We were bored! We were restless, too. Winter had arrived in Missouri, and good flying was sporadic to say the least.

On this particular non-flying day in early November, bored and restless, The Dawn Patrol had all gathered at Liberty Landing International Airport, just because we could. It was too cold and windy to fly. We just needed an airport fix. So, we all just kinda hung around. We were sitting there at the communal hangar table like a bunch of bored birds perched on a wire wishing something would happen.

Then it hit us. Yessireebob, it was time for our monthly visit to our favorite point of local aeronautical interest.

Road Trip

It’s a one-hour cross-country jaunt from beautiful Liberty Landing International Airport to Bullwhip Baslee’s House of Pain (also known as Robert Baslee’s Airdrome Airplanes plant in Holden, Missouri). We go there a lot. Airdrome Airplanes is where 99% of the affordable WW-I aircraft activity in the world is going on. We’re just lucky we live so close. I know Robert wishes we were another 200 miles farther away. When we show up, progress stumbles, gasps, and grinds to a stop.

The timing of the road trip is very important. Get to The House of Pain too early and Bullwhip will put you to work. Be advised…there are no idle hands in the House of Pain. We’ve learned over the years that Bullwhip and his merry band of elves always break for lunch at 11 a.m. So, if we plan the Stealth Van’s arrival between 9:30 and 10:00, we’ll get there in time to see what’s going on, help a little bit, but not get really whipped. Then, when 11:00 rolls around, we get to go to lunch with them and talk over all things aviation.

Robert and Sharon build a wingrib for the S.E.5a. Note the neat little fixture with stub front spar that the wingrib is fitted to. Then Robert holds a gusset in place, drills the rivet hole, and as soon as the drill is taken out, Sharon sticks a rivet in the hole and pulls the trigger on the rivet gun. They were really putting them out fast.

As I said, there are no idle hands in the House of Pain. Having said that, there are also no “blue sky moments” allowed to think things over about what needs doin’ next. Activity is constant and fast. Also, Robert and his merry band of elves don’t take any breaks. Remember, Robert and his crew built four full-scale Nieuport 17s for the movie Flyboys in only 52 days from construction start to first flights. They do not mess around. We call working under those conditions going into “Baslee mode.”

Sharon Starks, Mark Pierce, Dick Lemons, Tom Glaeser, and I mounted up in the Stealth Van and blasted off for The House of Pain. We arrived at 9:45… Perfect timing. We pulled up beside the door leading to the shop and got out of the van. We could hear the sounds of feverish activity inside. Drills drilling. Rivets were being popped. A grinder was grinding away. That meant Robert and his elves were hard at work inside. We might be safe from being drafted. (Didn’t happen.)

Sharon helps and I watch while Mike Moore covers an elevator with lightweight Dacron. Like us, Robert also uses Stewart Systems Ekobond cement. We love its non-volatile characteristics. We particularly like its no-obnoxious-smell feature. Check out the dummy rotary engine on the stand behind them.

We all gathered by the door and looked at the doorknob.

“Are we sure we want to do this?” I asked. Opening that door could mean many things…some were pretty ominous.

“Go for it!” Dick Lemons said.

Mark, Tom, and Sharon didn’t say a thing. They knew what might be the result of opening that door.

Taking a deep breath, we opened the door and went in. As usual, what we saw was a big surprise.

Baslee’s Latest Design

In the spring of ’13, when we’d entered the shop, there was a covered replica of the Spirit of St. Louis being painted—which, by the way, Robert had built in only 35 days. It made a big splash at Oshkosh in 2013. What had really surprised us with the Spirit was the welded 4130 steel fuselage. This was a big departure from his usual tube and gusset aluminum construction.

This time we were stunned again to see another big welded fuselage standing tall and proud on the shop floor. Mounted on the fuselage were two big wings being fitted with wingribs.

There was a long silence while we took this all in. Then we started to sniff around. At least Mark, Dick, and Tom got to do some sniffing.

Sharon made the mistake of going too close to where Robert was busily making wingribs for the new plane. Robert snagged her with one of his claws as she tried to sneak by. He shoved a rivet gun into her hands and muttered, “Here… I’ll drill and you rivet. We’ll go a lot faster this way.”

