The first flight of any Experimental aircraft should be well planned and little advertised. That is to say, a great deal of time should go into the preparation, planning and training for the first flight—and thought should be put into who needs to be there for the event. No one else needs to know.

Why keep the first flight a carefully guarded secret? First, it’s to keep the crowds—and the distractions that come with them—to a minimum. Living at an airpark as we do, it is guaranteed that if one person knows a first flight is going to happen, almost the entire neighborhood will appear to see the event and want to be a part of it. That’s only natural, and it’s not a bad thing for folks to know and be around to congratulate the builder/owner/pilot. But congratulations should come after the event, not get in the way of making it happen. Let them celebrate and gather after the landing. Maybe watch from afar. But getting it off the ground is difficult enough without a crowd getting in the way.

The second reason to keep those “in the know” to a minimum again has to do with the crowds—but more importantly, to avoid “pressure to launch.” If you have advertised that you’re going to fly your new homebuilt at 8 a.m. on Saturday morning, then the winds come up, it’s much easier to decide to scrub if only two helpers are there rather than to disappoint the entire neighborhood (or airport crowd). In the space business, “go fever” was real and it was deadly, which is why we developed a thick skin (and often an aloof manner) when it came to scrubbing a flight. Best to have only those who know and understand the scrub criteria be in on the launch. That way you don’t have to explain it to everyone else.

So why is this important? In the case of our eXenos, we finally got it off the ground after something like eight or nine years in the build process. The entire airpark knew it was getting close. But since we weren’t going to use a chase plane and only needed a pilot, a crew chief/test conductor and a photographer, we kept the first flight quiet—and still had a full crowd when we landed. Which worked out great!

First Flight Prep

Normally, I fly about 350 hours a year, and much of that is in Experimental aircraft doing test and evaluation flying, so you’d think I’d be ready to hop in the eXenos and go. Sadly, our winter has been so bad that I have flown far less than I’d like since the snow began to fly in early December. So it made sense to commit some serious flying in familiar airplanes beforehand. By serious, I mean complete stall series, aerobatics and, above all, power-off landings to touchdown. It’s also important to be familiar with what you are going to fly. A short-wing RV is much different than a 46-foot-span wing on an LSA-weight airplane. Being current is not enough—you need to be “flight test current.”

Finally we need to prepare for the flight test program. Flight testing in Phase I is not about building hours—it is about testing the machine in a methodical manner. The easiest documented program I know of is the EAA Flight Test Program. It was developed for private pilots to test their homebuilts and contains many detailed test procedures for the types of test you need to prove the aircraft. But it was built for a typical light airplane, not a glider. That means I’ll go through it test card by test card and figure out what is appropriate, what can be deleted and what needs to be added. The first few flights will be pretty standard. But after that, we’ll be doing more work on glide performance than we will for cross-country cruise.

I had flown Gabe DeVault’s prototype eXenos previously and had received a Xenos checkout as part of an evaluation flight many years before at the factory. That meant I had a pretty good idea how the airplane would fly. I had carefully watched the motor management from my flight with Gabe, so operating the aircraft was not a mystery. The eXenos power system is so simple to operate that it almost feels like cheating.

Part of my flight prep includes power-off landings, as mentioned. Of course, the eXenos, being a glider, is designed to land power off (when needed), so it has a better glide capability than our short-wing RVs. But it was still valuable to pull power at various points on the downwind and get back into the rhythm of power-off landings. I also took up my SubSonex jet to do some slow flight and approach to stalls because the Y-tail (that it has in common with the eXenos) is a little different when it comes to yaw stability at the bottom end of the speed range. Getting back that feel of Dutch roll near the stall was important to expand the envelope of my skill set.

I also flew a full rehearsal of the first flight, including early power reductions (and the resulting poor climb that would result) on initial climb-out and getting familiar with where I would go at various points in the test plan if things didn’t go as planned. Again, the RVs can’t simulate the glide characteristics of the big eXenos wing, but working through the potential problems gets both the mind and muscle reflexes sharp.

First Flight

With the plane ready and the pilot sharpened up, it was simply a wait for good weather and winds. We wanted good visibility, high (or no) clouds and winds light down the runway—favoring our Runway 5, since that is both downhill and has better options for an engine out. Light to no winds would be ideal because Runway 23 (the opposite direction) has both a better (flatter) approach and is uphill—ideal landing conditions. These requirements pushed for an early morning launch, but not so early that the sun would be right in my eyes for takeoff. So we pegged a morning with predicted light winds until almost noon and, fortunately, got exactly that on a Saturday morning in April.

