Is it time to pick an engine for your project? Does the thought cause tremors, nausea, and chest pain? Although it’s possible you’re a victim of aboulomania, the pathological inability to make decisions, it’s more likely that you’re simply drowning in a sea of choices.

Take a deep breath. Choice is good, in moderation of course.

The Practical View

Frankly, most powerplant anguish is self-imposed. Airframe designers typically specify box stock engines, provide guidance for their installation, and even sell them at a discount. It’s a painless path, yet many builders burn countless hours agonizing over options large and small. We’ll talk about some of those choices in a moment, but first, a basic truth: Your airplane will fly great with perfectly ordinary power.

Stock is also pacific in the long term. As the builder of an Experimental, you’ll be expected to install and maintain an engine at a professional level. Are you willing to do the technical research necessary to support your choice? Stock installations (in particular those from Lycoming, Continental, and Superior) are familiar to everyone, including your local A&P. Less common configurations can (and often do) require that you become the local pro. Don’t be afraid, but do consider the personal requirements, and think about how you’ll meet them.

One last dose of reality: Changes drive more changes. An engine is the center of an ecosystem that spreads through the entire airframe. For every change, expect another in a supporting system. It’s equally true of small mods or major configuration changes, the difference being only how much work is required. Installing a turbine or radial can easily add several years to the build process, followed by several more years sorting it out. If you enjoy a challenge, go for it. If not, go with the KIS principle, and spend your time flying.

But I Want a (Insert Here)

Yep, you’re a gearhead. Stock won’t do, and too much is just enough. That’s cool; many here at KITPLANES share your psychosis. The majority of E/A-B aircraft will be powered with something flat and air cooled from Lycoming, Continental, or Superior, so let’s spend a few moments on popular options for that configuration.

Electronic Ignition: The current Number One, with good reason. High-performance ignition improves cycle-to-cycle variation, meaning each firing event tends to develop a uniform cylinder pressure. Compared to a magneto, an EI also extends the practical mixture range, successfully lighting very lean, very rich, and non-homogenous mixtures of air and fuel. Both characteristics are useful with every flight. EI-fired engines are typically easier to start, hot or cold, and later, in cruise, operating lean of peak EGT can significantly lower fuel expense. In the negative column, most EIs require support from a bulletproof electrical supply, usually dual. Even E-MAG’s P-MAG product (known for its internal backup generator) requires connection to airframe power.

Increased Compression Ratio: In return for a slight increase in combustion efficiency, more CR means less detonation margin. The long-term wildcard is the continued availability of 100LL fuel, as any fuel with a lower octane rating further reduces the margin. Opinions vary regarding the effect on long-term reliability due to stress. Old-school hot-rodders love it, others leave it. Changing CR means a piston swap. It can be changed either way at any time.

Fuel Injection: The standard is constant-flow mechanical injection, usually Bendix-pattern dual diaphragm for Lycoming-type engines, and an rpm-based system for legacy Continental models. Constant flow is simple and reliable, with no airframe electrical power requirement beyond occasional boost pump usage. In contrast, electronic speed-density systems use pulse width control of individual injectors at each intake port. The electronic injections offer better start and idle performance, higher resistance to vapor bubble formation, and superior fuel distribution at low flow rates. The use of 100LL fuel doesn’t allow closed loop control like an automobile (in the long term, O2 sensors are incompatible with lead), but baseline fuel delivery can be set to a reasonable compromise with a bit of button-pushing, then varied in flight by twisting a knob, with the same effect as the standard red push-pull knob. The downside is an absolute dependence on electrical power, which is required to drive the high-pressure pumps, as well as the ECU and injectors.

Improved Reciprocating and Rotating Balance: It’s not that stock motors are bad. They’re not, as the manufacturers have always had tolerance limits for balance. Special attention merely reduces imbalance to near nothing.

Cold Air Intake: The reality is that few of the available “cold air” manifolds actually deliver significantly colder air, but many offer less flow restriction. Naturally, everyone claims their manifold is the best, but good back-to-back comparison data is hard to find. It’s largely a case of picking a horse and placing your bet.

Porting and Polishing: The goal is not solely to increase airflow, but additionally, to equalize flow. A set of cylinders is measured on a standard flow bench. The ports are then hand worked until the least-flowing cylinders match the best one, or until all reach an airflow value considered optimum by the builder. Total engine airflow is increased, so torque is improved. However, the real bonus is smoothness; all cylinders now contribute equally.

Which to pick? Boosted CR, a good manifold, and good porting all increase power. Ignition, injection, and balance modifications can help power in more subtle ways, but largely make the engine nice to use. Buy them all if you wish, but proceed carefully. Some choices can be like Eve’s offer of the apple—acceptance may require a compromise in return. For sure, more power must always be matched by more cooling capacity, and generally requires more fuel.

The Rules

Before proceeding to the 2018 Engine Buyer’s Guide, let us first address the rules. The Guide is limited to engines available now or in the near future, as more or less complete units marketed to the Experimental community. We’ve skipped engines marketed as “certified only,” and those deemed impractical or unavailable. Along the same lines, we can’t list every individual engine variation a manufacturer may offer. Don’t worry, if you want a particular feature, someone will find a way to supply it. Just pick up the phone and ask.

You’ll find engines logically sorted by configuration or family, then listed in alphabetical order. We’ll make no distinction between traditional “aircraft engines” and “alternative engines,” as the line has begun to blur, particularly in the world of diesels.

The marketplace includes a wide variety of interesting small engines. Many don’t produce enough power to fly a typical E/A-B aircraft. We don’t have space to list them all anyway, so here we draw an arbitrary line at roughly 50 horsepower. Some listed manufacturers also sell smaller engines; call or check the websites.

Prices and weights are supplied by the vendors. Some prices are MSRP, while others may be a street price. Quotes to us in euros or other currencies were converted to U.S. dollars using exchange rates in effect at time of writing. All prices are subject to change. As priced, engines are supplied fully assembled, unless marked as “kit.” We’ve tried to determine exactly what accessories are included at a given price and weight, but in the end, what you see in the tables is largely manufacturer-supplied data. Trust, but verify!

The Engine Guide is a source of basic information. It is not an endorsement. Here at KITPLANES, we have personal opinions like everyone else, but in the Guide we make no judgments. You are the aircraft builder, so please, do your homework.

And now, ladies and gentlemen, in alphabetical order…the Guide.

Flat Four-Stroke Gas

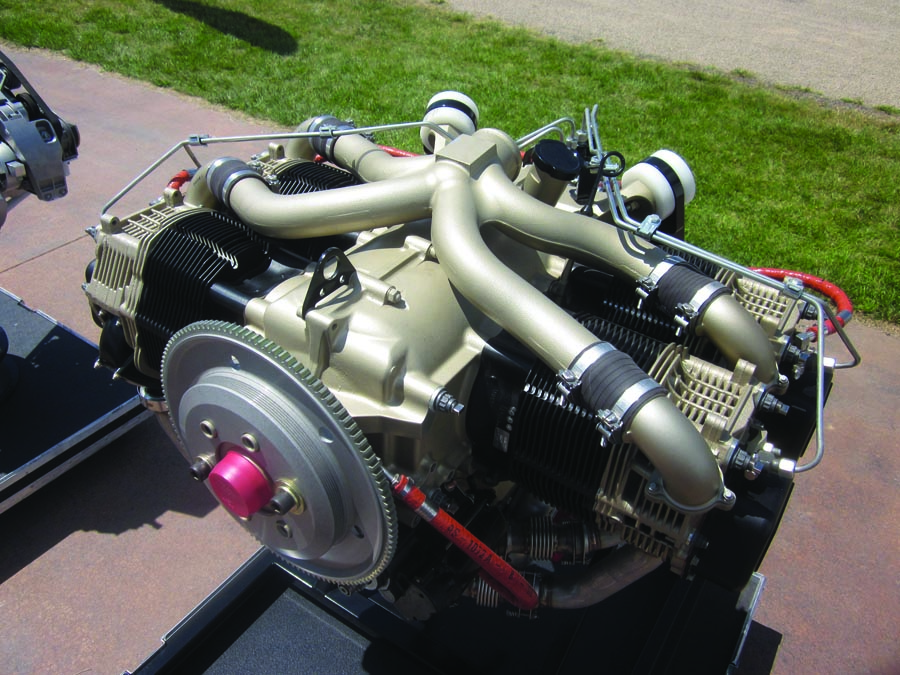

Japan-based design firm AC Corporation offers a variety of updates to existing flat-motor architecture. A monolithic air-cooled aluminum cylinder with a pressed-in liner is the signature product, but AC also offers a newly designed crankshaft, some interesting intake manifolds, and other fresh thinking. The latest addition is a line of oil-cooled cylinders, available only on complete engines tagged “Gladiator” and “Centurion.” The design cools both head and barrel, so no airflow is required at the engine itself. Instead, all cooling airflow would be ducted to a heat exchanger. Although stable cylinder temperature allows tighter clearances (and a slight power increase), the real benefit should come with optimized airframe design for reduced drag. The coolant is circulated using a pair of 24V electric pumps regulated to adjust flow based on temperature. An 80-amp alternator is standard.

AC Corporation has split from its previous U.S. representative, Advanced Component Engineering (ACE), so don’t be confused. For now, complete engines will be sold direct, with shipment from the European assembly facility in the U.K. Even with a shipping cost, the new factory-direct pricing is competitive with traditional offerings. Individual components for air-cooled engines are available on a limited basis to qualified engine builders.

