As first reported in Newsline on the KITPLANES website, California-based EFII debuted an all-new electronic engine management system for Experimental Lycoming-based engines last September. Shown at the National Championship Air Races in Reno, Nevada, the new hardware and software is a major advance in engine management sophistication and tunability for our kind of airplanes.

As we went to press, ignition-only versions of the new system were expected to be released in January 2018. Full systems are scheduled for sale in April 2018, with install kits available now.

Beginning in 2007, EFII sold a basic electronic engine management system. Assembling ignition and fuel system components from the aftermarket, Canada-based SDS, as well as their own supporting hardware, the legacy EFII system has been fitted to over 400 aircraft.

But now Robert Paisley, owner of EFII, has delivered an entirely new digital engine management system that is 100% designed and manufactured by EFII. It is much more capable and accurate, easier to install, and far easier to upgrade than the legacy unit. It also offers EFII total control over manufacturing.

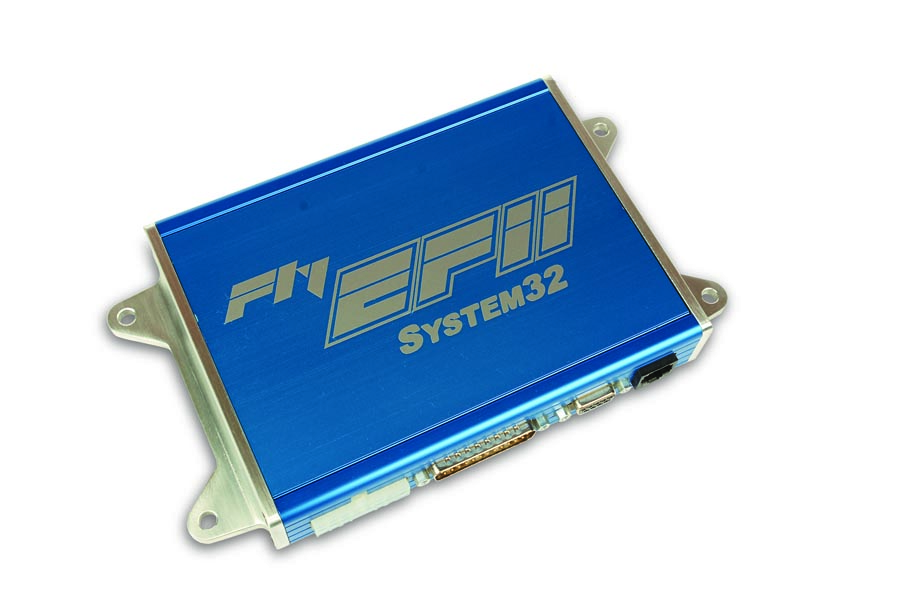

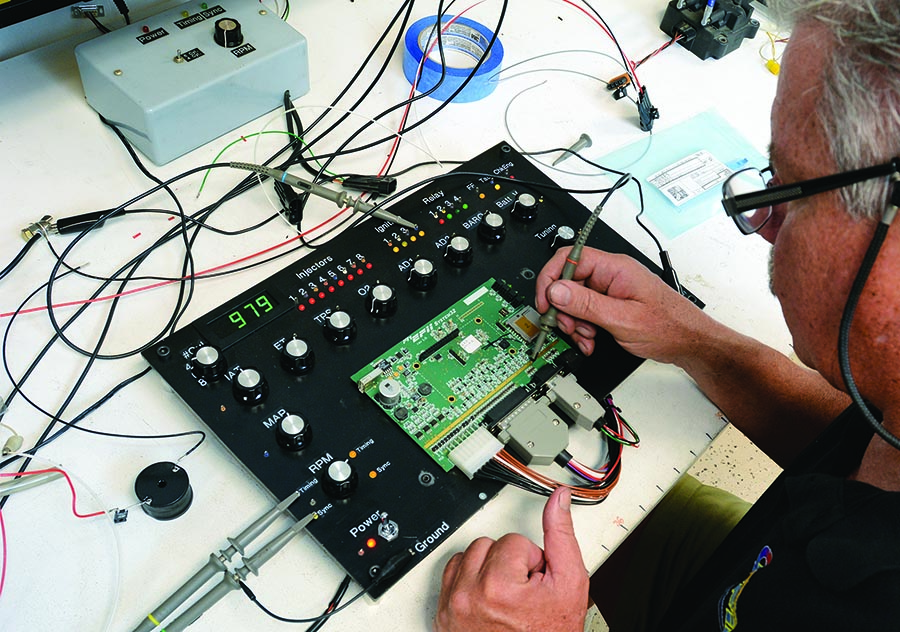

Like the rest of the system, the all-new System32 ECU was designed and is built by EFII. Paisley noted when asked about the circuit board, “We’re lucky to live near LA, one of the world’s technology centers,” where the board is built by specialists. Likewise, the ECU’s software was developed by Paisley and two consulting engineers he’s worked with for years.

Called System32 after its 32-bit RISC processor, EFII says the new system has at least 50 times the processing power of EFII’s previous system. The extra capability comes from the more modern processor, a unit that also offers the channels and processing power to optionally control boost pressure, ADI flow, up to three oxygen sensors, TECAT torque sensing, and real-time telemetry. System32 does not control constant-speed propellers, but it can operate up to 12-cylinder engines.

