Covering an airplane with fabric can seem a daunting task. Taken one step at a time, though, it is actually relatively simple. No matter what brand of fabric covering system you decide to use, the basics are the same. The surface being covered must be cleaned, repaired, inspected and then primed or varnished before the fabric can be attached to the structure. After accomplishing those steps, you then protect the fabric from sharp edges, ridges, etc. by using anti-chafe tape. The next step is to attach the fabric to the part.

Lets Get Started

Attaching the fabric is the first major task involved in the actual covering process. It is imperative that this step be done correctly. Proper attachment provides the foundation for the remainder of the process.

There are two ways to attach fabric to a part, either by using a pre-sewn envelope or by simply cutting the fabric and attaching it. If you elect to purchase a fabric envelope, it will slide over the part being covered like a sock. You would then attach one end and begin the shrinking process. You can save time by using an envelope, but the cost is higher. They are available for most aircraft.

Envelopes have a sewn seam that needs to be properly placed and hidden. This seam will be located on the outside of the envelope. You must then turn the envelope inside out to make sure the seam will be on the inside of the envelope against the structure, which will help hide the seam.

Can you buy the material and sew an envelope yourself? You could do this, providing you use the approved machine sewing thread. However, I do not recommend sewing your own envelope unless you have a commercial-grade machine. The fabric will wreak havoc on a regular sewing machine needle. Save yourself time and grief and order an envelope rather than attempting to sew it yourself. And if you are going to do any stitching at all, even by hand, you must use the proper polyester thread.

A Blanket Endorsement

If you want to save money and not worry about dealing with a sewn seam, you can cover the airplane surfaces using what we call the blanket method. The blanket method simply means you cut the fabric to fit and then attach it with fabric cement to the surface. With this in mind, lets go through the steps involved in attaching the fabric with this method, using a wing to illustrate the process.

Well assume that the wing is ready for cover. For a new fabric covering-that is, not a replacement or restoration-its essential that all of the surfaces are properly prepped. The preparation steps are explained in the manuals and videos, and we have touched on them in the previous installments of this series.

If you have elected to use the Poly-Fiber covering system, it is essential that you apply two coats of Poly-Brush on the leading edge of the wings and any other large plywood or metal surfaces prior to placing the fabric. This step provides a bed that will help the fabric adhere to large surfaces and also reduces the possibility of pinholes in later steps.

A few considerations before we begin. Fabric is generally attached using fabric cement. This is a special type of glue that has high strength in shear loads. Poly-Tak cement is used with the Poly-Fiber process. This cement is applied initially to the structure itself, and the fabric is then placed over the cement. The cement is worked up through the fabric to provide a bond.

This step is used only to hold the fabric in place on the structure. You will then wrap the fabric around the surface you are covering and overlap it where the fabric joins, which provides the necessary strength to secure the fabric to the surface. Again, fabric cement is applied to the fabric that you initially glued in place, and then the overlap is placed over the top of the cement and worked through the fabric. The overlap of fabric should be a minimum of 1 inch on all surfaces except the leading edge of wings, where it needs to be a minimum of 2 inches.

The First Cut Is the Deepest

Now it is time to cut the fabric. Most small aircraft wings have a chord that measures less than 70 inches. The width of both Ceconite and Poly-Fiber fabric is 70 inches. This means that you should be able to lay a piece of fabric on both the top and bottom of the wing and glue them in place, overlapping them as described later. Roll out a piece of fabric over the top of the wing, leaving enough extra to cover the entire butt end of the wing along with about 1 foot at the tip. (You will see later why we need the extra length at the tip.) Cut another piece the exact same length for the other side of the wing.

Before we actually attach the fabric, lets consider an issue that has to do strictly with the visual appeal of the finished product. Which side of the wing can you see when you are standing next to the airplane-top or bottom? If it is a high-wing airplane, you’ll more than likely be looking at the bottom. If its a low-wing airplane or the bottom wing of a biplane, you will see the top side of the wing

Once you’ve considered which side you can see, plan to glue the seams on the opposite side. This way, if the final cemented seam isn’t perfect, no one will notice. For example, on the lower wing of a biplane you will want to cover the bottom of the wing first, so that the top piece of fabric is overlapped and cemented to the bottom piece on the underside of the wing. This is purely cosmetic, but it is good to be thinking from the start about ways to make the finished piece not only technically correct but also visually attractive.

