Hi, my name is Gabe and I’m an unabashed electric airplane nerd. I have built and flown two of my own electric aircraft, and I have assisted in another dozen or so electric aircraft efforts, both recreational and professional.

I was a founding team member and ran R&D for Zero Motorcycles for about five years. I worked at JOBY when they were just a small team of a dozen engineers or so, I did a five-year stint as an industrial drone designer, and I now work for ZeroAvia as head of drivetrain, where we are developing hydrogen fuel cell electric powerplants for commercial aircraft. Oh, I also designed the electric powerplant you might have seen in the Aerolite 103 EV flying around at Sun ’n Fun and AirVenture this year.

While that might sound like a lot of high-tech nerdiness, rest assured, I am just like you, and I just want to build and fly airplanes!

After Paul Dye and Marc Cook visited and wrote the article on my Electric Xenos, and Dean Sigler had done a few articles on my E-Gull, it dawned on me that perhaps there is enough interest for me to start a series of articles on electric aircraft, components and technology, and how they are relevant to kitbuilding today.

One of the more amusing/frustrating aspects of electric aviation (and all EVs in general) is just how misunderstood the basic fundamentals are. There’s a good chance you know how an internal combustion engine (ICE) works, right? Pistons, cylinders, carbs, valves, ignitions, CHT, EGT, 100LL, etc. But if I tell you my electric plane has a 55 kW motor and a 15 kWh battery, does that mean anything to you? If it does, you may find some of this material boring. if not, read on and I will do my best to elevate your knowledge on the subject of electric flight.

I plan to write a series of articles demystifying and explaining many aspects of electric aviation. I’ll cover electric powerplant basics, motors, batteries, controllers, safety, cost, charging, etc. But I’d like to start by helping you expand your knowledge of ICE powerplants and electric powerplants. Once you wrap your mind around a few simple concepts, you’ll find they are not so different after all. The propeller doesn’t know or care what’s making it spin around.

So let’s get started on “power” and “energy” (and apologies in advance to users of the metric system).

Translating Watts to Horsepower

What’s the number one metric everyone wants to know about an ICE powerplant? How about power, specifically horsepower? When I tell you my ICE has 75 hp, you probably intuitively know what that means, right? You know that’s plenty of power for a Piper Cub or similar small aircraft but probably not enough for much more. An ultralight or self-launching sailplane can fly on as little as 20 hp or so. A Cessna 140 has an 85-hp engine, a 150 has 100 hp, a 172 has 160 hp, and so on.

When I tell you my electric Xenos has a 55 kW motor, this translates to approximately 75 hp. Watts translate to horsepower directly; they are both units of power. Don’t be confused or led astray by the fact they have different rpm and torque characteristics. Power is power. To convert from watts to horsepower, you just divide the number of watts by 745 to get horsepower. Using the more normal metric of kW, you can simply multiply by 1.34 to get horsepower.

Because 55,000 watts is a cumbersome number, we condense to kilowatts (thousands of watts) and then abbreviate kilowatts to kW. Thus 55 kW; simple, right? You’d be amazed how many genuinely intelligent folks get this wrong. One of the most common mistakes I see is folks using kWh in error and mixing up kW and kWh. A kilowatt hour is a unit of energy, not a unit of power. Saying you have a 55 kWh motor would be like saying you have a 75 gallon engine, which is of course just silly.

This provides us a nice segue to energy. In electric energy storage systems, it is customary to use watt hours as the measurement for capacity. This is simply the amount of power your energy storage could provide in one hour and would be just like measuring your ICE fuel in horsepower hours. This is actually quite convenient. If your plane cruises at 50 hp and you have 100 “horsepower hours” remaining, you’d have two hours duration. Get it? To keep the units reasonable we use “kilowatt hours,” and this is generally analogous to saying “gallons of fuel.” Once again, there is a very direct conversion of energy from gallons (or liters) of gas to kWh of energy. One gallon of gas is equivalent to 33.7 kWh of energy.

So now, when I tell you my electric Xenos has a 55 kW motor and a 15 kWh battery, you can do some simple math and determine that this means my airplane has approximately 75 hp and a bit less than half a gallon of gas equivalent energy storage. So you might say, “It’s got plenty of power, but not much gas,” and you’d be right.

