If small airplane pilots were to get so frustrated with today’s engines that they “rioted” for new engines, they might well be chanting:

“What do we want?” “Easier starting!”

“What do we want?” “Better power-to-weight ratios!”

“What do we want?” “Full FADEC!”

“What do we want?” “Multi-fuel engines!”

“What do we want?” “Easy maintenance!”

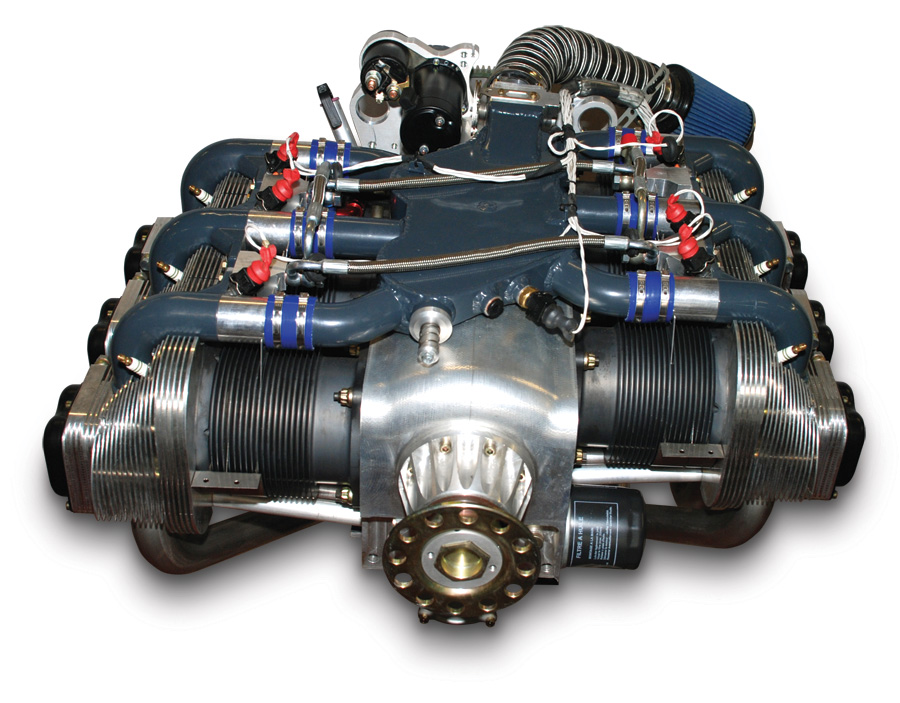

ULPower is gaining a foothold in the Experimental fleet because they deliver these wants. The company builds a total of eight different engines with power ratings from 97 to 200 horsepower. These are clean-sheet, air-cooled, direct-drive engines that were designed and built using 21st century technologies. All of them weigh less than existing engines of the same power, and they automatically adjust the spark timing and fuel/air mixture to optimize performance. They are so adaptable that they fit almost any application, and they incorporate subtle, but proven, features gleaned from decades of developing automotive racing engines.

Each design includes five crankshaft main bearings, a large roller-type thrust bearing, positive-pressure oil lubrication to the cylinder valve operating mechanisms, solid-valve lifters with diamond-coated faces, and other user- and maintenance-friendly features.

