While I see lots of recurring maintenance problems every day, tough ones that require some additional thinking for the Diagnosis column don’t always happen with the regularity that I would like. Just when I thought I wasn’t going to have anything for this month, a couple popped up that I get to share with you.

While I see lots of recurring maintenance problems every day, tough ones that require some additional thinking for the Diagnosis column don’t always happen with the regularity that I would like. Just when I thought I wasn’t going to have anything for this month, a couple popped up that I get to share with you.

The first has to do with my continued learning as a newly minted rotor-wing pilot. I continue to say new, even though it’s been a year and 160 hours of flight time. I still remind myself every time I get in the helicopter that I am inexperienced compared to my fixed-wing time. So it was one day last week on the way home that I found myself presented with an interesting problem.

Decreasing Airspeed

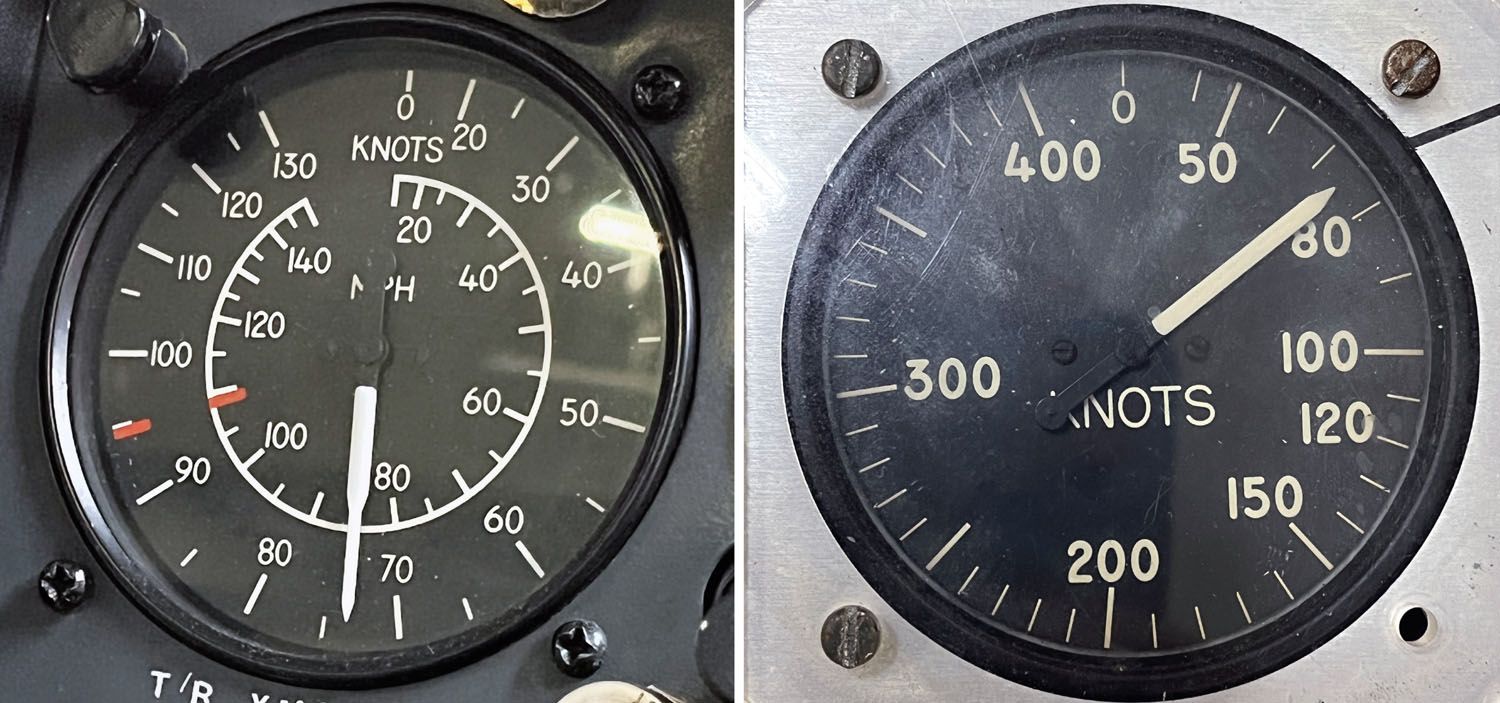

My usual practice after level off is to settle into a 65- to 70-knot cruise, which is usually accomplished with 21 inches of manifold pressure and 3100 rpm. I am constantly scanning inside and outside, as even with the friction lock on the collective, the manifold pressure and rpm can vary a little. Besides, the helicopter has all analog gauges with no audio warnings as I am accustomed to in the RV-10, so a good engine gauge scan is important. Since the training portion of helicopter flying is a lot of engine failure scenarios, I am still always primed for some such failure. So, there I was, flying along trying to enjoy the nice, clear blue day, and I noticed the airspeed was reading about 60 knots.

Hmm. I checked the MAP, and it was down about a half inch, so I corrected back to 21 inches and didn’t think much about it. Until the next scan about 20–30 seconds later. Airspeed was a little less than 60 knots and MAP was still the same. I sat up a little straighter and got my thinking cap on. From my 10,000+ plus hours of fixed-wing flying, I had seen three scenarios that caused a decrease in airspeed: 1) power reduction, such as carb ice, 2) airframe icing and 3) mountain waves/thermals.

The engine instruments all looked normal. I even waited for the CHT/EGT gauge to cycle through all cylinders to check the EGTs, which were all close to each other. Since the engine is injected, carb ice was not a suspect. One of the things you are always in tune with in a helicopter is the engine noise. It’s amazing how the slightest rpm change is noticeable, as it has a very distinct whine to it. There had been no changes in rpm, either audibly or on the gauge. One of the failure scenarios during instruction was a slight reduction of the throttle by the instructor.

I was in the clear blue sky, so airframe icing was not in the cards, nor was mountain wave activity. However, it was hot outside, around 85° F, so I did question thermal activity as being responsible, even though winds on the ground were basically light and variable. By the time I got through eliminating the potential causes and happened to glance at the airspeed indicator, it was now reading 55 knots.