Powerplant and Airframe Efficiency

Electric powerplants have no problem delivering lots of power. It’s energy storage that is their weakness. But electric powerplants have an incredible performance edge that allows them to claw back some of that deficiency, namely efficiency. Efficiency is the ability to turn stored energy into motive power. Power is what makes the propeller spin, and an electric drive can do this about three times more efficiently than an ICE powerplant. A good electric powerplant is about 90% efficient, while traditional aircraft ICE engines are about 30% efficient. This means my half gallon of energy storage in my electric Xenos, is actually equivalent to about 1.5 gallons of stored energy in a traditional ICE powerplant. “Well that’s still not very much,” an astute reader might say. And you’d be right again.

And here we must use our last trick to make electric airplanes work: efficient airframes. How much power does your Cessna need to fly 100 mph (or knots, or whatever), I’m pretty sure the Cessna 150 I learned to fly in burned about 4.5 gph at just about 100 mph. So that’s 4 gallons at 33.7 kWh equivalent energy to equal approximately 150 kWh of energy total for one hour of flight at 100 mph. We then apply the abysmal 30% efficiency of the ICE to give us approximately 45 kW (about 60 hp) of power required. We just showed that a Cessna 150 needs about 45 kW to fly 100 mph by calculating the energy used through fuel consumption rate. Are you still with me? Good. If not, apologies for not being a better teacher. Regardless, let’s carry on.

