Top and side view of a typical strap duplicator. The pin is placed into the desired hole to duplicate; the bushing guides a drill to its proper location.

There is a good chance that you won’t finish your homebuilt aircraft without accidentally damaging a metal part at some point during the building process. This could take the form of a mistake while drilling, cutting, or bending. We are all human and stuff happens! If we choose to recreate the damaged part ourselves, one of the tasks we face is to precisely drill the holes in that part so it can be reattached to its original location on the aircraft. Using the damaged part as a template to locate the new holes is the easiest way to accomplish this, but sometimes this is just not possible. And there are occasions where the holes in one part do not match exactly to their mating holes in another part due to design revisions and builder modifications.

The good news is that there is an inexpensive, easy-to-use tool that was designed to solve this problem. Known as a strap duplicator or hole finder, this tool can be homemade or purchased at an aviation tool supply store. The concept for using the duplicator can be understood by examining the construction of the tool. Two narrow straps are joined together at one end and the other ends have a tip and a bushing mounted opposite each other. The tip and bushing are sized to a specific hole size of your choice. We will demonstrate with a #20 drill bit size.

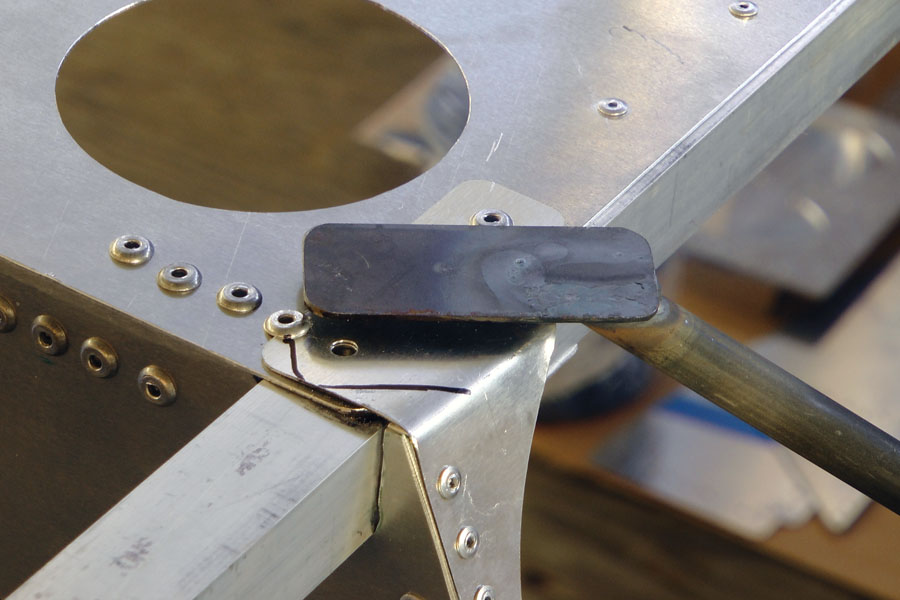

In the example, we have an undrilled pad from a steel mounting brace that needs to be bolted to an existing hole in the aircraft structure. There is no access from the other side of this structure to back-drill this hole, so we are left with the challenge of finding the correct location on the pad to drill. This hole needs to be very accurately located, as this steel brace has no wiggle room.

To find the exact location of the hole on the pad, we insert the tip of the duplicator into the airframe hole and slide our steel pad in between the straps. This leaves the bushing exposed and positioned precisely above the hole. We simply drill (using the correct drill bit size) through the bushing and into the steel pad. Remove the duplicator when done drilling and you have a perfectly positioned hole—simple and extremely effective!

The pin of the duplicator is placed in the airframe hole; the steel pad is placed underneath the bushing. The new hole is drilled precisely above the airframe hole.

A pin punch can be used in the bushing to set a mark if drilling is not desired at this time, or to simply test and verify the hole location before drilling. If a series of adjacent holes need to be located and drilled, as on the edge of a replacement undrilled skin, the duplicator is repeatedly used for each hole. Make sure you Cleco the previously drilled holes to hold the skin accurately in place while advancing the duplicator. It seems that I have used this tool most often when involved with replacement parts. Unless you are dealing with a late-model CNC matched-hole aircraft kit where replacement parts always seem to fit, the strap duplicator will become one of your most useful tools for metal parts repair and replacement.

![]()

As the founder of HomebuiltHELP.com, Jon Croke has produced instructional videos for Experimental aircraft builders for over 10 years. He has built (and helped others build) over a dozen kit aircraft of all makes and models. Jon is a private pilot and currently owns and flies a Zenith Cruzer.