The optional capability is great for tinkerers, racers, and development engineers, but for average Joes, System32’s brainpower is put to most practical use by running its 3-dimensional rather than the old 2D fuel and spark maps. In other words, the data points System32 uses to select the fuel and spark events are more nuanced for easier starting over a wider range of environmental and engine conditions, plus smoother running and transitions such as quickly adding throttle for takeoff, climb, or acro.

Connector plug-ins are all located on one edge of the System32 ECU box. With no directional requirement by the ECU, the blue boxes can be installed in any convenient orientation in the airplane.

Naturally, System32 employs a fully redundant dual ECU layout, so if one computer fails, the other can take over by flipping a switch. Just as basically, System32 eliminates the mixture control in the cockpit. The software automatically chooses the best air/fuel ratio for the amount of air the engine is ingesting, plus there is a fuel trim knob that further trims the fuel delivery should the pilot so desire.

This last feature will likely be rarely needed by average users, but does give instant adaptability to each specific installation, special conditions, or equipment changes such as an engine overhaul, cold air intake, and so on.

One end of the ECU contains the SD card slot and four LED annunciator lamps, so access to this side of the ECU is desirable as mounted in the airframe. This is especially so in ignition-only installations as this card slot is the only access to the system. In full fuel-and-spark installations, the cockpit display offers an SD card slot that makes these on the ECUs redundant.

Furthermore, this adjustment knob has tremendous authority, much as a manual mixture control does. EFII’s legacy engine management had a similar feature that allowed -50 to +50% values, and Paisley is doing the same with System32. Besides offering deep tuning, the big adjustment range is a hedge should a sensor go bad and result in dramatically rich or lean mixtures. In that case the pilot could simply turn the knob and restore a running mixture to the engine.

Speaking of a wide dynamic range, System32 software is written to support everything from fuel misers to rip-snorting race systems. If you bolt twin turbos onto your O-290 GPU conversion, System32 won’t need reprogramming to keep up. Its increased sophistication also includes ignition timing retards for excessive over-square engine operation the previous system did not have.

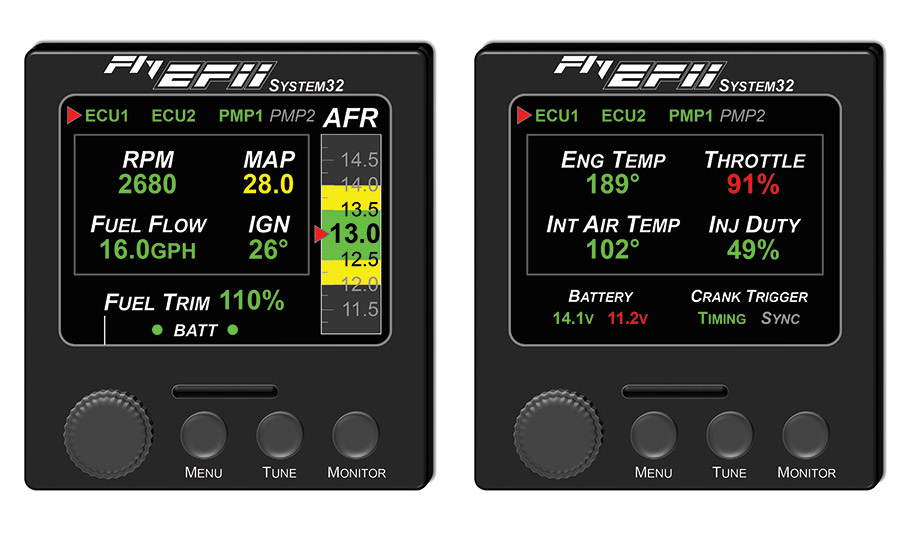

That’s a Garmin G5 at left and the new System32 display at right. The System32 uses the identical screen as the Garmin, so the days of apologetic, science-fair-quality engine management interfaces has been replaced by a modern display that blends perfectly with other Garmin electronics. The SD card slot on the System32 display is front and center for easy access; all system upgrades can be done through this slot.

System Description

Before moving into aviation Paisley earned an electrical engineering degree and had a long, successful run building electronic ignitions and other controls for a broad array of ground vehicles. There was an emphasis on motorcycles, including drag race bikes, a discipline he competed in personally. Along the way he realized engine management systems should have all necessary capabilities, but always with simplicity and robustness in mind. It’s fairly easy to over-feature electronics, adding complication and failure points in exchange for gee-whiz features of questionable usefulness. The fewer gizmos in the loop, the fewer gizmos there are to fail.

Designed to fit in a standard 31/8-inch instrument panel opening, the System32 display takes up little panel room, either in front or back.

Applied to System32, this means it’s a competent engine manager, but one working within the realities of Lycoming engines and not concerned with anything more than unfailingly getting the right amount of fuel and spark into the combustion chamber at the right time. Thus, System32 is a batch-fire (all injectors fire simultaneously), speed density design (no mass air sensor). It uses two identical computers (Engine Control Units), two crankshaft triggers, two intake air temperature (IAT) sensors, two manifold absolute pressure (MAP) sensors, a throttle position sensor (TPS) and an engine temperature sensor. Two ignition coil packs are used, each controlled by one of the two computers. The only major single-point in the system is the fuel injectors; there is one injector per cylinder, and all injectors are fired by one of the ECUs.

So configured, should the ECU not operating the injectors fail, the result will be one-half of the spark plugs will quit firing—an almost imperceptible condition given the powerful inductive ignition. If the failed ECU was operating the injectors, then all the injectors and half the spark plugs will quit, and you’ll definitely notice that! Simply switching to the other ECU using a switch on the instrument panel restores injector function so the flight can continue to an airport on one ignition system.

EFII supplied us with two screens the System32 display can show. Most of this is self-explanatory, and there’s plenty more information not shown here, but the vertical scale with yellow and green bands is especially nifty. It is the air/fuel ratio display with the red bug identifying the current A/F ratio and the green and yellow bands denoting the ideal and usable ranges of A/F ratio, which the pilot can dial-in via the display’s knob in real time. These ranges vary depending on engine load. Other red bugs show which ECU is controlling fuel delivery—spark duties are always split between both ECUs. There are some engine monitor values shown here, but a complete engine geek would still enjoy a multi-probe EGT/CHT monitor for pinpointing errant cylinders.

As for the throttle position and engine temperature sensors, the TPS simply identifies rapid throttle openings to act as an electronic accelerator pump. That is, a little extra fuel is needed immediately when the throttle is enthusiastically opened because air is lighter than fuel, plus the engine is trying to accelerate under a load. Without the extra shot of go juice, the engine would momentarily lean out.

The System32 engine temperature sensor is there to identify a cold engine, and thus a little extra fuel for sufficient atomization and smooth running is needed. With System32 the temp sensor screws into the 1/8-inch pipe threads where the mechanical fuel injector nozzles would otherwise be. There is only one engine temp sensor per installation.