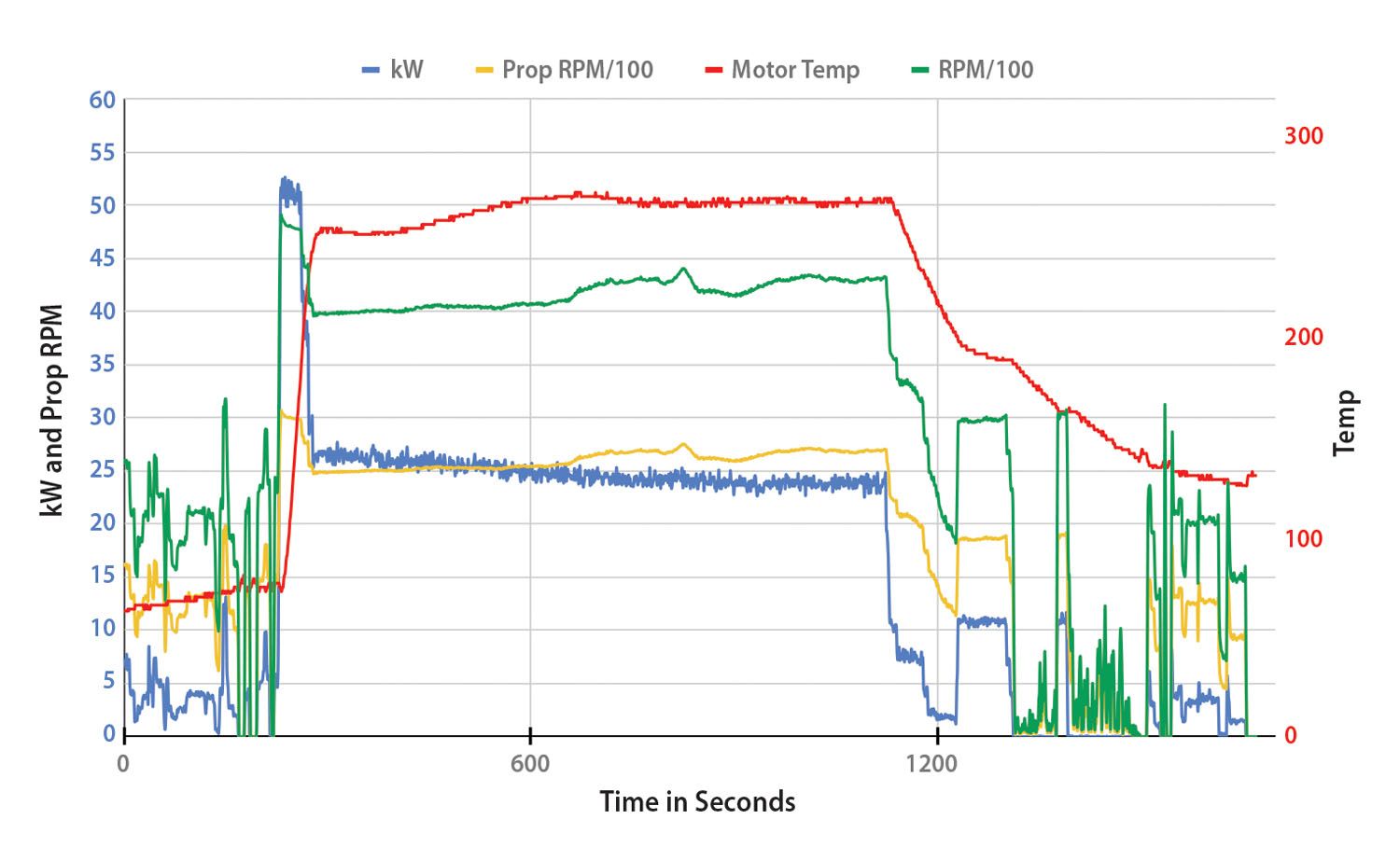

Back to the topic at hand. What if I told you my electric Xenos needs only about 21 kW (approximately 28 hp) to fly 100 mph? It’s true and I can prove it. Below is a video and data log (Figure 1) of a flight in California from Watsonville (KWVI) to Hollister (KCVH). After leveling at about 2500 feet, I just let it run and clocked approximately 110 mph airspeed at about 24 kW and approximately 100 mph at about 21 kW.

That’s a bit more than double the efficiency of energy turned into range (compared to the Cessna 150) based purely on aerodynamics and has nothing to do with the electric powerplant. Aerodynamic efficiency is like magic and makes all airplanes better regardless of power or energy source.

OK, so now we’re getting somewhere, right? Because of our efficient airframe, we can turn that 1.5-gallon equivalent of energy into about 3.5 gallons of equivalent performance. “Well that’s still not much,” you’re probably saying, so now say it with me: “You’d be right.”

Consuming 21 kW from our 15 kWh battery, we only get 15/21 of an hour: about 43 minutes of flight. “Not much after factoring in 30 minutes of VFR reserves,” you might say, but this is where we push the efficiency even higher. We fly slower, we fly at best glide (Vbg) speed. Did you know Vbg is also your most efficient speed for level flight? It’s true! But because of the non-linear power-efficiency curve of an ICE powerplant, this does not mean your Cessna will be most efficient at this speed. But because electric powerplants do have fairly linear efficiencies across most of their rpm range, it does hold true for electric airplanes.

