As a kid, I built my own surfboards from foam and fiberglass. They worked as well as anybody’s. In my home, we eat off of a wood trestle dining table I built using only sharp hand tools. I’ve made thousands of pieces of stoneware, using clay, glazes I’ve mixed and kilns I’ve built. I’ve completed three aluminum airplanes, and in the course of doing so, set tens of thousands of rivets, flared fuel lines and installed engines. In retrospect, none of these skills proved too difficult for a person of average intelligence and exceedingly average manual skills to learn.

A typical TIG welding machine.

But, welding…. What was it about welding, in particular, that made it so darn intimidating?

I’m not sure, but finally, after years of seeking out people who could weld to do simple jobs for me, I decided it was time to just get over it.

It became instantly apparent that “welding” was a huge ocean, wide and deep. The very word covers an infinite array of metals, tools and techniques. Chemistry, metallurgy and for all I could tell from books and Internet sites, voodoo, were all part of the mysterious technique of sticking two pieces of metal together.

I quickly decided I didn’t need to know anything other than what I needed to know. I just wanted to weld stands for rain barrels so I could gravity-feed water to my tomatoes, or make a simple steel rack for my latest set of wings or build my own engine mount for an airplane I was contemplating. I wasn’t going to be making parts for arctic oil pipelines or close-tolerance pieces of spacecraft. I wasn’t going to be working underwater, or with exotic metals.

All I really needed was a way to join metal bits, usually steel, of various dimensions in my home hangar without overwhelming expense or complexity.

American industry has anticipated the needs of people like me, and affordable alternatives abound. There is a large body of equipment priced and sized for the home shop, and it’s easy to find. Any big-box home improvement store stocks welding equipment, and even the cluster of small towns around my home has two dedicated welding supply shops. Even though their main business is with professional welders, I found the people behind the desks to be patient and eager to help a newbie get off to a good start.

I decided to explore three different methods of welding, and then purchase equipment for my own shop based on the results.

TIG (tungsten inert gas) welding. This is widely used for a variety of metals. Also known as heliarc, it has become the de facto method of building steel aircraft components.

Wire-feed arc welding. Small welders are widely and inexpensively available. Not a particularly delicate method, but great for a wide variety of shop projects. We’ll get into this discussion next month.

Oxyacetylene gas welding. Well- suited for places without electricity. (Both TIG and arc welding require lots of electric current, usually at 220 volts.) This format will be our topic month after next.

The inert argon gas is stored in heavy-duty steel bottles.

Gearing Up

The first task was to get access to the equipment. Traditionally, community college or high school extension classes have filled the need. They are well-equipped, the instructors know their stuff, they are quite affordable, and classes are offered in the evenings when working people can attend. Unfortunately, this all seems to be in the past tense. Oregon’s budget woes have drastically cut back extracurricular offerings at the community college level, and shop classes have virtually disappeared at many high schools. Combine this with thousands of laid-off workers, and the demand for vocational training has overwhelmed the supply. One community college responded by scheduling extra welding classes from midnight to 3 a.m.! Now, besides working a standard 45-hour week, I’m someone who considers dawn a bit late to be getting up, and the best part of the day gone by 10 a.m. I rarely see midnight and won’t even admit to the existence of 3 a.m. I certainly cannot maintain enough consciousness to learn anything at such ungodly hours.

The author, fully equipped to waste metal.

That left the choice of buying the equipment and teaching myself, or begging favors from others. In the hopes of saving money and shortening the learning curve, I chose to beg.

Even though TIG welding requires some expensive equipment, it was the most accessible to me, simply because the company I work for does a lot of it. A large welding shop over our hangar has stations for three full-time welders. Our lead welder, Donovan, succumbed to my pleading (and the lure of a bit of beer money) and agreed to stay after work one day a week and provide some one-on-one instruction.

“OK, Donnie. What do I need to bring?” I asked.

He suggested the usual welder’s rig: a sturdy long-sleeve shirt, a full-face welder’s helmet, and welding gloves. I’d need all of these for virtually any welding I would be doing.