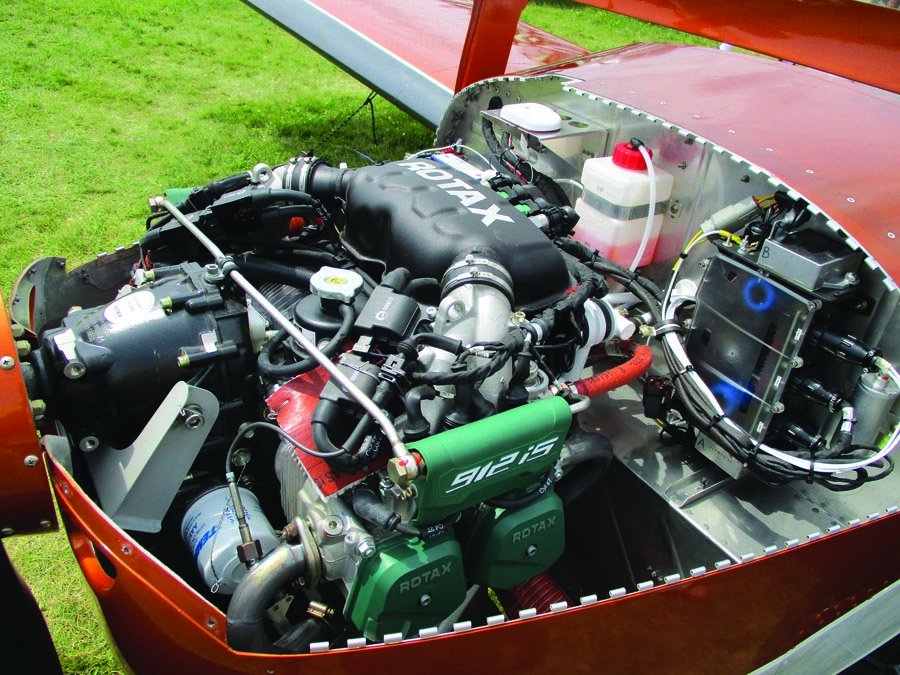

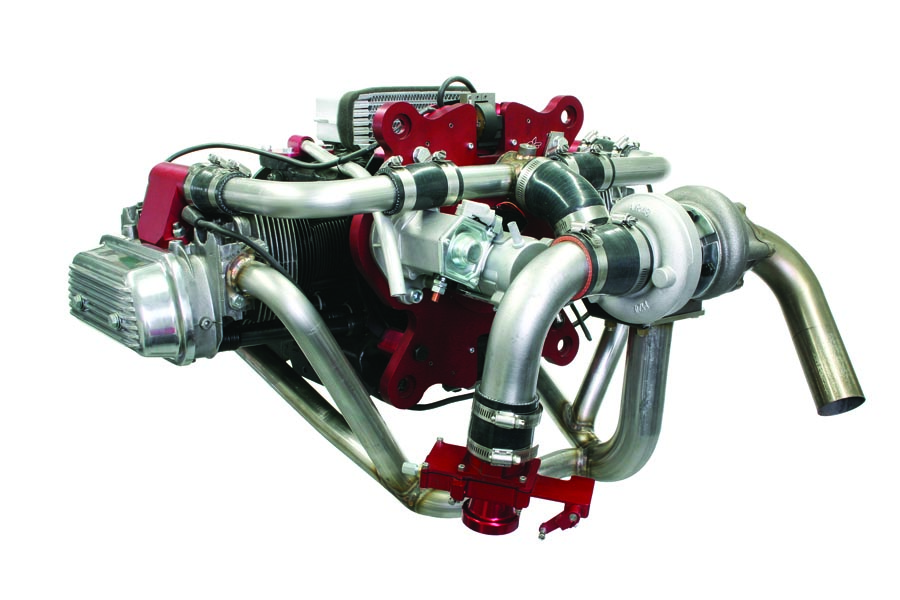

BRP Rotax continues as the dominant supplier of piston engines for Light Sport and microlight class aircraft. Although the best seller continues to be the 100-hp carbureted 912, the new 915iS is on schedule for delivery early in 2018. Turbocharged, intercooled, and fuel injected, the 915iS will deliver its 135 hp all the way up to 15,000 feet.

Although once maligned by the old school, today many consider the Rotax to be a premium choice. A mid-October review of the 912 series found only two significant bulletins year to date, one relating to a problem with the finish on the ends of some recent pushrods, and another to visually check an external driven plug on the generator case of a dozen 912iSc engines. The offending pushrods are identified visually after removing the rocker arm covers; Rotax will exchange them for new pushrods and rocker arms at no charge. The drive plug SB is also a visual inspection. If necessary, the plug can be reset in the field with a hammer and a special punch. In typical precise Rotax fashion, the bulletin specifies the hammer weight and instructs mechanics to “Intuitively control your manual insertion force just to set the ball in correct position. See Fig. 3.” We admit to some amusement (shop translation: “Whack it until it looks right”), but it’s hard to argue with precision.

Last spring, Continental Motors Group announced plans to build an all-new manufacturing facility, with an estimated total investment of around 70 million U.S. dollars. The new building will replace an entire campus of old structures at The Mobile Aeroplex. Alabama is Continental’s longtime home, and local politicians didn’t want them to leave, kicking in significant incentives for construction and employee training. Retraining is necessary because Continental intends to fill the new building with flexible machining centers several generations beyond existing equipment. The end result should exceed the already high technology level at the Continental facility in St. Egidien, Germany, which produces CMG diesel products, as well as Titan cases, cranks, camshafts, and other parts. In a related move, CMG also announced the creation of a new engineering and design center in China.

Traditional Conti models for the E/A-B and LSA markets continue, notably the O-200, and the big 550 sixes for Lancair builders. They’re generally installed box stock, and do a fine job. Continental magnetos (aka Bendix-type) now have a 12-year calendar TBO, with 500-hour inspections.

CMG hopes to increase market share with their Titan-branded line of engines, largely based on a growing array of PMA-certified parts for the Lycoming aftermarket. They’ve been successful in certain niche markets. For example, the current darling of the STOL world is the lightweight IO-340, delivered in several versions for factory-built LSAs. A homebuilder may order one in practically any configuration. The option list includes roller lifters (soon to be standard on all models), nickel-carbide cylinder coating (for corrosion resistance), a magnesium oil sump (saves seven pounds), and a lightweight accessory case with electronic ignition.

CMG has picked the IO-370 as the first Titan model to receive a type certificate. As planned, expect 9.6:1 compression (meaning 100LL only) and a pendulum crankshaft to limit propeller restrictions. For Titan, IO-370 certification is really part of a larger effort to bring Experimental engine production into CMG’s standard process and quality-control system.

The Titan line also includes a 540-pattern six cylinder, built with all-new PMA parts and notable as the market’s only direct competitor to Lycoming’s original O and IO-540. For now, all Titans are assembled at CMG’s Fairhope, Alabama, service center, just across Mobile Bay from the new plant site at the Aeroplex. A purchaser may select paint colors in any combination. Prices include a three-hour run on a test stand for break-in and preservation for storage. The warranty is homebuilder-friendly: up to one year on the shelf, followed by two years in service, with a maximum of three years total.

Belgium’s D-Motor is a fascinating flathead, available in both four- and six-cylinder versions. Although we often associate flatheads with lawnmowers and early Ford V-8s, valve in block is a reasonable layout for a low-rpm, direct-drive aircraft engine. The key virtues are simplicity, a narrow width, and less weight. Cylinders are Nikasil, for very low wear. Electronic ignition and fuel injection are standard, and the injection does not require a fuel system tank return. The mounting-point dimensions are identical to those found on Jabiru and ULPower engines, thus tubular mount structures are easier to source.

North American builders who have previously looked at D-Motor will note a change: At press time it appeared the new N.A. dealer would be Dave Hertner of Fisher Flying Products, from London, Ontario. As always, consult the manufacturer’s website for dealer information.

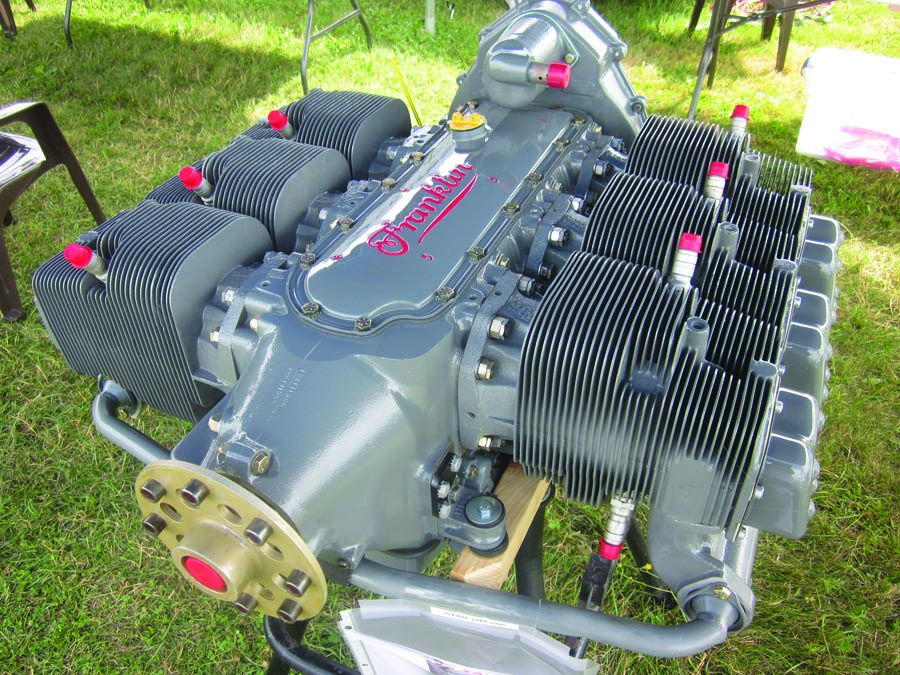

At press time, Kelly Bartlett of Franklin Aerospace reported some minor difficulty with delivery of the Franklin SP.Z-designed direct fuel injection system, but otherwise things are going well. The direct injection was intended for a certified version, and does not affect E/A-B sales. Bartlett offers two engines, the 4A-235 four cylinder and the 6A-350 six cylinder. The E/A-B version of the 4A comes with Electroair electronic ignition and a Rotec TBI (throttle body injection). The 6A remains available in the original 220-hp carbureted version, with 10.5-to-1 compression and Slick mags. A 6A with an 8.5 CR allows the use of lower octane fuels at 200 hp, and offers a nice price break compared to other engines with similar power.

Partners Chris Hatin and Jerry Olenik carry on as worldwide distributors of the trusty twin from HKS. United States-based distribution of the Japanese twin is interesting because Olenik reports fully two-thirds of their sales are outside North America. The 700E is a sweetheart: a four-stroke opposed twin with four valves per cylinder and dual CDI (capacitor discharge ignition). Oiling is dry sump, with an oil tank and both scavenge and pressure pumps. The stated 121-pound weight includes the gearbox, exhaust system, oil tank, and oil cooler, so the whole installation weighs about the same as an installed two-stroke with the same power.

Jabiru has now completed the long transition to engines of their own design, the fourth-generation 2200cc four and 3300cc six. Unlike previous engines built by CAMit Aero (now defunct), the new crankcase, cylinder barrels, and heads are cast, not machined, and the aluminum cylinders have nickel/silicon carbide bores with screwed-on heads. Long case and cylinder clamp studs now extend from the top of the cylinder to the opposite crankcase. Jabiru has posted a really good fourth-generation page on their website, and we recommend you go there for a complete list of all the changes. The new engines have been under development about four years, and meet both ASTM and JAR standards.

Shoppers may note an interesting difference in philosophy as compared to competitors. Although a clean-sheet design, Jabiru has elected to stay with a single Bing carburetor, a mechanical fuel pump, and simple distributed dual ignitions requiring no external power. The only ignition wiring is a grounding lead from each coil pack.

For E/A-B buyers desiring performance, the big news at Lycoming is a resurgent Thunderbolt custom engine program. In return for a moderate upcharge, a Thunderbolt buyer receives an engine produced by Lycoming’s Advanced Technology Center, best known as the source of all Red Bull Air Race motors.

Each custom Thunderbolt build combines a dynamically balanced crank with reciprocating parts matched to within half a gram. Cylinder head air flow rates are measured on a flow bench. All ports are opened to a matched flow value previously found optimum in the Lycoming dyno facility, followed by port polishing, after which the valves are installed for the last time and leak checked.

Buyers can specify 10:1 compression if desired, although it will restrict the engine to 100LL fuel. Airflow Performance and AVStar constant-flow injection is the standard, but the ATC crew will cheerfully deliver a new engine ready for customer installation of electronic fuel injection. Available ignition choices are new Slicks, a new P-MAG, or the shop will drill the case nose for customer installation of a Lightspeed CDI. Choose from three standard paint colors (in solid or two-tone combinations), or specify custom paint colors at a small extra charge. Chrome is available too. Every Lycoming gets 1.5 to 3.0 hours in a factory test cell, so there’s no need to worry about initial ring seal or mechanical integrity when the day arrives for a first flight.

Van’s Aircraft is Lycoming’s largest distributor in the E/A-B market, under an agreement that allocates one new engine to each owner of an airframe kit. As announced last summer, Van’s can now offer the Thunderbolt line, in addition to stock Y-prefix (Experimental only) models. Van’s is also a dealer for Hartzell, Sensenich, and MT propellers, and they typically offer “show special” pricing twice a year, valid if engine and propeller are ordered together. Van’s builders are well advised to check the list at Sun ‘n Fun, and again at AirVenture. Past show specials have included free shipping, plus free engine preservation packaging, so a builder with dry storage can order early without too much worry.

Speaking of early delivery, Lycoming’s warranty terms are excellent. The clock starts running when the engine is placed in service or 24 months from shipment by Lycoming, whichever comes first. It means a builder typically has as much as 23 months to ready the airplane for first flight; there’s no need to rush completion just to avoid losing warranty. Once started, all non-certified and Thunderbolt Signature models are protected 24 months or 2000 hours, whichever comes first. Do note that certain high-performance options shorten or eliminate warranty coverage, so ask when you place your order.

Lycoming now offers a marvelous benefit to owners, quietly digitizing operation, service, and parts publications, and posting the documents on the company website for download at no charge. Readers may also sign up for email notification of new publications. To select from this huge trove of information, simply visit lycoming.com/techpub and scroll down the page.

MW Fly Aero Power is offering a total of six models intended for fixed-wing flight, in two displacements, with direct drive or one of two reduction ratios. The ratios allow increased rpm for more horsepower, while swinging larger-diameter propellers. The engines are technically interesting: water cooled, fuel injected, dual ignition, dual FADEC with data export, and automatic compression release for low rpm vibration control.

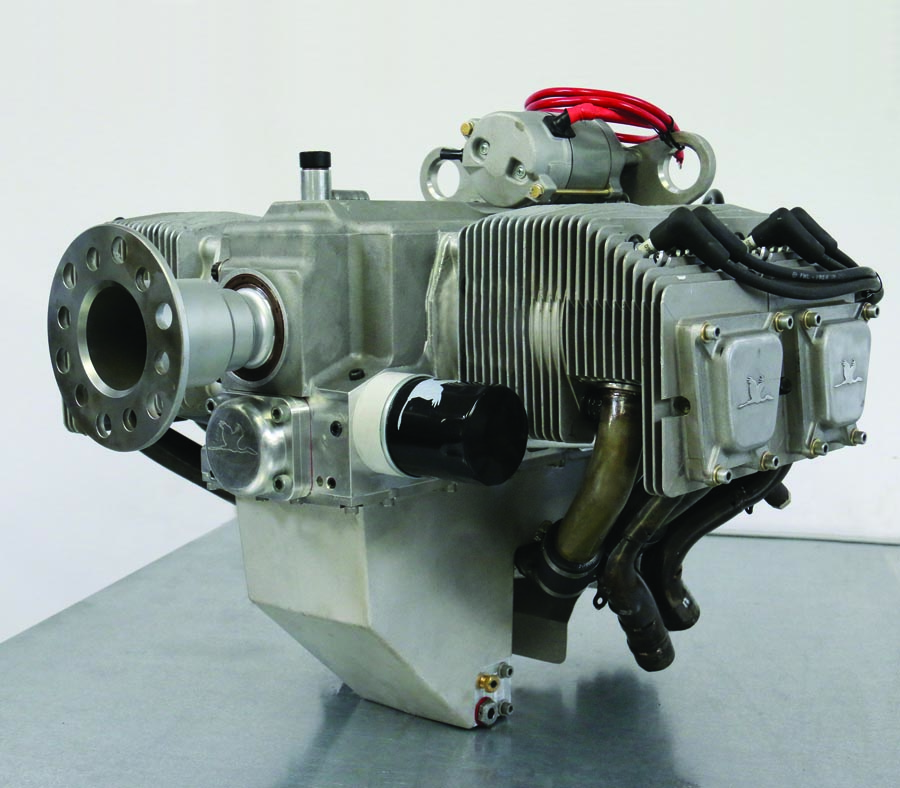

The Pegasus Power Systems DP-1 kit motor is finally available. Developer Pete Plumb laughs and says the effort has been equal to “estimated times pi,” but he is finally flying and ready to deliver kits. The Pegasus can be thought of as a twin-cylinder O-200 Continental, and in fact the builder will purchase quite a few Continental or Superior parts to go with the kit. Plumb supplies a new two-hole case, a balanced crank optimized for a twin, connecting rods with new pistons and pins, and an accessory case with a built-in side-draft intake manifold. The builder will source cylinders, rings, bearings, hydraulic lifters, gaskets, ignition, a carb, and a prop. Most builders will use 4300-series Slick mags, which are easily modified for two-cylinder operation. The preferred carb is a Zenith/Bendix 13859 intended for a Harley. The test aircraft is swinging a 64×32 Catto prop, and cruising at 2650.

Competition is good; the third source for traditional E/A-B power is Superior Air Parts. Their strategy is tightly focused: concentrate on the core PMA parts business, while selling a limited lineup of high-value avgas engines centered on the largest market segments.

Superior’s Lycoming-pattern XP engines are offered from 160 to 215 hp. They’re built largely from certified PMA components, marketed as better than the originals they were designed to replace. XP engine buyers may select flat tappets or roller tappets, then choose Precision or Airflow Performance fuel injection, all at the same standard price. A carb is available for those who like things simple. Superior’s own optimized updraft sump is standard, but with FI most buyers option the popular horizontal “cold air” manifold. XP engines (the exception being the XP-400) are approved for 91UL auto fuel.

Superior XP Series four-cylinder engines are available factory direct or at your favorite engine shop.

Superior offers attractively priced complete engine kits to selected independent shops. The major outlets appear to be Aero Sport Power in Kamloops, British Columbia, and Barrett Precision Engines of Tulsa, Oklahoma. Although either is perfectly capable of building anything (and they do), Aero Sport tends to feature the 382 Wildcat. The basic XP-382 kit is fundamentally a 360 case with a 400 crank and rods, combined with parallel-valve Millennium cylinders and roller tappets. Wildcat buyers get balancing, ported cylinder assemblies (with flow bench graphs documenting the results), the cold air intake, dual P-MAGs, custom paint, and even two cases of break-in oil and two filters. At Oshkosh, the package price was $37,450.

Barrett originated the IO-390, and when Lycoming ended kit engine sales, the Superior XP-400 became the natural replacement. The big angle-valve 400 is about the same physical size, one pound heavier, and makes similar power. Buyers may choose Airflow Performance, Bendix, or Precision Silver Hawk constant-flow injection, or select between SDS Aero and EFII-brand electronic fuel injection. With constant flow, select new Slick, overhauled Bendix, or P-MAGs. BPE assembly includes tightened balance tolerance (matched recip parts, plus a dynamic balance check of the crankshaft), dimensional checks, moderate port cleanup, and recut valve seats to establish proprietary lead and exit angles. Custom paint is standard. All engines spend time on BPE’s water-brake dyno, and come with a complete printout. A typical BPE XP-400 runs about $39,440.

Of course, Superior buyers may also place an order with the factory, with the option of visiting to watch Superior technicians assemble their engine, or even assembling the engine themselves under the direction of a Superior technician. Warranty is 24 months or 1000 hours, with up to 12 months between the date of delivery and first flight.

Belgium’s ULPower is arguably the high-tech choice in the flat, air-cooled group. All models are standard with electronic, multi-point fuel injection, as well as electronic ignition. System operation is largely “turn-the-key-and-go,” much like a car. Dual ECUs are an option, as are dual high-pressure electric fuel pumps (there is no engine-driven pump) and dual alternator output. An inverted oil system is available for all models. The hardware is beautiful, and the six-cylinder in particular feels and sounds great in the air.

As should be expected, a ULPower installation is heavily dependent on electrical power. The six cylinder requires 21 amps to run, with a generating capacity of 50 amps. There are also specific fuel system requirements. If you’re curious, the factory publishes really good installation, maintenance, and operating manuals, available for free download at the Belgian website. The install manual includes comprehensive wiring and plumbing guidance for builders.

