At this point in our series, you have decided to buy a used E/A-B airplane, picked out a make and model, and found a likely candidate for purchase. You are just about to take the last big step, but you need to be sure the plane of your dreams will not become a nightmare as soon as you get it home. You need a pre-buy inspection.

A pre-buy inspection is a thorough examination of a particular airplane, to be performed by a qualified person prior to completing the purchase of that airplane. It is typically done after a buyer and seller have reached an agreement to enter into the purchase transaction but before the transaction actually becomes final—in other words before the money and title have changed hands. Usually the buyer will put up some sort of earnest money deposit and execute a purchase agreement contingent on the outcome of the inspection. All of this is done with the assumption that there will be no substantial airworthiness issues with the plane to be purchased. If there are, the purchase agreement should have provisions for getting those issues corrected by the seller prior to completing the purchase or canceling the purchase. Either that or there will be an agreement for some sort of price reduction to compensate for the deficiencies.

The Aircraft Owners and Pilots Association (AOPA) has some great resources for handling the purchase transaction, including escrow and title insurance, that many buyers and sellers agree to utilize to expedite the sale. There is little need to repeat that information here except to refer you to their website. As an aside, there are good reasons for airplane owners and pilots to support both AOPA and EAA.

A differential compression test is a standard item on any pre-buy inspection. Although lower compression readings are acceptable, a buyer is hoping to see all cylinders in the 70+ over 80 range. If the first test yields some low numbers, it is worthwhile to repeat the test after running the engine for a brief period.

The Pre-Purchase Inspection

The pre-purchase inspection, that examination you need to do once you are actually standing next to the plane you hope to buy, has three parts in this order: review of the paperwork, physical inspection, and the test flight.

Before you make arrangements to inspect an airplane, be sure you have a clear understanding with the seller that you will need to review the airframe, engine, and propeller logbooks before you can proceed further. Ideally this is done before you travel to inspect the plane because there may be things there that might make you decide to forgo the trip. The logbooks will show the model number and serial number of the engine and prop, and the serial number of the airframe. With this information you can see if these components have been the subject of any service bulletins or airworthiness directives (ADs). Once you are the owner, you can choose to thumb your nose at service bulletins and airworthiness directives in most cases, not that you should, but as the buyer you will want to know how these things affect the safety of the plane you are about to buy. Compliance with these items should be noted in the logbooks. If they are not, it is worth asking, why not? The best place to find out if there are any ADs that apply to the engine or propeller that you are considering is to go to the FAA website and look under Airworthiness Directives. These will only apply to certificated parts, typically the engine and propeller.

Each kit manufacturer should have service bulletin information on their kits. This is often on their website, but sometimes you will need to call them or check with the appropriate owner/builder group.

Whenever hoses or wires are attached to engine mount tubes, it is best to use cushioned Adel clamps instead of zip ties. This prevents chafing damage to the engine mount tubes.

While perusing the logbooks, note any significant repairs such as a replaced cylinder or an alternator. Look for regular maintenance at frequent intervals over time. A big time gap between services is worth exploring further. There may be a perfectly good reason why a plane didn’t fly for several months or more, but it may also alert you to damage that took time to repair but was not noted. In any case, a lack of regular flying invites corrosion, especially engine corrosion on things like cams and lifters. These may not be apparent during a physical inspection, but they can cause big, expensive problems if they show up later.

Be on the lookout for alterations that the owner may have made. Some alterations are desirable and others aren’t. These can be deal killers in some cases. Once you have thoroughly reviewed the logs, you should have a pretty good idea of what to look for in your physical inspection.

Planes that have spent their life outdoors are prime candidates for corrosion damage such as seen here. This much corrosion calls for some more serious exploration to see if there is other corrosion that is unseen.