Now lets proceed with the attachment of the fabric to the wing. When applying the first piece of fabric, you should cement a 2-inch-wide area of fabric to the leading edge of the wing. Where this is located is up to you. The only requirement is that the second piece of fabric you install reaches far enough around the leading edge so that you can cement it to the first piece with a 2-inch overlap. This is for strength purposes. In other areas the overlap requirement is only 1 inch.

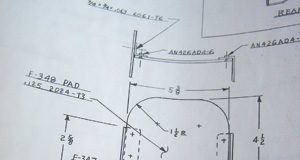

We will make our overlap on the centerline of the wings leading edge. To ensure that its straight use a chalk line and snap a line along the centerline as a marker. Then measure 1 inch above the centerline and 1 inch below the centerline and snap parallel lines at these marks. (Regular blue carpenters chalk line will disappear later and wont bleed through the final coatings-do not use red chalk). These chalk lines will be used as a guide later when cutting and cementing the fabric to the leading edge. When marking fabric for cutting, always use a pencil-never an ink pen. Ink will bleed through the final paint coat.

Over You Go…

Next, position the wing topside up. You will now need lots of clothespins and spring clamps to clamp the fabric in place. Lay the fabric on the wing, ensuring that it rests smoothly on the surface, and then clamp it in place exactly in the position where it will be cemented. You will usually have to reposition the clamps at least once before you are ready to cement. Keep repositioning the fabric until it rests smoothly on the surface. Do not start to cut or glue until the fabric is clamped in position. This is true when you are covering any structure.

How tight should the fabric be when you initially glue it in place? The tightness here will affect the final tautness of the fabric. Heat tightening will shrink the fabric about 10%, so on a 50-inch-wide wing, the fabric will shrink about 5 inches. You do not want the fabric so loose that it will not properly tighten and, conversely, you do not want it so tight that structural damage results from the heat-shrinking process. You can actually bend or warp light structures during heat shrinking if the fabric is too taut to begin with.

For example, if you are covering a wing, the fabric should be attached loose enough to allow you to pull the fabric above the top of the structure about an inch. This is a rule of thumb. As you gain experience with the process you will be able to properly judge the amount of tautness required.

The first question is where to begin gluing the fabric to the wing, and the answer is that it doesn’t really matter. Do whatever seems most practical-with one exception: Always do the wingtip bow last. We will begin with the trailing edge and aileron.

Apply a wet bed of cement to the surface using a 1-inch brush and then press the fabric into the wet cement. Its important that you don’t go over the top of the fabric with more cement. You want the solvents to evaporate out through the fabric.

Work with no more than a 12- to 18-inch strip of cement at a time. It is advisable to go over the fabric using a small plastic or rubber squeegee to remove the excess cement so that there are no lumps in the seams. In some areas you will not be able to use a squeegee, and you will have to use your fingers. (Protect your hands using latex gloves or Invisible Glove hand cream.)

Next, well cement the fabric to the butt or wingroot rib. This is done on the side of the rib that will be next to the fuselage. You are not actually attaching fabric to the capstrip area of the rib, but doing this now will help secure the fabric in position before turning the wing over to cement the leading edge. We now have the fabric glued in position on the trailing edge and at the butt rib where the wing attaches to the fuselage.

Now we are looking at the bottom side of the wing where we will glue the fabric to the leading edge. (Again, we are assuming the wing we are covering will be visible from the bottom side, so we will want our overlap on the top of the wing.) The next step is to cut the fabric along the snapped chalk line that is 1 inch from the centerline toward the top of the wing. You should be able to see the chalk line through the fabric, and this will show you where to cut. Now snap a chalk line on the piece of fabric that exactly corresponds to the chalk line already on the wing.

Before cementing the fabric to the leading edge it must be cut to the proper size so that the seam follows our chalk line on the leading edge. Don’t make the cut yet. The fabric will want to fray badly when cut. If this happens, and you glue it down with the frayed ends, you will forever see them in the finished piece. Remember, in fabric covering, if you can feel it, you’ll see it in the final product.

There is a trick to keeping the fabric from fraying, and you should do this every time you’re about to cut a piece of fabric. With a 1-inch brush, coat the area you are about to cut with a small amount of cement. This seals the fabric weave and will keep the fabric from fraying. Always use a good pair of straight scissors (not pinking shears) to cut the fabric. We want a straight edge for this seam. Why not pinking shears? We want to hide this cut under the second piece of fabric. A pinked edge has about 40% more edge area than a straight cut, so it is much more difficult to hide.