Although ULPower prefers to call their engine management system a FADEC (full authority digital engine control), buyers should note it is not strictly true for any engine in this class when the installation calls for a controllable-pitch propeller. With one, the single power lever installed in the typical FADEC-equipped aircraft controls rpm (i.e., prop pitch) in addition to fuel and spark. Here the popular electric Airmaster hub, which controls blade pitch via a pilot-operated mode selector on the instrument panel, is not linked to the engine ECU.

The Airmaster installation is of particular interest because Ray Lawrence, based in Sandersville, Georgia, has been leading an effort to adapt ULPower engines to Van’s RV-series aircraft. Power is rated at 3300 rpm, but only for 5 minutes; continuous power is at 2800. The wide speed range of the RV, coupled with the rpm requirements, make a controllable-pitch system a practical requirement for competitive performance. At press time Lawrence reports about 60 hours on his RV-4 test bed, with an RV-7 project scheduled to take flight in the near future. Watch this space.

Flat Four-Stroke

| Engine Model | Drive Type | Horsepower | Weight | Price |

|---|---|---|---|---|

AC Corporation | ||||

| AC-379RS | direct | 230 hp 4-cyl | 248 lb FP, wo/ fuel system, ignition, or starter | $34,562 |

| ACE-568RS | direct | 350 hp 6-cyl | 370 lb FP, wo/ fuel system, ignition, or starter | $53,000 |

| ACE-758RS | direct | 475 hp 8-cyl | Special order | TBD |

| AC-335RS Gladiator | direct | 210 hp 4-cyl, liquid cooled | 226 lb FP, wo/ fuel system, ignition, or starter | $28,895 |

| AC-379RS Gladiator | direct | 240 hp 4-cyl, liquid cooled | 236.5 lb FP, wo/ fuel system, ignition, or starter | $34,562 |

| AC-568RS Centurion | direct | 360 hp 4-cyl, liquid cooled | 354 lb FP, wo/ fuel system, ignition, or starter | $53,000 |

BRP Rotax | ||||

| 912UL | geared | 80 hp @ 5800 rpm carbureted | 130 lb w/ exhaust, internal alternator | $14,871 |

| 912ULS | geared | 100 hp @ 5800 rpm carbureted | 137 lb w/ exhaust, internal alternator | $17,747 |

| 912iS | geared | 100 hp @ 5800 rpm EFI | 155 lb w/ exhaust, internal alternator | $21,236 |

| 914UL | geared | 115 hp @ 5800 rpm carbureted, turbo | 155 lb w/ exhaust, internal alternator | $28,469 |

| 915iS | geared | 135 hp @ 5800 rpm EFI, turbo, intercooled | 185 lb bare, approx. 245 installed | $38,000 Est. |

Continental Motors | ||||

| O-200-D4B | direct | 100 hp @ 2750 rpm carburetor | 199.7 lb w/ mags, starter, carb | $26,384 |

| O-200-A | direct | 100 hp @ 2750 rpm carburetor | 224 lb w/mags, starter, carb, alternator | $28,370 |

| IO-240-B | direct | 125 hp @ 2800 rpm injected | 246 lb w/ mags, starter, fuel injection | $30,598 |

| R-IO-550-N8B | direct | 310 hp @ 2700 rpm injected | 450 lb w/ mags, starter, alternator, oil cooler, FI | $52,288 |

| R-TSIO-550-E18B | direct | 350 hp @ 2700 rpm injected | 566 lb w/ above plus turbos, aftercoolers, exhaust | $98,368 |

Continental Motors—Titan Engines | ||||

| OX320 | direct | 160 – 167 hp carburetor | 240 lb w/ mags, fuel system, starter | $25,500 |

| IOX320 | direct | 160 – 167 hp injected | 240 lb w/ mags, fuel system, starter | $26,900 |

| OX340 | direct | 166 – 180 hp carburetor | 244 lb w/ mags, fuel system, starter | $27,100 |

| IOX340 | direct | 166 – 180 hp injected | 244 lb w/ mags, fuel system, starter | $28,500 |

| OX360 | direct | 180 – 185 hp carburetor | 277 lb w/ mags, fuel system, starter | $27,000 |

| IOX360 | direct | 180 – 185 hp injected | 277 lb w/ mags, fuel system, starter | $28,400 |

| OX370 | direct | 185 – 187 hp carburetor | 278 lb w/ mags, fuel system, starter | $28,100 |

| IOX370 | direct | 185 – 187 hp injected | 278 lb w/ mags, fuel system, starter | $29,500 |

| OX370 | direct | 195 hp carburetor, counterweighted crank | 283 lb w/ mags, fuel system, starter | $28,500 |

| IOX370 | direct | 195 hp carburetor, counterweighted crank | 283 lb w/ mags, fuel system, starter | $28,900 |

| OX540 | direct | 260 hp carburetor, counterweighted crank | 401 lb w/ mags, fuel system, starter | $42,900 |

| IOX540 | direct | 260 hp carburetor, counterweighted crank | 401 lb w/ mags, fuel system, starter | $43,400 |

D-Motor | ||||

| LF26 2690cc 4-cyl | direct | 91.8 hp @3000 rpm | 137 lb w/ alternator, starter, dual ECU, exhaust, fluids | $16,500 |

| LF39 3993cc 6-cyl | direct | 125 hp @ 3000 rpm | 184 lb w/ alternator, starter, dual ECU, exhaust, fluids | $24,500 |

Franklin Aerospace | ||||

| 4A-235 4-cyl | direct | 125 hp @ 2800 rpm | 207 lb w/ starter, alternator, TBI, ignition | $17,590 |

| 6A-350 | direct | 200 hp @ 2800 rpm | 344 lb w/ starter, alternator, fuel injection, ignition | $24,000 |

| 6A-350 | direct | 220 hp @ 2800 rpm | 344 lb w/ starter, alternator, fuel injection, ignition | $28,900 |

HKS Co. Ltd | Alternate website: quicksilverne | |||

| 700E Twin | geared | 60 hp @ 6200 rpm (3 min), 56 hp @ 5800 rpm continuous | 121 lb w/ carburetors, fuel pump, dual CDI | $10,998 |

| 700i Twin | geared | 70 hp – sequential fuel injection | TBA Spring 2019 | TBD |

Jabiru AU | ||||

| Generation 4 2200 (4-cyl) | direct | 85 hp @3300 rpm | 136 lb w/ exhaust, carb, starter, alternator, ignition | $14,500 |

| Generation 4 3300 (6-cyl) | direct | 120 hp @3300 rpm | 184 lb w/ exhaust, carb, starter, alternator, ignition | $18,500 |

Lycoming | ||||

| YO-235-EXP | direct | 118 hp @ 2800 rpm carburetor parallel valve | 250 lb w/ mags, fuel system, starter | $25,700 S*; $29,300 T** |

| YIO-235-EXP | direct | 115 hp @ 2800 rpm injected parallel valve | 250 lb w/ mags, fuel system, starter | $27,200 S*; $30,800 T** |

| YO-320-D1A | direct | 160 hp @ 2700 rpm carburetor parallel valve | 255 lb w/ mags, fuel system, starter | $26,900 S*; $30,500 T** |

| YIO-320-D1A | direct | 160 hp @ 2700 rpm injected parallel valve | 270 lb w/ mags, fuel system, starter | $28,500 S*; $32,100 T** |

| YO-320-D2G | direct | 160 hp @ 2700 rpm carburetor parallel valve | 250 lb w/ mags, fuel system, starter | $26,400 S*; $30,000 T** |

| YO-360-A1A | direct | 180 hp @ 2700 rpm carburetor parallel valve | 285 lb w/ mags, fuel system, starter | $27,500 S*; $31,100 T** |

| YO-360-A4M | direct | 180 hp @ 2700 rpm carburetor parallel valve | 285 lb w/ mags, fuel system, starter | $27,400 S*; $31,000 T** |

| YIO-360-M1B | direct | 180 hp @ 2700 rpm injected parallel valve | 290 lb w/ mags, fuel system, starter | $28,700 S*; $32,300 T** |

| YIO-360-A1B6 | direct | 200 hp @ 2700 rpm injected angle valve | 325 lb w/ mags, fuel system, starter | $33,100 S*; $36,700 T** |

| YIO-390-A3B6 | direct | 210 hp @ 2700 rpm injected angle valve | 315 lb w/ mags, fuel system, starter | $33,800 S*; $37,400 T** |

| YIO-390-EXP (10:1 CR) | direct | 220 hp @ 2700 rpm injected angle valve | 315 lb w/ mags, fuel system, starter | $NA S*; $38,000 T** |

| YIO-540-D4A5 | direct | 260 hp @ 2700 rpm injected parallel valve | 400 lb w/ mags, fuel system, starter | $47,700 S*; $51,300 T** |

| YIO-580-B1A | direct | 315 hp @ 2700 rpm injected angle valve | 440 lb w/ mags, fuel system, starter | $65,000 S*; $68,600 T** |

| YIO-580-B1A (10:1 CR) | direct | 320 hp @ 2700 rpm injected angle valve | 440 lb w/ mags, fuel system, starter | $NA S*; $69,500 T** |

| *Standard ; **Thunderbolt | ||||

MW Fly | ||||

| B22d-100, 4-cyl | direct | 100 hp @ 3300 rpm | 176 lb w/alt, starter, FADEC ECU, oil & water tanks | $19,924 |

| B22g-120, 4-cyl | geared (1.730) | 120 hp @ 3950 rpm (2400 prop) | 185 lb w/alt, starter, FADEC ECU, oil & water tanks | $23,057 |

| B22g-130, 4-cyl | geared (1.958) | 130 hp @ 4550 rpm (2400 prop) | 185 lb w/alt, starter, FADEC ECU, oil & water tanks | $24,310 |

| B22d-130, 4-cyl (helicopter) | NA | 130 hp @ 4550 rpm | 174 lb w/alt, starter, FADEC ECU, oil & water tanks | $24,936 |

| B25d-115, 4-cyl | direct | 115 hp @ 3300 rpm | 176 lb w/alt, starter, FADEC ECU, oil & water tanks | $22,430 |

| B25g-135, 4-cyl | geared (1.730) | 135 hp @ 3950 rpm (2400 prop) | 185 lb w/alt, starter, FADEC ECU, oil & water tanks | $31,202 |

| B25g-155, 4-cyl | geared (1.958) | 155 hp @ 4550 rpm (2400 prop) | 185 lb w/alt, starter, FADEC ECU, oil & water tanks | $33,708 |

| B25d-155, 4 cyl (helicopter) | NA | 135hp @ 4550 rpm | 174 lb w/alt, starter, FADEC ECU, oil & water tanks | $28,696 |