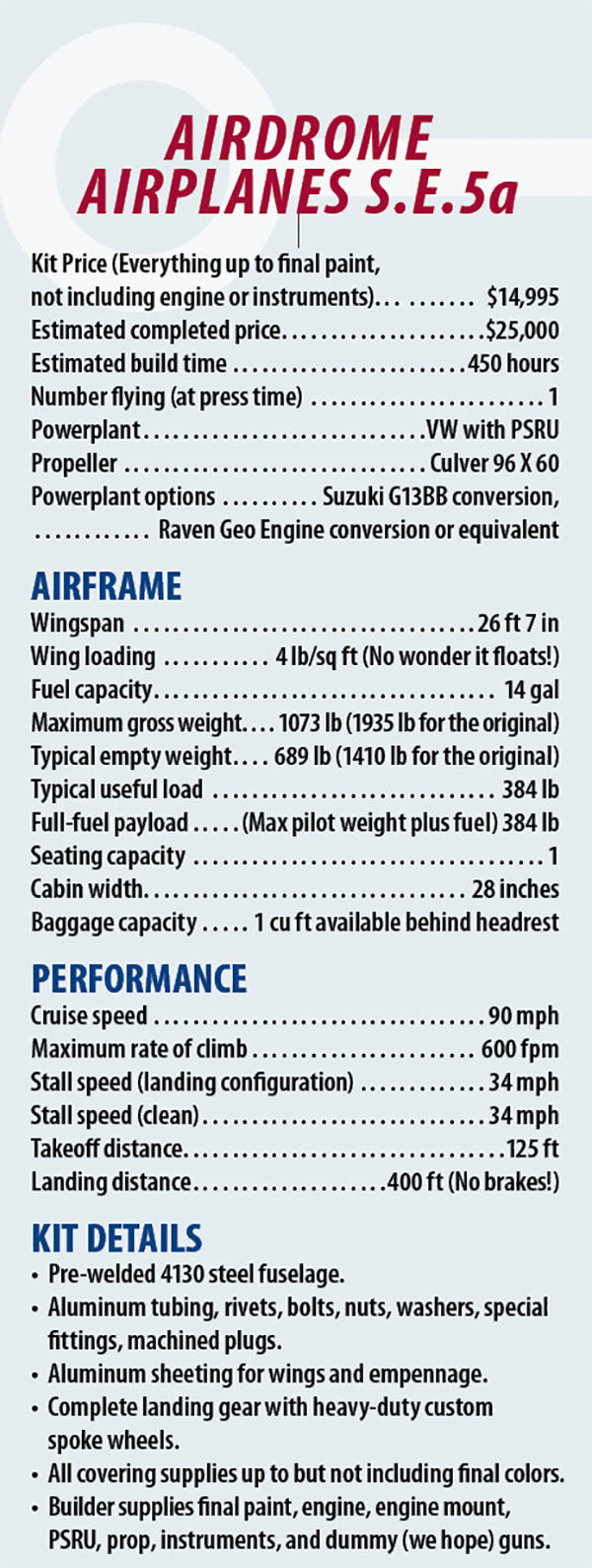

Specifications are manufacturer’s estimates and are based on the configuration of the demonstrator aircraft.

I tried to edge by the two of them, but Sharon hooked me with one of her talons and said, “Freeze! There’s no way you’re getting out of this!”

The upshot was that as fast as Robert and Sharon whipped out a rib, I delivered it to Mark Anderson, who was fitting them to the wingspars and riveting them in place.

Pretty soon we had a heck of a system going with Robert fitting the rib pieces to the fixture and drilling. Sharon was popping rivets as fast as she could load them in the gun. I was hustling the ready-to-mount ribs over to Mark Anderson who, being another member of the band who knew what he was doing, was fitting them to the wingspars and riveting them in place as fast as I could bring them over to him.

The wings magically took shape while we were standing there. When you’ve built as many planes as Robert Baslee and Mark Anderson have, you know what to do, how to do it, and as long as your sweating helpers can keep up, things happen in a real hurry.