When it is time to begin the physical inspection, it is time to have a talk with the seller about what he or she is willing to let you do. If you have not yet made a deal and put down a deposit, the seller may not be willing to let you take things apart or perform invasive procedures such as a compression test or removing and cutting open an oil filter. The seller may insist that you make a firm offer subject to a physical inspection and put up some earnest money. This will have to be negotiated on a case-by-case basis. Without a firm deal in hand, the seller may limit your physical inspection to a thorough preflight. On the other hand, if you have put up money and made a deal, an examination similar to a yearly condition inspection is in order. Who will perform this and where it will be done are subject to negotiation, but be sure to be there to take part in the process or have a trusted representative do it for you. A pre-purchase inspection performed by the seller or his mechanic isn’t worth much unless you actually witness the whole process.

Once the physical inspection is complete, you may have found things that need to be fixed right away, or you may have found things that make the plane worth less to you than your initial offer. You will have to negotiate these things with the seller or possibly walk away from the deal.

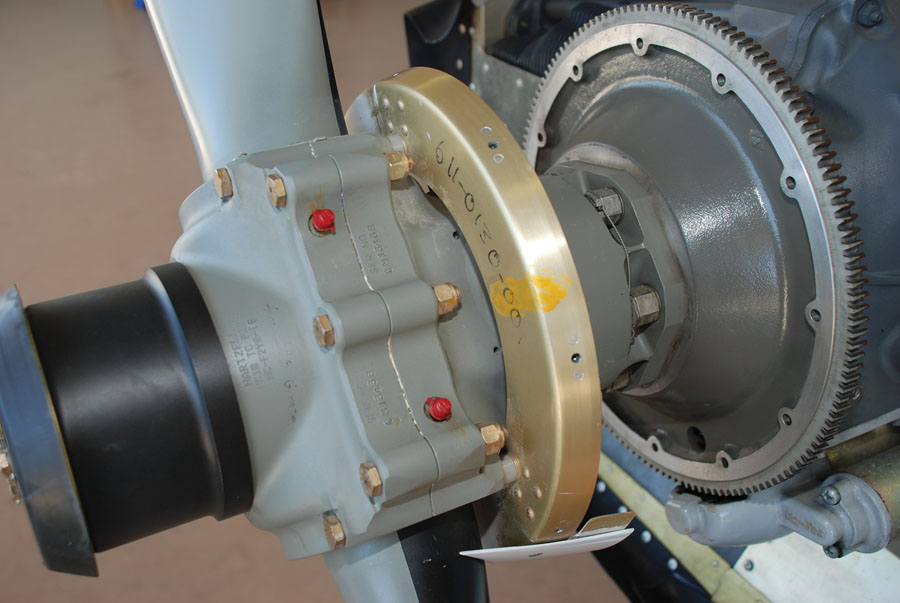

Part of the propeller inspection should include removing the spinner and checking for cracks in the backing plate. It is also a good time to check for leaks at the front main seal and the propeller hub.

What Should It Cost? How Long Should It Take?

A pre-purchase inspection is similar in scope to a yearly condition inspection. That said, they usually do not get quite as involved as condition inspections because no maintenance is done, only inspection. The process can usually be completed in a single day if all the tools and equipment needed are readily available and the weather cooperates for a flight test.

A pre-buy inspector/mechanic should have his or her own hand tools, but an air compressor will be needed for the compression test, and a bench with a vise is pretty nice to have for cutting open the oil filter. In addition, adequate light and heat will go a long way toward facilitating a successful inspection. The seller should arrange to have these things available wherever the inspection will take place. Do not be surprised if the seller is not enthusiastic about having the plane flown to the inspector’s shop for the pre-buy. In some cases, this may be possible, but don’t count on it.