Pegasus Power | ||||

| DP-1D 100ci Twin | direct | 57 hp @2900 rpm | 110 lb w/ Slick mags, carb, no starter | $4,995 (kit) |

Superior Air Parts | ||||

| XP-320 | direct | 160 – 165 hp injected | 285 – 290 lb w/ mags, fuel system, starter | $25,600 |

| XP-360 | direct | 180 – 185 hp injected | 288 – 297 lb w/ mags, fuel system, starter | $25,600 |

| XP-382 | direct | 195 – 200 hp injected, pendulum crank | 282 lb w/ mags, fuel system, starter | $32,500 |

| XP-400 | direct | 215 hp injected, pendulum crank | 283 lb w/ mags, fuel system, starter | $34,500 |

ULPower | ||||

| UL260i 4-cyl | direct | 97 hp @ 3300 rpm / 82 hp @ 2800 rpm | 159 lb w/ accessories, oil, and exhaust | $20,000 |

| UL260is 4-cyl | direct | 107 hp @ 3300 rpm | 159 lb w/ accessories, oil, and exhaust | $21,000 |

| UL350i 4-cyl | direct | 118 @ 3300 rpm | 173 lb w/ accessories, oil, and exhaust | $23,000 |

| UL350iS 4-cyl | direct | 130 @ 3300 rpm | 173 lb w/ accessories, oil, and exhaust | $24,000 |

| UL390i 6-cyl | direct | 140 hp @ 3200 rpm / 130 hp @ 2800 | 220 lb w/ accessories, oil, and exhaust | $29,000 |

| UL390iS 6-cyl | direct | 160 hp @ 3200 rpm / 140 hp @ 2800 | 220 lb w/ accessories, oil, and exhaust | $30,000 |

| UL520i 6-cyl | direct | 180 hp @ 3200 rpm / 169 hp @ 2800 | 238 lb w/ accessories, oil, and exhaust | $31,500 |

| UL520iS 6-cyl | direct | 200 hp @ 3200 rpm / 182 hp @ 2800 | 238 lb w/ accessories, oil, and exhaust | $32,500 |

Inline and V Four-Stroke

Ok, so you want advanced high-end power? At press time South Africa’s Adept Airmotive is on track to deliver the first production units to North America. The company had a display motor on a customer’s incomplete Lancair at AirVenture, but Lee Brinley, Adept’s North American representative, swears he will fly there with his ES in 2018.

All Adept models are dry sump, 120-degree DOHC V-6s with an integral spur gear speed reduction system. The 320- and 360-horse versions are turbocharged. The layout is large bore/short stroke (98x70mm) to accommodate four valves per cylinder while keeping piston speeds low; at peak torque (3800 rpm), the 320T has the same mean and max piston speed (1750 fpm) as a 540 Lycoming at 2400 rpm. The gearing puts max prop rpm at 2700, again identical to traditional power.

Brinley tells us the company has acquired a 170,000-square-foot facility and will be installing equipment through the first quarter of 2018, after which production can be ramped up. Until then, operations will continue at the Virginia Airport in Durban.

By now, surely everyone has seen the bright yellow and blue AeroMomentum display engines. Engineer Mark Kettering buys new components in Asia, then builds complete engines at his facility in Florida. The popular units have been 1300- and 1500-cc Suzuki-based fours, but now the line has expanded at both ends, adding a 1000-cc triple and a turbocharged 2.0L four rated at 210 hp. The 1.3L, 1.5L, and 2.0L engines are available in both upright and low-profile versions for cowl clearance.

AeroMomentum engines are standard with electronic injection and ignition. Until recently, a Bosch ECU provided the brainpower, but in an interesting switch, all models are now delivered with a MicroSquirt controller. Adopting an ECU from the open source “Squirt” family means owners never need to worry about technical support information. The units are fully programmable, without the undesirable software additions that cripple some factory ECU use.

Kettering designed and tested his own PSRU, incorporating a German-made giubo torsional coupler. The geared drives are tough; in addition to aircraft units, Kettering says there are over 100 of them being flogged in working airboats. All deliveries come complete with an exhaust system, an engine-mounted radiator, and an ND-style alternator. Prices are excellent, and that also includes component sales. Want to roll your own? Visit the AeroMomentum website and select from over 120 different items: exhaust systems, gearboxes, even whole long blocks. Check it out.

AutoPSRU’s is best known for its signature feature, a centrifugal clutch, which decouples the engine from the spur gear reduction box at idle. Owner Stuart Davis has upgraded the clutch, the cases, and other items. Formerly the business centered on the LS3 Chevy V-8, but now Davis has expanded the lineup to include both 2.5- and 3.0-liter Subarus, as well as a pair of Mazda rotaries. The company has moved to new facilities south of Fort Worth, Texas, in order to gain space.

Firewall Forward Aero Engines continues to offer the CAM100 Honda Civic package, as it has for more than 20 years. The 2.4:1 PSRU uses a 100-millimeter cog belt on well-supported sprockets. Dual electronic ignition is standard. Fueling is via downdraft carb. We’ve listed the normally aspirated version here, but it can be ordered with a turbo for 125 hp.

Firewall Forward also offers the Camdrive 500 PSRU for V-8s, with three helical gears to transmit power, inside a fully machined billet case. The hydraulic prop governor is on a separate mount plate, and is driven with a cog belt. Internal oiling is via pressure pump and spray nozzles.

Seabee specialist Robinson V8 Power offers Chevy LS3-based packages (the LS376 480-hp version) with their own drive system, which is also available separately. The proven power train works in terrestrial aircraft too, and can be optioned with single-lever FADEC control of prop pitch… which includes reverse, just in case you have an itch to back into a parking space. Robinson also offers software and hardware to feed GM ECU data directly to a Garmin or MGL EFIS. Last but not least, they can altitude-normalize the LS3 with a supercharger.

Valley Engineering is offering two Big Twin models, a standard 40-hp, and a hopped-up 48-hp version with high-compression pistons, plus some gentle porting/polishing for better airflow. Both swing a prop about six feet long, producing lots of usable thrust at a very affordable price. How affordable? Look closely at the tabular listing. The Culver prop, another Smith family product, is included.

Viking Aircraft Engines has again updated to the latest engines from Honda. The popular 130-hp 1.5-liter four is derived from the 2018 Fit, while the 170-hp 1.5-liter and 200-hp 2.0-liter turbocharged fours are 2018 Civic/Accord spec. All feature gasoline direct injection, variable valve timing, and Viking’s own geared reduction unit, complete with torsional soft element.

Inline and V Four-Stroke

| Engine Model | Drive Type | Horsepower | Weight | Price |

|---|---|---|---|---|

Adept Airmotive | ||||

| 280N V-6 | geared | 280 hp @ 5500 rpm normally aspirated | 306 lb w/ radiator, alt, EFI, starter, dry sump system | $65,000 |

| 320T V-6 | geared | 320 hp @ 5500 rpm turbocharged | 340 lb w/ radiator, alt, EFI, starter, dry sump system | $85,000 |

| 360T V-6 | geared | 360 hp @ 5500 rpm turbocharged | 340 lb w/ radiator, alt, EFI, starter, dry sump system | $95,000 |

AeroMomentum | ||||

| AM10 | geared | 75 hp @ 6000 rpm – upright | 139 lb w/ PSRU, starter, alternator, ECU | $6,995 |

| AM13u | geared | 100 hp @ 5800 rpm – upright | 170 lb w/ PSRU, starter, alternator, ECU | $7,995 |

| AM13h | geared | 100 hp @ 5800 rpm – low profile | 170 lb w/ PSRU, starter, alternator, ECU | $9,995 |

| AM15u | geared | 117 hp @ 5800 rpm – upright | 185 lb w/ PSRU, starter, alternator, ECU | $8,995 |

| AM15h | geared | 117 hp @ 5800 rpm – low profile | 185 lb w/ PSRU, starter, alternator, ECU | $10,995 |

| AM15hp | geared | 147 hp @ 6500 rpm – low profile | 189 lb w/ PSRU, starter, alternator, ECU | $14,995 |

| AM20T | geared | 210 hp @ 6000 rpm – low profile | 310 lb w/ PSRU, starter, alternator, ECU, turbo | $18,995 |

AutoPSRU’s | ||||

| LS3 Chevrolet | geared | 360 hp @ 4500 rpm (centrifugal clutch), 1.666:1 ratio | 580 lb installed, typical, complete | $39,200 FF |

| 2.5L Subaru | geared | 150 hp @ 5000 rpm (centrifugal clutch), 1.859:1 ratio | 355 lb installed, typical, complete | $27,400 FF |

| 3.0L Subaru | geared | 230 hp @ 5000 rpm (centrifugal clutch), 1.859:1 ratio | 375 lb installed, typical, complete | $27,600 FF |

Firewall Forward Aero Engines (CAM engines) | ||||

| CAM125 Honda | 100-mm belt | 130 hp @ 5500 rpm | 247 lb w/ PSRU, injection, no starter or alternator | $18,645 |

Robinson V-8 Power | ||||

| LS3 Chevrolet (LS-376/480) | geared | 450 hp @ 5000 rpm, 1:98:1 ratio | 525 lb installed, typical, ready to run | $39,500 base |

Valley Engineering Big Twin | ||||

| Big Twin | belt | 40 hp @ 3600 rpm | 126 lb wet w/ propeller, starter alternator, exhaust | $5,495 |

| Big Twin (high compression) | belt | 48 hp @ 3600 rpm | 126 lb wet w/ propeller, starter alternator, exhaust | $6,195 |