The shirt was no problem-TIG welding doesn’t throw a lot of sparks, so the sleeves don’t need to block flying bits of molten metal. They are necessary to block the ultraviolet rays, which are produced in quantities and wavelengths that will quickly “sunburn” any exposed skin. A dark shirt is preferred because it won’t reflect the rays up under the helmet and burn the wattles on your chin. Gloves serve the same function, as well as protecting the hands from burns while handling hot metal.

Donovan McMartin, welding instructor and taskmaster.

The most important piece of personal gear is the helmet.

“Spend some money,” Donnie advised. “A good helmet will last the rest of your life, but there’s some cheap imported crap out there that won’t last and won’t protect you adequately.” I didn’t need any further encouragement. I only have one set of eyeballs, and I knew the story of Charles Manly. (Manly, in the very early 1900s, single-handedly designed and built a 50+ horsepower aero engine that weighed less than the Wright brothers’ 14-hp unit, and ran 10 hours continuously without failure-an almost superhuman achievement for the time. He also permanently damaged his eyesight brazing and welding on the project.) I headed down to the local welding supply shop and asked for some advice.

There were a lot of choices. All of the helmets covered the entire face, from above the forehead to the chin. (There are lots of photographs showing welders wearing simple dark goggles, but that won’t work for TIG welding. The powerful electric arc demands more protection.) I wear bifocals full time, so the helmet and window had to fit over those. Windows (aka lenses) come several ways: full face, half face, permanently dark and auto-darkening. I finally chose a very light composite helmet with a half-face window that remained transparent until the welding started, then darkened automatically in 1⁄12,000 of a second. A small battery powered the lens, and there was an automatic-off feature that switched off the lens if it hadn’t been activated for a while. For about $250 I drove away with a high quality helmet and a set of gloves.

The components of a TIG torch: cup, collet, handle and tailpiece. Just above is the tungsten insert.

Know Your Equipment

Suitably equipped, I climbed the stairs to the welding shop and presented myself to Donovan. Lesson No. 1 started with an introduction to the basic tools of TIG welding. The principles are pretty simple, and instantly understandable to anybody who’s disconnected a car battery. Remember when you pulled the positive cable away from the terminal with the ground strap still connected? I’ll bet the sparks made you jump! Electric welding uses a controlled version of the phenomenon. A strong current is run though the metal to be welded. The path back to ground is interrupted by a gap, but the current is so strong it creates a spark or “arc” that bridges the gap. The arc is extremely hot, up to 35,000 F. By controlling the size of the gap and the power of the current, the welder can melt the edges of the metal pieces to be joined, making them flow together like water. When they cool, the pieces are permanently fused.

A lot of small pieces of steel are sacrificed during the learning process. Don’t be alarmed.

Accomplishing a controlled melt/joint requires a system with several components. First, there’s the welder itself. This is a box about 3 feet cubed, with an impressive array of dials, switches and knobs. It takes electricity from the wall-or in some cases, a generator-and modifies it into different forms that make a controlled arc possible. Beginning welders don’t need to know everything it does. They can, at least to begin with, just regard it as a big faucet that lets more or less properly configured electricity flow.

A power cable with a large clothespin-like clamp on the end, and another cable with a foot pedal emerge from the welder. The ground cable attaches to the metal being welded or, in the case of small parts, to the steel table the parts rest on. The pedal is much like the gas pedal in a car, letting welders regulate power with their feet while working with both hands.

The “torch” is the where the connection is made between human welder and mechanical equipment. It’s a small T-shaped wand that fits comfortably in the hand. It holds a tungsten electrode, a rod about an eighth-inch in diameter and a few inches long, sharpened like a pencil. The tip is the business end of the machine, the point where the arc forms, so there’s an electric cable that runs between it and the welder. The tungsten rod is not consumed by the arc, so as long it is not damaged or polluted, usually by letting it touch the melted metal it’s welding, it can last almost indefinitely.

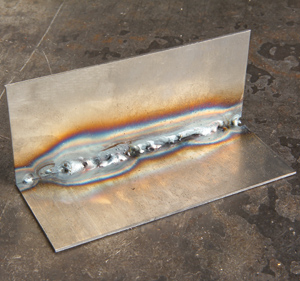

A skilled welder produces work like this…over and over.

Also connected to the torch are two small water lines. Torches, like engines, can be either air- or water-cooled. The machine we’d be using was designed for continuous production work, so a water-cooled tip keeps it at a more stable temperature for long periods.

