Findlay’s speedy Legacy is still finding its 400-mph racing legs, but it’s already a standout continent-crosser. Running lean of peak, it gets 21 mpg at over 280 mph. (Photo: Kevin Dobler)

Elsewhere this month Eric Stewart presents an interview with artisan fabricator and Sport Class pioneer Andy Chiavetta, who expertly maps the relevant, vibrant, Sport Class racing at Reno each September.

To get a little closer to the action, here we’re zeroing in on relatively new, but already well-established Sport Class pilot Andrew Findlay, his team, and details of his Lancair racer pertinent to Experimental builders. Andrew’s One Moment Racing is of particular interest because he combines the current generation’s facility with electronics, engine management, and team building with a competitive airframe and better than average sponsorship. The result is a remarkably fast and efficient Lancair Legacy.

One Moment’s Principal

One way to describe Findlay, manager, quality and reliability at Stihl, is a competitive young man with a bent for engines. Growing up in McCall, Idaho, his early interests were snocross racing snowmobiles in winter, dirt bikes in summer, and fast cars in between. These continued through a mechanical engineering degree from the University of Idaho, where his team built a snowmobile for the Society of Automotive Engineers Clean Snowmobile Challenge.

Given all that internal combustion snow blowing, it was logical Andrew joined Bombardier as an engine engineer, a move putting him in contact with many of those still with him at One Moment Racing. And those contacts are important to this airplane story, as while Andrew is certainly the center of gravity in his Lancair, this is very much a tale of team effort and talent.

Andrew had a meaningful run at Bombardier, but ultimately his major achievement was being “fired for insubordination,” a fact he led with when interviewing with Mark Voss at DeltaHawk. Apparently open-minded and with an eye for creative—if driven—talent, Mark hired Andrew, only to have DeltaHawk regroup financially within months. Mark moved on to engine maker Continental and Andrew to power equipment manufacturer Stihl.

Airplanes, of course, were right there along with the cars, bikes, and snowmobiles, and if the finances didn’t allow a Lancair, that didn’t mean Andrew wasn’t dreaming of flying high and fast around the country, or taking it down low around the pylons at Reno. Eventually Andrew found his Lancair in, where else, Bend, Oregon. It had not flown in years, was missing logbooks, had gone through a gear-up landing and repair, and consequently allowed a “smoking deal” that made ownership possible. Andrew quickly tore into the mechanicals and soon had a flying Legacy.

All hope was lost in 2013 when Andrew took the Legacy through pylon racing school, falling completely for the 310 mph rush around the Reno sticks. It was “Game on!” says Andrew.

Always a professional engine man, Andrew gravitated to hot rodding the Legacy’s TSIO-550 Continental. “My engine background made it too easy at first,” admits Andrew. Simply turning up the boost and adding ADI (anti-detonant injection) made a tremendous difference and earned a Rookie of the Year tin cup. Since then Andrew has added sponsorship from his Stihl employers, McCauley Propellers, Turbonetics, and many others, along with enough engine and airframe development to take his program well past those first easy steps and hard up against the development wall motivated racers know so well. By 2015 Findlay finished third in the hotly competitive Sport Class Gold at 357 mph, clearly with the potential for much more from this young, talented team.

Team Players

Likely the most populous team in the Sport Class, it’s impossible to even list the 30+ participants at One Moment Racing. They range from Andrew’s family to work colleagues and industry specialists, and certainly the depth of talent and resources has been a plus. But it’s also an operational and logistic challenge to keep so many people on the same heading, a trick that’s seemingly working well.

Naturally, a few One Moment team members are key. Mark Voss, now the certification guru and DER for engines at Continental Motors, has remained friends with Andrew since DeltaHawk. A thermodynamicist, Mark’s touch is everywhere on the Lancair, especially in his ability to quantify involved engineering processes into spreadsheets and ultimately to computer modeling. A gifted team player, gentleman, and efficient thinker, Mark is also smitten with air racing and a Pete Law disciple.