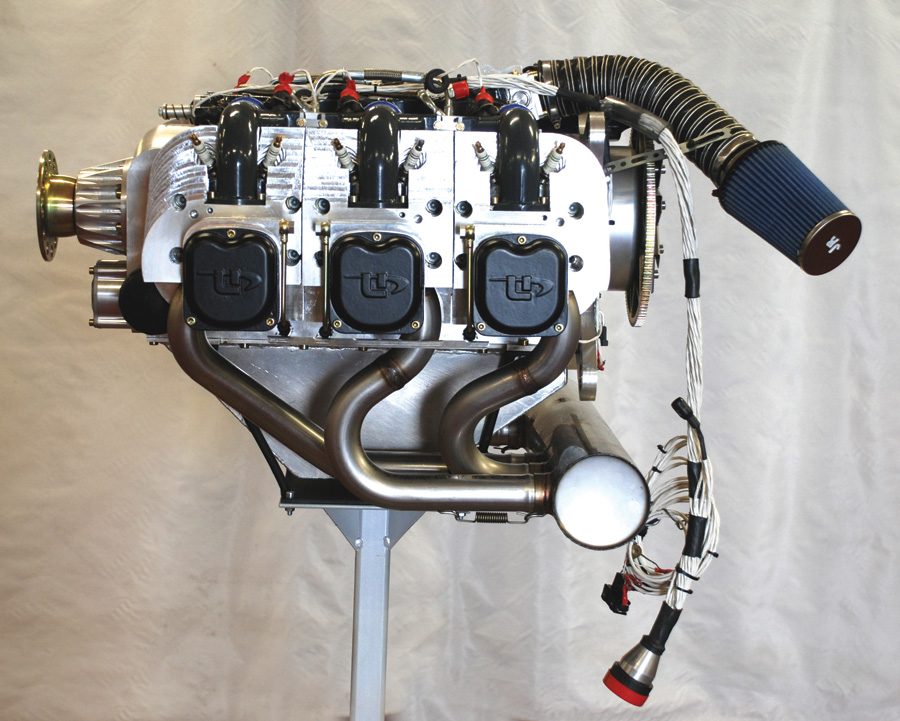

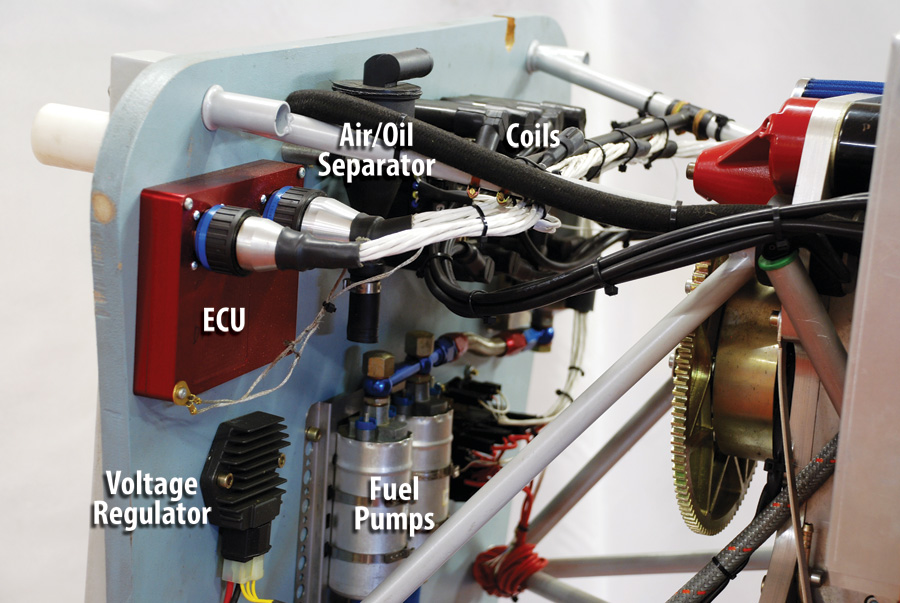

Each ULPower engine is delivered with a complete exhaust system, a wiring harness, an ECU, the ignition coil pack, an alternator rectifier, a voltage regulator, the left and right ram-air housings (not shown) and an air/oil separator.

Take Your Pick

The line of ULPower engines includes 4- and 6-cylinder models. Every engine is delivered to the buyer with an exhaust system, an incorporated alternator with rectifier and voltage regulator, electric fuel pump and regulator, and a starter.

The 4-cylinder engines start with the UL260 line. These include the UL260i (97 hp) and the UL260iS (107 hp). Displacement is 2592 cc (158.17 cu in), and the installed weight is reported at 159 pounds.

The higher-power 4-cylinder engines are the UL350 line. These include the UL350i (118 hp) and the UL350iS (130 hp). Displacement is 3503 cc (213.77 cu in). Installed weight is 172 pounds.

The 6-cylinder engines start with the UL390 line. These include the UL390i (140 hp) and the UL390iS (160 hp). The displacement for these engines is 3888 cc (237.2 cu in). Installed weight is 220 pounds.

The bigger-displacement 6-cylinder engines are the UL520 line. These include the UL520i (180 hp) and the UL520iS (200 hp). The 520 line has 5254 cc (320.6 cu in) displacement and an installed weight of 238 pounds.