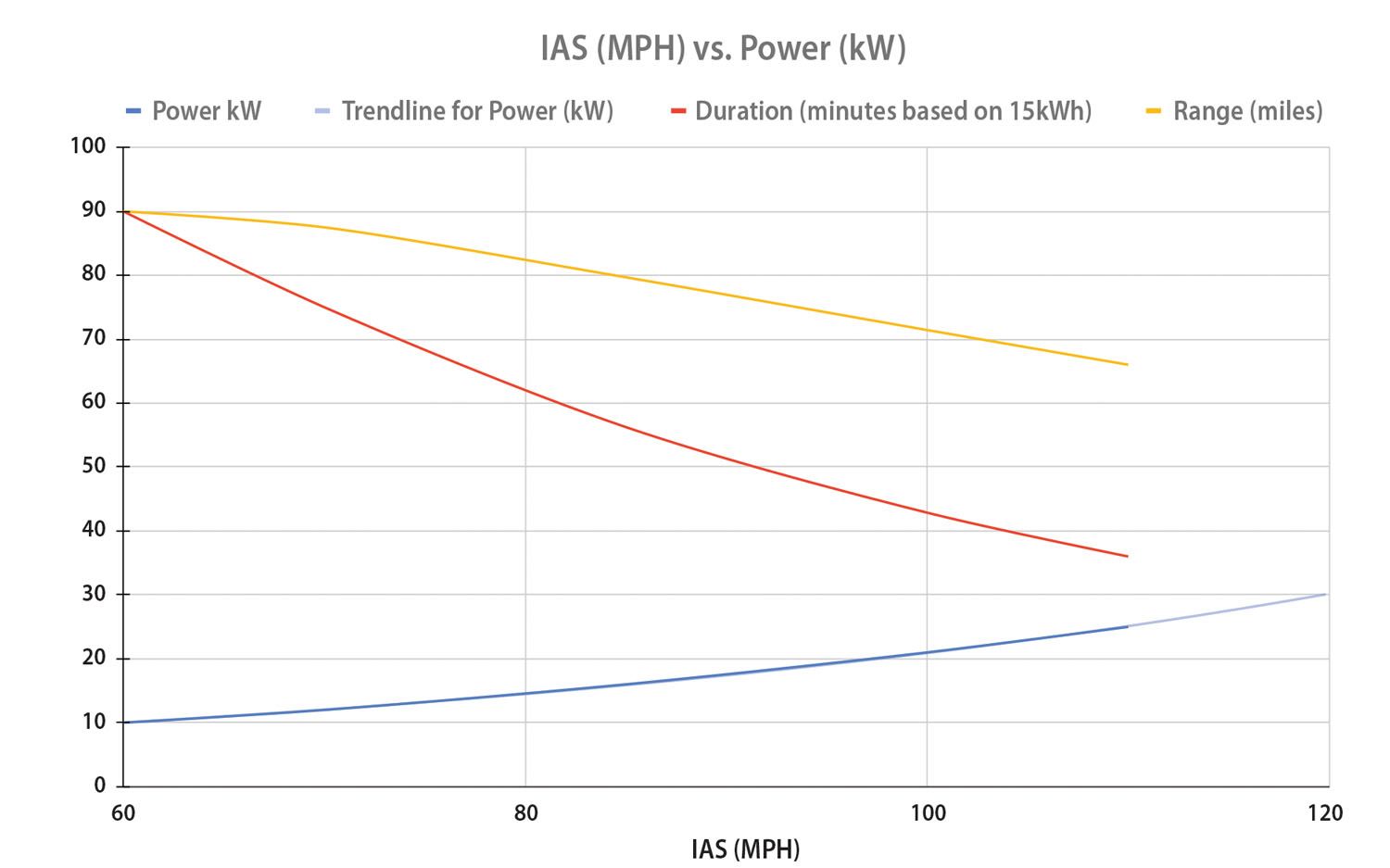

So, what if I told you (sorry, last time, I swear) that the electric Xenos can fly at 60 mph with only 9 kW of power? It’s true and I can prove it. Figure 2 is a speed to power graph I created using actual data-logged measurements.

As you can see, when flying at 100 mph, our duration is about 43 minutes and our range is about 72 miles. By reducing our airspeed to 60 mph, our range goes up to 100 miles and our duration to 100 minutes. Now that works out to 70 minutes over VFR reserves—not bad, eh?

I never claimed this was truly practical, and I never said we were going very far or very fast, but those are purely subjective sentiments, and everyone will have their own opinion. All I can say with authority is, I took an existing off-the-shelf electric powerplant and combined it with an existing off-the-shelf efficient airframe and, in my opinion, it’s lots of fun!

Homework Time

Your assignment, if you choose to accept it, is to do some quick calcs on other aircraft. How much power and energy do they have? You may notice if you Google an aircraft, it frequently lists the powerplant power in kW already. Welcome to the wonderful world of the metric system!

Here’s an example:

A Cessna 172 has 160 hp and 56 gallons of fuel capacity.

This works out to:

160 hp / 1.34 = 119.4 kW

56 gallons x 33.7 = 1887 kWh (or 1.887 MWh)

Now, 1.8 MWh is a lot of energy! A big Tesla battery is about 100 kWh these days. But also don’t forget that the Cessna has a very inefficient engine. If you stuffed a 100 kWh Tesla battery into a Cessna 172 (assuming equivalent weight and space of the fuel it replaced) and converted its energy into motive power at 90% efficiency instead of 30%, you’d get about 300 kWh equivalent energy, or about 1/6 a full fuel load. That’s good for about an hour. Only that battery actually weighs more than double the fuel it replaced. That means you can only load half the battery, which means you only get 1/12 of the equivalent fuel load. Plus you now have a big chunk of battery you have to package somewhere in your airframe. Sigh, electric airplanes are hard…

The big attractions of electric airplanes are the essentially near zero maintenance costs of electric motor, less local pollution and the low cost per mile of electricity vs 100LL. The flaw is their extremely low energy density, ie the lbs of fuel/battery to fly each mile.

As your article illustrates, electric airplanes may be practical only for low volume training academies that fly in 1 hour units, that can afford to let an expensive asset sit idle for 2 hours, while it recharges the battery. Even if swappable battery packs were developed, the time to safely do so plus the capital cost of an additional battery pack will offset any gains in increased productivity.