Andr Prager is One Moment’s mad scientist, full of vision and vested with the energy and skills to make dreams real via 3D printers and classic fabrication. Andr is central to the Lancair’s re-contoured, more aerodynamic belly profile and new intakes, to name just a couple things. Also a Stihl employee until recently—where he built a turbine-powered chainsaw and hyper-juiced electric blowers of epic coolness—Andr has been scooped up by Google X for their Wing project.

Bob Fair, Andrew’s newly minted father-in-law, was instrumental in returning the Lancair to flying condition in the summer of 2015. He removed the old engine, installed a new mount, and generally prepped the plane in preparation of the team coming to Bend to finish the engine install. He also added a few speed secrets of his own from his many years at Reno.

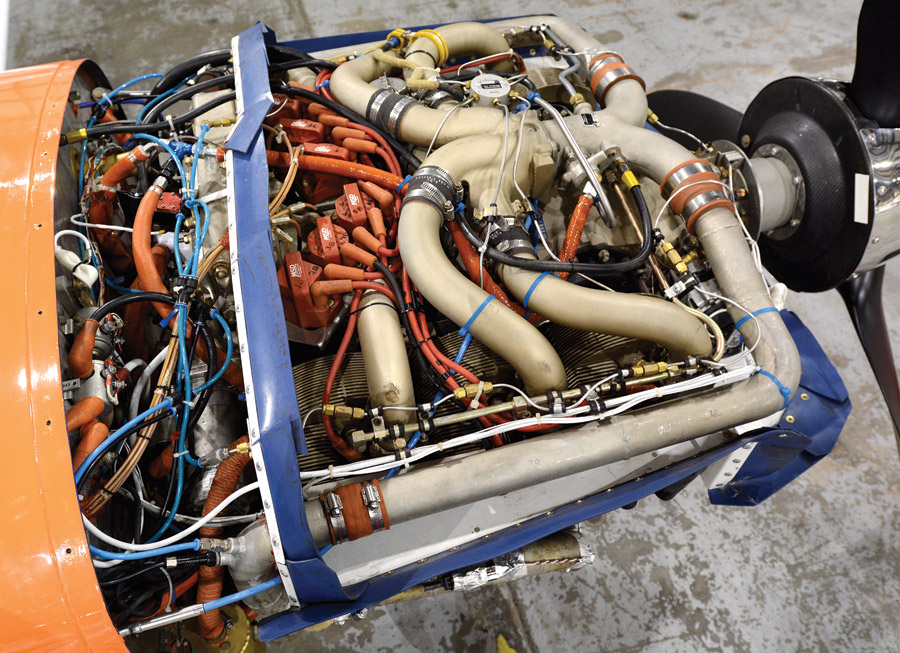

Continental’s 550 is Sport racing’s most popular engine. Findlay’s differs from most by foregoing air-to-air charge coolers in favor of heavy doses of ADI.

Power Play

Andrew’s Lancair started as a standard Legacy with TSIO-550 Continental power. Aerodynamic tweaks are found throughout, of course, including that lower aft fuselage filled in for reduced drag using Andr’s profile. Like most Sport racers, however, One Moment has mainly developed more horsepower, and as this hot rodding also translates into excellent cruise speeds and fuel burns—Andrew is still daily driving the Lancair—we’ll mainly confine ourselves to the noisy end of the airplane in this article.

Generally speaking, the big Continental has had its compression ratio reduced to a boost-friendly 6.5:1 via Ly-Con pistons and ported cylinders, uses Continental’s fuel system (for now) and intake manifolding, greater capacity Turbonetics turbochargers, and a slightly modified Light Speed Engineering ignition system.

