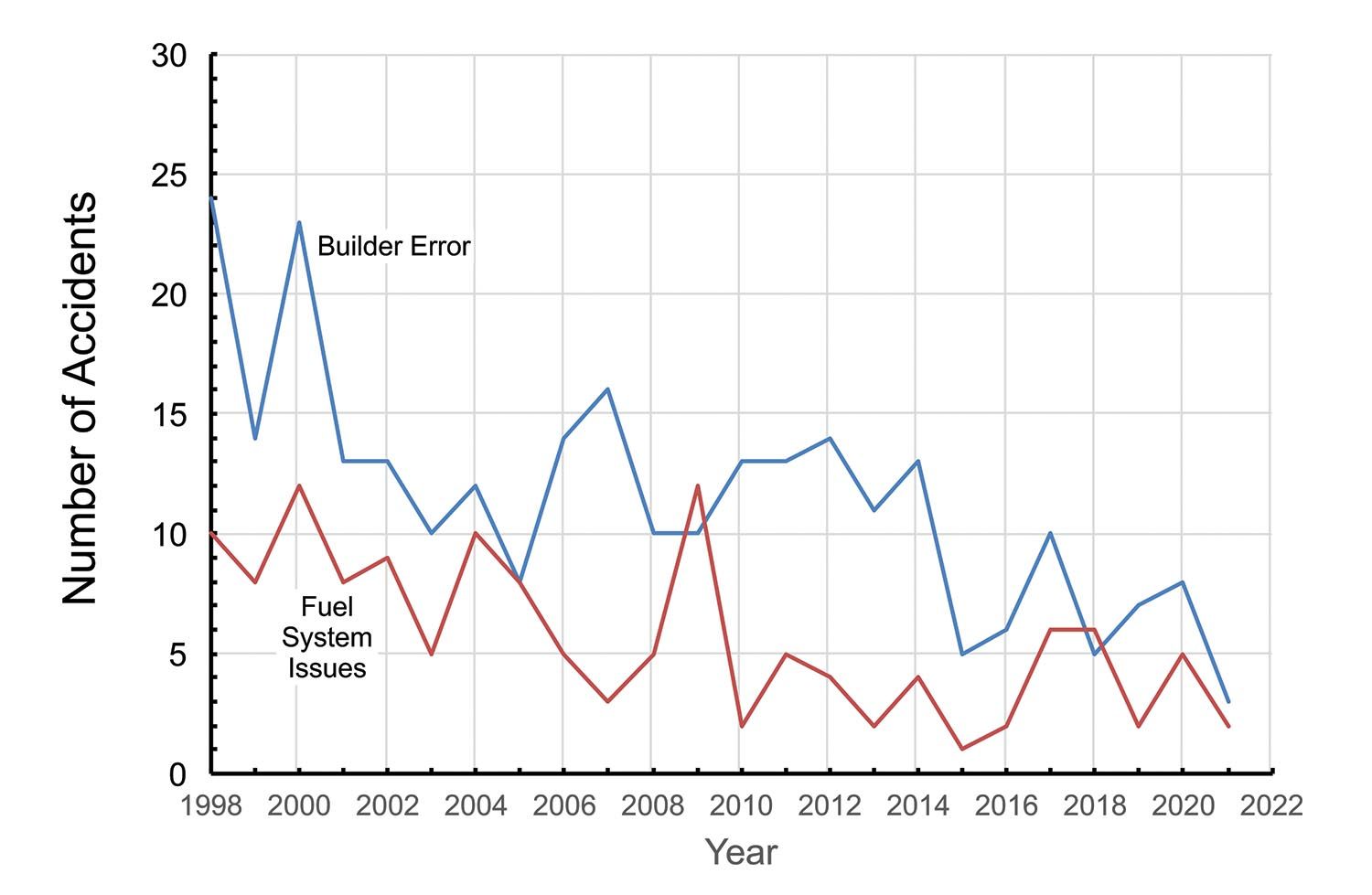

Why? Looking at causes over the time period, we see that the number of accidents involving builder error each year dropped significantly—from 24 to three. Also, the number of accidents involving problems with the aircraft fuel system dropped as well, from 10 to two.