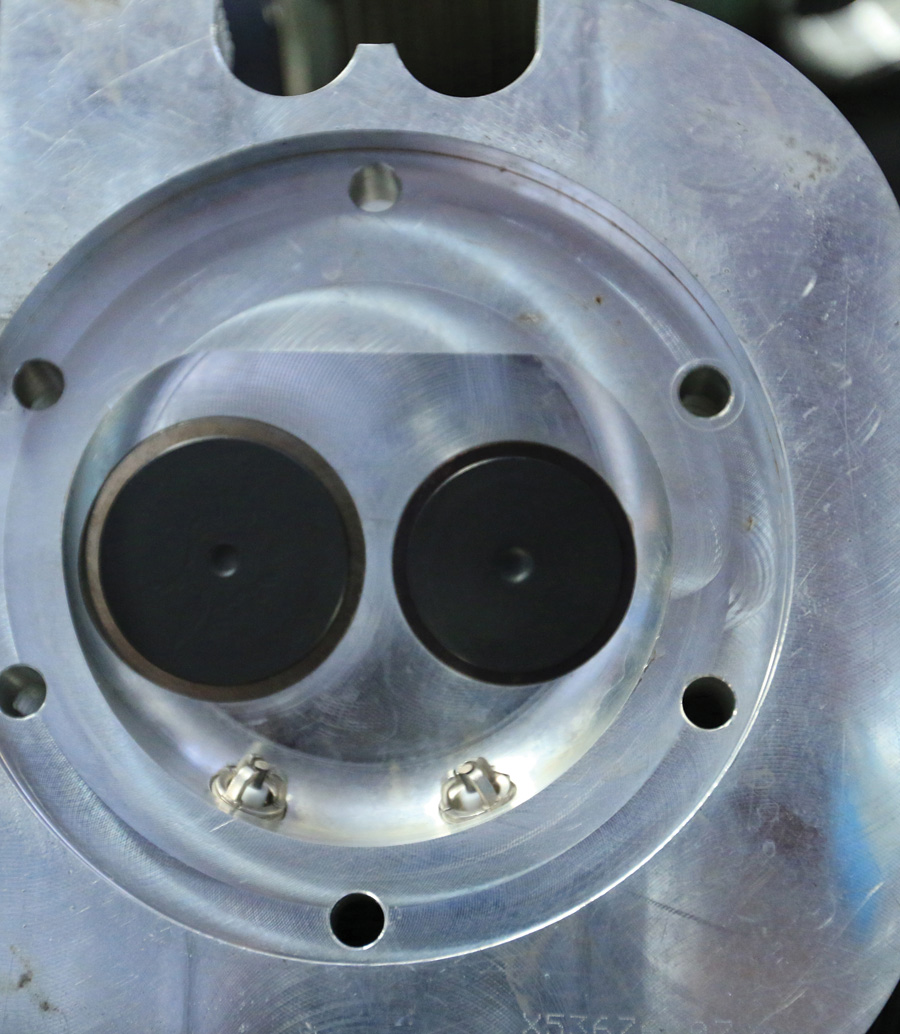

Each cylinder head is separate from the cylinder barrel. This permits valve and guide work without disturbing the ring-to-cylinder wall fit. The squish area generates turbulence to increase atomization and mixing of the fuel-air mixture.

All ULPower engines have a 105.6 cc (4.1 inch) bore. The 260 and 390 have a stroke of 74 mm (2.9 in); the 350 and 520 have a stroke of 100mm (3.9 in).

All ULPower engines are direct-drive, wet-sump engines, just like a Lycoming or Continental. But unlike the traditional engines, ULPower cylinder heads are not screwed onto the cylinder barrels to form a one-piece cylinder/head. ULPower heads are bolted to the barrels. This feature makes valve and head work much easier and less intrusive to the engine since the ring-to-barrel seal is maintained throughout the process. Another advantage is that the torque values for the cylinder case halves are not relaxed during head work, which maintains main bearing crush and fit.

Another difference between traditional engines and ULPower engines is cylinder head and upper cylinder valve train component lubrication. Each ULPower upper cylinder is constantly lubricated through an external oil line. This flow not only lubricates the valves and valve guides, but also cools the heads. Pressure oil also squirts at the underside of each piston and cylinder wall.