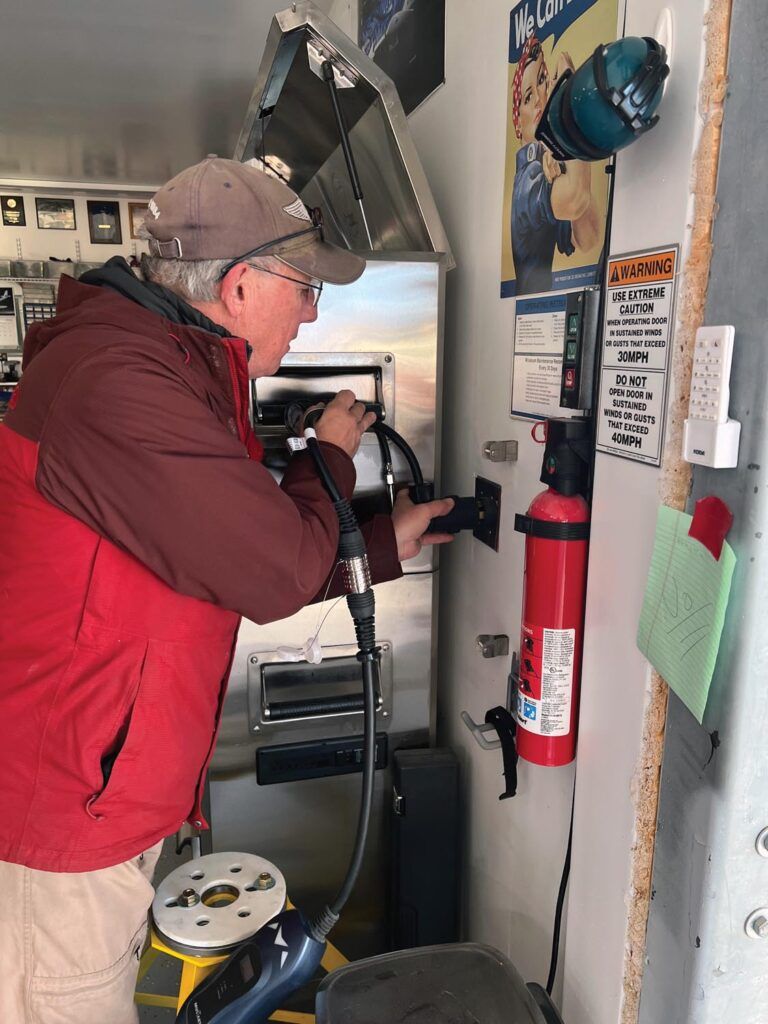

We rolled the airplane out of the storage hangar and taxied it to our shop, where the charging setup is located. This taxi gave me a chance to test my helmet with the radio and to make sure the power system was happy. As I’ll point out later, the com checkout was incomplete—a common problem with many first flights! We generally store the

eXenos with between 30% and 98% charge because it is better for the battery. This morning it was at 92%, so it needed a top-off before the first flight.

