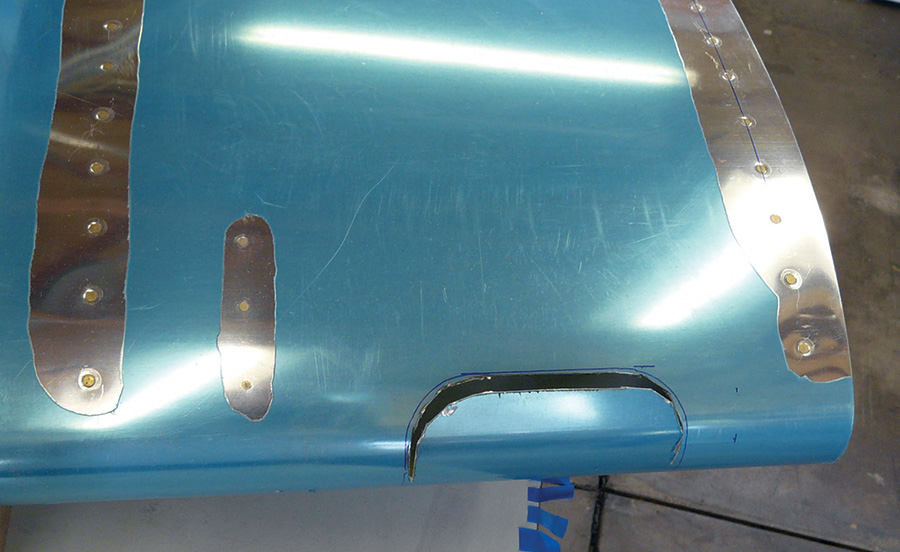

On my RV-3B, I decided to put a landing light on the left wing’s leading edge. First I had to mark its location, and since the cradle doesn’t enforce alignment spanwise, the top and bottom can shift slightly. But the spar secures that, so I placed the leading edge on the spar. Once marked, I got out the Dremel and put a new cutoff wheel on it and started cutting. With light passes a bit inside the line, it was easy. The photo below shows what it looked like after cutting the opening about half way. There’s so much tension on the leading edge that the cutout piece was almost perpendicular to the wing’s chord line.

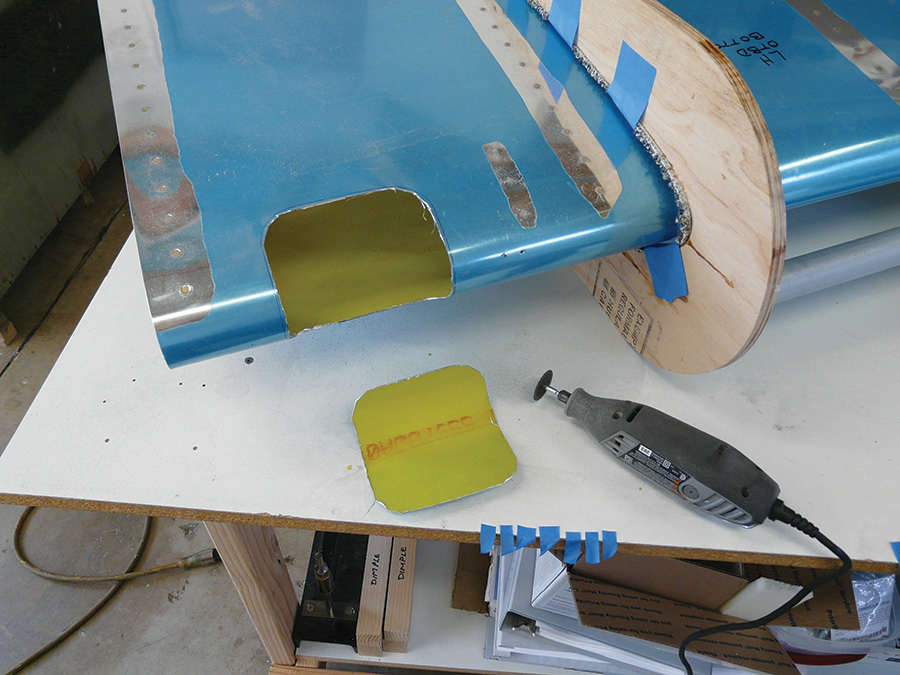

After flipping the leading edge, I finished the cutout. The cutting took about fifteen minutes and was easy.

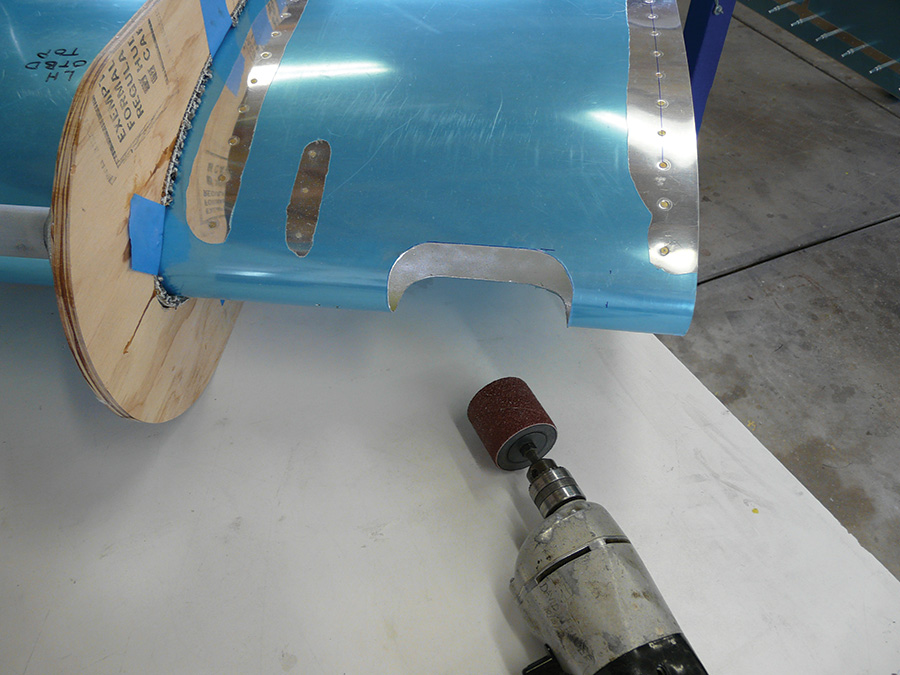

I put a coarse two-inch sanding drum in an electric drill and trimmed the edges after first removing a few of the high points with an Adel nibbler. The sanding drum works fast, but leaves an edge that needs final smoothing. The photo shows the opening close to the net shape, but the edge is still a bit rough. It only took another few minutes to finish it up.

The Dremel cutoff disk and the coarse sanding drum both throw lots of material, and the disk itself can break up. I used a dust mask under a full-face protector. I keep them handy and use them whenever I’ve got this sort of power cutting or sanding operation.

Next, I smoothed the edge using standard deburring techniques. Your choice of a sanding drum in the Dremel, files, sandpaper, or even a Scotch-Brite drum in a die grinder. Personally, I rarely use the Scotch-Brite drum, favoring the other tools.

It’s important that either the inside of the leading edge be accessible or that it is masked off because a lot of aluminum dust and debris will go in there. A shop vacuum with a narrow tip cleans it right up, if there’s access.