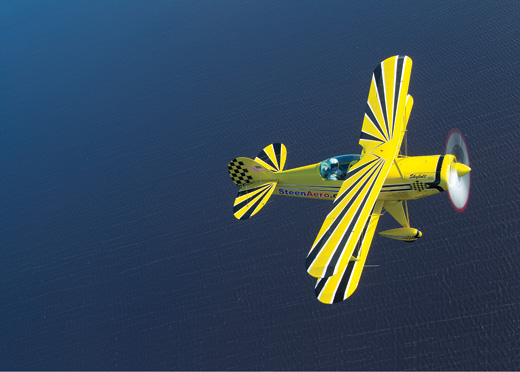

Our story starts with the late LaMar Steen flat on his back under a Pitts S-2 with a tape measure when the late Curtis Pitts walks up. “Aw, shucks, LaMar, I’ll give you a set of plans,” said Pitts, and the Skybolt was under way, a bigger S-2 for bigger pilots. And that’s what it is, a delightful aerobatic mount worthy of being classed right along with its step-siblings, the Pitts biplanes.

Entrepreneur Paul Goetsch went to buy an airplane, but he bought the company.

How They Got There

Eventually Hale Wallace took over the business, and Yellow Bird, the plane we flew, was the third one he built. Then Paul Goetsch, an obviously brilliant engineer, and his partner Jere Larson came onto the scene, looking to buy a Skybolt to fly. They wound up purchasing Steen Aero Lab from Wallace, adding it to their portfolio.

Have you seen the “vegetable peeler” winglets on the Falcon 50? Goetsch and Larson also own Shapes Aerospace International, which makes those winglets; they give almost twice the fuel savings of conventional units. They also make parts for the Airbus A-320 and the military A-400 turboprop transport, so they play with the big boys.

If you go into the Steen Aero shop in Melbourne, Florida, just a few miles inland from the Atlantic Ocean, the first thing you see is the Pitts Model 14. It’s a machine similar to the Model 12 with the same Russian engine, but the Model 14 has an unswept, three-piece upper wing. That change was to make the project easier to build, but it meant sacrificing some performance in snap rolls for a more docile plane. Hanging from the ceiling are several single-seat Pitts fuselages, welded in Argentina. Steen is the dealer for Bruntons flying wires as well.

The late Curtis Pitts used to come by the Steen shop, visiting for a week at a time to keep his hand in the airplane game, and Goetsch was a pall bearer at Pitts’s funeral.

The canopy gets tilted out of the way for access to the cockpits.

Unconventional Conventional Construction

The construction of the Skybolt is pretty conventional for a biplane: wood wing with built-up ribs, wood spars and compression struts, and wire bracing for anti-drag loads. The fuselage is welded steel, with aluminum panels at the front and fabric covering on the aft fuselage and all of the flying surfaces. Wallace made some improvements to the original design, such as increasing the number of stringers on the fuselage sides from three to five.

A four-blade prop on a biplane? Well, yes. You don’t have to dive for speed in maneuvers.

There is also a Firebolt derivative, and the company web site says the two designs often overlap. Steen also sells plans for Mac McKenzie’s Firebolt development of the Steen Skybolt, including all-new, detailed drawings. The Firebolt has a longer fuselage, stretched 2 inches in the front cockpit, Marquart Charger-type landing gear, different ailerons (with three hinges instead of two), a different nosebowl, a rearward-sliding canopy and various other modifications. Many flying aircraft are in fact “hybrids” between the Skybolt and Firebolt, with individual builders incorporating selected features from the Firebolt design into their Skybolt project, most often the sliding canopy or the nosebowl design.

But the most interesting part of the Skybolt has to be the wing kit. Traditionally, each wingrib has a trusswork of quarter-inch spruce capstrips to give the rib its shape and strength, a nosebowl and gussets at each intersection of the trusswork. The ribs are built in a jig, and the gussets, small rectangles of thin plywood, are traditionally glued onto the capstrips and then nailed with tiny brads to hold them in place till the glue dries.