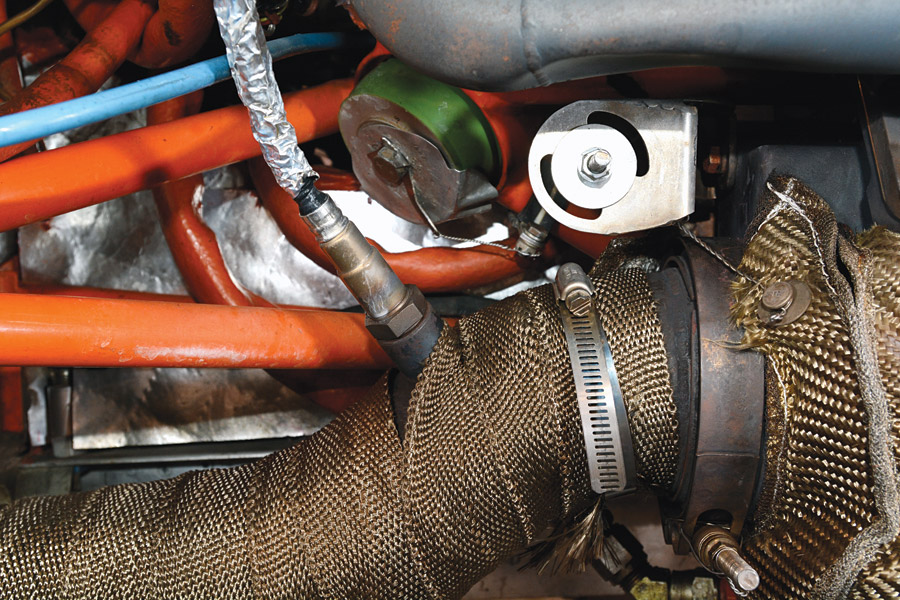

Standard issue on cars but rare on aircraft, the oxygen sensor on each turbo exhaust pipe tells Andrew precisely what his air/fuel ratio is rather than inferring it from EGTs. The sensors are high-performance wideband units (able to read a wide range of A/F ratios, rather than the narrow range used on production cars) from Innovate Motorsports. The A/F ratio is displayed both on the dedicated Innovate instruments in the lower right of the instrument panel and on the Dynon SkyView display.

One Moment Racing finds “a big fat spark” especially helps when the air/fuel ratio goes very rich (9:1) when transitioning from cruise to race power, hence this forest of MSD coils added to the Light Speed Engineering crank trigger ignition.

Being an engine engineer Andrew is conversant with the fundamentals of engine design and tuning, and has brought some of his ground-based motorsports tools to the cockpit. Fueling, for example, is measured more directly via oxygen sensors and is typically addressed in terms of air/fuel ratio rather than the more removed metrics of gallons per hour or EGTs.

A feature of Andrew’s engine philosophy is dispensing with air-to-air charge cooling (intercoolers) in favor of anti-detonation injection exclusively. The big advantage is eliminating the drag of ducting all that cooling air past the charge coolers, plus the boost penalty imposed by the charge cooler’s core to the intake air. The plumbing is hugely simplified as well, and an often overlooked benefit is the water’s mass impacts the turbocharger’s turbine harder, resulting in a couple pounds more boost pressure.

The cockpit is typical Legacy inside with a few interesting bits added. Among the toggle switches at the far, lower left are the spray bar and backup spray bar switches. All spray water is manually activated. Among the colored rocker switches is a red “race power” master switch for the ADI pumps, which are on separate buses and computer (primary) or manually (backup) controlled. The ADI master is there to avoid accidentally triggering “water” during less than race power, as it will put the fire out. The boost knob is yellow, the silver rim is boost with Innovate air/fuel instruments to the right. Vertical Power VPX e-circuit breakers control power to all systems; there is no telemetry to the pits.

The downside to ADI is the increased weight of five gallons of 50/50 water/methanol mix—most of which is pumped overboard via the exhaust pipes during the race anyway—along with managing the ADI flow relative to the engine’s needs.

The five-gallon water/alcohol ADI tank straps in place of the passenger seat; the prominent orange and three lobe black device is a video camera suction mount and the cylinders under the tank are the primary and backup ADI pumps. ADI is central to Andrew’s race power, but is not used outside of Reno. Barely visible behind the ADI tank is the 10-gallon spray bar water reservoir. Distilled water is used for spray to reduce mineral deposits all over the under-cowl machinery.