I checked the ground speed on ForeFlight, and it was reading 75 knots. The view out the canopy confirmed to me I was doing 75 knots or so across the ground. I know, some of you are already wondering how I can tell the groundspeed visually. Well, I’m much lower in the helicopter at 700 feet, as opposed to an airplane at 3000 feet, so yes, it is easier to recognize groundspeed.

This was getting interesting now. I decided to do a quick 180° turn and check the groundspeed against the airspeed. The groundspeed remained at 75 knots, but now the airspeed was reading 50 knots! I finally decided I had an indication problem. I was only 5 miles from home, so I told myself to just use the normal power settings and use the groundspeed indication to keep it above 51 knots until over the runway. Helicopters have a height velocity envelope, which you need to maintain to properly execute an autorotation in the event of an engine failure. Yes, you can hover out of ground effect at some very high altitudes, but it leaves you pretty exposed if there is a powerplant or drivetrain failure.

Everything worked out fine, but I sure was curious. I convinced myself it could be a plugged pitot tube, as it is that time of year in the Southeast for mud daubers. Once I landed and pulled it in the hangar, I shined a flashlight into the pitot tube. Sure enough, I could see little bits of dirt way down inside. I disconnected the tubing from the aft side of the pitot tube and tried to force a cable tie through the tube, to no avail. It took a stiff piece of 10 AWG wire to clear it, followed up with some compressed air. I then reconnected the tubing and connected it to the pitot-static tester, which now showed a fully functioning airspeed indicator in the cockpit. Yea! I also now have a pitot cover for it. In 31 years of flying in Georgia, that is the first mud dauber that has found any of my aircraft pitot tubes. I’m thinking it won’t be the last, as I have heard many other pilots complain about them.

Everything worked out fine, but I sure was curious. I convinced myself it could be a plugged pitot tube, as it is that time of year in the Southeast for mud daubers. Once I landed and pulled it in the hangar, I shined a flashlight into the pitot tube. Sure enough, I could see little bits of dirt way down inside. I disconnected the tubing from the aft side of the pitot tube and tried to force a cable tie through the tube, to no avail. It took a stiff piece of 10 AWG wire to clear it, followed up with some compressed air. I then reconnected the tubing and connected it to the pitot-static tester, which now showed a fully functioning airspeed indicator in the cockpit. Yea! I also now have a pitot cover for it. In 31 years of flying in Georgia, that is the first mud dauber that has found any of my aircraft pitot tubes. I’m thinking it won’t be the last, as I have heard many other pilots complain about them.

