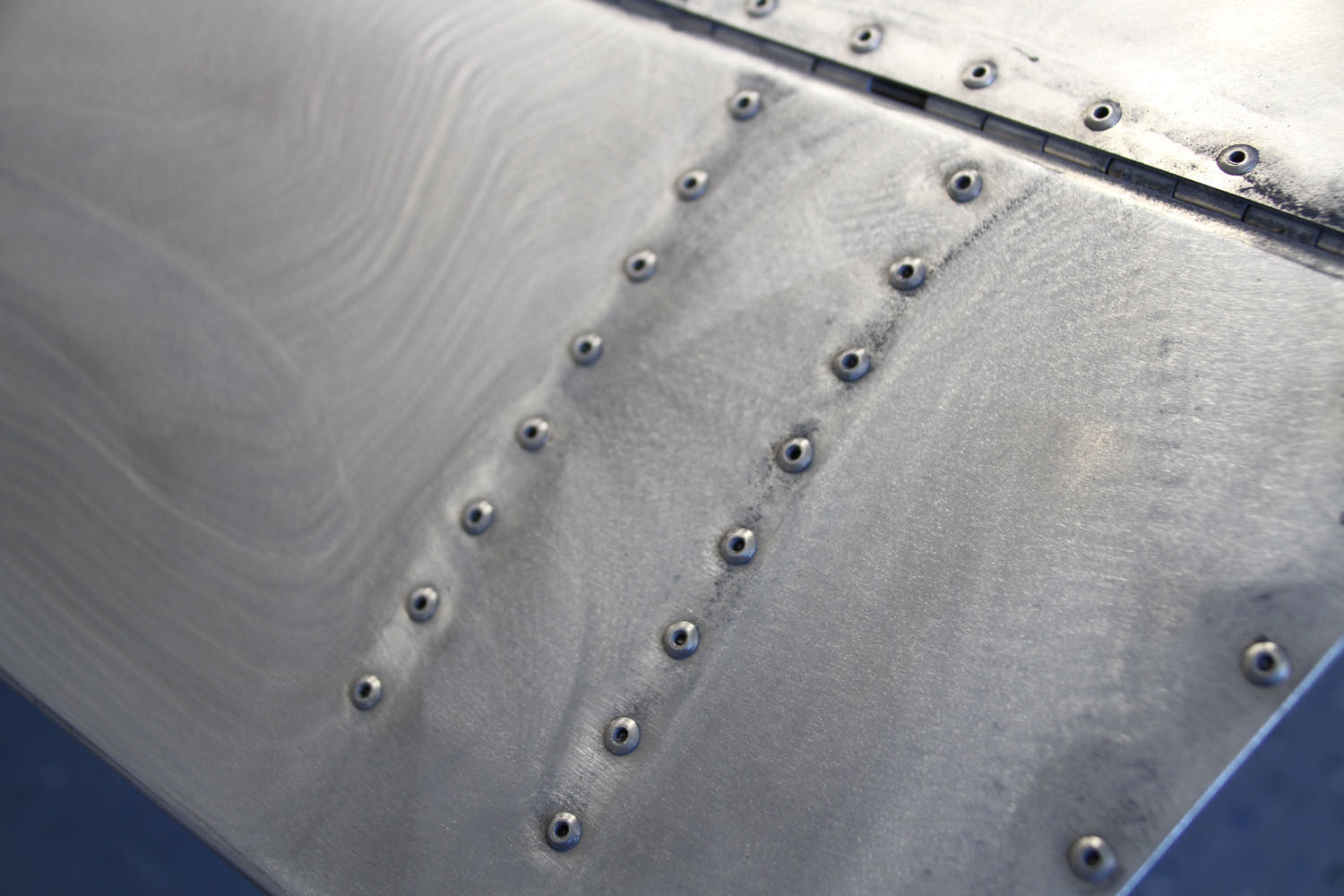

With most of the masking completed last night, the team immediately started into Scotchbriting all of the external aluminum areas on Paul Dye’s SubSonex jet. The rivets were attacked first with a rotary, power Scotchbrite wheel. Three passes at slightly different angles ensured that the rivets were adequately scuffed. The fiberglass nose cowl was also lightly sanded. Soon, neighbors started showing up and the broader surfaces received attention.

As scuffing progressed towards completion, team members started preparing the temporary paint booth. A shop fan was set up in an open window at one end of the shop to be used as the exhaust fan..

The paint “booth” is a remarkably simple structure. One hundred feet of 10′ wide Visqueen-type plastic was tapes from the ceiling to surround the project. A hole was cut into one side for access and ventilation with the plastic taped to the floor in that area. Air was now drawn into the “booth” and blown to the outside by the exhaust fan in a window immediately across the shop. Because the outside temperatures were near freezing and the shop doesn’t have central heat, a propane heater was set up just outside the intake opening to heat the air drawn into the booth. The system worked great. No fumes came into the rest of the shop and no cloud developed within the booth. Our only casualty of the day was an Exact-O knife puncture caused while cutting the plastic.

The last step before applying primer was to thoroughly clean the surfaces. First, Stahr wiped down the entire plane with damp towels to remove most of the aluminum and Scotchbrite dust. Then, pressurized air was blown into all the nooks and crannies. In the last step, Stahr wiped all of the aluminum surface with metal cleaner while two others followed right behind to wipe the surfaces dry.

About 5:30 pm, it was time to shot primer. It took about a half-hour for Stahr to finish the first coat. After maybe 15 minutes, he applied a second primer coat to the nose cowl and top of the wings. Done for the day.

Watch the day condensed into 7 minutes: