Most pilots who have flown tailwheel aircraft are familiar with the tailwheel spring—a stinger of springy steel, or a set of leaf springs harvested from an old car suspension that joins the tailwheel yoke to the rear of the fuselage. For those pilots and builders who never studied physics or engineering, a spring by itself is an interesting suspension choice: As you compress it, there is what amounts to energy storage going on. When the end of the stroke is released, this stored energy wants to escape, and the only way it can do that is by bending back toward its neutral position. So far, so good…right? We want the tailwheel spring to absorb energy.

Unfortunately, the effect of releasing that energy by going back to neutral accelerates the tailwheel, and spring steel, being fairly quick, is going to overshoot its neutral position. Then when it gets all the way out in the other direction, it is going to head back—and the process continues. Think about the old Wile E. Coyote of Road Runner chase fame. Every time he thought a spring or rubber band catapult was a good idea, it wasn’t.

What is missing in the standard tailwheel spring is a damper: something to dissipate the energy being stored and to slow down the acceleration that comes from a pure spring. In your car, you have springs—but you also have shock absorbers—and that is what keeps you from bouncing down the road. In your tailwheel airplane, the effect of a pure spring at the back end is to set up a potential hobbyhorse motion, a pitch oscillation that can easily lead to a PIO (pilot-induced oscillation) or a prop strike. So why don’t we use shock absorbers (dampers) on the tailwheel?

Dan Dufault, founder and creator of the T3 tailwheel suspension, asked just this question, and his answer was simple: He saw no reason not to give it a try. The result is the T3 suspension, sized in various configurations to handle airplanes from LSAs up through Super Cubs and on to larger four-seat aircraft. We have now flown it on a 180-hp Kitfox and have been using one provided by T3 on our much heavier (2550-pound gross weight) Tundra for several months and quite a few landings—both in the backcountry and on pavement.

T3 suspensions only come in black, but occasionally Dan Dufault, creator of the T3, has fun custom painting one like this.

Design

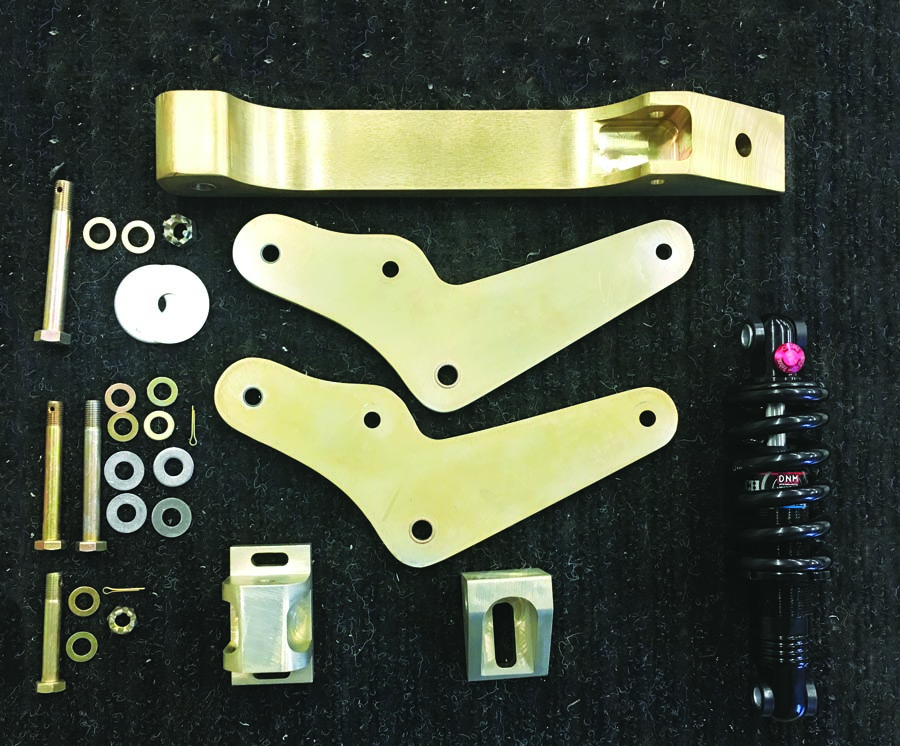

The T3 consists of a single or pair (depending on aircraft size and weight) of coil-over shock absorbers and springs. The springs are adjustable for length and tension, and there is a damping control on the shocks. The central tongue is hinged to an anchor bolt at the front, and also bolts to the side plates of the mount. A standard tailwheel yoke mounts to the back of the tongue, and the shocks attach to take up the load. In the case of the early model we received for the Tundra, all of the pieces were welded steel. Newer models are machined from billet aluminum, and we had to revise our installation with a billet aluminum front hinge point when the original steel weldment began to bend. Overall, as the construction has evolved, it has become sturdier and lighter as materials have changed.

The basic parts that go into a T3: the central shank, two side plates, mounting brackets, coil-over shocks, and assorted bolts.

Installation

We can only talk to installation on the Tundra, but all in all, it was straightforward. We provided T3 with the dimensions of our three mounting points—the single bolt in the center up front and the two side bolts in the rear. The mount came drilled for these locations and bolt sizes. Then it was simply a matter of gaining access to the inside of the fuselage (through convenient inspection holes) and removing the original tailwheel spring clamps and the spring itself.

Our original, factory-supplied configuration had a geometry that created quite a bit of rake in the tailwheel pivot axis. This contributed to very heavy steering on the ground. The T3 geometry, using the same Alaskan Bushwheel yoke, stands the steering axis up much more vertically, making the airplane feel like it has gained power steering. While this did tend to add a little bit of a shimmy problem on some landings, we have been able to tune the angle with a wedge—and that made the shimmy disappear.

Installing the T3 on the Tundra started with disconnecting the chains and removing the three bolts that secure the springs to the fuselage.

Because it is always going to be hard to predict bolt lengths with a new device like the T3, don’t be surprised if you need to lengthen your original bolts and wait for them to show up from your favorite hardware supplier. It’s sort of like opening a present on Christmas morning and finding that you have to run out and buy batteries, but there really isn’t much of a way around it. While I like to say I have a pretty good stock of AN hardware in my hangar, I don’t keep AN6 or 7 hardware in various lengths on hand—that would get a little excessive!

In addition to adjusting bolt lengths, you’ll probably have to play with tailwheel chains or links as well. With different geometries, you’ll find more or less sag. But once you get everything set up the way you like it, you’ll be ready to go try some landings.

The T3, seen here in a top view, attaches using one forward bolt (left) and two bolts on either side in the rear. Because of fuselage curvature, we machined an adapter plate to allow clearance from the T3 side plates and sandwiched it in between.

Flying the T3

Alas, for all of the coolness factor of having those dirt-bike springs and shocks hanging out, you’re just not going to notice much, if anything, while you’re flying—at least until someone comes alongside and takes some pictures. Takeoff performance is going to be similar. Most bush planes we know of are off the tailwheel pretty early in the roll, and once it’s airborne, you’re just not going to feel it.

It’s on landing that you’re going to notice a difference. I’d describe it best as a “squish” when you touch down on the tailwheel. The shock of touchdown is slowly absorbed, with no tendency to be relaunched if that touchdown is a bit firm. What this means is that you can easily go for the slow, three-pointer, smash the tailwheel down first, then let the mains come down, with little extra worry of the dreaded springy-tailwheel porpoise. If you have flown with low-pressure Tundra-style main gear, you know that you get a nice cushioning effect on touchdown—the T3 gives a similar effect for the tail.

The red knobs adjust the rate of transfer, allowing a fast or slow rebound. Spring tension can also be adjusted and fine tuned.

Worth a Try

The T3 is fairly new, although there are quite a few already in the field. Our test unit went through a couple of minor mods to make it more rugged and reliable, and I expect that this will continue as more time is accumulated on the fleet. All new technologies have bugs here and there, but Dufault seems serious about fixing those found by the growing number of pilots using the suspension on their own planes. Dufault has enlisted the power of Airframes Alaska to produce and market the T3. Known for their Alaskan Bushwheels and many other products and services that serve the backcountry pilot, Airframes Alaska is a perfect partner for bringing this new technology to the widest number of owners and pilots.

While we’d all love a fully engineered product that works perfectly and reliably right out of the box, that is not what Experimental aviation is about. We put up with a few bugs to enhance the products that will be reliable in the future as a result.

Each T3 is customized for the aircraft on which it will be installed. All T3s are currently for Experimental use only, but Airframes Alaska has a growing applications list.

Our current configuration appears to be stable for our heavy Tundra. I expect that others are getting good results and long life out of theirs, so if you’re looking to trick out your tailwheel, you might look into ditching the old-fashioned spring and giving the T3 a test.

For More information go to the Airframes Alaska website.