After 30 years as a mechanical design engineer in Silicon Valley, Ive become sufficiently aware of the distance between idea and execution. Thats a fancy way of saying that I know what I don’t know and rely on friends who are experts in a given field.

That said, I was dissatisfied with the mechanical appearance and last-century technology of a circuit breaker. The pull-type circuit breakers in my wifes Cessna 172 have a few problems: They collect smut around them, they don’t match, they wear out, they take up too much panel space, they’re spread out so that working on the back of the panel is a pain, and they cost about $20 each. Other than that, they’re great.

With all that staring at me as I designed the panel for my Jabiru, I got to thinking there must be a better way. What that better way was wasn’t apparent, so I put a 4×6 matrix of holes in the panel and decided to live with it.

Yes, I know: If you’d planned it better, you would’ve needed a bunch fewer holes. I assumed that if I just built it, they would come. Or not.

Actually, the thinking was that Id use as many holes as needed, then cut out the remaining and fabricate a fiberglass or aluminum map box to fill the hole. Or if there wasn’t enough space for that, Id have a nice plate engraved with This aircraft is amateur-built… and mount it over the remaining holes. Pragmatic, options-oriented, flexible.

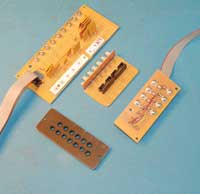

Jabiru supplied some cute little pop-out type circuit breakers, but not enough of them, and not in the right amperage ratings. That left me with the pop-out type circuit breakers with their mismatch, smut, etc. That is, until I remembered a device called a Polyfuse or PolySwitch. An Internet search brought me to an article by KITPLANES columnist Jim Weir, in which he clearly explained what these devices do, how they do it, when to use them, how to arrange them and where to get them. (Find the article here: www.rst-engr.com/kitplanes/KP0103/KP0103.htm.)

Polyfuses have been around for quite awhile. Anyone who’s had 5-year-olds in the back seat of the car has watched junior test engineers hold the window button in the down position for 30 seconds. Are they waiting for smoke? Perhaps they think the window will go up faster once its soaked up more power? They are soon disappointed to find that neither occurs, but what they don’t notice was a momentary pause when the switch was flipped to up.

The Polyfuse is the source of their disappointment. It’s a capsule filled with a mix of plastic and carbon that conducts electricity when cold, and opens the circuit when warm. It then passes a tiny amount of power, just enough to keep it warm as long as the circuit is energized. With the power off, there’s a short pause to cool and solidify the matrix, remaking the circuit.

When I went to the source Weir mentioned, Digi-Key, I was delighted to see that the only thing smaller than their size is their price: 50 cents up to $1.50. Its the first time I ever yelled Jackpot! on such small winnings.

Calling on the Experts

Im no electrical engineer (lets see, threaded end of the light bulb goes in the socket), so after laying it out as best I could I cajoled a neighbor, Rob Kirkpatrick, into looking over what Id done. When he quit laughing, his first comment was, How will you know if the thing has tripped? He then suggested that an LED placed in parallel would illuminate if the Polyfuse tripped, and offered to take one of them to his bench to fabricate and test a small circuit. Weir had suggested this in his column, so I knew that enlisting Kirkpatrick into my circle was a good move.

The next day I got a call: They work fine! Kirkpatrick had rigged up a 3-amp Polyfuse with an LED and a 1K-ohm resistor, pushed 3 amps through it overnight and got a clean circuit. When he cranked up the power to 4 amps, the Polyfuse opened and the LED came on. He then qualified the safe aspect of the rig by leaving it in that state for several hours. Nothing changed, no smoke, no pop sizzle. Bringing the power back to 3 amps extinguished the LED and restored current flow. Another jackpot.

High Tech to the Core

These Polyfuses will be supporting a truly modern avionics suite. The core technology on this panel is a Grand Rapids Technologies glass panel. Opening the manual made me think that Kirkpatrick had written it, because it started with: Make a wiring diagram!

Now, heres where free CAD programs such as Googles SketchUp (www.sketchup.com) and Alibre (www.alibre.com) are really useful. Editing is a breeze, and using colors and line-types makes tracking it all really easy. Perhaps the greatest benefit, though, is an infinitely large page on which to draw.

As I said, Im a mechanical type, so I called Carlos at Grand Rapids Technologies and pleaded my case. Carlos, ol’ buddy, Ill deed you my first-born male child if you’ll just tell me what goes where! Fifteen minutes later Im feeling the sun is out, the rain is sparkling on the lawn, and alls right with the world. I dive into the wiring diagram, draw the pin out-in wires from-to and…aw, nuts, wheres the transponder diagram?