A more major System32 evolution over the legacy system is in the software. Both systems are simple look-up designs, where information comes in to the ECU, which then plugs those values into either a fuel table or spark table to arrive at the amount of fuel and spark timing to command. The difference is in the tables. In the legacy system there is a simplified scheme that applies the same manifold pressure curve to every rpm for fuel or spark value look-up. This simplified mapping was forced by the limitations of the 8-bit microprocessor of the legacy ECU.

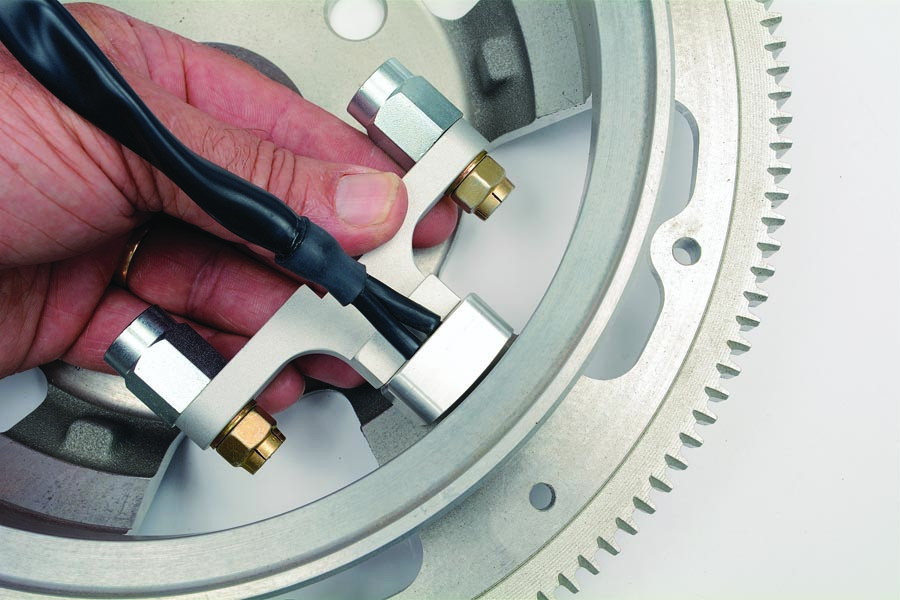

Wanting a much sturdier and more accurately mounted crank trigger, EFII whittles out this billet aluminum dual trigger and mount for Lycoming cases and flywheels. Both triggers are located under the dark strip in the center of the sensor.

In System32 the fuel and spark tables have a full range of rpm and manifold pressure points mapped, and as the manifold pressure changes with throttle position and altitude, there are corresponding changes in the fuel and spark delivery. Essentially, every rpm has its own manifold pressure curve. This is the essence of 3D mapping and is similar to how any modern car computer functions. This is why System32 is based around the entirely new high-speed processor.

Of course, there are complicating details, but not many. When you think about it, the ECU is inferring the air mass entering the engine because it knows the engine displacement, how fast the engine is operating, and what the manifold pressure is. But it is better to further refine this inference by knowing what the intake air temperature is (correcting for density altitude, you might say). Thus the IAT sensor is added. The computer uses the IAT signal as a correction factor, modifying the fuel injector duty cycle by whatever percentage the IAT table says to. This correction is fairly small, so much so the engine would run without it; but it runs better with it.

Practically speaking, the increased attention to manifold pressure in System32 software reduces engine load (mainly by retarding the ignition timing) in dangerous corners of the engine’s operating range. This shows most with fixed-pitch propellers where it’s possible to run the engine over square—more manifold pressure than rpm—during takeoff or full-throttle climbs. “With System32 we have a different manifold pressure retard curve for every rpm point,” says Paisley. “If you start getting over square, System32 retards the ignition timing to avoid detonation. At 2700 rpm you can bring in the ignition timing more aggressively because you won’t run over square. At 2350 rpm for example, we can retard the timing if the engine enters an over-square condition, and we can prevent detonation. This is a problem that can occur with fixed-pitch props in climb or with constant-speed props when descending. This is already in the software and is one of the main benefits of 3D mapping.”

Finally, there is a “return-to-base” mode for the rare chance both MAP sensors, or a combination of other casualties, occur. Then the software would rely on an electronic barometric pressure sensor in the ECU and the TPS signal to nicely approximate a workable fuel volume.