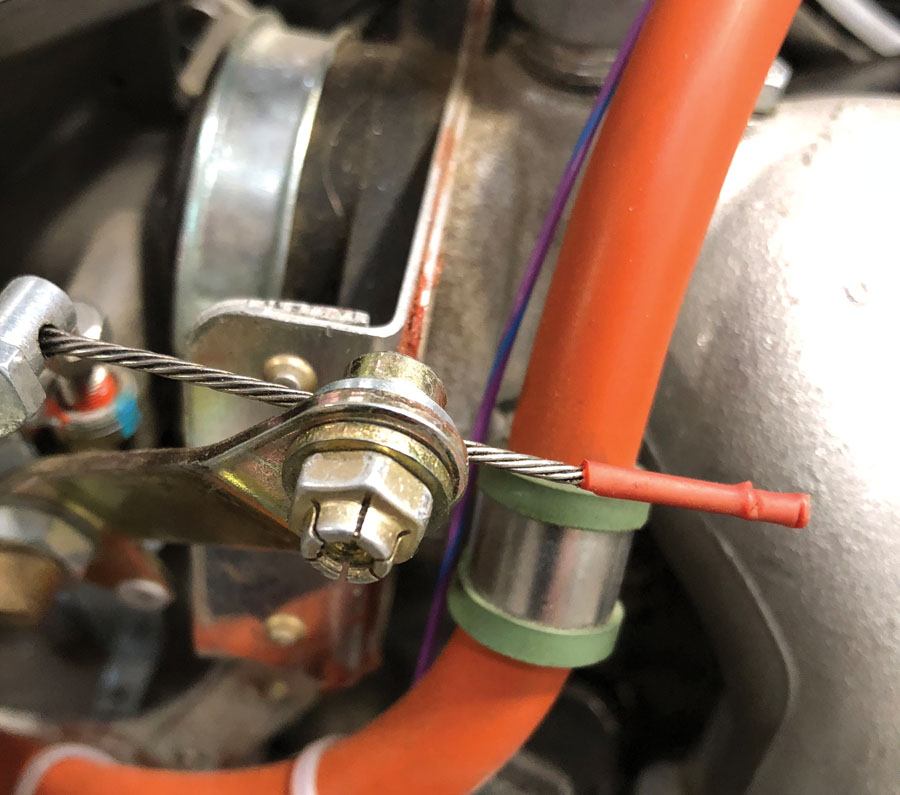

Here the bolt securing the throttle cable to a Rotax engine is clearly too short to fully engage the nut’s locking feature. On the plus side, it is an all-metal stop nut, which is the only kind that should be used in the engine compartment.

Sometimes the buyer and seller will decide that they would like to turn the pre-buy inspection into a condition inspection. That is fine if no major issues arise, but it can get complicated if remedial work is recommended by the person doing the inspection. The problem with a combined process is that everyone goes in with the assumption that there are no major issues, which may or may not be true. However, there is a lot of pressure to get it done with a sale hanging in the balance. The other problem is that if the buyer doesn’t like the results of the pre-buy inspection, who pays for the condition inspection? As you can see, things can get sticky when the two functions are combined. If an airplane is past its due date for a condition inspection, the test flight cannot be completed until the condition inspection is signed off. You can see how things can get difficult if the condition inspection does not go well.

Smoking rivets on this rudder need to be fixed before further flight. Such a discovery would definitely delay a purchase and/or the completion of a condition inspection.

Of course, cost is always an issue when it comes to the pre-buy. If an inspector has to come a long way to get to the plane, he or she may want to charge extra for that travel time in addition to the actual cost of getting there. I normally charge $500 for a pre-buy inspection on a typical plane such as an RV-6. If I have to travel farther than I can drive in an hour or fly in a half-hour, I will add fuel costs to that. If I have to go somewhere that would require an overnight stay, I would add for that, too.

Just as with condition inspections, prices will vary with the complexity of the airplane involved. A Lancair Evolution pre-buy will be, and should be, considerably more expensive than one for a Kitfox. Be sure to have an agreement on what the travel budget will be before you get too far into the process. These costs can easily be more than the actual pre-buy inspection. That said, it is well worth the investment to get a well-qualified person who is farther away rather than a poorly qualified person who is nearby to do your inspection. Check references before you get started and choose wisely.

Zip ties can damage engine mount tubes over time and even cut through them in extreme cases. This is a great example of how not to secure SCAT tubes and fuel lines to engine mount tubes.

Do It Yourself?

Why can’t you just do it yourself or have a buddy help you? Well, you can, but in most cases you probably shouldn’t. Most people do not have the knowledge, skill, and experience to do a thorough pre-buy. It is one thing to generally know about airplanes or even be an A&P mechanic. It is another to have a thorough knowledge of the particular type of airplane you are considering. For example, do you know where to find the cracks in the brackets that attach the motor mount to the fuselage on an RV-4? Did you even know that this was a potential problem area? Did you know that some common Lycoming engines are subject to an AD that will require replacing the crankshaft at the next overhaul? Or did you know that the rib stitching on a fabric-covered airplane needs to be closer together in the propwash slipstream than elsewhere? The point is that broad familiarity with airplanes may not be enough.