“Still, it’s worth it.” As Andrew points out, a stock Legacy’s charge cooling is designed to chill 140 to 150F charge air during extended cruising. This is a minimal requirement not in line with the burly temperatures and air volume while racing. “Typically discharge temperature is 350F out of the turbo, and the ADI takes that to 130F,” notes Andrew of his race settings. He uses 180F as the inlet temperature redline. During cruise inlet temps are just 130F and no ADI is used.

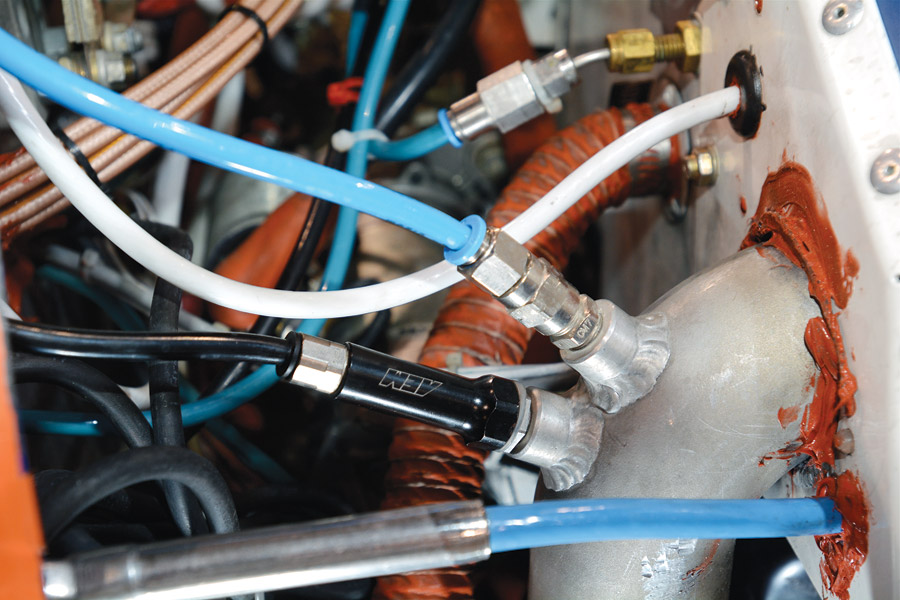

An easy way to tune the ADI metering is to “flow the ADI at 15 to 20% of the fuel flow, then adjust the ADI to the CHTs and engine response,” Andrew advises. His self-developed ADI system uses a stand-alone computer controller from automotive aftermarket tuner AEM to meter ADI flow based on intake manifold pressure. It begins ADI flow at 5 psi of boost—that’s about 40 inches manifold pressure at Reno’s 5000-foot altitude—and ramps up ADI delivery until maximum flow is reached at 15 psi of boost. A second pump provides manually controlled backup.