One goal of the new crank trigger mount was to present the crank triggers to the Lycoming flywheel in a curve conforming to the flywheel as shown. This fits the triggers closer to the flywheel and allows a more precise trigger signal. Because System32 does not use a camshaft position sensor (less cost, no real mounting place on a Lycoming) or multi-point flywheel magnets, the system does not support hand propping.

Flying Open Loop

The car that takes you to the airport has oxygen sensors sniffing the percent of oxygen in the exhaust stream to accurately assess the actual air/fuel ratio the engine is operating at. The ECU uses oxygen sensor input to further refine the amount of fuel delivered, a necessary step to protect the finicky catalytic converters that can only operate in a narrow air/fuel mixture range. Such post-combustion information requires more computations by the computer, as you may imagine.

This operating mode is called closed loop, as opposed to open loop, where the oxygen sensor input is ignored (during cold starts before the cats have warmed up, for example) or in a system where there are no oxygen sensors.

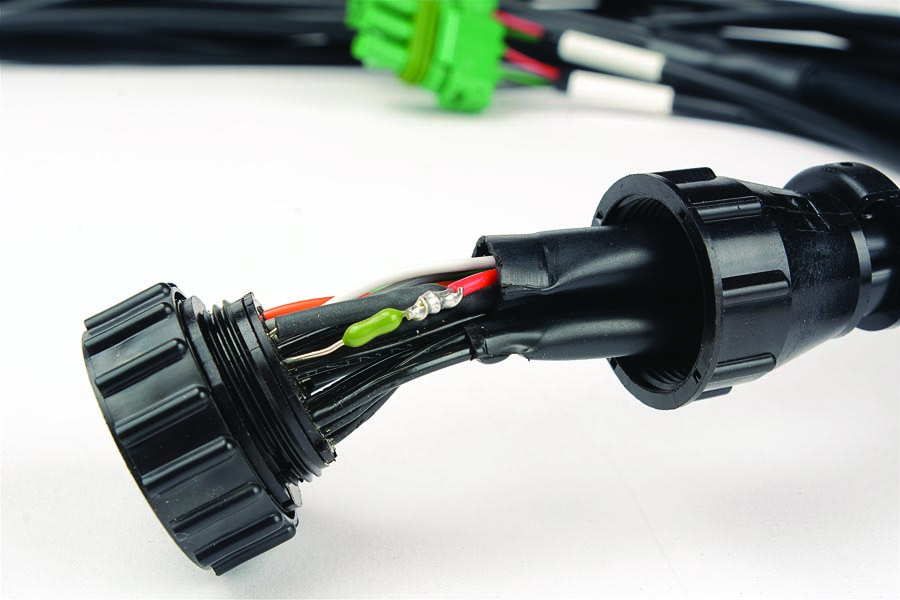

All System32 fuel injector and ignition wires are fitted with fusible links to protect the other injectors or coils in the harness. Here a harness has been cut open to reveal one of the small green fusible links. Because it’s at the end of the harness on the engine side of the firewall, it is easy enough to replace a blown fusible link once the cause has been rectified.

System32 is open loop by design because there are no catalytic converters to protect. Yet EFII has accommodated oxygen sensors in its systems, including System32, but strictly for pilot information. With oxygen sensors the air/fuel ratio can be shown on the cockpit display, so the pilot has an immediate view of the air/fuel ratio being supplied, rather then inferring it from EGT readings. But it’s worth noting the oxygen sensor input is simply passed to the cockpit display and doesn’t modify fuel delivery.

Finally, EFII is not a dealer for, and does not carry, oxygen sensors. Instead, they recommend purchasing “ox” sensors from PLX Devices. This eliminates the price markup necessary should EFII be a PLX Devices dealer, along with the associated shipping, stocking, and financing headaches. EFII maintains the same relationship with Andair for fuel valves, too.