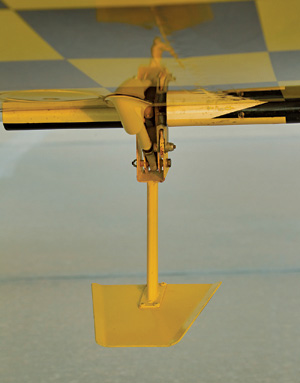

Note the redundant flying wires, standard on aerobatic biplanes.

In the Steen model, the nosebowl and gussets all come CNC cut, along with a pegboard jig. Put dowels into all of the pegboard holes and Voila! A jig that will hold all of the components in place with no nails. To put pressure on the glue joints while they’re curing, a matching clear plastic piece fits over all of those same dowels. Put weights on the plastic, and watch the glue dry.

If building one rib at a time is too slow, there’s now a jig with double-height dowels. Put one rib into the jig, lay a piece of waxed paper on top of it to keep the glue from wandering around, and then put another rib atop that. Add weights on top of the whole thing and build two ribs at once. Goetsch tells the story that one builder’s kids had so much fun building the first set of ribs that he ordered a second, unneeded set of ribs to give the kids something to do. If you’re not so inclined, another grand will buy one-piece routed ribs.

Aileron spades. They may not be necessary, but the ailerons had a great feel with them.

You can buy wing leading edges ready to go, too. Those are made of two laminations of plywood, with each laminate three-ply, 1⁄32 inch thick. The plywood is so flexible that you don’t have to steam the leading edges to bend them.

Steen Aero has reinvented the traditional wood spar, fabricating it out of laminations of spruce instead of solid pieces. Surprisingly, the laminated spars are 30% to 40% stronger than the solid spars, and when they break, they will not fail catastrophically. Instead, the laminates fail individually, and the company’s tests show that even a failed spar can still have enough strength to get the airplane home. Some spars with carbon fiber between the laminations were also tried, but the laminated versions are already stronger, so there’s no need to spend the extra money.

The bottom line is that although this is a plansbuilt design, there are enough components available so that building a biplane doesn’t have to be the massive fabrication of the old days. The total effort of building with a full set of Steen components would be comparable to building a pre-punched metal airplane, but Goetsch says that the added complexity of a biplane does take more passion to build.

Further, Goetsch said that no two Skybolts are really alike. Some are open cockpit, some are closed, and a variety of engines and propellers is available. One builder even put a Continental radial engine on the front of his that was from a WW-II tank.

Getting ready to go do some aerobatics in a delightful airplane. The author is in front, with demo pilot John Testerman in the back.

Aerobatics R Us

Yellow Bird is not your average Skybolt. Up front is 350 horsepower of Lycoming engine, and the novel canopy gets completely out of the way as you climb aboard. The front cockpit is not as compact as in some other homebuilt biplanes, but there’s not room to stretch your legs out. Reaching all the belts and straps for the parachute and shoulder harness is best left to the young and limber or to an assistant such as master mechanic Butch Childres, who took care that all was well up front.

The canopy arrangement is unique, and the canopy can only be released from the back seat.

Yellow Bird’s rear instrument panel. The airplane is normally piloted from the back seat.

In an emergency, the back-seater would release the two canopy latches in the back cockpit. The aerodynamicists say that the down-flow off the top wing would lift the canopy into the slipstream without giving the front-seater a bonk on the noggin, but good manners would dictate a warning to duck. Once above the fuselage, the canopy would be out of the way, but the slipstream would undoubtedly rip it off.

In the back, demo pilot John Testerman did all of the normal pilot things until there was the sound of an electric fuel pump. “Clear prop,” he said, and the very tall stick came back, along with the sound of a big engine starting up. Initially, it had an easy loping baritone like a big radial with that wonderful smell of engine-start burnt oil before accelerating to a faster, even idle.

Extra credit if this looks just like the center section of a Pitts to you.

Not many biplanes have 350 hp attached to the other end of the throttle quadrant.

Testerman cautiously S-turned us past the parked vehicles for the early-morning flight and past the parked Piper Tri-Pacer photo ship. Out from between the hangars, he called Melbourne ground and S-turned us out to Runway 27 Right.

