I’ve spent so much time at the nose of my GlaStar, what with the engine change and all, that I was starting to get bleary eyed. It happens, and sometimes when it does you miss details in the haze of work. Fortunately, this time I caught something at the right time.

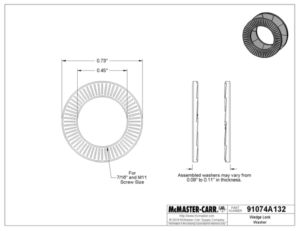

As I work to break in and tweak my new Titan IO-340 engine, I’ve been changing pitch settings on the Sensenich ground-adjustable prop. That’s easily done thanks to the prop’s use of Nord-Lock self-locking washers. No need to torque then safety-wire the bolts that hold the blades into the hub with every change of pitch. Love that part…

On this day, I’d decided to change the clocking of the prop as well as try a new pitch setting. Builders say that if you place the prop so that it points to the 11 and 5 o’clock direction when the engine comes to a stop it’ll have lower vibration than other orientations, a result of where the prop blades and crankpins line up. I wanted to test the theory.

In the Sensenich, there are eight bolts on the face of the hub, four long ones that extend into the crankshaft or, in my case, the Saber prop extension. Four more clamp the blades outboard of this. If you’re counting, you know there are two more, and these live inside recesses on the back part of the split hub. They’re left undisturbed by pitch changes and so only come out when you remove the entire hub.

I was also planning to replace the Nord-Lock washers. I don’t have a lot of experience with them and they seemed to be working fine, but I didn’t have a good idea of what to look for when they’re worn to the point they aren’t able to resist fastener movement. Nord-Locks are available from Sensenich as well as my go-to hardware store, McMaster-Carr for a very reasonable price. Erring on the side of caution, I decided to put new ones in when I changed the prop clocking. I’d removed all the bolts, changed the hub orientation (actually remembering to move the spinner backplate, too, so that the blade cutout alignment was maintained) and then fitted new Nord-Locks.

All went well until I realized that one of the two bolts that would later be hidden wasn’t protruding far enough through the threaded inserts on the back face of the prop extension. Hmm. I thought for a moment that I’d mixed it up with one of the four outboard clamping bolts, but they’re all the same length. Hmmmm. I had started the torquing process but stopped part way. Even at half torque, the threads were uneven. It had to be something.

I pulled the bolt wondering if I hadn’t somehow missed part of the Nord-Lock, though I was fairly sure I hadn’t. When new, these washers have an adhesive between the two faces and they act like one washer until you torque them for the first time. So, look at the other one. The single Nord-Lock was on the shank of the bolt and the interior socket of the hub looked fine. It wasn’t until I’d turned to my mobile work bench and noticed that my pile of old Nord-Locks was missing one half. Ah-hah! Look more carefully inside the hub and there it is: half of one of the washers, which looked a lot like the hub itself. Why? The Nord-Locks turn a little dark between their halves and the lighter serration on the outward-facing surfaces can dig into the aluminum hub and make the area look a little shiny. I’d become accustomed to this trait and just didn’t notice when half of the washer stayed with the hub. They looked enough alike that I’d not noted the difference at a glance.

Mystery solved, and another lesson to remember: If something doesn’t seem right, keep going until you understand the reasons why.

The phrase, “Huh… that’s weird…” can be one of the most educational, or the most dangerous things in aviation, depending on how you react to it. And yes, I speak from personal experience!

Exactly. It’s all what you do with it.

Your lock wire on the engine side looks like it was done wrong (bolt closest to the viewer) it looks like slacking the bolt will loosen the wire. May be optical allusion in the photo.

Mike

It’s an optical illusion. The safety wire does angle down toward the other bolt, so it would be in tension if the bolt tried to back out.

I had never known of Nord Lock or wedge lock washers until I read this article, which stimulated me to study the science of lock washers and nuts. Amazing – nothing really works, not even metal lock nuts – except these wedge lock washers. Watch the Junker Vibration test videos on You Tube. These lock washers (which are really not expensive) should be used wherever mission critical fasteners are required. Even castle nuts and wired nuts can vibrate enough to lose compression tension.