While all this was going on, I kept looking at the welded steel fuselage and wings, trying to figure out what in the heck he was building. Robert was being coy and wasn’t saying a thing.

Then I recognized the vertical fin and rudder. Well, what do you know…Robert was building a full-scale replica of one of the most recognizable planes the allies flew in WW-I.

Yep, it was an S.E.5a—the premier high-altitude fighter that some very famous WW-I aces loved for its speed (138 mph), inherent stability, and durability. The S.E.5 was not received well by pilots when it was introduced into combat. It was underpowered. But the introduction of the S.E.5a, with a different engine, transformed the plane into a real fighter pilot’s dream.

The S.E.5a had the ability to fight at high altitudes, too. James McCudden and his mechanics tinkered with his S.E.5a’s Wolseley Viper engine and increased its service ceiling from the factory standard of 17,000 feet to 20,000 feet. The inline English-built Wolseley Viper 200-hp, direct-drive, water-cooled, V-8 engine became the standard powerplant for this aircraft. (No high-torque, spinning, oil-spewing rotary engine in this sweet-flying bird.) In the hands of a good pilot, the S.E.5a was a plane that could fight on even terms with the best fighter the German High Command possessed during the final months of the war, the famous Fokker D-VII. (However, it should be said, a really good pilot in a D-7, who knew what was going on, was dang-near invincible. That was the basic reason the treaty of Versailles stipulated that no Fokker D-7s were to be destroyed. They were to be turned over intact to the allies.)

Once we’d found out what Robert was building, he spilled the other bag of beans. He was building a plane for another WW-I movie that was going to feature two of his aircraft…and his antique truck!

Rear fuselage cockpit details with wood formers and stringers for the upper rear cockpit turtledeck.

It’s Movie Time Again!

Back in 2004, Robert was contacted by a film company working on a movie about the Lafayette Escadrille in WW-I. The movie was Flyboys (and a darn good movie it is, too!).

Anyway, the Flyboys producers wanted him to build a full-scale Nieuport 17 for the movie. After the contract was signed, Robert started to work at his usual “take no prisoners” rate. After a week or so, the moviemakers called him up and asked how it was going. He told them he had a fuselage sitting on the gear. They were kinda stunned at this unbelievable progress. So, they asked him if he could build three more. Robert, being Robert, said, “Sure…when do you want them?” They said, “Two months.” Robert, being Robert, said, “Sure, no problem.” Two of his workers fainted when they heard him say that.

He had all four planes in the air in 52 days. They were shipped over to England where the movie was made. When the movie was finished, Robert brought all four planes back from England with him.

One of these Flyboys Nieuport 17s was supposed to be the plane used in the new movie, but Robert, being Robert, and needing a new project, asked them if they’d like a different plane. They said, “Sure.” The S.E.5a was started with the usual “Baslee mode” beehive of activity.

Construction started in late November, right before Thanksgiving. Forty-two days later the plane was finished, inspected, licensed, and flying. Harvey Cleveland, who was going to be the pilot of both planes in the movie, was at the controls. After a week of shakedown and tune-up flights, the plane was declared ready to go. It was, as are most of the planes designed by Robert, very trailer friendly. The plane was broken down, packed on a trailer, and they blasted off for Nevada. Also included in the caravan was a full-scale Fokker DR-1 triplane and Robert’s antique 1918 Model T.

We still didn’t know anything about what the movie is about. All we knew was they wanted Robert and Harvey, with both planes and the truck, on location somewhere in the desert in Nevada.

We’ve since learned that the movie is Out of the Burning Blue starring Chris Klein, Victoria Summer, and Werner Daehn. It’s the story of a WW-I American pilot who is sent to the Arabian Desert on a mission to recover a downed German pilot and the top-secret information he is carrying. Harvey received credit as a stunt pilot, and Robert is credited, too. As I write this, the movie is in post-production, so it should be coming out soon.

Robert showed up at AirVenture 2014 with the S.E.5a and is shipping kits, so the word is definitely out! I tell you what sports fans…this adventure is just beginning.