Takeoff acceleration provided a good push back into the seat, and the front airspeed indicator showed 130 mph as we passed the departure end of the runway, a speed so high that I questioned its accuracy. Then again, maybe we were accelerating that much, because the Barrett Precision Engines IO-540 with Airflow Performance fuel injection and one Light Speed Engineering ignition was not your typical biplane powerplant. The four-blade MT propeller was also doing its bit to help convert dead dinosaurs to thrust.

Why can’t all airplanes have engine access like this? All the better to check up on the Lycoming.

Once we were out of the traffic pattern, it was my turn to take the controls. As one might expect for an aerobatic airplane, my initial impression was that the Skybolt was smooth, light and powerful, just exactly what you would want in this type of airplane.

Out over the Atlantic, a few clearing turns confirmed the first impression. Then it was time to exercise the aircraft in its design mission: aerobatics. First was an aileron roll, entered from level flight at 155 mph indicated. Nose up to 15° or so, lots of left aileron, and around we went. Maybe halfway around, it occurred to me that I might not have full aileron in, and sure enough there was more to exploit. Roll rate was quick, seemingly faster than an RV, but not obscenely fast like the airshow monoplanes that fly routines more appropriate for model airplanes.

Dual exhausts for that big engine.

Then came a windup turn, increasing to 4 G to recalibrate my internal G force sensor with callouts from the back cockpit, as there was no indicator up front. Then I did another one to get a feel for stick force pull as I built up G load. Those forces were light and increased proportionally to the G forces, with 4 G requiring roughly 12 to 15 pounds of pull on the long control stick. For aerobatics, those light pitch forces were perfect: You can fly a bunch of maneuvers without feeling like you’re giving your arm a workout. For flying a long cross-country in turbulence, should you ever need to, those forces might be on the light side. Having done horizontal circles, it was time for a vertical circle, also known as a loop. I used a 4-G pull OK, but being rusty, I didn’t relax enough pressure over the top, getting a little pre-stall buffet. Testerman demonstrated a loop and needed only a 3-G pull as the big engine gave us plenty of smash all the way around.

The front instrument panel is typically sparse, which may necessitate cooperative communication with the back-seater.

Next on the agenda was a super slow roll. This being my first time in the airplane, I wasn’t watching the altitude at all, but it was easy to keep the Skybolt on heading all the way around, easily within a few degrees, while feeling the gravity vector rotate around the airplane. Inverted, I pushed too hard and got -1.8 G, but it was a smooth overcontrol and not jerky, another tribute to the design.

It had been years since my last snap roll, and Testerman recommended a 125-mph entry speed. I slowed to 120, brought the power back in and, as we passed 125, pulled the stick back and put in a bunch of left rudder. Pow! Around we went at blazing speed, and by the time I quit being amazed and got around to recovering, we were 80° past level. One interesting detail was that I could feel the stall buffet all the way around during the snap roll. And with that sparkling roll rate, I could have fun doing all those maneuvers that Jungmeister pilots used to do in the 1930s, like quarter snaps. (One of their more famous maneuvers was to touch down with a little extra speed, bounce the landing, snap roll it, and then complete the landing.) On a later solo flight for the camera plane, Testerman snapped it at 100 mph. At that speed and center of gravity, he reported that buffeting is absent.

Testerman did more clearing turns while I took notes, and then it was time for a stall. With power back, buffeting started with the front airspeed indicator showing 73 mph. (The company quotes a 68-mph stall speed.) The buffeting built up, and the nose and right wing dropped gently. Keeping the stick back, I picked up the right wing with left rudder and the plane then rolled to the left. Again I picked up the low left wing with right rudder, and the Skybolt did a quarter snap roll before I recovered.

The Skybolt sits relatively flat on the ground and, from this angle, somehow is reminiscent of a WW-II fighter.