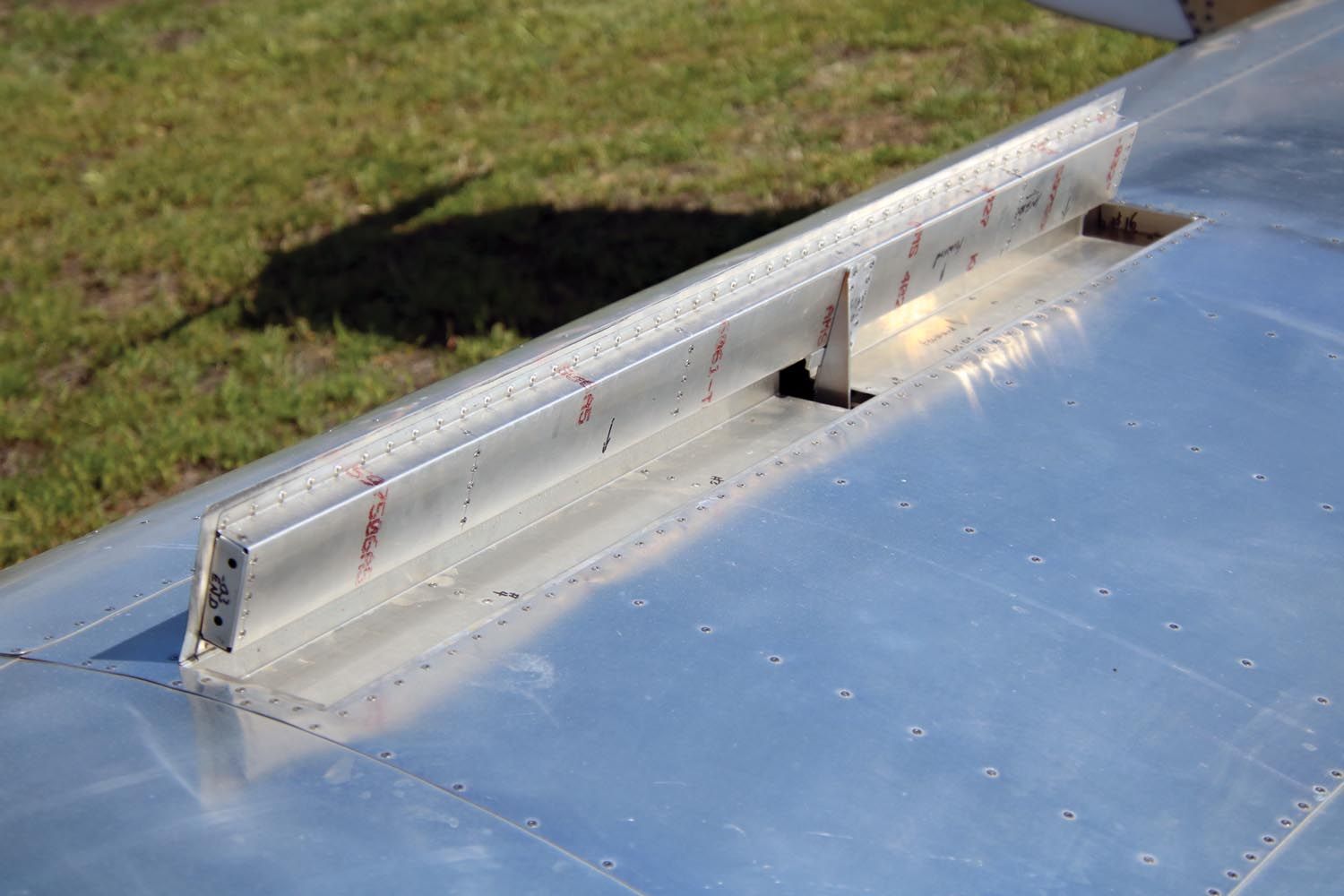

Our first flight used the EAA Flight Test Manual Test Card #2 (First Flight) with a very simple plan. Basically, this was a takeoff and climb to a safe altitude over the field, a few checks of stability in all three axes, some approaches to stalls, a practice landing at altitude and then a landing. Simple, quick and to the point. I crossed off anything having to do with internal combustion—checking oil and cylinder head temps—and added checks of motor, controller and battery temps instead. Instead of checking that the flaps were in takeoff position (there are no flaps) I added checking that the spoilers were closed.

Because I was not planning on climbing more than 2000 feet agl (6400 feet msl), I eliminated the use of a parachute because I wasn’t really going to be high enough to use it. Plus, the cockpit is small enough that when I tried wearing a parachute, I didn’t have full use of the elevator control. So the ’chute stayed on the ground. I did, however, wear a helmet in case I ended up in the desert or had an off-runway excursion. It would be silly to have a head injury due to a low-speed flip when there is a helmet sitting in the gear locker.

It was also important to install an iPhone in a bracket on the panel because you use the Zero Motorcycle app to monitor temperatures and power levels. The motorcycle dash on the glareshield is great for state of charge (SOC) but not much else. It turns out that the iPhone is more useful during flight operations because you can see motor, controller and battery temps, as well as output power (in kW) and SOC.

Now’s the Time

With the battery topped off it was time to go fly! Strapped in, with the test card on the kneeboard, the most remarkable thing about flying the eXenos was how there was essentially nothing to do but fly! The start procedure is to turn on the master, then turn on the motor arm switch. Then simply push the throttle forward to taxi to the runway. No complicated startup, no fuel management, no watching temperatures. Taxiing does take a little more attention than with your typical light aircraft because, with wingtips in the next zip code, you need to be careful not to drag one through the sagebrush or a neighbor’s hedge.

It should be noted that we had modified the standard Xenos tailwheel setup to allow us to make sharper turns in order to stay out of the weeds at our airpark. Instead of a single brake lever for both wheels and a non-swiveling tailwheel fixed to the rudder, we had installed a swiveling, steerable tailwheel and individual toe brakes. This worked out well, and so long as you watch for those hedges and sagebrush, ground handling was fine.

When I got to the runway there was just nothing to do. A CIGAR check—controls, instruments, gas [!], altimeter, radio—was about it. As happens during taxiing, when you pull to the hold-short line to check for traffic and pull the throttle back to idle, the prop stops. No, the engine hasn’t stalled—it’s just off until you push the knob forward again.

With the few preliminaries complete, I rolled out on the runway, lined up and added full power. And of course at this point the intercom squelch opened and all I got in my helmet ear cups was motor noise and static. Note to self: For future first flights, check the com system at full power on the ground! I could just hear radio traffic on CTAF, however, so I proceeded, since this airplane was already light on the gear. Acceleration is far from spectacular, but that is probably partly because I am used to the overpowered RVs with constant-speed props.