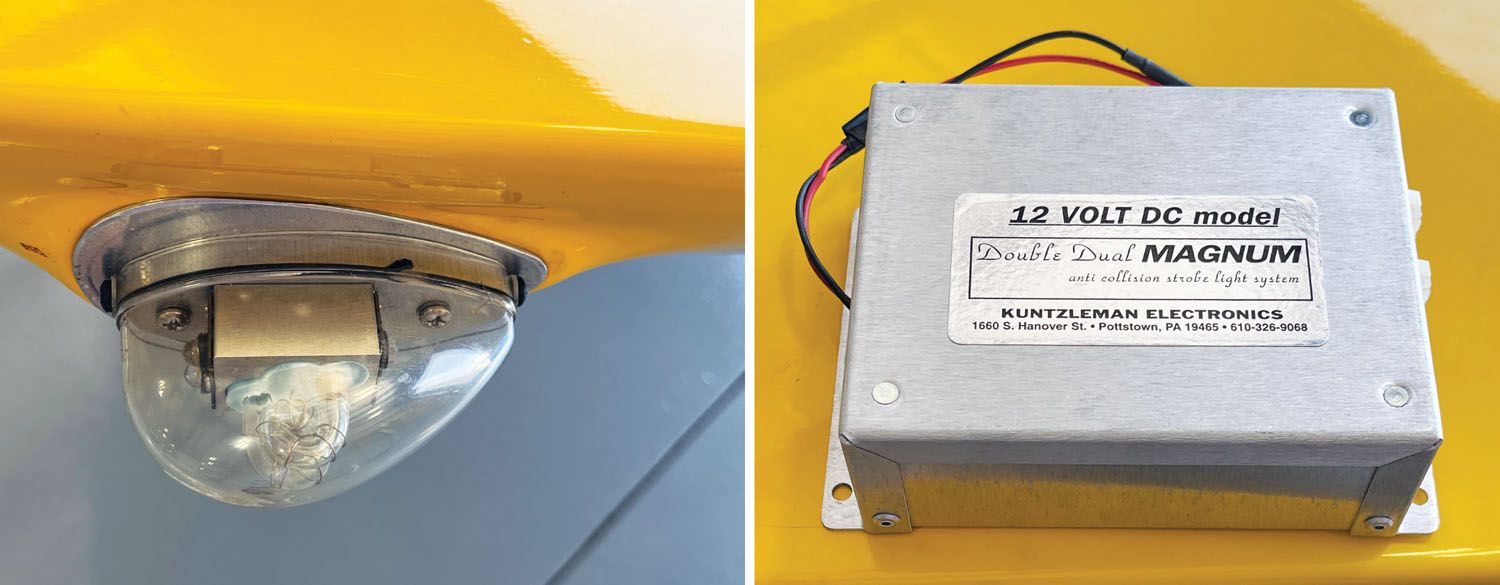

Where’s the Strobe Power Supply?

The second problem had to do with an RV-7 that came to us for a CI. It had a pretty long list of discrepancies, which I won’t go into here. One of the last things we check is that all switches and lights work properly. In this case, neither of the wing strobes worked. Usually, when both fail at the same time, it is the strobe power supply that is the culprit. However, neither of us could remember seeing a strobe power supply when the fuselage was opened for the inspection. That usually means the power supplies are mounted in the wingtips with the strobe. Removing the strobe light from the right wingtip and peering into the wing revealed no power supply. Hmm. On a whim I removed the left strobe and peered into the wing, which revealed a power supply. Removing the wingtip showed the power supply was a dual supply and in fact was wired to the strobe on the right wingtip as well.

I checked that there was 12 volts at the supply, and there was. Luckily, Aircraft Spruce had an exact duplicate power supply, which fixed the problem.

I hadn’t seen one wingtip-mounted power supply running both strobes before, but just like the helicopter airspeed indication issue, there is a first time for everything.

It just goes to show you that we are always learning.