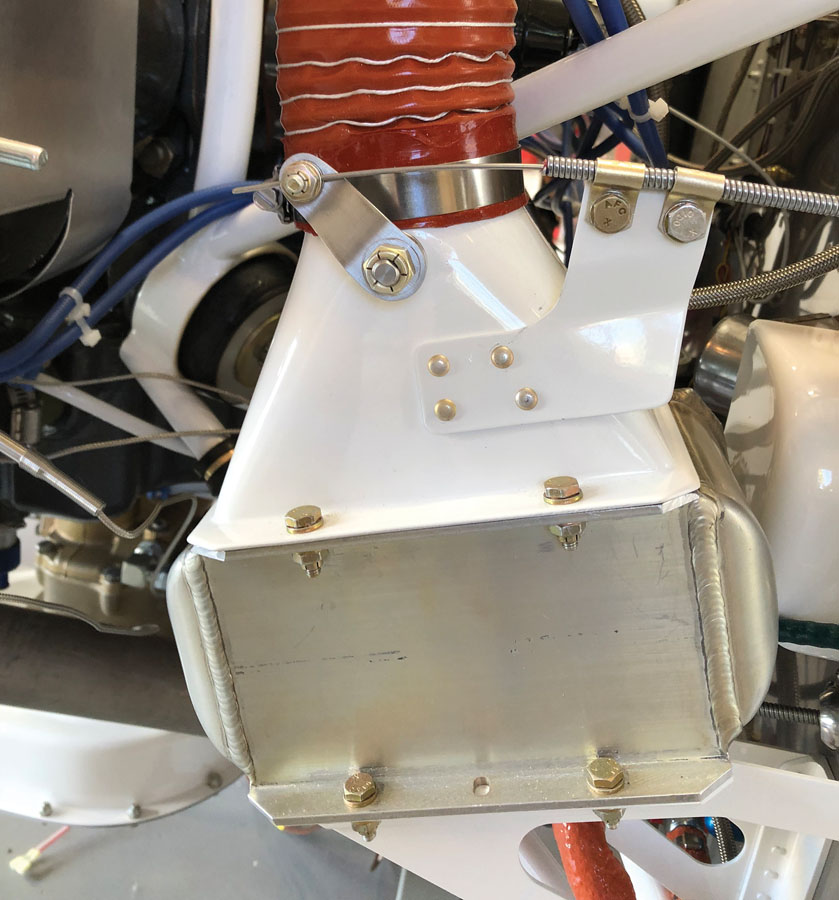

Here a builder has added a damper to the air intake for the oil cooler. This is the kind of deviation from the plans that actually adds value. Some other modifications do not.

Another good reason not to do your own pre-buy is that you will lack objectivity. It is very easy to rationalize overlooking things when you have your heart set on a particular airplane. The independent pre-buy inspector has no such emotional involvement in the process. As a pre-buy inspector, his or her interest is in making sure you get a good airplane that isn’t going to give you trouble or, frankly, make them look bad down the road. If you have traveled some distance to check out a plane, you have the added the pressure of not wanting to waste the trip. These things may seem trivial, but they add pressure to buy in a situation where objectivity is paramount.

Tailwheels normally get little attention, but a tailwheel with the wrong caster such as this one is very likely to shimmy when landing. It is more expensive than you think to replace a spring that is bent at the wrong angle.

What to Expect from a Pre-Buy Report

Here is what a pre-buy inspection report should cover. Any discrepancies found should be noted in the pre-buy report.

Paperwork

- Verify the registration is current and that the serial number and registration number match the airworthiness certificate and data plate. Examine the airworthiness certificate to be sure the serial number and tail number match the other documents. Check to be sure it has not expired—most do not, but some do. Make sure the certificate states that it is Experimental/Amateur-Built, not some other type of experimental. The name of the owner does not need to match the airworthiness certificate, but the seller should be the person shown on the registration as the owner. The airworthiness certificate should be displayed in the cockpit. The registration need not be displayed but should be in the airplane, as should the operating limitations and weight and balance.