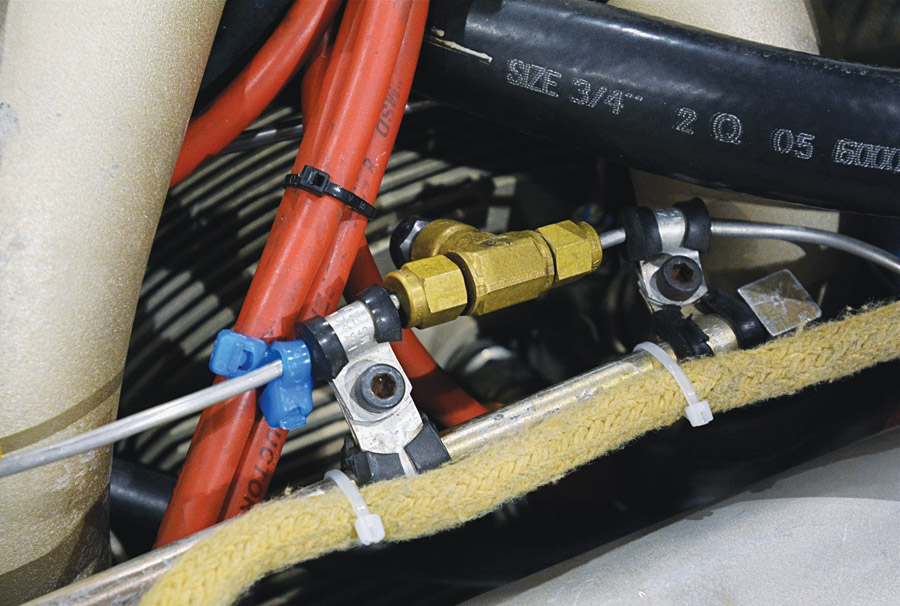

There’s another 24 gph of water being sprayed on the exterior of the engine, too. The spray bar circuit is one big loop with 16 emitters, starting with three 2-gph nozzles inside of each of the cowling’s two cooling air inlets as shown here.

Magnetos aren’t up to sparking this engine that alternately runs at both ends of the rich/lean spectrum, not to mention the high boost. Therefore a Light Speed Engineering Plasma crank-trigger ignition is used, but with hotter MSD coils. They help fire rich mixtures, which during engine transients may reach all the way to 9:1, with 10.5 – 11:1 being the typical racing A/F ratio range.

Andrew fitted his own potentiometers into the ignition system to allow +/-10 of ignition timing (Light Speed offers the same capability, Andrew simply used different potentiometers). “They’re real handy when going cross country. I run 44 of advance and super lean of peak, usually at 17:1 AF. The [previous, higher compression] motor could do 18:1,” says Andrew.

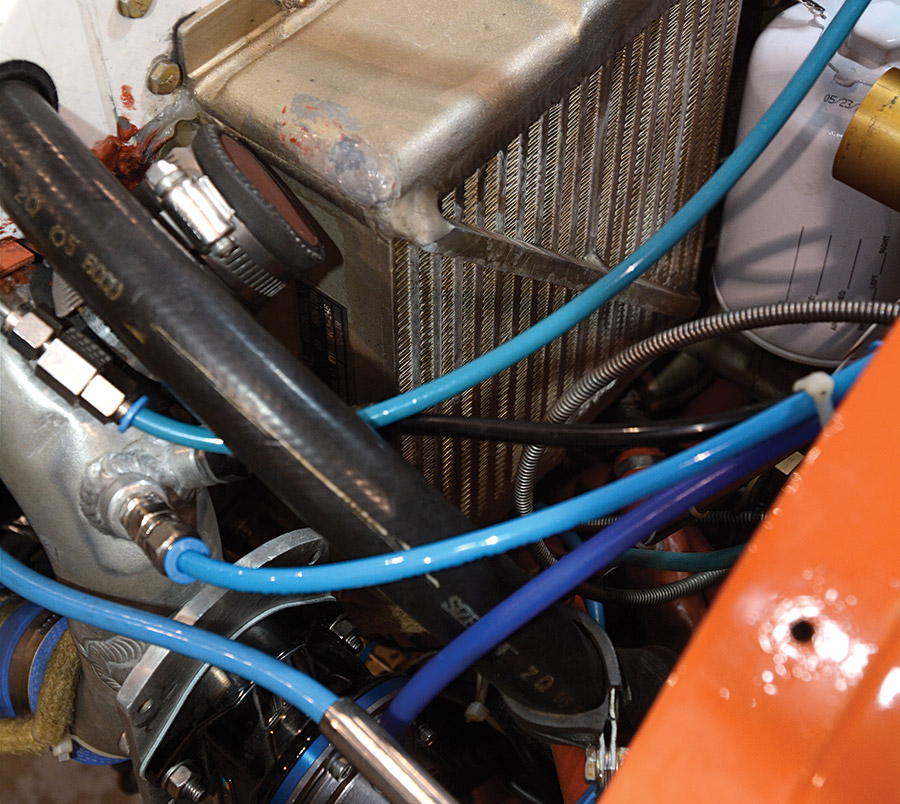

As Sport racer twin-turbo installations go, Findlay’s is relatively simple and compact. Turbonetics uses data supplied by One Moment to assemble the appropriate compressor (a little larger for 2015 and unchanged for 2016) and turbine sections. They also integrated the pneumatically operated wastegate. There have been minor exhaust manifold cracking issues, but that’s par for turbo fitments.

