An RV-10 owner recently brought his airplane to the shop due to high CHTs. He also mentioned that the problems started after the panel upgrade. When I asked what he meant by “high,” he responded that they were reaching 460° F on climb-out after just a few thousand feet, and he had to reduce power to stop any further rise in the temps. Yikes! That is really a high temp, especially for an RV-10 that previously had not had any temperature issues.

An RV-10 owner recently brought his airplane to the shop due to high CHTs. He also mentioned that the problems started after the panel upgrade. When I asked what he meant by “high,” he responded that they were reaching 460° F on climb-out after just a few thousand feet, and he had to reduce power to stop any further rise in the temps. Yikes! That is really a high temp, especially for an RV-10 that previously had not had any temperature issues.

My initial thoughts were one of two things: Either something had gotten changed/broken with the cooling systems, such as baffles or the plenum, or perhaps it was a configuration system with the new panel. Examination of the engine compartment revealed nothing was amiss. The new Garmin panel requires proper configuration of the CHT and EGT thermocouples for accurate temperatures, and I verified the configuration was correct for the J-type thermocouples that were installed.

One other thing had occurred since the panel upgrade—we had installed a SureFly electronic ignition system. Occasionally I have seen electronic ignition systems cause higher CHTs, and I had configured this SureFly for variable timing during the installation. We verified the configuration on the SureFly was correct and that both it and the magneto were timed properly for 23° before top dead center. Yes, over time we have found that the six-cylinder Lycoming engines perform better at 23° of ignition timing versus 25°.

So, the next step was to put on my thinking cap and ponder what would cause high CHTs. Since it wasn’t the ignition timing, there was a high probability it could be lean-running cylinders. My next thought was to check the intake gaskets and O-rings. This one had a cold-air induction intake system, so there were O-rings at the bottom of the intake tubes versus the hoses that are usually installed. Sure enough, they looked horrible and I could see some blue stains from the fuel around a couple of them.

Interestingly, the customer stated that the panel upgrade took about 10 months, during which time the aircraft was not flown. Bingo—the seals had all dried out. Boy, they had really dried out. It took quite a bit of scraping and wire brushing to get the gaskets off the cylinder heads, and on top of that, a couple of the O-rings looked like they had not been installed correctly.

The engine start-up after replacing everything was very telling. The engine idled noticeably smoother and all EGTs were evenly matched. The run-up was also very good, and things were looking very promising. Of course, we were anxiously watching the CHTs as full power was applied.

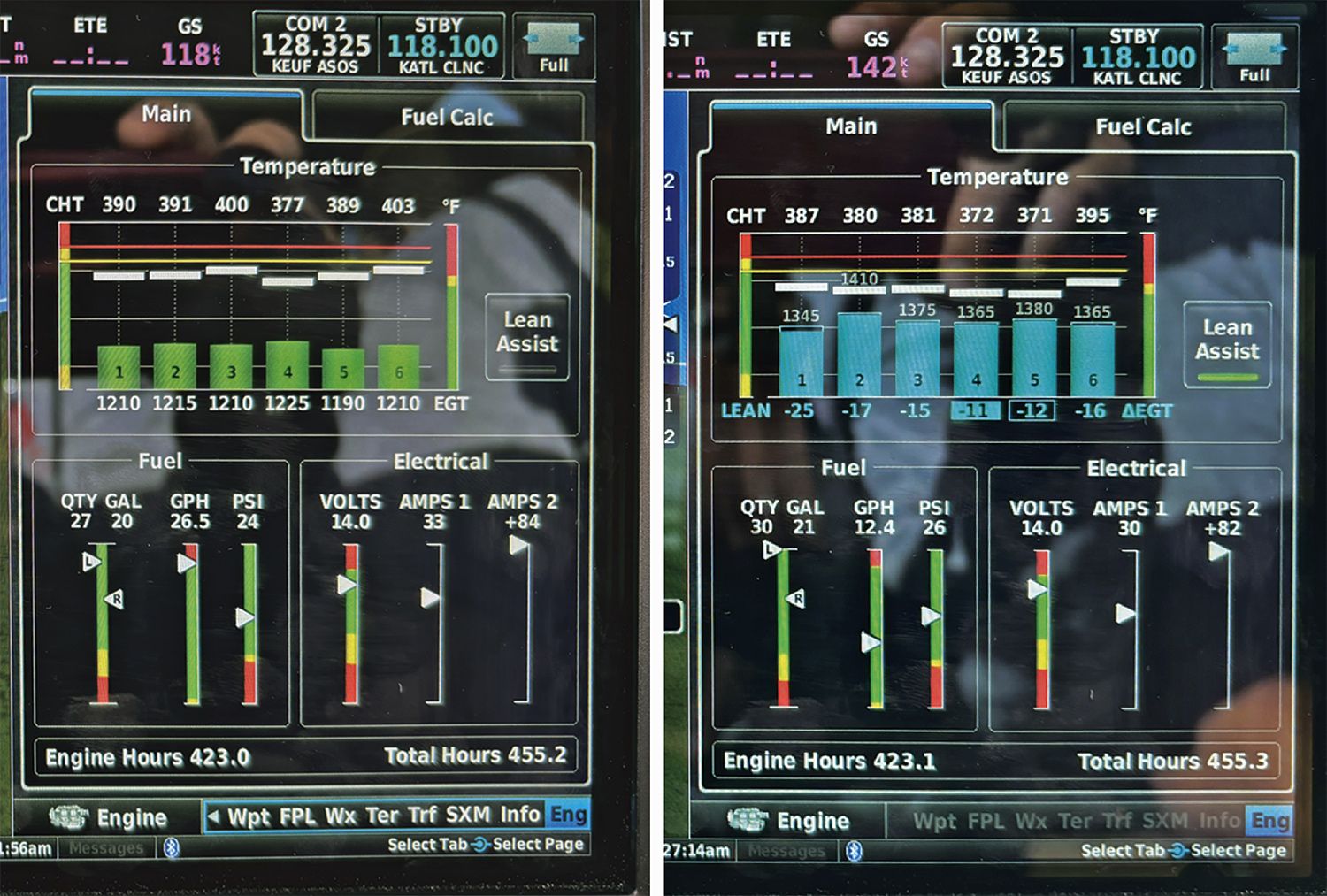

We took pictures at every thousand feet of altitude while climbing to 5500 feet. The results were amazing. The highest temperature on any one cylinder was around 403° F, and all the temperatures started to decrease above 4000 feet. I was really happy with the results and so was the customer.

The bottom line is that we are more often seeing intake gaskets and hoses/O-rings as being the culprit for high CHTs. For some reason, they are often overlooked during normal inspections. I encourage all of you who are doing your own maintenance to routinely check them every 300–400 hours and, of course, after the engine has sat for any length of time.

The Surefly mag is NOT “timed” to 23 degrees or 15 degrees. It is times to zero degrees, and the ignition event occurs at 25 or 23 or whatever the DIP switch configuration is set to.

The word “at” was supposed to be “for”. It was this way in my original draft. I didn’t notice it got changed. Thank you.

Vic