- Review the operating limitations to be sure they have not expired and that all pertinent information matches the airworthiness certificate. The date issued must match the airworthiness certificate. The name of the builder, model designation, tail number, and serial number should all match other documents.

- Any limitations on areas or types of flying should be noted. Some older operating limitations do not allow IFR flight, night flight, or flight over densely populated areas. These limitations can usually be removed with an amended airworthiness certificate.

- Weight and balance paperwork must be in the airplane. Review it to see what gross weight and empty weight are used for weight and balance calculations. Be aware that quite a few builders will use a gross weight that exceeds the kit manufacturer’s recommendation. Review some typical load calculations to be sure you can carry the loads you anticipate once you own it.

- Review the aircraft logbook. The logbook should reference the registration number and serial number of the aircraft. Verify the original condition inspection, airworthiness sign-off, and completion of Phase I flight- testing endorsements are in place, as are any subsequent yearly condition inspections. Condition inspections must be signed by the holder of the repairman certificate for that plane or an A&P mechanic. Look for notations on completion of service bulletin work. Look for mention of any repairs or alterations. Major alterations must have been flight tested as per the operating limitations.

- Look for current transponder and pitot/static certifications if applicable.

- Review engine and prop logbooks. Make sure the engine make, model, and serial number in the logbook match the engine data plate. Search the FAA database for applicable airworthiness directives (ADs) on the engine and prop. Note yearly condition inspections including differential compression test results. Note oil and filter changes—maximum interval is six months or 50 hours. Note any repair work done on the engine.

- There should be a separate prop logbook with notes of any service work or repairs.

Damage to a wheel such as this is cause for replacement, but it may also point to a ground loop in the past that might have caused other damage. Some pointed questions should follow such a discovery.

Airframe—Fuselage and Wings

- The exterior inspection of the airframe should look for paint condition, signs of corrosion, damage or evidence of repaired damage, and workmanship of the original assembly.

- Be sure that doors, windows, and canopy work properly and are free of cracks and crazing. Replacing a cracked canopy on many planes—an RV-8 for example—is no easy task.

- Inspect the wings and struts for condition and proper attachment. Open all inspection covers and check bellcranks and other control linkage. Also check wings for fuel leaks. Leaking RV wing tanks can be difficult to repair.

- Inspect the empennage and open up all inspection covers and close-outs. This is where you are most likely to find poor workmanship since this is where almost every airplane builder begins.

- Inspect control surfaces: ailerons, flaps, elevator, rudder, trim tabs. Check for condition, security, and proper travel. Also, be on the lookout for loose jam nuts or any signs of chafing.

- Check cables for proper turnbuckle installation and safety wire or clips.

- Inspect fuel tanks, filler caps, drains, wet wings, and required decals.

- Are there fuel drains at all low points? Are there low points in vent lines? Are vent exits unobstructed?

- Inspect wing tips and elevator and rudder tips for cracks and missing screws.

- Test pitot heat (if installed) to be sure it works.

- Check static ports.

- Inspect landing lights, navigation lights, and strobes or beacon.

Airframe—Add for Composite Airplanes

- Look for delamination or cracking of composite surfaces and signs of improper repairs.

- Look at workmanship—flat seams, proper bonding, insufficient or excess resin.

Airframe—Add for Tube and Fabric Airplanes

- Paint—general and cracks.

- Fabric condition—teconditionst if in doubt.

- Damage or improper repair of damage to fabric.

- Damage to or improper repair of frame tubes or wing structure.

- Proper rib stitching at correct spacing in and out of propwash slipstream.

- Workmanship—smooth seams at tapes and reinforcements.

- Check for proper reinforcement around penetrations.

- Inspect all drain holes in wings and control surfaces.

Landing Gear—Fixed

- Make sure gear legs are unbent and free of obvious damage.

- Inspect brakes—pad and rotor wear, proper function, no leaks, calipers safety wired.