That and short distance commutes in a motor glider.

So, IMHO, the real future of electric lies in Hybrid Systems, where a lightweight ICE running at it’s most efficient settings, is geared to provide cruise power (either driving prop or generator), engaged at an altitude above AGL, with takeoff under the authority of the electric engine only, with limited battery energy sufficient for that task. (Recharge during cruise)

Ideally I like to see an electric traction motor up front, with ICE and batteries aft – which would move the passenger cabin forward of the wing, vastly improving visibility.

Thanks Gabe! Already your first article is helping me a lot. I’m working on my homework and other calculations.

Perhaps you could provide some advice on sourcing motors, drivers, batteries, etc. Components seem inaccessible compared to internal combustion.

Thomas EV West is a good place to find Tesla battery packs. Such as the Tesla S model 18 650 they produce 5.3 kwh at 22.8. And weigh in at 55 lb. So two packs for 48 volt motor. They have a variety of motors with different horsepower and torque ranges. But there are more efficient Motors out there such as radials or radial axial Motors. Pay attention to the RPMs if it needs to be reduced available torque will be multiplied.

Motors are the inexpensive part. That Tesla pack will set you back $1,500 (per pack) many cars will run 8 to 10 packs but also get a 200 mile range. I’ve built a few planes over the decades and have two that Can Go the Distance. I have a current build. I’m planning on electric for local flight.

But my only experience with electric has been with 2 buggies I have built. Good luck have fun be safe.

Great job. I taught Electrical Trades for 30 years and co-wrote a text book “Electrical Principles for the Electrical Trades” . One concept Mechanics need to appreciate is that Mechanical Engines are rated at maximum output, usually for a limited period, while Electric Motors are normally rated 24/7, all year in many cases as long as the energy is available, and can produce 6 to 7 times that power for short bursts.

The second comment I want to make is that in the same spirit as gliding, Electric Propulsion and energy storage can regenerate the energy back into the storage device.

I will be following your series enthusiastically, with thanks, Bob Harper.

I’m too old to start building but have worked with electricity my whole life and am very interested. Better batteries are coming, maybe within the year. Thanks for the article.

Art Dobson

Thank you your input is very appreciated my current build will be Electric. But my only experience has been with buggies. Does regenerative braking make sense? Can you actually recoup energy on your descent? And what about the idle function found in many of the speed controller nowdays? Obviously what works on the ground may not necessarily work in the air.

And what about the electric radial Motors or radial axial Motors? They seem to give a higher broader torque range for a lot less weight.

Great article! Looking forward to your future articles. Also looking forward to tech improvements like solid state batteries.

I have an airplane (Starlite) I would like to convert to electric power. Very efficient airplane at 256 pounds empty and 40 hp two cycle motor cruises at 120 mph. 300 mile/3 hour range on 7 gallons gas. I could be very happy cruising at 60 with only an hour duration. The big issue is I know little about electronics and limited budget. (social security). Seems like a motor controller would be the biggest issue. Would be interested in hearing any helpful information.

You can check my plane out in action on YouTube. StarLite Experimental GoPro HD

Thanks Gabriel. I have been waiting for a long time for a series like this. Like many here, I would like to be able to source the right combination of Motor, Controller, and Battery package. Hopefully, your series will give us all the ability to speak intelligently with those in the field.

Hi Gabriel,

I enjoyed the primer on electric aircraft. Thank you. I am looking at making (including designing) an electric (possibly hybrid) airplane. I am thinking Blended Wing Body because it is likely to have superior load capacity and lots of room for bulky batteries and bulky me! My thinking is to spread the load out into the wings (not me, just the batts) to keep structural weight down. Not asking you to design it but would like to hear your thoughts on what you feel might be the optimum platform to start with. You chose Xenos as it is more efficient aerodynamically. Do you think a motor glider would be even better as a starting point?

The zoomed in screen shot above shows a 200fpm dive at 110mph. Confirmed on the video flight, looks more like 95mph is level flight to me.

About the range of an electric aircraft:

Gabriel states that an aircraft for cruise should be flown at best range speed, which is of course true. With the motor glider that he is flying this is a very low speed. Most aircraft however are already designed for cruising at their best range speed together with a reasonable power setting for having a good engine efficiency. Besides that, flying slow with headwind gives a very bad range.