Viking Aircraft Engines | ||||

| V-130 Honda Fit | geared | 130 hp @ 5400 rpm | 220 lb w/ radiator, exhaust, alternator | $9,995 |

| V-170 Honda Civic | geared | 170 hp @ 5400 rpm | 250 lb w/ radiator, exhaust, alternator | $15,995 |

| V-220 Honda Accord | geared | 200 hp @ 5400 rpm | 280 lb w/ radiator, exhaust, alternator | $16,995 |

Radial and Rotary (Traditional)

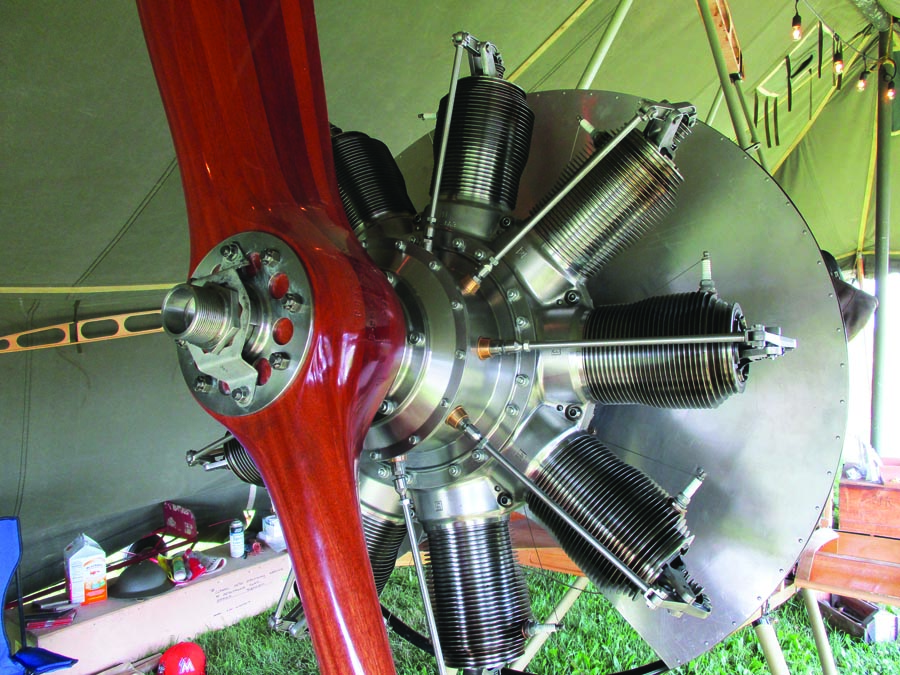

Possibly the most interesting engine displayed at AirVenture was the Gnome Monosoupape rotary recreated by Classic Aero Machining of New Zealand. Best known for powering a wide variety of Allied WW-I aircraft, a version was also built in Germany by Oberursel as the U.I.

A traditional rotary fixes the crankshaft to the airframe, then bolts the prop to the crankcase. The entire engine whirls around, cylinders and all. Oiling is total loss, flinging about two gallons of castor oil per hour. There is no throttle in the conventional sense. Instead a needle valve (aka a “Tampier valve,” also available from CAM) controls fuel flow, with limited effect. A very rich mixture is delivered to the crankcase via the hollow crank, then passed to each cylinder via transfer ports, where it mixes with more air to form an ignitable mixture. The single valve (monosoupape) in each cylinder head is both intake and exhaust.

Classic Aero specializes in recreating almost anything made of metal, usually better than the original. Bored with the same old homebuilts? Want to drench yourself in castor oil and romance? Call the like-minded folks at Kip Aero in Dallas (www.kipaero.com) to place your order for a brand new Sopwith kit…Pup, Triplane, 11/2 Strutter, or Camel, your choice. Curse you, Red Baron!

Suddenly radials are popping up all over. The latest effort is from Monocoupe Aeroplane Corporation, who intends to put the Warner 185 back on the market. It’s a serious effort; they bought all the available NOS (new old stock) parts and have since digitized every machined part for CNC production. The test mule is running with a Holly carb, but the production plan includes constant-flow mechanical fuel injection. The NOS stock included 350 original magnetos, which should keep everyone in sparks for a while.

Why the Warner? It fits a nice power/weight niche, and it’s very attractive. But mostly it’s the right engine for the Monocoupe 110 Special, the company’s primary product. You can bet KITPLANES will be begging a ride in due course.

Apparently George Coy’s Motorstar NA remains the only place to go for a new M-14, available in limited numbers from Romanian production. It’s not that the engine isn’t popular, but rather, multiple sources for good used and remanufactured M-14s make new production seem like an extravagance. Motorstar sells remans, too, of course. Jill Gernetzke’s M-14P Inc. (Kingman, Arizona) is also popular, and Barrett Performance Engines (Tulsa, Oklahoma) builds high-output versions with U.S. made pistons, electronic ignition, and Airflow Performance fuel injection.

Australia’s Rotec Aerosport remains the leading radial engine supplier to the E/A-B market. The seven-cylinder R2800 produces 110 hp at 2450, and typically swings a 76-inch fixed-pitch propeller. The nine-cylinder R3600 produces 150 hp, and swings a prop as large as 90 inches. A Bing carb is standard, but Rotec’s own TBI (throttle body injection) allows inverted operation when teamed with an appropriate oil tank and fuel pickup.

One significant change is the appointment of Brian Kelly (Radial Conversions) to represent Rotec in the USA. Kelly is best known for his RV-8R, a Van’s RV-8 with an R3600 in the nose, now used as the test bed for a variety of products intended to ease the installation of a radial. Perhaps the most significant development is a controllable-pitch electric GT propeller from Italy. Look for a flight test in KITPLANES soon.

Radials from Verner Motor are beginning to show up on flying projects in both North America and Europe. The selection includes a 42-hp 3-cyl at only 28 inches diameter, two entirely different 5-cylinder models at 68 and 83 hp, and a 124-hp 7-cylinder at about 32 inches. A 160-hp 9-cylinder is in the works. Verner’s design philosophy is simplicity and displacement; the propshaft is not geared, and there are no superchargers. Designs are modular. The 3 and the smaller 5 share the same bore, stroke, and cylinder assemblies. The large 5 and the 7 likewise share components. All have coil-on-plug electronic ignition systems.

Radial and Rotary (Traditional)

| Engine Model | Drive Type | Horsepower | Weight | Price |

|---|---|---|---|---|

Classic Aero Machining Service | ||||

| Gnome Monosoupape | rotary | 125 hp @ 1125 rpm | 260 lb w/ oil pump, air pump, ignition | $60,000 |

Monocoupe Aeroplane Corporation | ||||

| Warner 185 | direct | 185@ 2175 rpm (200@ 2475 for 5 min) | 304 lb w/starter, alternator, MFI, ignition | $49,500 |

Motorstar NA | ||||

| M14-P | geared | 360 hp @ 2900 rpm | 515 lb w/ air or electric start, B&C alternator | $52,000 |

| M14-PF | geared | 400 hp @ 2900 rpm | 515 lb w/ air or electric start, B&C alternator | $55,000 (28K – 32K reman) |

Rotec Aerosport Pty Ltd | ||||

| R-2800 | geared | 110 hp @ 3600 rpm | 224 w/ starter, alternator, carb, ignition, stub exhaust | $22,500 |

| R3600 | geared | 150 hp @ 3600 rpm | 275 w/ starter, alternator, carb, ignition, stub exhaust | $27,500 |

Verner Motor | ||||

| Scarlett Radial 3VW, 100ci | direct | 42 HP @ 2500 RPM | 71 lb w/ alternator, carb, ignition | $7,500 |

| Scarlett Radial 5VW, 166ci | direct | 60 HP @ 2300 RPM | 114 lb w/ starter, alternator, carb, ignition | $9,500 |

| Scarlett Radial 5Si, 207ci | direct | 83 HP @ 2200 RPM | 154 lb w/ starter, alternator, EFI, ignition | $15,000 |

| Scarlett Radial 7U, 290ci | direct | 124 HP @ 2300 RPM | 183 lb w/ starter, alternator, EFI, ignition | $22,000 |

| Scarlett Radial 9S, 372ci | direct | TBD (Approx 160 HP) | 233 lb w/ starter, alternator, EFI, ignition | $31,600 |

Rotary (Wankel)

Dave Atkins at American Rotary Engine tells us they continue to make progress on their own new rotary, built with exotic materials where necessary, and incorporating Mazda parts where Mazda works well. ARE’s sister company, Atkins Rotary, owns what is claimed to be the world’s largest storehouse of Mazda rotary parts, and now they machine new parts in house. Aviation engines are built to order and equipped with the well-regarded Powersport PSRU.

As mentioned earlier, AutoPSRU’s has added two Mazda rotary packages to its lineup, both 13B-based, one normally aspirated, and one turbocharged. They’re coupled to AutoPSRU’s 200Z gearbox with their signature centrifugal clutch. The price in the listing is a complete bolt-on package for the Van’s RV-6, RV-7, and RV-9, and includes a cowl mod kit. The prop and prop governor are not included.

Rotary (Wankel)

| Engine Model | Drive Type | Horsepower | Weight | Price |

|---|---|---|---|---|

American Rotary Engine | ||||

| 2 rotor 13B | geared | 180 hp @ 6000 rpm | 320 lb wet w/ alternator, starter, ECU, EFI and EI | $16,000 |

AutoPSRU’s | ||||

| Mazda 13B | geared | 180 hp @ 7600 rpm (centrifugal clutch), 2:778:1 ratio | 385 lb installed, typical, complete | $28,400 FF |

| Mazda 13B Turbo Normalized | geared | 200 hp @ 7600 rpm (centrifugal clutch), 2:778:1 ratio | 410 lb installed, typical, complete | $36,900 FF |

Compression Ignition (Diesel and Jet A)

There really isn’t a lot of say about diesels for homebuilders; industry wide, mostly what we hear is “not yet.” For example, market leader Continental is busy installing water-cooled CD-155s in new and used certified aircraft (the Cessna Turbo Skyhawk JT-A being the most familiar), and it is possible to buy one in a Glasair Sportsman, if installation is supervised at the Glasair Aviation facility. By Continental’s own reckoning, more than 5000 of the 100-Series diesels have been produced in the last 15 years, accumulating more than 5 million flight hours. Despite the volume, CMG has still not offered any indication of when it might release the engine to the E/A-B market as a whole. Can it really be too complex for mere mortals?

