I fly my Pulsar with a 60-inch GSC ground-adjustable wood prop because it smoothes out engine pulses from the Rotax 912, and it allows for customized pitch settings for flying out of my high-altitude airport in Big Bear, California. About every three years, the prop needs refinishing of the surface from sun exposure and service dings and scratches. That only takes a couple of hours of easy work to fix, but after any sanding or varnishing, the prop requires rebalancing. I found a simple, motorcycle static wheel balancer at Harbor Freight for $50 and adapted it to do my prop, and also the wheels of the plane (Fig. 1). Turns out to be a good addition to my hangar goodies.

Fig.1. This $50 motorcycle static wheel balancer from Harbor Freight can be adapted to balance a propeller or the wheels of a plane.

The balancer consists of two upright legs from the base, and a set of roller bearings on each leg allows a shaft to rotate easily. The shaft has two tapered cones that lock with a setscrew, intended to insert into wheel bearings on a typical motorcycle hub.

Fig. 2. To use the motorcycle wheel balancer with a prop, it’s necessary to drill a half-inch hole in the center of the prop hub for the balancer shaft to pass through.

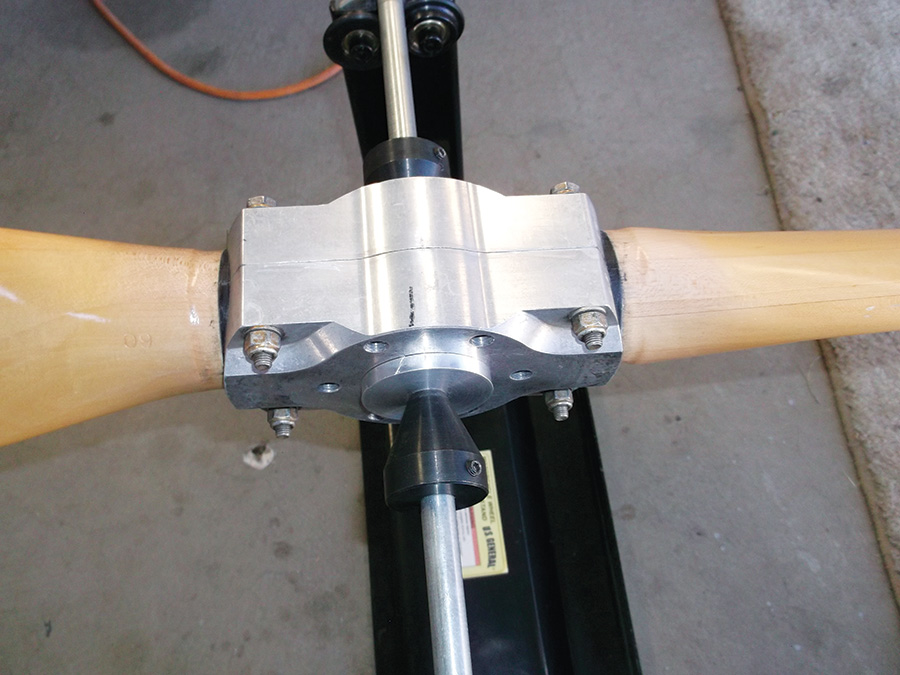

To adapt the balancer for the prop, I placed the aluminum prop hub into a lathe and accurately drilled a half-inch hole for the balancer shaft to pass through (Fig. 2). The opposing side of the hub has a large hole to attach to the engine flange, so an adapter was made to accept the half-inch diameter shaft (Fig. 3). Now the prop hub can be tied to the balancer shaft and placed on the leg bearings (Fig. 4).

Fig. 3. The back side of the hub has a large hole to attach to the engine flange, so an adapter was made to accept the wheel balancer’s half-inch diameter shaft.

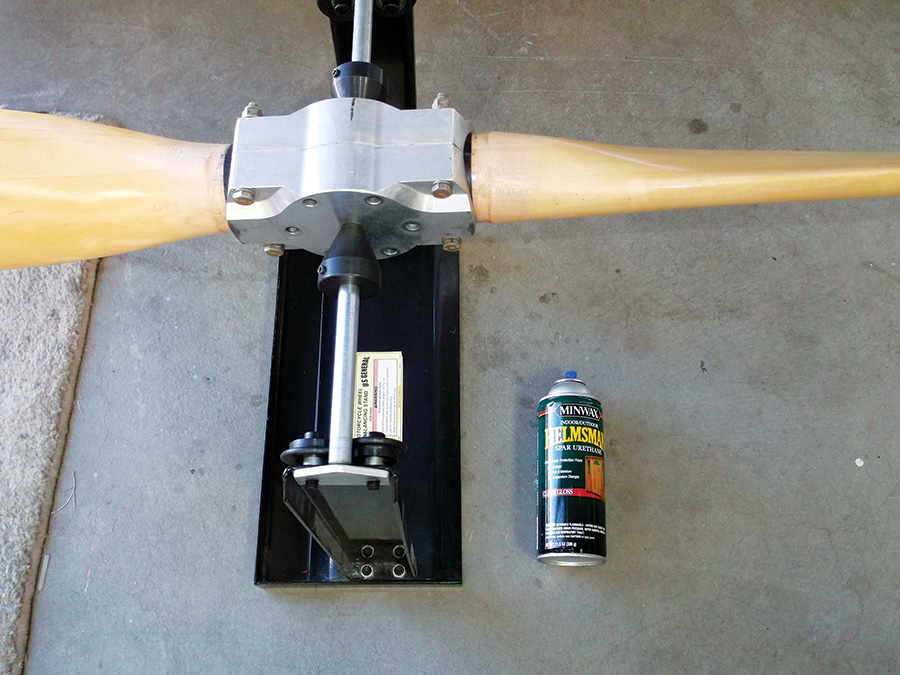

The heavier blade gradually drops toward the ground. To balance it, take a spray can of spar varnish and lightly spray the backside of the light blade for approximately one-third of its length from the tip (Fig. 5). This may not seem like much balancing weight, but it makes the prop move toward an equal, horizontal position. As the solvent in the varnish evaporates, the prop may need another light hit. When it remains motionless horizontally, the blade assembly is statically balanced.

Fig. 4. With the adapter in place, the prop hub can be attached to the balancer shaft and placed on the leg bearings.

I wasn’t sure how effective this static balance was compared to a dynamic balance, so I hired a friend to dynamically balance my prop after I did my work on it. The normal dynamic balance brings a prop within 0.2 units; mine came in at 0.1 units!

Fig. 5. To balance the prop, take a spray can of spar varnish and lightly spray the backside of the light blade for approximately one-third of its length from the tip.

My whole GSC prop assembly only weighs 7 pounds, so at this low weight, the static balance provides a close comparison to a dynamic balance. Heavier blades may not be so close. The system works well for me, and I can balance 5.00 X 5 wheels, as well as the prop, on the same equipment.