- Check gear attach points.

- Wheel pants—cracks, security (remove to inspect wheels and brakes).

- Wheels and tires—check general condition, damage to or cracks in wheels.

- Check tire wear for signs of bent or improperly installed gear.

- Check condition of bungies or other shock absorption system.

- Inspect tailwheel, tailwheel spring, and cables if installed. Check caster.

- Inspect nosewheel steering linkage if present and shimmy damper for proper friction drag on nosewheel.

Landing Gear—Add for Retractable Gear

- Perform a retraction system test. Look for smooth operation and proper operation of emergency gear extension system.

- Make sure gear doors fully close and that linkage is in good condition.

- Check hydraulic pump if installed or gear motor and microswitches.

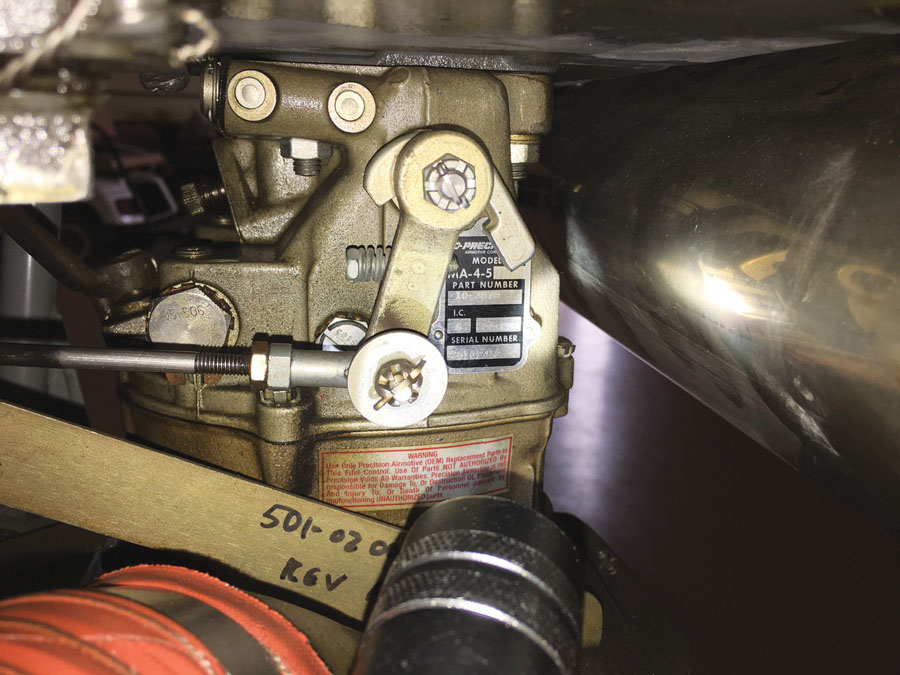

Engine controls should have cushion. In other words, there should be some travel left in the control after the device being controlled—throttle, prop, etc.—has reached its full range of motion. This ensures that full power, for example, is not limited by the control.

Cabin Interior

- Seats and cushions should be in good condition, easily adjustable, comfortable, and easily accessible.

- Seat belts and shoulder harnesses should be in good condition and well-anchored.

- Door latches or canopy should function properly and fully seal.

- EXPERIMENTAL and passenger warning decals should be in plain sight.

- Make sure controls function properly and are free of interference throughout their entire travel.

- Be sure that cabin heat, cabin vent, and defrost controls are plainly marked and work correctly.

- The fuel selector valve must be properly marked and accessible. No “Both” position in low-wing aircraft.

- Engine controls should have cushion (see photo below).

Rod ends with ball joints should have oversized washers installed to prevent the joint from coming apart if the rod end should fail.

Avionics and Instruments

- Installed avionics should work correctly and have current databases installed.

- All flight and engine instruments should work correctly and have proper limits programmed or otherwise clearly marked.

- If IFR flight is anticipated, are proper avionics and instruments installed?

- Is an ELT installed (406 MHz preferred)? Test that it works and check battery condition.

- Is a transponder installed and the certification current if operating in B, C, or D airspace? ADS-B Out is required after January 1, 2020.

- Circuit breakers or fuses should be accessible and clearly marked. If fuses are used, replacement fuses should be easily accessible.

- All switches should be clearly marked.

- There should be backup power for all-electric panels.

- Check wiring and antennas for proper installation.

- Check battery for age, condition, and proper installation.

Always cut open the oil filter and look for signs of metal when conducting a pre-buy inspection. Lycoming Service Instruction 1492 offers detailed guidance to evaluate oil filters with signs of metal inside. The sump screen should also be checked at the same time for larger pieces of metal.

Firewall Forward

- Compression test—best done with a warm engine.

- Remove and inspect spark plugs.

- Borescope cylinders—check valve condition. Hash marks should be clearly visible on cylinder walls.

- Cut open and inspect oil filter.

- Remove oil sump drain and inspect.

- The firewall should be well-sealed with 2000-degree caulking, not red RTV.

- Engine mount should be secure and free of rust, cracks, and chafing. Bushings should be in good condition.

- All-metal lock nuts should be used in the engine compartment. No nylon-insert lock nuts.

- The engine should be grounded to the airframe or battery.

- The exhaust system should be secure and in good condition—no cracks or leaks.

- Exhaust tubes should be clear of hoses and wires.

- Exhaust should be clear of cowl—no blistered paint or burnt fiberglass.

- Cabin heat valve should be stainless steel and function properly.

- Carburetor heat should be installed and working properly if required.

- A sniffle valve is required on horizontal-intake engines. Fuel drains should be clear of the exhaust.

- Spark plug and engine sensor wires should be secure and properly routed.

- Engine controls must have full travel, and mounting brackets should be secure.

- Look for oversized washers at rod ends. Castle nuts need cotter pins installed.

- Baffles and seals should be in good condition and seal well.

- Oil cooler should be well supported. Oil lines should be well-made and in good condition.

- Fuel lines should be protected with Fire Sleeve or equal.

- Attempt to determine age of rubber hoses—10-year maximum life. No life limit on PTFE hoses.

- Crankcase vent line should be properly routed and unobstructed.

- Engine cowl should close properly with good prop clearance and exhaust clearance.

- Check propeller condition—track, play, nicks within limits.

- Prop bolts should be torqued and safety wired.

- Spinner and backing plate should be secure and free of cracks.

- Propeller ground clearance should be a minimum of 7 inches.

- Engine should start easily and run well with temperatures in normal ranges.

Here is a sump screen from an engine with some serious problems. This is why you need a pre-buy inspection—to save you from the cost of an unexpected overhaul. (Photo: Vic Syracuse)

Flight Test

- If, and only if, the condition inspection is current and logged, and the airplane is found to be in a safe condition for flight, conduct a brief test flight with the owner.

- Perform standard maneuvers and note how the plane handles. Especially see how it flies hands-off.

- Monitor engine temperatures, pressures, and fuel flow.

- Operate avionics and autopilot to check for proper function.

- If everything looks good, return to the airport. This test flight shouldn’t take more than 30 minutes in most cases.

Decision Time

With a good pre-buy inspection report in hand, you are now in a good position to decide to go ahead with, or give up on, your planned purchase. In many cases your lender, if you have one, will be very interested in reviewing the report before handing over their money. If all goes well, you should be ready to buy the airplane. Good luck with your new purchase. With the thorough examination you have made of your new ride, you should have a very good chance of flying for a long time with few, if any, problems.

There are two things you should take away from this. One, it is borderline crazy to buy a used airplane without a thorough pre-buy inspection unless you are very familiar with the plane in question and the integrity of the seller. Two, seek out and hire the best-qualified person available to conduct the inspection, even if it costs more, or even if it costs a lot more. Once you own the plane, any undetected problems will be yours. Due diligence done up front will save you money and heartache down the road.

Hello!

I’m looking at purchasing a Zenith 750 STOL in Hitchcock Texas.

I live in Florida and I’m not being able to locate someone near there to do a prebuilt inspection for me.

Can you recommend someone or is there a list of inspectors I could choose from?

Thank you,

Nelson