I attribute this to the rise of kit aircraft versus scratch-built examples. They not only often include detailed instructions for builders to follow, but there are plenty of previous builders who can help them when problems arise.

An interesting revelation: Over the time period involved, the number of accidents each year involving aircraft with two-stroke engines dropped from 60 to eight. Was that due to more-reliable two-stroke engines or did more people opt for the four-stroke Rotax 912? No way to tell, really.

A final, telling point: Not only did the number of accidents decrease by a third over that 21-year period, the number of homebuilts increased by about 18%.

So yes, we’ve done pretty good. In 2021, only one out of every ~160 homebuilts suffered an accident.

Causes

So, in a given year, is there a 1-in-160 chance that you will have an accident?

That’s not how statistics work. Sure, there’ll typically be one accident in a group that size—but it doesn’t have to be you.

Look at Las Vegas. The average visitor loses about $500 gambling in the casinos. Yet there are some—using a combination of skill, knowledge, ability to assess risk and luck—who manage to go home with more money than they came with.

The same thing works with homebuilt safety. With skill, knowledge, the ability to assess risk and yes, luck, you can reduce your chances of being the one out of the 160.

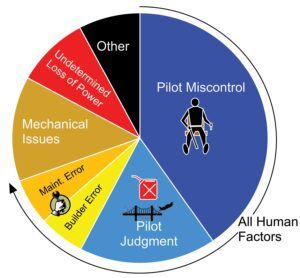

Figure 2 shows the causes of homebuilt accidents in the 24-year period my database covers. “Pilot miscontrol” refers to errors in the physical operation of the aircraft; “Pilot judgment” covers decision-making issues such as running out of gas, buzzing and continued VFR into IFR conditions.

The next two slices address issues caused by builder or maintainer error.

The upshot? Human factors are involved in over two-thirds of homebuilt accidents. If we could eliminate human errors, the homebuilt accident rate would drop significantly.

We all know that isn’t going to happen. But we can strive to do better. Being more skeptical about the weather, not stretching the fuel, keeping a close watch on the engine and watching your workmanship during construction, etc. will help keep you from being the “one.”

Another Look at Engines

We’ve looked at engines pretty thoroughly in my series of articles. Mechanical failures of the engine (including those induced by the builder or maintainer) are involved in about 7% of accidents involving homebuilts with traditional powerplants. That percentage rises to 18% for E/A-Bs with two-stroke engines and 25% for homebuilts using converted auto engines.

There’s a lot of confusion over this statistic. It looks at the total accidents that were due to mechanical failure of the engine and divides it by the number of aircraft with engines of that type that were involved in accidents with any cause.

It is not the likelihood that a given engine type will fail—just an indication of how often accidents are due to engine issues versus other causes.

It does not mean “25% of auto engine conversions fail,” as many people misinterpret it. People are used to seeing statistics on how many engines of a given type have failed, versus the total number of homebuilts in the U.S. fleet that use that engine. This is not that statistic.

Reliable information on the types of engines installed in E/A-B aircraft isn’t available. More than 12% of the ~27,000 homebuilts in the FAA registry just list “AMA/EXPR” as the engine. This merely means that the specific engine type isn’t identified. There’s about equal chance an AMA/EXPR engine is a Lycoming or Continental as an auto engine.

What’s more, over 500 entries just list “Rotax” without stating what the actual engine type is. It could be a brand-new four-stroke Rotax 915; it also could be a 30-year-old two-stroke 447.