Lets cut the fabric carefully along the blue chalk line. Now we are ready to glue the fabric in place. Starting in the middle, cement the fabric to the leading edge using the chalk line previously snapped as a guide. Work in sections of 12 to 18 inches. Brush at least a 2-inch-wide wet bed of cement on the leading edge, press the fabric down into it and, using a squeegee, remove the excess.

The squeegee accomplishes two things: It firmly presses the fabric into the cement and also keeps the glued area free from lumps. As you squeegee, put a slight side load on the fabric in the direction you’re cementing, but do not pull and tug on the fabric.

When you arrive at the tip end of the leading-edge skin where the wingtip starts, make a small vertical cut down the leading edge material and cement that area. Leave the tip fabric loose for the moment. We are going to use a process called heat forming to mold the fabric around the wingtip. We will actually pull the fabric tight around the tip and iron it to the contour.

First, set your iron to 250 to 300 F-this is for reference at this point. Well get into the details of how much heat to use when, and how to calibrate your iron in the next installment. Then begin ironing toward the hand thats pulling, but always perpendicular to the tip bow. Pull straight, and do a little at a time until the fabric lies perfectly flat. Carefully cut off the excess fabric along the curve, and start cementing in the center. Apply a bed of cement and then press the fabric into it. Hand-squeegee out the excess.

Bottoms Up

Now we have fabric attached to the top side of our wing. We are ready to glue the other piece we have cut to the bottom side. Before we begin this process, take a look at your cemented areas. Any lumps or excesses? If so, they should be smoothed out, otherwise they will show in the final product. Remove the cement with a clean rag and MEK (protect your hands). Be sure not to scrub the seams, as that will fuzz up the edge. Always rub in the direction that causes the fibers to lie down in the seam edge.

Now smooth out any wrinkled areas with your iron set at about 200. If you have a wrinkle that wont go away, you may turn the temperature of the iron up a bit, but be careful. Too much heat will release the cement bond. The objective here is to clean up and smooth out all areas where you will be cementing the second piece of fabric onto the first one.

Lets glue the other piece and complete the attachment step. Initially, position the wing with the covered side up. First, snap a line 1 inch inboard of the trailing edge on the fabric. This will give you a guide for gluing the fabric, ensuring the proper 1-inch overlap. On the leading edge, snap a line 2 inches past the edge of our first piece of fabric.

Now for the bottom piece. Turn the wing over and clamp the fabric in place as before, making sure it rests smoothly on the surface. Begin cementing in the aileron well (if there is one). You will have to cut the fabric to get it to properly fit. Remember to coat the fabric with cement before cutting. You can cut into corners at a 45 angle to remove the excess fabric. Next, cement the fabric onto the butt or root rib.

We now need to turn the wing over to glue the seams. You can spot-glue areas of the leading fabric to hold it in place while rotating the wing. You will be able to see the chalk line previously snapped on both the leading and trailing edges through the fabric. Snap a chalk line onto the fabric itself that corresponds to each line underneath. Apply cement to the line and carefully cut the fabric.

You can now use fabric clamps to hold the trailing edge fabric in position while you cement the leading-edge seam. Important: You have a blue chalk line on both the leading and trailing edges, and you have a corresponding blue chalk line on the second piece of fabric that is about to be cemented to the first. These two lines should meet when you cement the seams. If they do, you will have a perfectly straight seam.

Cement the fabric to the leading edge with a 2-inch-wide glue area. Start in the middle and, with the squeegee, work your way to each end, using a slight sideways motion as you go. Cement the trailing edge using this same technique. It really does not matter whether you cement the leading edge or the trailing edge first.

The last step is the wingtip bow. Heat form the tip just as you did before. Pull and iron toward your hand. Keep going until there is an inch of fabric resting flat around the tip. Using your pencil and a ruler, carefully draw a line 1 inch in from the tip bow radius. Cement the line and make the cut. Now use the cement to secure this edge in place.

You now have successfully covered the wing. Go back over any rough areas, and smooth them. Next time, well discuss how to calibrate your iron and take a detailed look at shrinking the fabric to the airplane structures.