Some people follow their dreams; others hunt them down and beat them mercilessly into submission.-Neil Kendall

Career, marriage, age and just life in general conspire not so much to rob us of the dreams of youth as to simply fossilize them, turning living things to stone in so slow a process that we don’t even notice it until someone like Dan Parker rockets past in a rush of giddy enthusiasm and good will. Where most folks are doing the wife, 2.2 kids, dog, cubicle job, SUV waltz through life, Parker is a breakdancer. Whats his dream? Not much: just design, build and fly his own airplane to a new world-record altitude.

The current record for powered aircraft with a takeoff weight of not more than 300 kilograms (for the metrically challenged, thats 661 pounds) is 30,147 feet. To set a new record he has to beat it by 3%, going to 31,051 feet. The question of why was at first met with, “I was looking for something to do” and later, “Itll make a good resume bullet.” However, the truth of it is that Parker just loves a challenge.

That level of interest is usually inherited, but not in this case. “My dad wasn’t a pilot until I got the bug,” Parker says. “He saw how much fun I was having and bought first a Grumman Yankee and then a Cessna 182.” The encouragement continues even now. On one of their frequent visits to his shop, it was clear that Parkers parents are his biggest fans.

His ex-landlord missed a place in history, though, by complaining that building an airplane in his apartment was not part of Parkers lease agreement. Result? Exodus number one. Exodus number two occurred when Parker left the working world. His “promised land” turned out to be a rented space in an industrial park for himself and his project, where he now lives in a loft and works full time on the plane, which is scattered about on the shop floor below.

But why this particular project? Simply put, it was a way of scratching an itch. “I wanted to do something slightly crazy, something that would make a mark in aviation…something fun!” Parker said. Casting about, he came across a report of the current altitude record holder, an aircraft called the Facet Opel, and was immediately struck by the plausibility of trying for a new altitude record.

Oddly enough for a dreamer, pragmatism and practicality played a significant part in the process. “I wanted [the aircraft] to be simple enough that I didn’t burn out. The number one goal here is not to break a world record, although that would be fun, too; the goal is do something cool.”

Qualifications

Parkers background reads as if it were an intentional preparation for this project. “I started building my RagWing Pitts replica while I was working on my bachelors degree in mechanical engineering, and found that it was a lot of fun and a significant part of my education. Halfway through grad school I got bored with all the theory and went to work for Dave Ronneberg at the Berkut factory, where I learned the hands-on composites skills I needed. I went back to Stanford to finish up my masters in aero/astro, spent 18 months as a design engineer at Robinson Helicopter, and have spent the past four years as a failure analysis consultant.”

Having decided what to do and laid the foundation, the next step was to decide what the aircraft should look like. Parker quite rightly observed that streamlining to reduce parasite (“dirty”) drag was rather down on the list of criteria, less important than low weight and an efficient wing. That seems, at first, counterintuitive; after all, virtually every airplane built since WW-I has worried about a clean shape. Parker explained:

“The basic story is this:

1. High altitude means you have very little engine power.

2. Very little engine power means you need an airframe that uses very little power to fly.

3. We all know that parasite drag goes up with speed, and induced drag goes down, and where they’re equal is the minimum drag on the airplane (the best L/D speed).

4. Because power is drag multiplied by speed, going a tiny bit slower than minimum drag reduces the speed and uses less power than the best L/D speed.

5. If you keep going slower and slower, eventually the induced drag increase balances the reduced power from going slower, and you reach the new minimum power point, where induced drag matters three times more than parasite drag.”

(Yes, he really does talk like that.)

The engineering and enthusiasm, though, are tempered with a dose of realistic thinking in that Parker not only knows what the aircraft should do and how its going to do it, but also what hes willing to do to build the aircraft. This change from the too frequent scenario of starting something and then finding that its too tough, takes too long and/or costs too much gives the entire project another notch of credibility. “I wanted this to be a Lockheed Skunkworks type project,” he said, “that is, one which uses as much simple technology as possible and concentrates on out-of-the-box design only where it matters.”