I open the box for the shiny new Garmin GTX 327 transponder and find there’s nothing but a little pamphlet telling me what a smart person I am for ordering this state-of-the-art product-the Pilots Guide, in other words. An installation manual is nowhere to be found-and nothing on Garmins web site, either. I called and was told that the company doesn’t send those out with the unit to prevent someone installing it who doesn’t know what he’s doing. (And so I ask: How can you know what you’re doing if you don’t have instructions?) I was told to call the place I bought it from.

I don’t know, but I’ll find out, was the response from Michelle at Aircraft Spruce. I’ll call you back.

Then I remembered Ron, a good buddy with a GTX 330 in a Jabiru. Where’d you get the diagram? I asked. Off the Internet, he says. So I typed in installation manual garmin gtx327 and there at the top of the list is exactly what I want. The clouds are parted again. Thirty minutes later Michelle called back and said she could email it. Good folks.

My curiosity doubled when I realized that in the box with the Garmin SL40 com, which I mounted right above the transponder, were 44 pages of information for that magic box. Hmmm.

Over the Wall

Nuts! The wires are too short between the firewall and the EGT and CHT sensors. Rumor has it that I cant extend them with anything other than Thermocouple wire (true), that I shouldn’t extend them period (false), that they all have to be the same length (false), and that if I do extend them, the joints should be soldered (false).

A 15-minute phone call to Sandy at Grand Rapids put all of those misconceptions to right. Sandy explained that the proper way to do this installation was to have as few junctions as possible; the length of the wire is not that important, only that it be TC wire. And though the use of solder on regular wires is preferable in some applications for lossless connections, soldering TC wire can create stress-risers with the potential for subsequent cracking. Instead, you should use spade-type junctions, and don’t over-crimp them or you’ll nick the wire, inducing a stress-riser.

Antenna Considerations

Now that Im hooking up the radios I did some research on antennas. I was immediately buried in jargon and tech-speak. Guidance came over the hill in the form of Bob Archer. Archers a one-man company in Torrance, California. He’s been designing antennas for aircraft since the early 1950s and, as he put it in a letter to me, …didn’t just fall off the turnip truck.

He sent me several pages he’d written on the subject of antennas, and it seemed to make sense. One of the more interesting points he related had to do with the rudder hinge. The Jabiru kit came with a com antenna in the form of a half-inch-wide strip of aluminum bonded into the trailing edge of the vertical stabilizer just a couple of inches away from the rudder hinge. It offered me the opportunity to avoid the error of excess.

It seems obvious in hindsight that a metal strip near an antenna will create a shadow; that is, you will have a blind spot of reception. The hinge is specified to be in three pieces rather than one long, continuous run. I was congratulating myself on having resisted the If enough is OK, more is better, and too much is just right urge, and did not make it a single strip. That became a moot point, though.

I bought Archers com antenna based partly on his claims of performance, but also because the antenna installed by Jabiru is a single length of aluminum with the coax cable connected to one end, not at midpoint. The instructions directed me to install a second aluminum strip such that the coax connects to the midpoint of this composite antenna. One problem: The only way to mount that second strip was to extend it out the bottom of the tail into the airstream.

Rather than puzzle over this I just decided to install the Archer unit. It’s a thin sheet of metal that you assemble with three (included) zpop rivets and then mount directly on the inner fuselage wall. I was also attracted to Archers transponder antenna because it doesn’t need a ground plane. It mounts vertically inside the fuselage. Archer sells his antennas through Aircraft Spruce, and though they are a tad more costly than some others, Ive decided to try them. More on this in a later report.

Lights, Cameras, Smoke…Not

Id previously hung the panel housing on the firewall, so it wasn’t too difficult to fit it into the airplane. Kirkpatrick came down, and I played surgeons assistant as he made the connections between the sensors, power and ground. The battery was charged, so a flip of the switch and…nothing. He grabbed a voltmeter, and in 5 minutes we had lights all around.

Further electrical debugging included rolling the plane outside, finding North, and calibrating the flux-gate compass in the GRT panel. Error. Calibration range exceeded or something to that effect was the message. Id mounted the sensor within the wing, well away from the fuselage, but not far enough from the aileron cable clamps. Shifting it about 10 inches was all that was needed.

In reality, the sequence of events is not exactly as Ive described it. They did occur as they should have, but given availabilities, inclinations, setbacks and weather, things never go by the book. Thats part of the fun of building your own airplane. If it were not like that, you’d just be an assembler. As it is, you’re as much a part of the airplane as the designer, and thats why we do it.

Next month well install a faring over the pitot tube with a dandy trick using a laser, and fit the fire-extinguisher system. This is not your generic handheld bottle. Its a remote feed, cockpit triggered, three-nozzle system that weighs less than 10 pounds and feeds both engine and instruments.

For more information on the Jabiru J250, call 559/431-1701 or visit www.jabirupacific.com.