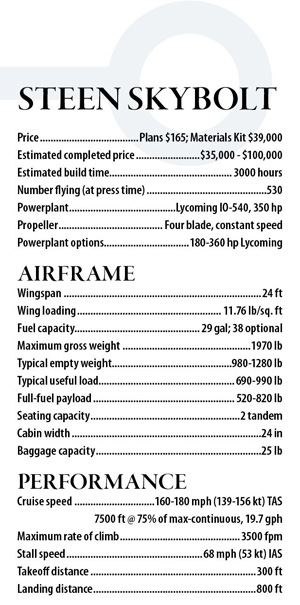

Specifications are representative; expect considerable variation from airplane to airplane depending on weight, canopy or open cockpit, engine and prop.

This behavior is not unexpected in an aerobatic biplane. Many cruising airplanes will diverge in roll when you “deep stall” them, but the snap was different. However, consider that this is an aerobatic biplane with the top wing swept for snap rolls, and a NACA 63A2015 laminar flow airfoil with abrupt stall characteristics to give you a crisp entry. The airplane did what it was designed to do, and this is entirely in keeping with its character. The lesson is that the Skybolt will do what you tell it to do, not what you hope that some plain-vanilla trainer might do. (The airfoil on the lower wing is a symmetrical NACA 0012, an airfoil series commonly used on tail surfaces. These are the same airfoils used on the later Pitts models.)

Testerman showed me his rudder power demonstration, as many new Skybolt pilots have not flown a plane with significant rudder authority. I then tried a rudder doublet (lots of rudder one way followed immediately by lots of rudder the other, then feet off the rudders). The Skybolt straightened itself out in just over one full cycle, showing excellent yaw stability.

I wanted to finish with a spin, but Testerman had recently recovered from a sinus infection and didn’t want to push his luck, so we passed on that. He reports that the Skybolt rotation rate will wind up in a spin.

As we flew back to the airport, I tried some rudder exercises. One was a slow Dutch roll, slowly rolling the plane back and forth while keeping it straight with the rudders. In most airplanes, the trick to doing this maneuver at all is to roll the airplane slowly. In the Skybolt, the handling was so good that there was no need to inch your way through the maneuver. Impressive. Fast Dutch rolls were a piece of cake, but they’re also easy in the vast majority of airplanes out there.

After those delightful aerobatics and maneuvers, I must admit I was thinking about anything but cross-countries, or cross-country numbers. Depending on engine, prop, canopy, how many coats of paint are on the airplane and all of the variations that come with homebuilt aircraft, expect a payload of 690 to 990 pounds out of the gross weight of 1970 pounds. Fuel capacity is 29 gallons, optionally 38, which is fine for the smaller 180-hp engines, but the bigger engines can easily burn 13 gph at low cruise power. Advertised cruise speeds are 160 to 180 mph. And although open cockpits look really cool, they can slow the plane down by 15 to 18 mph. Only the front-seater gets buffeted with open cockpits.

Spiffily painted wheelpants add to the airplane’s appeal.

Finally, it was time to give the airplane back to Testerman for the landing. Turning final over the beach, miles from the runway, the airspeed was 125 mph, slowing to 80 mph on short final. He did a wheel landing in the crosswind, and then added power to keep the tail up for better visibility on the way to the next taxiway.

For Those Who Do Aerobatics

While I am not the ace of the base for aerobatics, this Skybolt was a delight to fly. The advertised build prices are $35,000 to $100,000, and you get a lot of bang for the buck. The big engine meant that we never had to dive for speed of course, but the airplane also made me look good. The Skybolt literature quotes a number of pilots who compare it favorably with various Pitts models, often characterizing it as easier to land and easier to handle in some aerobatic maneuvers. I certainly found nothing lacking for the entry-level aerobatic pilot. The Skybolt’s 24-foot wingspan, versus 20 feet for a two-seat Pitts, may be a factor there.

Goetsch says that he doesn’t market the Skybolt against other planes because he doesn’t need to; the airplane has a following. Testerman says that when used Skybolts come on the market, they sell quickly. Usually after landing from a pilot report, I contemplate the flight and work on putting it into context. This time, a big smile said it all.

For more information, call 321/725-4160 or visit www.steenaero.com.