Taking that cue, we contacted Alan Brown, chief designer of the F-117 and a leader in the creation of the SR-71, and asked him to visit Parkers shop to review the project. The synergy was immediate. After many questions, both there at the shop and in subsequent emails, Parker went back to another from-scratch performance analysis of the airplane. “I may have a little bit of extra chord, but not much,” he said. “To illustrate the relative importance of parasite versus induced drag, consider that to save half a horsepower, I need to either add 3 feet of wingspan (about 7%) or reduce the parasite drag by 25%. Needless to say, adding some aluminum tip hoops to get a little extra span is a no-brainer!”

He went on to explain that, “[The additional wing chord adds] a few mph of stall margin below the minimum-power speed. Since Im not an A+ test pilot, and wouldn’t want to have to hold a tight mph margin over stall for 3 hours, I think this result is just about where I want it.”

Simplicity Is Key

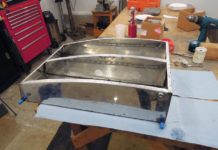

Sometimes design trade-offs are more than a battle of weight, drag, speed and budget. In this case, that extra bit of wingspan just barely fits within the longest distance in the shop. But with a clock that ticks off not in seconds, but in efficiency, money and enthusiasm, Parker didn’t want to get extravagant on molds. Consider the mainspar: Its carbon fiber and fiberglass, needs to be straight and about 9 inches high by 2 inches wide. Rather than construct a mold, he started with a 25-foot length of aluminum channel. By good luck, the inside curve has exactly the dimensions he designed around and is straight enough for a mold. Add a coating of release wax, and in a few hours he had half of a 20-foot spar.

The other molds were almost as ingenious. The leading edges of the wing are a glass-and-foam sandwich made in two 10-foot sections. To get the molds finished quickly, he went to the computer, fired up the CAD program, whipped out a design, emailed it to a laser-cutting shop and picked up the forms a couple of days later, having never been to the shop. Tucking a sheet of aluminum into the laser-cut cradles provided an inexpensive but accurate mold. The same procedure gave him the mold for the cabin. “That allowed me to build all the composite parts in molds rather than by carving or hot wire and do it in about one-tenth the time,” he said. “And with the advent of CAD, email and NC controlled lasers, the cost came in very reasonably as well.”

The plan for now is that the finished airplane will be 415 pounds empty, have a 46-foot wingspan, be 17.5 feet long, and have a Rotax 503 powering it to a Vne of 80 mph. Parker likes to compare it to an F-15: “Its got the same wingspan at 1.5% the weight.” Its price is probably equally low.

Another trick to achieve an ultra-smooth fit to the door is what Parker describes as “co-molded construction.” This technique is a bit reversed. Normally wed make the fuselage and then the door; he did it the other way around by first making the door within the fuselage mold, then trimming the door and returning it to the mold, and building the fuselage around the door. When it all comes out of the mold, the door pops loose, but its a perfect fit.

Lest you think that its all high-tech and clever engineering, a walk through the shop reveals hand tools and clamps galore, but no lathe or mill, only a bandsaw. Yet the workmanship on even the simplest parts is beyond reproach with square edges and no burrs; all of the aluminum is anodized a rich black.

Will It Succeed?

Our expert, Alan Brown of Lockheeds Skunkworks, quite rightly offered no guarantees, but he was willing to state a strong confidence in Parkers design and construction. The only other factors are the gods of luck and pilot skills. In walking around Parkers home/shop, I swear I kept hearing Master Yoda whispering, “Do…or do not. There is no try.”

For more information about this project, visit www.parkerprojects.com. Follow that up with a tour of www.twitt.org/baxter.html to learn more about the Facet Opel. In reviewing these web sites, one is immediately struck by the successful but totally different approaches to achieving the same goal.