I made calculations with my D2 delta aircraft, which has a high best range speed due to its low aspect ratio. The payload is 325 kg with the Rotax 912S, an electric motor is lighter, say 30 kgs lighter, so that leaves 355 kg for pilot and batteries. I weigh 75 kg, say 80 incl clothes, leaves for batteries 275 kg. The energy density nowadays is about 0,2 kWh/kg, so 55 kWh. Power for best range at MTOW is 50 kW. Endurance 55/50 = 1.1 hr, at a speed of 130 kts this is 143 Nm. With 30 min reserve it would be 78 Nm, 90 miles. So the same as the Xenos but more than 2 times faster.

Questions can be put at the 30 min reserve, that is meant for safety when you have to fly around showers or have to divert to another airport. A slower aircraft needs more time for this than a fast one.

Hybrid drives are bullshit, good for petrol cars but not even for diesel cars.

I bought a Strojnik S-2A self launching sailplane 5 years ago and I’ve been waiting since then to convert it to electric power, I hope to start on it next winter. Your series is much appreciated and timely. I’m especially interested in regenerative charging. The dream is to be able to fly coast to coast without plugging in.

Regenerative sailplane flying will be quite interesting. I hope you could turn real this Paul MacReady,s dream

Great article Gabe! Ive been avidly following your story since the early days of the electric Xenos and would love to build something electric one day.

It would also be interesting to get a sense of where we’re at on the electric aircraft (well, battery development) timeline – and how likely energy storage density (esp as it relates to electric aircraft) is likely to improve over the next, say 5 to 10 years. And then compare that to where we were at in the very early days of aviation, regarding aircraft endurance — albeit then due to the super low efficiency and power vs weight of the ICE engine itself back then.

Gabe,

Great article, and as an electrical engineer, you’ve explained the electrical drive vs ice drive very well !

You should also mention the cooling needs for the motor, battery and controller.

I see that the Zero motor is aircooled, but higher power motors and controllers will most likely need liquid cooling and associated pumps and radiators.

I look forward to your future articles.!

Jim Hughes, Cessna 175B

Recent developments may offer some promise on larger airframes. The following taken from another article by Electric Motors Research,

“Koenigsegg continues its in-house technology development and advanced component offers to the market. It started with David, the recently introduced revolutionary 6-phase inverter – and that is now followed by the company’s newest innovation, the Quark electric motor that utilizes a novel torque/power-rich balance between radial(power-dense) and axial(torque-dense) flux topology dubbed Raxial Flux”

I hope to see many of you at Oshkosh 2022, where I will be giving a talk on electric powered aircraft (as I did in 2021).. I like to tell everybody that we are just one major metric away from ubiquitous electric powered personal aircraft. That metric is battery energy density, normally referred to as watthours per kilogram of mass (wh/kg). For the sake of commonality with electric powered cars, where this technology will be optimized, we will use units of 1000 wh/kg, or kWh/kg.

The typical Tesla car has a battery cell energy density of approximately 0.250 kWh/kg. That means that the 100 kWh battery in the Tesla Model S or X has a weight of 400 kg (880 pounds) of battery cells (100 kWh divided by 0.250 equals 400 kg of battery cells).

In addition, there are hardware bits that are required for the complete battery, notably a cooling system and its coolant, bus bars, switches (contactors), fire suppression, “G” switches, electronics for a Battery Management System (BMS), and of course, some type of battery container.

A car needs a battery container that can handle severe impacts from crashes, while an aircraft does not. Let’s say that a car battery has a 20% weight penalty for its battery hardware, and an optimized aircraft battery design might only have a 15% penalty for the same hardware.

In addition, the battery can only use about 97% of the total capacity of the cells, so there’s a 3% penalty of additional cells required to reach the usable battery capacity. For example, a Tesla battery with 100 kWh of usable capacity needs 103 kWh of actual battery cells.

So, how much battery energy density is required for a practical 4 seat 200 hp (150 kW) aircraft that can fly about 3 hours? Using 75% of the rated power of 150 kW equals 112.5 kW of power. There’s another metric to consider, and that is the 90% efficiency of the motor and inverter assembly., so we need 111% of that power, or 125 kW.