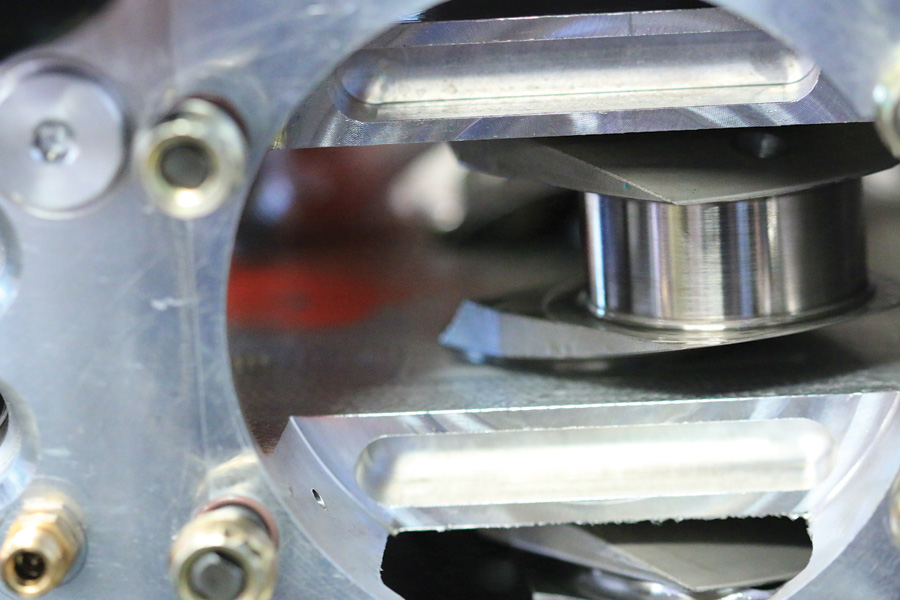

Crankshaft connecting rod journals are large to lessen loading forces. Crankshafts in the four-cylinder engines are supported in five main bearings.

Lionel D’ Hondt, owner of DL Racing and designer of the ULPower line of engines at the ULPower display at Sun ‘n Fun in 2015.

The Squish

All ULPower engines are multi-fuel engines. They are designed to run on mogas, including mogas blended with up to 15% ethanol, as well as on 100LL leaded avgas. The “i” models use mogas with an anti-knock index (AKI) of 91, while the “iS” models require an AKI of at least 93.

When asked how ULPower is able to safely use mogas in its engines with compression ratios of 9:1, Lionel D’Hondt, the designer of the engine, explained that it is possible due to the “squish” designed into the cylinder head/combustion chamber. As the piston nears top dead center (TDC) on the compression stroke, a portion of the fuel/air mixture is “squished” between a portion of the piston and the head. Squish design utilizes a very narrow gap of less than 1 mm between a portion of the piston and the cylinder head. Squish creates turbulence, causing a more homogeneous fuel/air mixture that results in a better-controlled and faster combustion event.

Pre-Takeoff Full-Power Check

The fuel injection system utilized with ULPower engines is a closed loop system. Fuel flows from the tank(s) to a pressure pump—a second pump is available as an option—and then to the two fuel injector blocks mounted on each side of the inlet collector atop the engine. The fuel pressure at the blocks is regulated to maintain 43 psi (3 bar) above the existing atmospheric pressure. Changes in atmospheric pressure automatically result in changes in the fuel/air mixture. Since maintaining this pressure is critical for safe engine operation, the ULPower operating manual requires a full-power engine run of at least 5 seconds prior to takeoff to determine if the fuel pump(s) is/are functioning correctly.

The gerotor-type oil pump is externally mounted on the front of the engine to permit easy servicing and inspection.

Cool Runnings

The redline (maximum) cylinder head temperature (CHT) for ULPower engines is surprisingly low at 356 F (180 C), especially for pilots and technicians familiar with the 460 F (238 C) and 500 F (260 C) CHT red lines for Continental and Lycoming engines, respectively. Maximum continuous CHT is 320 F (160 C).

There are three reasons for these surprisingly low numbers. The first is the sheer number and large size of the cylinder head cooling fins, especially in the exhaust port area of each cylinder.

Each ULPower engine is also shipped with a left and right cylinder head ram air box. The design of these boxes is not left up to the airframe manufacturers; ULPower designs them. In addition to supplying these boxes, part of the post-installation testing and evaluation procedures consists of measuring the air pressure differential across the cylinders and across the oil cooler (if installed). When testing cylinder cooling effectiveness, one end of a simple water tube manometer is open to the pressure of the ram air above the cylinders, while the other end is open to air pressure below the cylinders near the cooling air exit from the cowling. A differential of at least 20 mm (0.78 in) at 120 km/hr (64.7 kts/hr) TAS is required across both the cylinders and the oil cooler.