As an example, a friend gave me a list of 105 aircraft known to have flown using one common auto-engine conversion. Three were licensed in other countries. Of the remainder, 20 had been deregistered and over half the remainder were “AMA/EXPR” engines. Just 33 aircraft on the active U.S. registry had the specific engine listed. So one can’t just tally the engines listed in the FAA registry.

What to do in cases like this? I matched aircraft listed with AMA/EXPR engines with accidents involving those aircraft. The NTSB accident database usually gives the actual engine type. The results were used to estimate the percentage of AMA/EXPR engines that came out as specific types. Aircraft that had been deregistered were included as well, since it would reflect the total number of aircraft completed with that engine.

The process doubled the fleet size of most auto-engine conversions, a four-times increase for some types. Running the same process on the generic “Bombardier” listings for Rotax engines, most of the two-strokes saw a tripling of the fleet size. Even the Rotax 912 doubled.

From that point, it was easy enough to divide the number of engine-failure accidents for that type with this newly generated fleet size.

Best reliability was seen in traditional certified engines. About 0.03% of homebuilts powered by Lycoming or Continental engines suffered an engine failure in a given year. That’s one out of about 3000. About the same results for aftermarket versions of the certified engines—Mattituck, Superior, Aero Sport, etc.

The worst engine I found (a popular two-stroke) had a 0.24% failure rate—about eight times worse. Most of the two-strokes and the auto engines were running a bit better, from 0.08% to 0.15%. Still three to five times worse than traditional engines.

But convert those percentages into real-world numbers. The annual failure rate for the most common auto-engine conversion, for example, came out at 0.08%, which is one out of 1250 installed engines.

Sure, it’s not one out of 3000—but really isn’t that bad. It’s worse, yes, but we are still looking at relatively few engines failing. Getting better, too. That particular engine averaged a bit over two failures per year for the full 24 years of my analysis, but in the last 10 years had dropped down to an average of just one per year.

First Flights/Test Period

Good news here, too. In 1998, there were 40 accidents involving planes in their Phase 1 test period (40 hours assumed for all aircraft). In 2021 this had dropped to 12.

Similarly, 11 accidents in 1998 occurred during the first flight. This dropped to just one in 2021.

On average, about 1000 new homebuilts are added to the registry each year. The loss rate for first flights is about 0.60%, or about one out of 165 aircraft. The rate is almost identical to the overall fleet rate, but remember, we’re talking about all this risk on a single flight.

The rate of builder error accidents increases during the first flight and the test period—probably no surprise there. About 5.8% of all homebuilt accidents involve builder error. This rises to 15.2% during the test period and a rather stunning 26.2% for accidents occurring during the first flight.

Wrap-Up

Aviation is unusual compared to most other motorsports: Its participants are actively interested in safety issues. You won’t find many articles in car magazines on how to be a safer driver, but the various flying magazines are chock-full of pieces on how to be a better pilot.

Homebuilt aviation has gotten a “bad rap” over the years. It’s true our accident rate is higher than that of “normal” general aviation. After all, we’re flying planes that were built, maintained, flown and sometimes even designed by amateurs.

There’s a lot of hysteria about home-built accident rates, and it’s really not justified. We can do our part in reducing the concerns by more attention to our piloting skills, in-flight judgment and ensuring our aircraft are properly built.

I first started flying in 1954 and my first flying lesson was in J-3 with an A-65 that you hand propped. Ah, the good old days. Most engines were flat and we are still using many of them almost 70 years later. Look at the automotive industry and see how they have changed. An aircraft engine is not really much different from a lawnmower except that your lawnmover has a more modern ignition syatem. The typical car/pickup engine will last almost 5000 hours with minimal upkeep and many automotive engines were used in industrial applications as well and some of these engines will run 7000 hours or more. These engines operate at a higher RPM than aircraft engines as well. If we (as a group do not find a way to produce aircraft that most of our population can afford to purchase, build, or fly. We are on pretty shaky ground. Lets face it, an automobile is a heck of a lot more complex than a small aircrft.