The landing gear is formed from a single piece of aluminum.

I wasn’t sure wed ever get to this place. After all, even though my husband and I are ardent aviators, it was difficult to recognize a glimmer, even a spark of interest in aviation in our teenage daughters.

The brake lines emerge right where they’re needed. These tires are considerably narrower and taller than the former golf cart tires. Landings are liable to feel a little firmer, but these tires should last longer.

Early on I decided that I would not push my children into aviation just because I loved it, and their father was with me on that tack. Instead, we simply lived our aviation-infused lives, his mostly in big airliners or out in the hangar building small stuff, mine teaching students and flying what he built, and writing about all of it.

The girls have come along on quite a few epic cross-country trips, from the Bahamas and the Caymans, to Vermont, Wisconsin and Canada. We’ve flown ourselves as far west as Grand Junction, Colorado, Salt Lake City and Moab, Utah. From the bayous of Louisiana to the skyscrapers of Chicago, from the graceful hills of the Ozarks to the mountains of eastern New Mexico, theyve seen it all, slept through it all and soaked it all in. They even did a week volunteering at EAAs AirVenture. So you cant say our flying habit did not influence them.

They went off to college, though, without ever really pushing the learn to fly card. It made me a little sad, but I stuck to my position-you need to want to learn to fly, especially if your parents are going to be the ones to teach you (in an airplane built by your dad).

Popping the Question

And then one day, home on break from school, my older daughter lamented, I hate driving across the state to see my boyfriend. Do you think Dad would let me fly the Kitfox if I knew how?

I held my breath and answered slowly, so as not to sound too enthusiastic. Uh, yeah, he might consider something like that, I said, as nonchalant as I could be.

The trim lever had to be adjusted once the new landing gear was installed.

The younger daughter chimed in, Yeah, that might be fun, learning to fly. Could we do that this summer? Maybe get a class together? I might have another friend who wants to do it, too, she said, and I could see the wheels spinning in her head. I caught myself and tried not to sound too happy as I responded: If you’re willing to get up early, because thats the only civilized time to fly around here in the summer.

I could probably do that a couple of times each week, maybe before work? she asked. Maybe…. I let the word slip from my lips slowly, almost tentatively. Ive learned from years of parenting these two that it is bad to show too much enthusiasm for their antics, because it means whatever they are thinking of doing couldn’t possibly be cool.

But thats how it began. When they left after spring break we took a hard look at the Kitfox 4 wed been flying for the past 16 years. Its been a great kick around the patch airplane, and fine for trips up to about 2 hours in any direction (2 hours in an airplane of this caliber gets you to a lot of places with the wind on your tail, and not so far with a headwind). Wed replaced the engine in 2000 with the Australian-made Jabiru 2200, an air-cooled, four-stroke mated to a wood Sensenich propeller. Wed replaced the Lexan windscreen with one of molded acrylic, and retrofitted the original tach and engine instrumentation with a Grand Rapids Technologies simple EIS years ago. About the only thing this airplane really needed to make it suitable for training was some new landing gear.

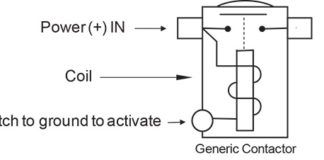

The brake lines exit the fuselage and feed directly to internal lines in the landing gear.

Why? The original gear, though well-braced for fore and aft movement, wasn’t really set up to take a punch laterally. It was tube and wood, covered in PolyFiber and painted, and the covering made it difficult to inspect the tubing for integrity. Besides, wed heard of several occasions where this type of landing gear had simply folded up in a ground loop.

Students are prone to putting side loads on landing gear, and it isn’t outside of their realm to ground loop a taildragger airplane. We were truly worried that might happen, so we decided to see what other gear were available.

Options Abound

Trips to the Kitfox booth during EAA AirVenture and Sun n Fun showed us there were plenty of other options. The company produces one retrofit that looks a little like the springy cross-braced Piper Cub landing gear, but the legs that really caught our eye were machined as one piece from aluminum and graced all of the later model Kitfoxes. It turns out that Grove Aircraft Landing Systems makes the gear both for the stock kits and for retrofit on the Kitfox Model 3 and 4 (as well as replacement gear for the Kitfox Models 5 to 7). After a bit of research we discovered that we could retrofit our airplane with the Grove spring-style aluminum one-piece gear, but to do it wed also be committed to changing out the brake lines, brakes, axles, wheels, tires and tubes. Altogether the equipment would cost us $2300, new.

The good news was that once the old landing gear was off and we had the airplane safely resting in a homemade cradle, the actual labor took about a day. The toughest part of the installation was getting the tires on the wheels because of the way the tubes and stems were set.

The new landing gear spreads a little wider than the older gear, and has the airplane sitting about 3 inches closer to the ground. Propeller clearance is still good at 14 inches (thats with the bubble centered on a level in the cockpit and the tail up in the classic takeoff position). The hope is that the wider, squattier stance will make it a more stable beast for student pilots. Even if that fails, the drop test video on Groves web site is convincing-this landing gear can take a hammering.

The installation is heavier than the wood/tube/cloth gear it replaces by about 25 pounds. Thats acceptable, because our Kitfox had always come in light, weighing less than 600 pounds before (and now just about 600 pounds empty). The CG has shifted 2 full inches forward, because this gear mounts forward of the other. However, the change is still well within the limits of the aircrafts CG range, and it simply required some adjustments to the trim settings (handled through the flaperons) so that the airplane can be properly trimmed for nose-level, hands-off flight. That took about four flights to tweak.

The plus side of the retrofit, on top of the added strength and utility, is speed. The new landing gear, with its integral brake line and sleek profile, creates less drag, and from what we can tell the airplane has picked up about 5 knots. Not that it matters, because flying the Kitfox is not about going anywhere fast. But it probably enhances the overall efficiency of the beast, which translates into possibly better gas mileage. I could learn to like that.

Now What?

Well, school is on a break, and our new students have wandered back to the nest. My hope is that they will soon be ready to settle in and spend some time studying in the sky. Ill let you know how that turns out.

![]()

Amy Laboda holds an Airline Transport rating, multi-engine and single-engine flight instructor ratings, and glider and rotorcraft (gyroplane) ratings. She and her husband live in Florida, along with two daughters, and recently finished building a Vans RV-10.