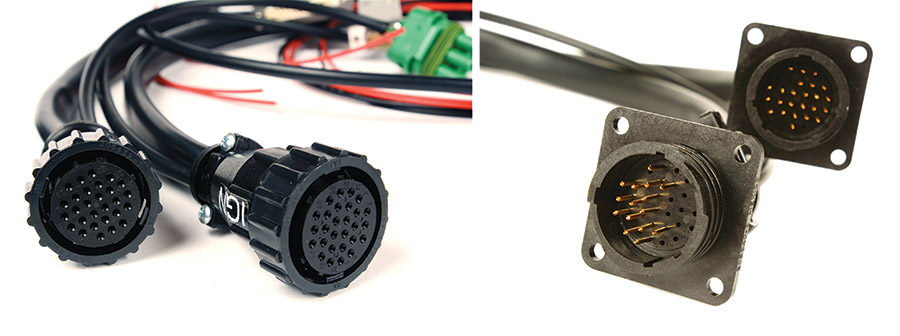

Stronger harness connectors were on the System32 wish list, and these round bulkhead fittings—one for fuel, one for ignition—fill the bill nicely. The side with the square flange fits behind the firewall, leaving a clean round plug on the engine side.

The New Hardware

System32 is built around five new major components: the ECU, cockpit controller, wiring harness, crank trigger, and fuel injector mounting.

Each System32 uses two of the blue ECU boxes. Both ECUs could be housed in a single box, but Paisley notes that keeping the ECUs separate allows easier troubleshooting. If an ECU is suspected, it is easy to disconnect or replace it, something not so easy to do if both computers share one box.

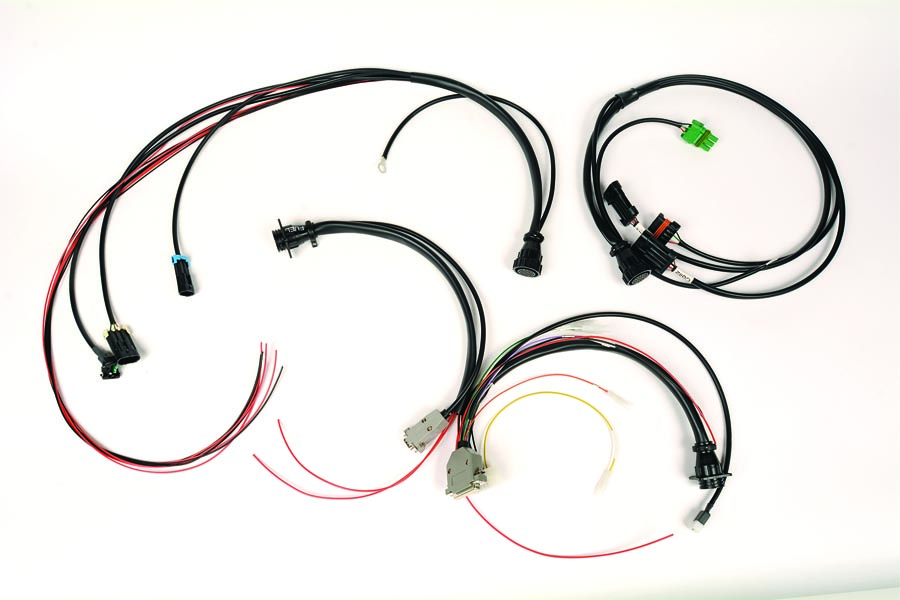

System32 uses new wiring that’s more robust and user-friendly than before. The three System32 harnesses are built by EFII at their Cable Airport (KCCB) facility in Upland, California, using unique, mistake-proof terminal ends, Tefzel insulated wire, and round, multi-pin bulkhead fittings.

The cockpit controller is especially full of promise thanks to a screen identical to Garmin hardware and ultra-easy system initial setup and in-flight trimming of ignition timing or fuel mixture. Taking up very little space fore-and-aft in a standard 31/8-inch round panel opening, the shallow new controller displays alarm and annunciator functions for ECU power, fuel pump power, two battery voltages, plus an air/fuel ratio graphic display, and offers easy updateability via an SD card port. Access to the entire system is thus immediately in front of the pilot, and should upgrades be necessary, they’re equally accessible via the SD card reader.

EFII is using the same Bosch fuel injectors as in their legacy management system but has developed this new, more compact fuel rail arrangement.

Because the System32 components plug into existing EFII wiring harnesses, customers already running EFII’s legacy system can update to System32 without rewiring their airframes if desired. This backwards compatibility is also giving EFII the needed beta testing of the new ECU. The new ECU will first fly by replacing the existing ECU on EFII legacy systems, followed by the new display, injectors, and so on.