There is one bright spot: a single RV-10 is flying with an owner-installed CD-230 air-cooled four. The owner was bound by a CMG non-disclosure agreement, but at press time a spokesman has agreed to lift the NDA for a KITPLANES flight report; stay tuned. Eventually the aircraft will receive an upgrade to the new 265-hp version, with the 230 going back to Continental. The CD-265 is undergoing final development in a push for certification in 2018. Its cruise economy and rated power at altitude would seem like a perfect match for a large segment of the RV-10 fleet, so let’s hope everything goes well.

Last, CMG received an EASA Type Certificate for their CD-300 V-6 last July. The model was announced three years earlier at AirVenture 2014. Continental’s Rhett Ross was quoted as saying the CD-300 will likely find OEM application, rather than certified retrofit, so don’t expect an E/A-B release any time soon.

Development of the opposed-piston Superior Gemini diesel has slowed. There are no showstoppers; the decision guys have simply decided to place their chips on increased parts production for the avgas side, as those investments pay dividends right now.

At press time, the folks at EPS were busy wrapping up the last items for FAA certification of their high-tech flat-V diesel. They’re concentrating on military, OEM, and STC customers; a spokesman told us it’s unlikely to be offered to the E/A-B market in 2018. For now we’ve removed both engines from the listings, but expect to see them return in the future.

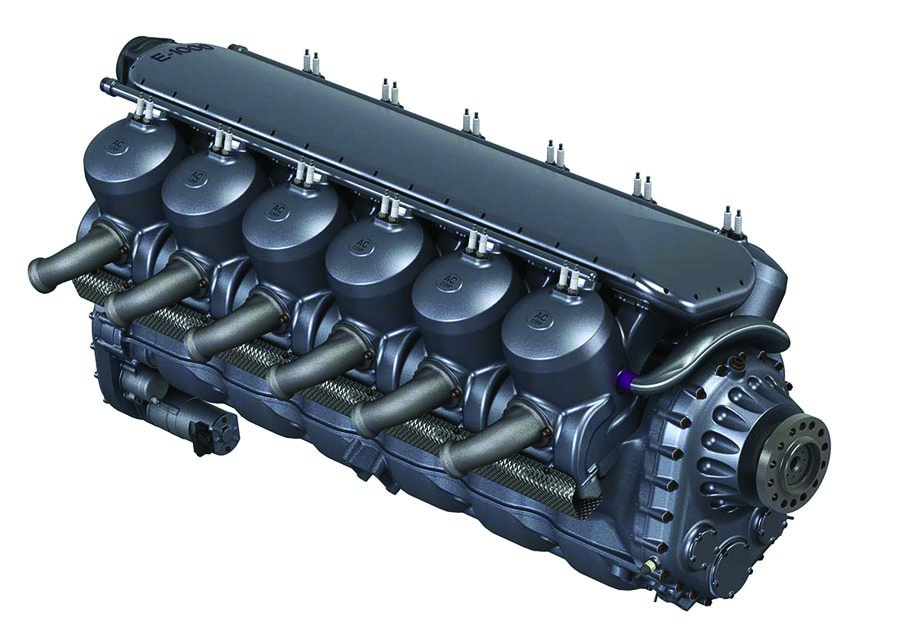

There are three new engines to watch, the E1000 V-12, the E330 V-4, and the little FL1500 inverted V-4, all from Andrew Higgs at AC Corporation. Higgs will deliver the first E1000s to a Japanese power generation company in late spring, with a few more committed to aircraft. Yes, the model designation means 1000 hp. The design is modular, with an unusual internal arrangement. The E330 V-4 shares the same components. The little FL1500 is slightly smaller than a Rotax 912, with 120 hp, and shares little with its big brothers. Stay tuned.

Compression Ignition (Diesel and Jet A)

| Engine Model | Drive Type | Horsepower | Weight | Price |

|---|---|---|---|---|

Continental Motors | ||||

| CD-135 | geared | 135 hp @ 3890 rpm | 295.4 lb with accessories, dual FADEC | Kit program only |

| CD-155 | geared | 155 hp @ 3890 rpm | 295.4 lb with accessories, dual FADEC | Kit program only |

| CD-230 | direct | 235 hp @ 2200 rpm | 450 lb with accessories | Beta program |

Volkswagen

AeroConversions is the engine shop side of Sonex Aircraft. They offer two versions of their 2180cc AeroVee, naturally aspirated or turbocharged. The AeroVee is a kit engine, requiring owner assembly. Dual ignition is standard. The AeroVee crank and prop hub are a bit different; the hub is shrunk onto a straight section of the crank nose, which runs in a standard case, rather than being mounted on a tapered crank nose with hub support from an additional bearing housing. Although most components are off-the-shelf aftermarket VW, AeroConversions-sourced parts are well finished billet aluminum, anodized red.

Bush King Performance offers an extensive “all-in-one” package. The 2.1L is available in two models, standard and a turbo-normalized version, which maintains sea level rated power as the aircraft climbs to altitude. Like the name suggests, the focus is on STOL performance, so a redrive unit is standard in order to swing a large prop diameter. Alone among the VW choices, Bush King engines are standard with electronic fuel injection and include a matched propeller. The current favorite is a P-Prop from South Africa, built with a eucalyptus saligna wood core and a glass/carbon sheath. All packages are delivered complete and ready to run.

Another long-term source for flying VWs is Great Plains Aviation Supply. GPAS is all about choice. In addition to “conventional” VWs driving the prop with a well-supported hub at the accessory end of the crank, they also offer VWs with prop hubs at the flywheel end, and reduction drives as well. All GPAS engines are kits; in return for some careful work, a builder saves money and learns a lot about the engine he/she will fly.

The “people’s engine guy” in this group is probably Scott Casler of Hummel Engines. The Casler theme is simplicity, much like Ferdinand Porsche’s early Beetle. The typical Hummel is magneto fired and hand propped, with no starter or alternator. The result is an inexpensive, very light VW suited to simple airplanes. Need something even lighter? Although not listed here, Casler also builds half-VWs, twin-cylinder engines from 28 to 45 hp. Everything is delivered fully assembled, after a test run.

Joe Horvath and Ralph Maloof of Revmaster Aviation probably know more about tough air-cooled VWs than anyone on Planet Earth. Horvath founded Revmaster in 1959 to rebuild VWs for the auto market. Around 1965 he called on Maloof, a talented aeronautical engineer and (at the time) a manufacturer of small VW-powered hovercraft. By 1969 they were partners.

The R-2300 is a purpose-built engine for the aviation side of Revmaster, available naturally aspirated and turbocharged. Key features are Revmaster’s 049 big-fin heads, their own forged and nitrided crank, fully machined forged connecting rods, a full-flow filter, CDI ignition with two plugs per cylinder, and dual alternators to keep them firing. Maloof’s latest engineering project is a redrive unit for the R-2300.

Volkswagen

| Engine Model | Drive Type | Horsepower | Weight | Price |

|---|---|---|---|---|

AeroConversions (Sonex) | ||||

| AeroVee 2.1 | direct | 80 hp @ 3400 rpm | 160 lb w/ alternator, starter, carb, ignition | $7,495 kit |

| AeroVee 2.1 Turbo | direct | 100 hp @ 3400 rpm | 185 lb w/ alternator, starter, carb, ignition | $10,995 kit |

Bush King Performance | ||||

| 2.1L EFI | belt | 80 hp @ 4280 rpm, 70 @ 3800 continuous | 184 lb w/ alternator, starter, fuel injection, ECU, oil cooler | $13,200 w/prop |

| 2.1L EFI (turbo normalized) | belt | 80 hp @ 4280 rpm, 70 @ 3800 continuous | 188 lb w/ alternator, starter, fuel injection, ECU, oil cooler | $15,185 w/prop |

Great Plains Aircraft Supply | ||||

| 1835cc front drive | direct | 65 hp @ 3600 rpm, 60 @ 3400 continuous | 163 lb w/ alternator, starter, carb, Slick 4220 | $6,239 (kit) |

| 1835cc flywheel drive | direct | 65 hp @ 3600 rpm, 60 @ 3400 continuous | 156.5 lb w/ alternator, starter, carb, distributor | $5,898 (kit) |

| 1835cc reduction | belt | 85 hp @ 4200 rpm, 65 @ 3400 continuous | 176.8 lb w/ alternator, starter, carb, Slick 4220 | $6,766 (kit) |

| 1915cc front drive | direct | 69 hp @ 3600 rpm, 65 @ 3400 continuous | 163.2 lb w/ alternator, starter, carb, Slick 4220 | $6,239 (kit) |

| 1915cc flywheel drive | direct | 69 hp @ 3600 rpm, 65 @ 3400 continuous | 156.7 lb w/ alternator, starter, carb, distributor | $5,898 (kit) |

| 1915cc reduction | belt | 85 hp @ 4200 rpm, 65 @ 3400 continuous | 177 lb w/ alternator, starter, carb, Slick 4220 | $6,766 (kit) |

| 2180cc front drive | direct | 76 hp @ 3600 rpm, 70 @ 3400 continuous | 164.5 lb w/ alternator, starter, carb, Slick 4220 | $7,070 (kit) |

| 2180cc flywheel drive | direct | 76 hp @ 3600 rpm, 70 @ 3400 continuous | 158 lb w/ alternator, starter, carb, distributor | $6,228 (kit) |

| 2180cc reduction | belt | 103 hp @ 4200 rpm, 70 @ 3400 continuous | 180 lb w/ alternator, starter, carb, Slick 4220 | $7,205 (kit) |

| 2276cc front drive | direct | 80 hp @ 3600 rpm, 76 @ 3400 continuous | 165 lb w/ alternator, starter, carb, Slick 4220 | $7,070 (kit) |

| 2276cc flywheel drive | direct | 80 hp @ 3600 rpm, 76 @ 3400 continuous | 158.5 lb w/ alternator, starter, carb, distributor | $6,228 (kit) |

| 2276cc reduction | belt | 105 hp @ 4200 rpm, 72 @ 3400 continuous | 180.5 lb w/ alternator, starter, carb, Slick 4220 | $7,205 (kit) |