The third reason, although it’s one not touted by ULPower, is the transfer of cylinder head heat due to the continuous flow of lubricating oil flowing to the valve mechanism in the head and being sprayed on the bottom of the aluminum pistons. That’s the reason it’s critical to ensure there’s a sufficient pressure drop across each oil cooler installation.

The compact ULPower components fit onto any firewall. This installation shows the optional second fuel pump.

Mounting Options

Each ULPower engine is shipped with a straight (not Dynafocal) four-lug mounting plate bolted to the back of the engine. There’s also an option to add a two-lug mount at the front of the engine to utilize a cradle mount system. Engines are shipped with a standard-length 55 mm (2.166 in) prop flange, but since the flange can be removed without splitting the case—try that on your Lycoming or Continental engine—three optional lengths can be used if desired: 35 mm (1.38 in), 90 mm (3.54 in), and 110 mm (4.33 in). Propellers are available from companies such as Sensenich, WhirlWind, Catto, Prince and Airmaster.

Due to the large roller-type thrust bearing, all ULPower engines can be installed in tractor (prop in front) or pusher (prop in back) configurations. All that’s required to adapt the engine for pusher use is to rotate the inlet air collector, the exhaust system, and ram air collector boxes 180 to accommodate the change. ULPower also offers a fan and ducting kit to convert any of its engines to helicopter use.

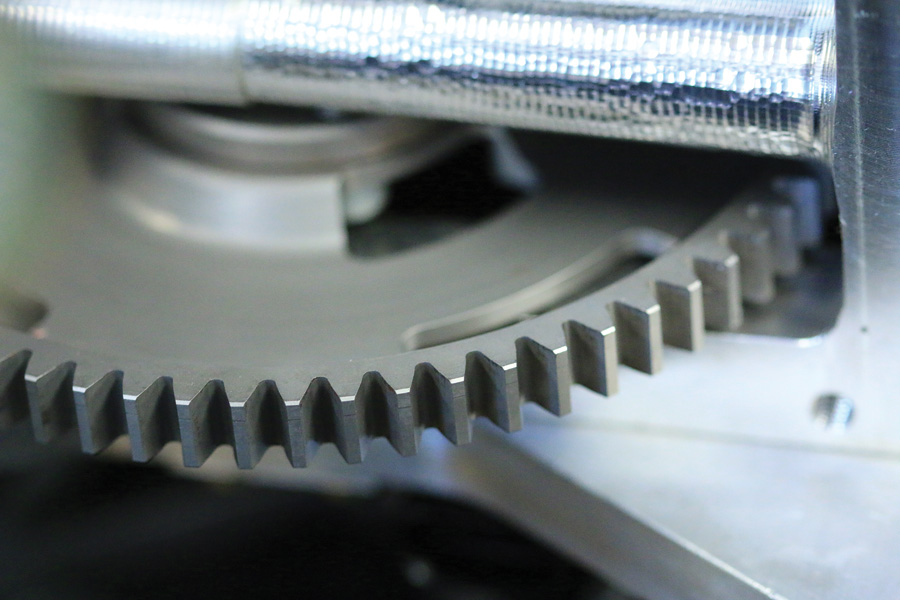

Slots machined in the starter ring gear send crankshaft position data to the ECU for ignition timing.

Manuals and Tools

The ULPower web site provides a full complement of installation, operation, parts, and maintenance manuals, as well as service bulletins on every engine. All of these files are available for download in pdf format. In addition to the manuals, all of the engine service bulletins are also on the web site pages.

The only part of the engine that is not fully illustrated in an exploded view is the engine control unit (ECU), the ignition coils, and the starter motor. Every part of the engine, as well as every part of the alternator, is shown in the parts manual.

U.S. owners will need to buy a set of metric-sized internal wrenching sockets, as well as a conversion chart for converting European torque specifications to U.S. torque specs, since all specs in the manuals are in Newton/meters. For those that want to get started right away, it’s helpful to know that 1.35581794833 N-m equals 1 foot-lb.

For example, the torque specification for the four engine-mount bolts that secure the 350 series engines to the mount is written as 25Nm. Conversion to 18.4 foot-pounds is easy by using any of the online conversion sites.

There are other metric notations such as thread sizes (M12 x 1.5) and wire sizes (2.5 mm), but these are relatively easy to convert.