Key to the new fuel injector installation is the injectors have been moved from the intake tube and into the Lycoming cylinder’s primer port. This saves having to weld bungs onto the intake runners and gives a straighter shot of fuel toward the cylinder. It’s also more compact packaging on the engine.

While existing EFII customers could install System32 using their existing wiring, Paisley expects most customers will update to the new wiring harness to gain the new bulkhead connectors and built-in fusible link protection among other things.

System32 is priced identically to the legacy system, at least initially. That older system has ceased production, but will “absolutely” be supported by EFII.

These representatives of the ignition side of System32 have changed little since the legacy system. They are a two-coil coil pack, automotive style NGK Iridium spark plug with brass adapter, MAP sensors, and the ignition leads. Two coil packs are required; EFII fits them with a flat aluminum mounting plate to aid installation under the cowling.

System32 is offered only as a dual ECU system, so there are two blue boxes per System32 installation, and it’s a complete kit. All sensors, wiring, injectors, and their plumbing, coil packs, ignition harness, spark plugs, cockpit controller, crank trigger, and associated mounts and hardware are included. Pricing for a complete fuel and spark 4-cylinder System32 is $6,195. A 6-cylinder complete system is $7,695.

The ignition-only derivative of System32 is available at $2,750 for the 4-cyl ignition and $3,395 for the 6-cyl ignition. Like the complete systems, the ignitions are 2-box ECU installations.

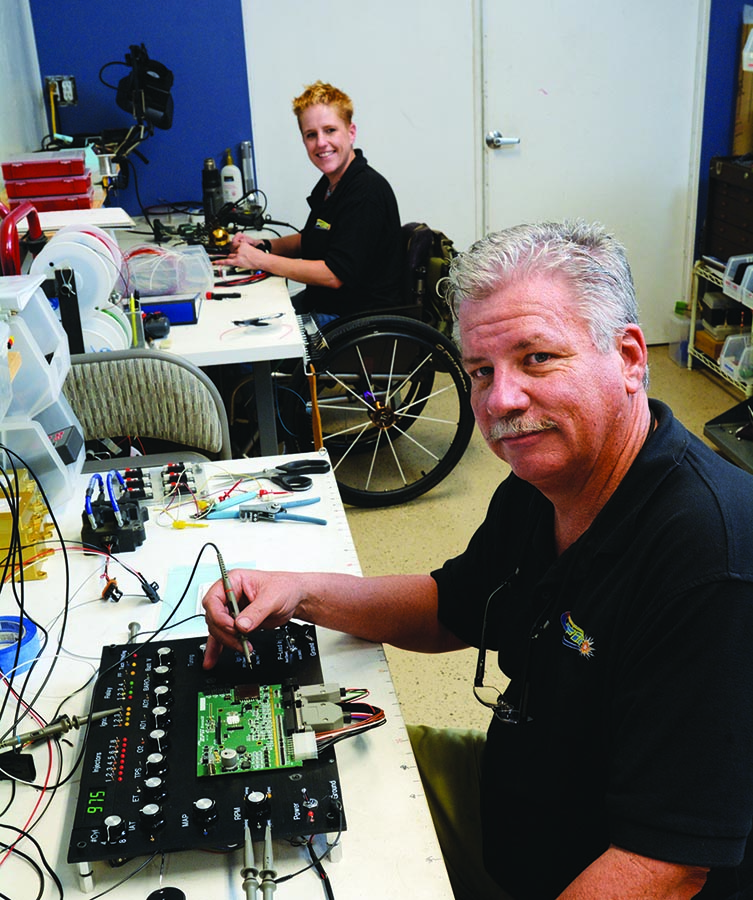

Robert Paisley and Lylah Bradford are EFII. Robert is the technical guru while Lylah is key to production. If you have an EFII wiring harness—among many other EFII parts—Lylah built it.

Finally, we’ll close by noting as with any digital engine management system, the airframe it’s going into must be electrically sound. The ground circuit, battery(ies) and charging system(s), and bus design must be top notch because as with all electronics, System32 depends on a steady flow of electrons.