Hummel Engines | ||||

| 1600cc | direct | 50 hp @ 3600 rpm | 140 lb w/ carb, Slick mag, wo/ starter or alt | $4,150 |

| 1835cc | direct | 60 hp @ 3600 rpm | 145 lb w/ carb, Slick mag, wo/ starter or alt | $4,350 |

| 1915cc | direct | 65 hp @ 3600 rpm | 145 lb w/ carb, Slick mag, wo/ starter or alt | $4,375 |

| 2180cc | direct | 76 hp @ 3600 rpm | 147 lb w/ carb, Slick mag, wo/ starter or alt | $5,500 |

| 2400cc | direct | 85 hp @ 3600 rpm | 147 lb w/ carb, Slick mag, wo/ starter or alt | $5,800 |

Revmaster Aviation LLC | ||||

| R-2300D | direct | 85 hp @ 3200 rpm | 170 lb w/ alternator, starter, carb, dual CDI | $8,850 |

| R-2300DT Turbo | direct | 102 hp @ 3200 rpm, to 12,000 feet | 190 lb w/ alternator, starter, carb, dual CDI | $11,850 |

| R-2300 with Redrive | belt | 90 hp @ 3650 rpm | TBA | $11,500 (est) |

Jets and Turboprops

Back in 2008 GE Aviation entered the general aviation market with the purchase of Walter Engines, naming the new subsidiary GE Aviation Czech. They set about updating the Walter design, the result being the H-series turboprops. The first applications were by STC, and later as an OEM choice, mostly small commuter transports and agricultural aircraft. In 2016, GE agreed to try the E/A-B market with the H75 as the power for the Venom, an updated Turbine Legend. GE will not sell an H-series to just anyone, not yet anyway. For now, engine access will be kit program only…but serious kit manufacturers are certainly invited to inquire.

The PBS TJ100 turbojet is familiar to most EAA’ers as the little kerosene torch powering the SubSonex personal jet. The TJ100 also powers at least one self-launched sailplane. The TP100 turboprop is available from Turbine Solutions Group as a complete firewall forward package for the Van’s RV-10; read the Amy Laboda flight review, “Turbine-Powered RV-10,” in the June 2015 issue of KITPLANES. We recently learned of two new projects involving the TP100 and another for the TS100 turboshaft; more later. PBS has established an office in Atlanta, Georgia, for direct inquires. We’re told they will sell an engine to any adventurous homebuilder, so if you have some spare cash and a need for speed…

Jets and Turboprops

| Engine Model | Drive Type | Horsepower | Weight | Price |

|---|---|---|---|---|

GE Aviation | ||||

| H75 | geared | 751 HP @ 2080 prop RPM | 390 lb dry w/ alternator and starter | Kit program only |

| H80 | geared | 800 HP @ 2080 prop RPM | 390 lb dry w/ alternator and starter | Kit program only |

| H85 | geared | 850 HP @ 2080 prop RPM | 390 lb dry w/ alternator and starter | Kit program only |

PBS Velk Bteš | ||||

| TJ100 turbojet | NA | Thrust – 247 lbf, 173 continuous | 43 lb w/accessories | $66,000 w/o accessories |

| TP100 turboprop | geared | 241 hp (5 min), 214 continuous | 136 lb without accessories | $90,000 w/o accessories |

| TS100 turboshaft | geared | 241 hp (5 min), 214 continuous | 126 lb or 139 lb (gearing choice), no accessories | $90,000 w/o accessories |

Corvair

Azalea Aviation builds attractive Corvairs to order at the Cook County Airport, way down in south Georgia. Bill and Kyoung Clapp hold monthly barbeques and regular workshops for engine and airframe assembly; we dropped in one weekend to find the Azalea shop full of builders having fun. Both 100- and 125-hp Corvairs are available, and at press time they were reporting about 60 hours on a turbo-normalized version flown in the company Sabrewing demonstrator. Azalea can supply firewall-forward kits for Zenith and Sonex, too; call for details.

Ask about flying GM’s iconic flat six, and sooner or later someone will mention William Wynne of Fly Corvair. Nobody has written more, spoken more, or taught more about Corvair conversions than Wynne. Be warned; Wynne loves to teach. Ask him about buying a complete engine, and a few hours later, you’ll be convinced that you simply must build it yourself. Wynne, like the guy in the beer commercial, is also an interesting fellow. Don’t believe it? Visit flycorvair.com and start reading. Leave plenty of time in your schedule.

Fly Corvair and Sport Performance Aviation team up to provide complete Corvair engines and engine kits.

Sharp-eyed readers will note that Dan Weseman’s Sport Performance Aviation and Fly Corvair have identical listings in the tabular data. It’s not a misprint, but rather a collaboration between long-time friends. Both manufacture parts; some are Wynne developments, and others are Weseman’s. Both told me it really doesn’t matter where you place your order; you’ll get exactly the same product, and calling either phone will get help when you need it. Listed prices are for a complete “engine in a box” kit, but they are available fully assembled for a few extra dollars.

Corvair

| Engine Model | Drive Type | Horsepower | Weight | Price |

|---|---|---|---|---|

Azalea Aviation | ||||

| Spyder 100 | direct | 100 hp | 210-215 lb wet with alternator | $10,500 |

| Spyder 125 | direct | 120 hp | 210-215 lb wet with alternator | $12,900 |

Fly Corvair | ||||

| 2775cc (169ci) 6-cyl | direct | 105 hp @ 3150 rpm | 225 lb w/ starter, ignition, and alternator | $12,495 kit |

| 3000cc (183ci) 6-cyl | direct | 125 hp @ 3150 rpm | 225 lb w/ starter, ignition, and alternator | $13,495 kit |

| 3300cc (201ci) 6-cyl | direct | 119 hp @ 2800 / 125 hp @ 3300 rpm | 225 lb w/ starter, ignition, and alternator | $15,795 kit |

Sport Performance Aviation LLC | ||||

| 2775cc (169ci) 6-cyl | direct | 105 hp @ 3150 rpm | 225 lb w/ starter, ignition, and alternator | $12,495 kit |

| 3000cc (183ci) 6-cyl | direct | 115 hp @ 3300 rpm | 225 lb w/ starter, ignition, and alternator | $13,495 kit |

| 3300cc (201ci) 6-cyl | direct | 119 hp @ 2800 / 125 hp @ 3300 rpm | 225 lb w/ starter, ignition, and alternator | $15,795 kit |

The trusty 582 is the only remaining two-stroke in the BRP Rotax lineup. We’ve priced it here with a Rotax E-gearbox, which includes an electric starter and rubber soft coupler. It’s a highly developed package; the “Blue Head” version sold today began as the 532 more than 30 years ago. Rotax has sold more than 30,000 582s worldwide.

Germany’s Hirth continues to offer a full line of two-strokes. They’re distributed in North America by Recreational Power Engineering of Tiffin, Ohio. The Guide lists nine models suitable for typical homebuilts, from 28 to 110 hp. Buyers should take a close look at the hp and rpm tables, as most models are available in two versions; one is ported to move maximum torque to a lower rpm than the other. Although doing so reduces maximum power, it increases cruise fuel efficiency and reduces noise.

All engines have dual CDI ignition. Every Hirth in the Guide can be ordered with optional electronic fuel injection. The listed prices do not include a belt reduction or gearbox. However, RPE maintains an excellent website, which clearly details options and prices on each engine data page.

Two-Stroke

| Engine Model | Drive Type | Horsepower | Weight | Price |

|---|---|---|---|---|

BRP Rotax | ||||

| 582UL inline WC twin | geared | 65 hp @ 6500 rpm carbureted | 104 lb w/o radiator, w/ E gearbox and exhaust | $7,445 |

Hirth | ||||

| F-33 single cylinder | belt | 28 hp @ 6000 rpm | 41 lb free air w/ recoil start, exhaust | $2,857 |

| 2702 inline twin | geared | 40 hp @ 5500 rpm | 82 lb fan cooled w/ starter, exhaust | $3,476 |

| F-23 opposed twin | belt | 50 hp @ 6150 rpm | 71 lb free air w/ recoil start, exhaust | $4,959 |

| 3202 inline twin | geared | 55 hp @ 5500 rpm | 82 lb fan cooled w/ starter, exhaust | $4,423 |

| 3203 inline twin | geared | 65 hp @ 6300 rpm | 82 lb fan cooled w/ starter, exhaust | $5,143 |

| 3502 inline WC twin | geared | 60 hp @ 5000 rpm | 79 lb wo/radiator, w/ starter, exhaust | $5,480 |

| 3503 inline WC twin | geared | 70 hp @ 6500 rpm | 79 lb wo/radiator, w/ starter, exhaust | $6,327 |

| 3002 flat-4 | geared | 80 hp @ 5500 rpm | 105 lb fan cooled w/ starter, exhaust | $9,983 |

| 3003 flat-4 | geared | 100 hp @ 6200 rpm | 105 lb fan cooled w/ starter, exhaust | $10,500 |

Electric

Pipistrel offers a complete battery-electric propulsion package, essentially identical to the one installed in the company’s factory-built aircraft. The system is available with two choices of battery storage capacity, a charger, battery management system, motor controller, and of course the electric motor. Pipistrel can also supply a prop and, if desired, the necessary hardware and controls for a retractable motor arm like the one installed in the Taurus Electro motorglider. The system certainly brings new meaning to the phrase “plug and play.”

Pipistrel offers a complete battery-electric propulsion package, which includes the motor and all other necessary components. (Photo: Matjaz Milavec, Pipistrel)

We hope you enjoyed the 2018 Engine Buyer’s Guide. If we’ve made an error or missed any obvious sources of propulsion (within the stated limits), send an email please, and we’ll endeavor to do better next time. Until then, fly safe!

Electric

| Engine Model | Drive Type | Horsepower | Weight | Price |

|---|---|---|---|---|

Pipistrel Aircraft | US website | |||

| 30 Ah 7.10 kWh Electric Propulsion System | direct | 40 kW takeoff, 30 kW climb | 165 lb with batteries, motor, and controls | $25,250 |

| 40 Ah 9.70 kWh Electric Propulsion System | direct | 40 kW takeoff, 30 kW climb | 200 lb with batteries, motor, and controls | $29,720 |