Insulated from heat, the wire at 2 o’clock on the compressor volute is for an rpm sensor. “We use the (turbo) rpm to plot where the compressors are on the speed/pressure ratio map. Maximum rpm for the turbos is around 136,000 rpm. The sensors output a signal we measure with a multimeter,” explains Andrew.

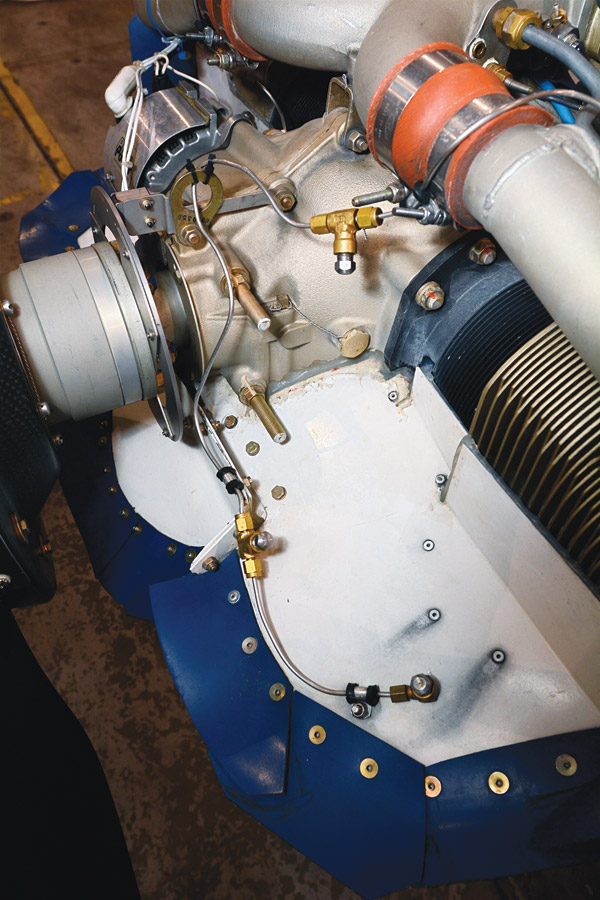

In 2014 the team’s issue was not enough air to and from the turbos; Mark’s analytics gave target values for the induction path from the cowling to the turbos, plus the needed turbo output. Shown the data, Turbonetics responded with larger, slower-spinning compressors, plus integrated their wastegates to the turbo housing to save weight and simplify. After considering NACA ducts Mark and Andr developed new pressure recovery cowling inlets for the 2015 race, pleasing Mark greatly as the inlets exceeded expectations.

ADI—which is critical to the Continental’s health at race power—is normally managed by an AEM controller signaled by this manifold pressure sensor and its mate on the other side of the engine. Should this system fail Andrew can switch on a separate backup pump—which he must remember to switch off when pulling the throttle back or risk drowning the engine. The ADI is injected at the back of the intake plumbing, giving it about four feet of manifolding to vaporize in. Two nozzles—one large, one small—are fitted to each turbo discharge pipe; four nozzles are used to give finer ADI tuning capabilities.

In fact, the new inlet/turbo combination worked so well the problem at the 2015 race was the fuel system could not supply enough fuel for the boost available. Many workarounds were tried at the races—the team was time-crunched in 2015—but found the Continental fuel system was far past its designed flow and control limits. Therefore no more than 65 inches of manifold pressure could be run.

To reduce pilot workload, the pneumatically actuated wastegates were rigged to give no more than 65 inches when the control was fully closed and the throttle wide open. This kept the turbos from over-boosting and sending the EGTs past 1800F and the pistons melting out the exhaust pipes.

Each cylinder has its own spray bar mister. They emit 1 gph each and are principle in keeping CHTs between 400 and 420F while pulling 600+ hp during a race. Even with spray water the CHTs climb if the A/F ratio leans below a rather fat 10:1. So do the TITs. One Moment finds their target CHT temps important in avoiding cylinder-to-head integrity issues.