Yet another hose runs into the torch handle, connected to a large tank a few feet away. The tungsten of the “tungsten inert gas” is in the torch. The inert gas, in almost every case, is argon, a gas about 1.5 times as heavy as air, and so inert that it reacts with almost nothing, even when drastically heated. The area being welded is continuously bathed in argon, which keeps atmospheric gases like nitrogen and oxygen away from the molten metal formed by the electric arc. If those gasses were allowed to contact the molten metal, bubbles and porosity would seriously weaken the weld. A ceramic cup around the electrode helps keep the flowing argon concentrated around the arc.

Small wire welding machines are fine for infrequent jobs. More on this machine’s functions next month.

First Foray

So, eventually everything is ready. A couple of small bits of 0.090 thick steel lie on the welding table. The argon tank is on, the power and ground cables connected, the foot pedal under my shoe. On with the helmet, deep breath, and lower the torch.

“Hold the torch just above the metal and push the pedal slowly,” Donnie counsels. “In a couple of seconds the arc will melt a puddle in the metal, and you want to push the puddle ahead of the torch to make a bead. Take it nice and easy.”

Nervously, I stab the pedal to full power. There’s a flash, not too bright as the helmet lens instantly dims, followed by a buzz and a snicker from Donnie. The electrode is stuck to the metal. Brisk wiggling breaks it free, but now the sharp tip of the electrode is all messed up. I suddenly realize why Donnie has stacked about 20 sharpened electrodes on the table. I spin the back of the torch to release the collet, dump out the damaged electrode and insert a new one.

Becky Breckenridge bought a small TIG outfit, and learned to weld. She’s using it to build her Christavia.

I do this quite a few times over the next half hour as I learn that the truth contained in a passage in the Miller Electric TIG Handbook (we’re using Miller equipment, and in preparation, I’ve read the well-written and organized handbook that came with the welding machine) that reads “(A) disadvantage is that the hand-eye coordination necessary to accomplish the weld is difficult to learn.”

I found the most difficult part was not the hand, nor hand-to-eye, coordination; it was the eye itself. Working with bifocals inside the helmet was a real pain. Eventually I discovered that taking my glasses off altogether and holding my head a bit closer to the work than most people solved the in-focus/out-of-focus problem. It did not solve the real problem, though, which was that I didn’t know what to look at. There was the arc, the torch, the metal…what was important? Finally, one evening, it clicked. I pulled the helmet back to regard yet another wobbly weld with pits and a hole I never saw form. For some reason I flashed back to evening classes I used to teach in calligraphy and lettering. Students invariably concentrated so hard on the line that they lost the idea of form. When I had them visualize the shape of the spaces contained within a letter and surround it with a line, there was immediate improvement. It wasn’t a matter of seeing-it was seeing the right thing.

An Aha Moment

I put the helmet back down, started the arc, and realized that when I really looked at the puddle, particularly the leading edge of it (in other words, the left edge as I moved the torch from right to left), I became aware of the metal becoming molten and flowing into the puddle, and I could time the movement and power of the arc to move the weld along.

Before you begin welding pieces for an actual airplane, you’ll need plenty of practice. But with time you’ll feel confident in your skills and be ready to tackle even larger jobs. Really.

Donovan is a patient man, and over several sessions I slowly gained the motor skills to tack bits of scrap metal together, get a “puddle” of molten metal started without burning a hole clear through, and move it along the seam to form the characteristic “bead” that marks a welded joint. We built dozens of little square steel tubes, about an inch across and 2 or 3 inches long. Each contained four rectangles that had to be tacked and then welded, sometimes to an inside corner, sometimes to an outside one.

Once I was able to do that, Donnie added to the mix by putting a filler rod in my left hand. Now the coordination exercise not only included my eye, foot and right hand, but a long, wiggly metal wand in my left hand that I had to dip into the puddle and add metal as the weld moved along. It was like starting all over again.

Sitting back and massaging my neck, regarding the various bits of damaged metal strewn across the bench and the slowly increasing number of acceptable stretches of welding bead that appeared on some of them, I was reminded of the guy with the violin case standing on the street corner in New York City. A tourist asked him, “Say, how do you get to Carnegie Hall?” The answer: “Practice. Lots and lots of practice.”