Real-World Experience

Since the ULPower engine’s first introduction in 2002, over 550 engines have been shipped from the factory in Belgium. In 2009 the Twister Aerobatics Team (www.twister-aerobatics.co.uk), a two-airplane aerobatic team flying Silence SA1100 Twister single-seat airplanes, selected ULPower engines when it needed more power to expand its aerobatic routine. Peter Wells of Twister worked with ULPower to develop an aerobatic version of its 107-hp UL260iS engine, the UL260iSA. Working in conjunction with the ULPower design team to track engine performance, these engines have now been flying for over 900 hours. According to a spokesman from the factory, a ULPower engine in France has logged over 1,100 hours.

As a result of its work with the Twister Duo and Just Aircraft, it is now possible to order any ULPower engine in an aerobatic configuration.

ULPower engines are just beginning to gain traction in the U.S. According to Robert Helms, general manager of ULPower North America in Lake Ozark, Missouri, approximately 150 ULPower engines have been shipped to users here.

One of the first companies in the U.S. to embrace ULPower was Zenith Aircraft in Mexico, Missouri. Zenith offers full firewall-forward installation kits for ULPower engines for the STOL CH750, the CH750 Cruzer and the Zenith CH650.

Helms also told me that ULPower North America has agreements to supply ULPower engines to many airplane original equipment manufacturers (OEMs) including Arion Aircraft, Kitfox, Hatz Bantam, Bede Corp, Just Aircraft, RANS, Sport Performance Aircraft (Panther), and others. These companies have developed, or are in the process of developing, firewall-forward kits for ULPower engines. The kits vary from very complete to those that supply only a mount and cowling. Additional packages for other kit aircraft are also being developed.

Zenith Aircraft offers full firewall-forward installation kits for ULPower engines for the CH750 Cruzer (shown here), the STOL CH750, and the Zenith CH650. (Photo: Notley Hawkins)

Just Aircraft’s Installation

Just Aircraft recently introduced a ULPower 180-hp UL520i engine in the Stretch XL version of its popular SuperSTOL (see page 6). After installing the engine, Just discovered that, due to the extremely high deck angles achieved during maximum-performance takeoffs, the oil pickup tube in the engine sump would unport momentarily. ULPower solved the problem by quickly delivering a flop tube that automatically adjusts for steep deck angle operations.

“Since the oil pan is simple to remove and replace, we had the new pickup installed in less than four hours,” said Harrison Smith, Just Aircraft’s test and instructor pilot. “We’ve now flown the ULPower 520i on the Stretch XL for over 70 hours.”

Like others, Smith would like to see the data from “50 of these engines with over 500 hours each” before he’s convinced that ULPower is going to be as favored by remote operators as the much heavier, but extremely durable, Lycoming 4-cylinder engines. However, “I’ve really been putting the motor through its paces, and it’s been a good experience so far,” he said.

Smith has run a variety of fuels in the 520i. “It does best on high octane mogas,” he explained. He also reports that the crew at Just has been sending in oil samples, and to date “they’ve been clean.” So far, so good.

North-American Parts and Support

Helms recently announced that Wicks Aircraft and Motorsports of Highland, Illinois, has been named the exclusive parts supplier for ULPower North America. Keith Gibbs is the primary contact.

Ray Lawrence at Kaolin Aviation in Sandersville, Georgia, has been named the first authorized ULPower service center in the U.S. Kaolin is also developing firewall-forward kits for additional aircraft, including the Van’s RV-4.

The RV-4 was designed for Lycoming O-320 and O-360 engines from 150 to 180 hp. According to Lawrence, the 200-hp UL520iS weighs about 40 pounds less than a typical Lycoming installation. More power from a smaller package that weighs less; what’s not to like?

Lawrence also says he will begin development of a 4-cylinder engine firewall-forward package for the Sonex family of airplanes in the near future. He can be reached at [email protected] or by calling (478) 232-9560.

So there it is. ULPower engines have been slow to cross the Atlantic—they’re manufactured in Belgium—but are rapidly gaining favor as satisfied users spread the word through online chat rooms and owners groups.

The question that’s unanswered today is will these engines achieve the “bulletproof” status of Lycoming’s 4-cylinder aero engines. Time will tell that story, but from what I know about these engines I’d love to see one installed on my airplane.

For more information on prices and delivery, contact Robert Helms at [email protected] or (573) 434-0075.