After lack of airflow limited the Lancair in 2014, Mark Voss and Andr Prager gathered data, then defined the size and position for these new pressure recovery inlets, which Andr CAD modeled and built with the help of a 3D printer. The two new ducts add some smoothly faired frontal area, but give excellent pressure recovery. NACA ducts were considered, but rejected as less desirable.

New in 2015, McCauley’s propeller was designed and built specifically for One Moment in an impossibly short two months. Its three, heavily twisted, wide-chord blades are optimized for 600-700 hp and 400 mph. Diameter is a diminutive 64 inches and it turns 2900 rpm. Simulations show 15-20% more thrust than Hartzell’s race prop that nearly all other Sport racers run, but One Moment has yet to make the necessary horsepower to prove the point. “It’s frustrating,” laments Mark Voss. “We were converging on an optimum setup (in 2015). It’s when you learn a lot.”

Most of the Sport Class at Reno runs a Hartzell race prop, but looking for the next step ahead, and with an established relationship with McCauley, One Moment Racing has been working with the McCauley Blackworks team to develop a new high-speed constant speed. This was born of necessity as an engine failure sheared off the old prop somewhere over Utah at 17,000 feet—on Andrew’s birthday no less. That was June 20, 2015, and after a successful 28-mile glide to Wendover, Andrew was talking with McCauley, who really stepped up to the plate. As Robert Rucker, business leader at McCauley Propeller Systems put it, “The team started designing the propeller in July of 2015 and in less than a month, the custom race propeller was finalized and rolling down the production line.” That’s amazingly fast to design and build a prototype prop, and so far it’s proven efficient, quiet, and not fully tested as One Moment was fighting fuel issues at the 2015 races and wasn’t making design power.

You may notice all those MSD ignition coils partially block airflow to the stock Continental oil cooler. The offset is four spray bar nozzles misting the cooler, the top two each flowing 2 gph and the lower two at 1 gph apiece. Mark Voss says the bone-dry Reno air is a big enabler because the evaporative cooling from spray water is so powerful there. With spray water the air entering the oil cooler is typically 50F, and sometimes in the 40s.

The Challenges

If Andrew and team were playing catch-up in 2015— it wasn’t until two weeks before Reno in September that the new engine and prop were on the plane and ready to fly—then it’s understandable that 2016 will mainly see refinement of last year’s hardware.

Beringer wheels and brakes are a welcome upgrade to the One Moment Lancair. Andrew reports a “nice light touch on the brakes, very smooth. Now that we have those, it rolls around easier on the hangar floor—and they look awesome.” The landing light telltales the Lancair’s dual personality as racer and sport plane, something that will eventually change as the class eventually modifies itself into pure race status.

For the 2016 races One Moment is continuing with the Continental fuel system augmented by a larger fuel pump and increased automation, likely of a mechanical fuel control nature.

This latter point is to help with a major issue: transient engine response during race starts where the power must rise rapidly from cruise to full-throttle. With the ignition and fuel systems completely segregated and almost wholly manually adjusted, this means Andrew is juggling the throttle, propeller, mixture, wastegates, ADI, spray bar and ignition timing controls. Obviously this is far too much for a two-handed human hanging onto a stick to manipulate, especially when computers do such things so well.

Eventually the team will end up with an integrated electronic fuel injection system with the bandwidth to handle idle to hair-on-fire power settings, but such improvements require more time and money to develop than has been available so far. In the meantime, if you see the Stihl Lancair lagging at the start you know why—the few naturally aspirated competitors have hammered the throttle while Andrew and most of his turbo competitors are anxiously twisting knobs. If anyone is going to develop a sophisticated aftermarket single-lever power control, these guys are it.

When 400+ mph is the goal, aerodynamics take on a whole new importance. Custom fairings, gap seals, and plenty of tape help clean up the airframe, but the flap actuators remain dragging out in the breeze even though the flaps are taped shut at Reno.

That’s why it’s worth keeping an eye on what racers such as Andrew are up to. Dusting pylons is likely not your goal, but the speed and efficiency mods these racers develop transfer directly to daily aviation.