Over 3 hours of flying, plus the typical regulatory requirement of 45 minutes of reserve energy at cruise power requires 469 kWh of usable energy, plus 3% of unusable battery cells equals or 483 kWh of total battery energy.

Using our weight metric of 0.250 kWh/kg, that 483 kWh battery weighs 1932 kg (4250 pounds), plus 15% for ancillary bits equals 4888 pounds battery weight.

Using a 4 times multiple of 1.000 kWh/kg battery density of a 483 kWh equals just 483 kg (1063 pounds), plus 15% for ancillary bits equals 556 kg (1223 pounds).

The electric motor and inverter assembly might only weigh 68 kg (150 pounds), therefore the entire conversion from a petroleum powered aircraft is 624 kg (1373 pounds).

Compare that to the petroleum powered 200 hp engine with all accessories at about 227 kg (500 pounds), and 50 US gallons of gasoline is about 136 kg (300 pounds), for a total of 363 kg (800 pounds)

So, carrying only two people instead of four people is possible with the 1.000 kWh/kg battery cell energy density.

Once those batteries arrive, we will then need electric vehicle recharging infrastructure at 10,000 airports across the USA, and that is likely a bigger challenge than building electric powered aircraft in the future.

Great piece. need more.

Hi Gabe,

I read in the latest edition of Kitplanes Weekly, April 11th, 2023, that you got the eXenos into the air — contgratulation.

There was mention in one of the associated links on the build — that you had a company “…Zaero…” that I cannot find anywhere on the Net.

Would it be possible for you to varify this as I’m very interested in your gear reduction system.

Thanks

I think the development of high efficiency Axial Flux motors at a much lower weight than current products from Tesla could improve packaging, weight and balance with added reliability.

Good morning, this is a contact to see if you can help us because we need to buy an electric engine, batteries, control unit, … for an aircraft amateur construction.

My name is Luis Abelleira, I am the owner of an aircraft maintenance center (AEROLUGO ES.CAO.014), Part 66 mechanic (ES.66.00044772), I have a pilot school (Real Aero Club de Lugo), and also I am teaching to Aeromechanical Maintenance Technicians at the CIFP As Mercedes public institute, in Lugo, Spain. In addition, we have been awarded for projects carried out in innovation and we have won many competitions with the students, they are spectacular students, all those who finish the course end up hired in various aeronautical companies. And last year we were declared the best public institute in Spain in aeromechanics(excellence center) by the goverment. You can see that in this government page:https://www.educacionyfp.gob.es/prensa/actualidad/2022/11/221123-redexcelenciafp.html

One of my last projects is the construction of an electric aircraft, two places. We already have the authorization from the Spanish aeronautical authority AESA. We have the structure very advanced and now I need two things:-To buy the engine, batteries, electric components…-To obtain training about that components.

Can you help to us?What we need is the engine and related components for at least 80 CV, better 100 CV.

You can see a lot of new of us:https://www.lavozdegalicia.es/noticia/lugo/2022/03/31/alumnos-as-mercedes-pioneros-construir-avion-cero/0003_202203L31C1991.htm

https://www.xunta.gal/notas-de-prensa/-/nova/79786/cifp-mercedes-muestra-los-proyectos-innovadores-los-ciclos-aeromecanica-energias

https://www.lavozdegalicia.es/noticia/lugo/2023/06/29/curso-cifp-as-mercedes-creara-dron-transportar-medicamentos-u-organos/00031688050180141525560.htm

https://www.lavozdegalicia.es/noticia/galicia/2022/11/22/tres-nuevos-centros-fp-gallegos-red-estatal-excelencia/00031669135839577185465.htm

https://cadenaser.com/emisora/2018/05/28/radio_lugo/1527531855_401094.html

https://www.lavozdegalicia.es/noticia/lugo/lugo/2020/12/18/cifp-as-mercedes-unico-centro-gallego-fabrica-piezas-aeronautica/0003_202012L18C2997.htm

https://www.lavozdegalicia.es/noticia/lugo/lugo/2021/01/07/odisea-transportar-falcon-17-metros-torrejon-lugo/0003_202101L7C5991.htm

https://www.lavozdegalicia.es/noticia/lugo/2020/12/16/ejercito-aire-cede-motor-cifp-as-mercedes/00031608147283315649504.htm

Best regards,

Luis Abelleira Álvarez

(0034) 619 76 77 20