Nevertheless, the eXenos tail came up with a little coaxing in maybe 300 feet and we lifted off at about the 600-foot point. It accelerated in ground effect for a few seconds, then I lifted it to about 50 feet to check roll and pitch controls. With positive control assured, I eased back on the stick and began a climb. If I hadn’t liked the control feel, I could have set back down on the long runway. Now I was headed to the pattern.

The motor heats up quickly at full power and low airspeed. By the time I was at 300 feet, I was seeing the temperature climbing through 200° F, headed for our arbitrary limit of 250°, which protects the real limit of 300°. Fortunately, throttling back to a good climb power of about 25 kW (about half the maximum of 55 and below the max-continuous of 28) slowed and then quickly reversed the temperature rise—and still gave me a 300–400 fpm climb. Temperature management is important but not difficult. It’s also important to note that we’re at an altitude of 4400 feet msl to begin with, so the cooling air is a little thinner than at sea level, where Gabe developed the package.

With positive rate assured, I climbed into a circling pattern 2000 feet agl, making sure I was within gliding distance of the airport. Gabe had informed me that the minimum level flight power for his eXenos was about 10 kW, so I set about 18, where the motor temps kept dropping, and that gave about 65 knots indicated (KIAS). The aircraft was comfortable to fly at that speed. I watched temperatures for a few minutes while feeling out the controls a little more. Pulling half spoilers gave little trim change, but initiated about a 400 fpm descent rate. Good to know!

Throttling back to idle, the prop windmilled because there is no compression for it to work against. I eased back in a slow deceleration. A bit of a rattling buffet set in at 42 KIAS and the nose dropped slightly when the stall came at 38 KIAS, with a slow right-wing drop. I repeated the stall a couple of times and got the same response. Sonex says the stall occurs at 38, so I was happy with the airframe as well as the rough calibration of the airspeed indicator.

Next I added power back in to climb back to 2000 feet agl, then set half spoilers for the planned landing configuration and once again achieved level flight. It takes a fair amount of power to counteract the spoilers—they aren’t speed brakes, they spoil the lift. Level with half spoilers, I pulled power back for a 400-fpm descent and simulated a final approach and flare, all of which felt stable. With that test complete, it was time to head back to the runway and call it a flight. I had been advised by former Sonex Flight Operations Manager Joe Norris to use half spoilers for landing or the airplane would never land—“they’ll have to shoot you down” was something I heard. So that’s how I landed. The first touchdown was just slightly tailwheel first but well controlled. After touchdown, full spoilers kept the eXenos pinned to the ground and the flight was complete!

I taxied to a ramp full of neighbors, which was great! They didn’t get in the way before and they stayed out of the way during the first flight, so we toasted the new airplane with sparkling (non-alcoholic) juice so that I could go up again after the batteries were recharged. With the first flight out of the way, the real test program could commence!

celebratory crowd is after the first flight.

Moving Forward—Test, Test, Test

Because our new operating limitations permit us to do a task-based Phase I instead of a mandatory 40 hours—there is no way a powerplant from a motorcycle is going to qualify for a 25-hour test program—we opened up the rest of the EAA test cards and looked at what needed to stay, what could go and what just needed to be modified. For instance, with no flaps and fixed gear, the Flaps and Gear card certainly was on the “go” list. But spoilers need to be tested, and the rates of descent and stall characteristics quantified for the spoilers, so they’ll get their own card. Cross-country performance will be of limited value, but I’ll get speed/power numbers at various altitudes so that we have an idea of what’s possible.

I completed the second flight as a repeat of the first, simply because this is such a new powerplant configuration. There is no rule saying that you can’t “mark time” in the test program until you’re comfortable. In fact, the expectation is that you’ll continue to work on each test card until you’re happy with the results of each test. You can repeat cards as you need to.

The electric powerplant will take some quantification and getting used to, so I’ll probably make up a few more cards on temperature management versus flight regime. But many of the cards—stall test, Vx/Vy, etc.—will be flown just as they are written.

When all is said and done, I expect Phase I to take longer on the calendar than our other planes because flights are going to be shorter—it takes a couple of hours to charge the battery and it’s not expected that the eXenos will have tremendous endurance. In our neck of the woods, winds pick up significantly as the day goes on, so an early morning flight followed by a charge cycle might or might not lead to a second flight.

The best news is that aside from the differences in managing power and temps, the eXenos flies pretty much like the gas-powered Xenos, with stall speeds nearly identical. At comparable weights, I expect that we’ll match the factory numbers and charts in the Sonex flight manual relatively closely, so when we finish the test program and fill in the blanks we should have a well-documented machine. And that, after all, is the point of task-based testing. It’s not about getting into Phase II earlier, it is about getting there better.

Photos: Paul Dye, Louise Hose, Barry Wingate & Marc Cook