One of the most common materials used in aircraft construction is aluminum. Even if you are building a plastic or fabric aircraft, you will still have some parts made of this metal.

Many builders have learned the hard way that paint can be troublesome when trying to cover aluminum. While paint will appear to stick just fine after an initial application, long-term durability generally falls short if the painted aluminum component is subject to a harsh environment. It is common to find paint flaking off if abrasive forces challenge its adhesion. The issue is not the paint quality—the best paint is no help if it just won’t stick to the surface! For example, I have seen paint pull off instrument panels when self-adhesive labels for switches and circuit breakers were removed.

There are many techniques of aluminum surface preparation that claim to solve the paint adhesion problem. Some work well, and some require a lot of work on your part. Outlined below is a tried and true, simple and easy procedure for preparing your aluminum components for paint that will not disappoint. This procedure is used by aircraft professionals and is outlined in the FAA’s Aviation Maintenance Technician Handbook—Airframe, Volume 1, Chapter 8.

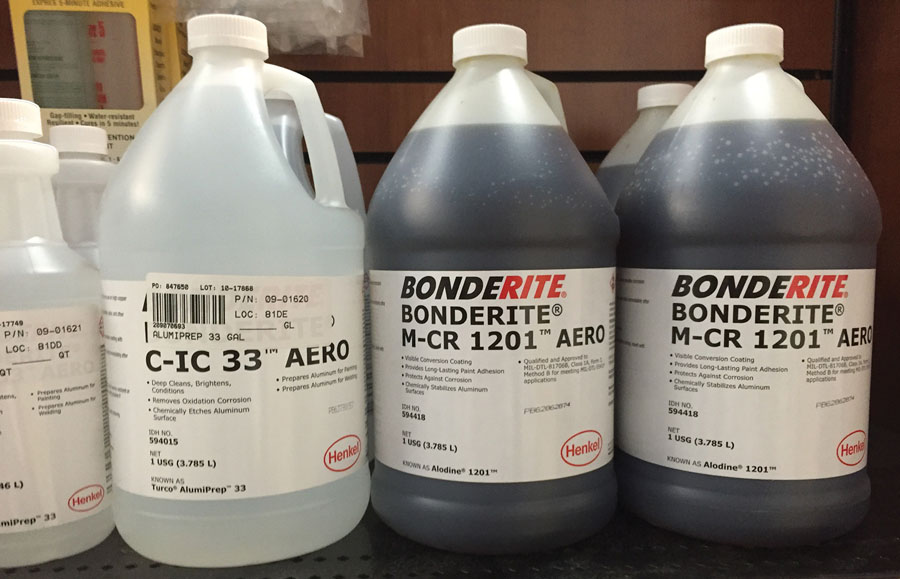

The key to successful aluminum painting is to perform a chemical conversion of the aluminum surface. Two relatively inexpensive chemicals are needed, both available from your aircraft supply store: AlumiPrep 33 (now called Bonderite C-IC 33 Aero Acid Deoxidizer) and Alodine 1201 (now known as Bonderite M-CR 1201 Aero Chromate Coating).

Same products, new names: The fine print on the labels says that Bonderite C-IC 33 Aero Acid Deoxidizer is known as AlumiPrep 33, and Bonderite M-CR 1201 Aero Chromate Coating is known as Alodine 1201. (Photo: Courtesy of Aircraft Spruce & Specialty Co.)

AlumiPrep (or a similar product) is an acid etch that is designed to deep clean the aluminum surface. It does this by removing the oxide coating that normally forms on any aluminum surface (a reaction with the oxygen in the air). Alodine is a chemical that converts the aluminum surface. This conversion produces a coating that provides both corrosion protection and a surface that paint loves to stick to. This new surface does not add any weight and can be primed and painted (or just painted) as desired.

Application of these two chemicals is straightforward. Of course, the manufacturer’s directions need to be followed, but the procedure can be summarized with these simple steps:

1. Wash the aluminum part with a degreaser if needed and remove any markings (they will bleed through the final paint).

2. Wet the aluminum part with diluted AlumiPrep (use a brush, sponge, or submerge if the part is small enough), keeping the surface wet for 2-5 minutes. If your aluminum part has corrosion on the surface, you may use a Scotch-Brite pad to scrub the part with the acid (use gloves!).

3. Rinse the part thoroughly with water.

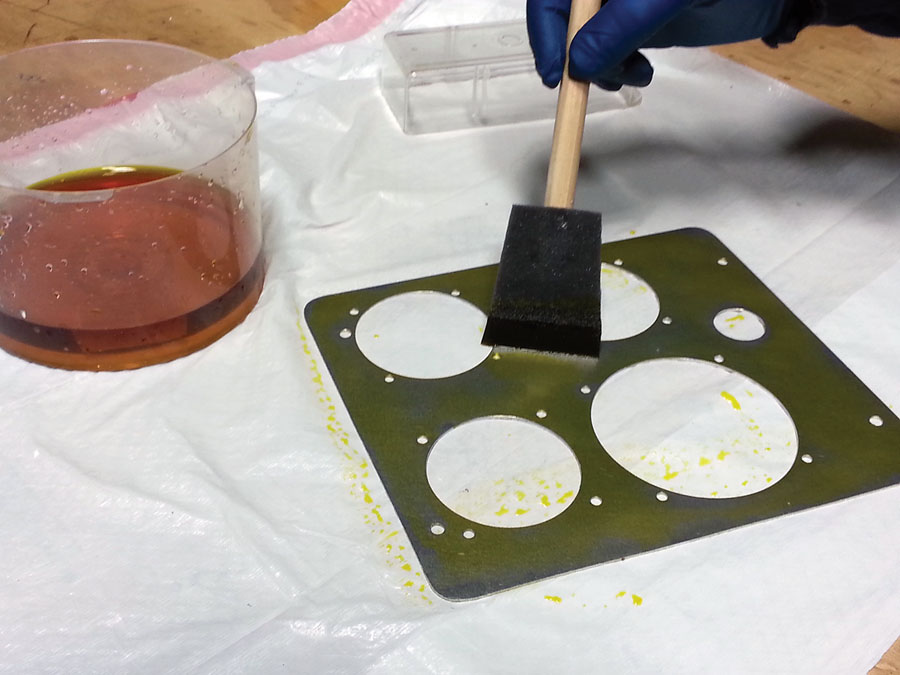

4. Repeat steps 2 and 3, but this time use the Alodine. (The surface will now turn a light tan or gold color—an indicator of conversion.)

After washing with AlumiPrep, aluminum will be bright and free of corrosion. The next step is treat it with Alodine, which is brushed on (or submerged if possible) and kept wet for 2 to 5 minutes. Rinse with water, let dry, and you are ready to paint.

Once dry, you are now ready to paint. What is nice about this method is that it not only works well, but is also fast and easy. Within minutes you can have your aluminum ready for painting and be confident that there will be no issues with paint adhesion—even in harsh environments. Of course, the quality and type of primer or paint you choose is still an important consideration based on the component’s function in your aircraft. The procedure using these chemicals simply guarantees that the aluminum surface is exceedingly paint ready.

![]()

As the founder of HomebuiltHELP.com, Jon Croke has produced instructional videos for Experimental aircraft builders for over 10 years. He has built (and helped others build) over a dozen kit aircraft of all makes and models. Jon is a private pilot and currently owns and flies a Zenith Cruzer.