There’s an old engineer’s quote that says “Perfection in design comes not when there is nothing left to add, but rather, when there is nothing left to take away.” Another interpretation of good engineering practice is to “make things as simple as you can – but no simpler.” I try to follow these dictums in everything I design or work on – but if you see my three RVs that are fully IFR capable, you might not think it. Redundancy breeds duplication, and duplication breeds extra wiring. Designing things as simple as I can for the function desired is a challenge – but it becomes a lot simpler when the airplane’s function is… simple.

Such is the case for our Xenos motor glider. The aircraft has a single AeroVee engine, which you shut down after climbing out and finding lift – so you can forget about flying in the weather. I am still a believer that modern electronic instrumentation is more reliable and cost-effective than steam gauges – but there is nothing that says electronics have to be complicated.

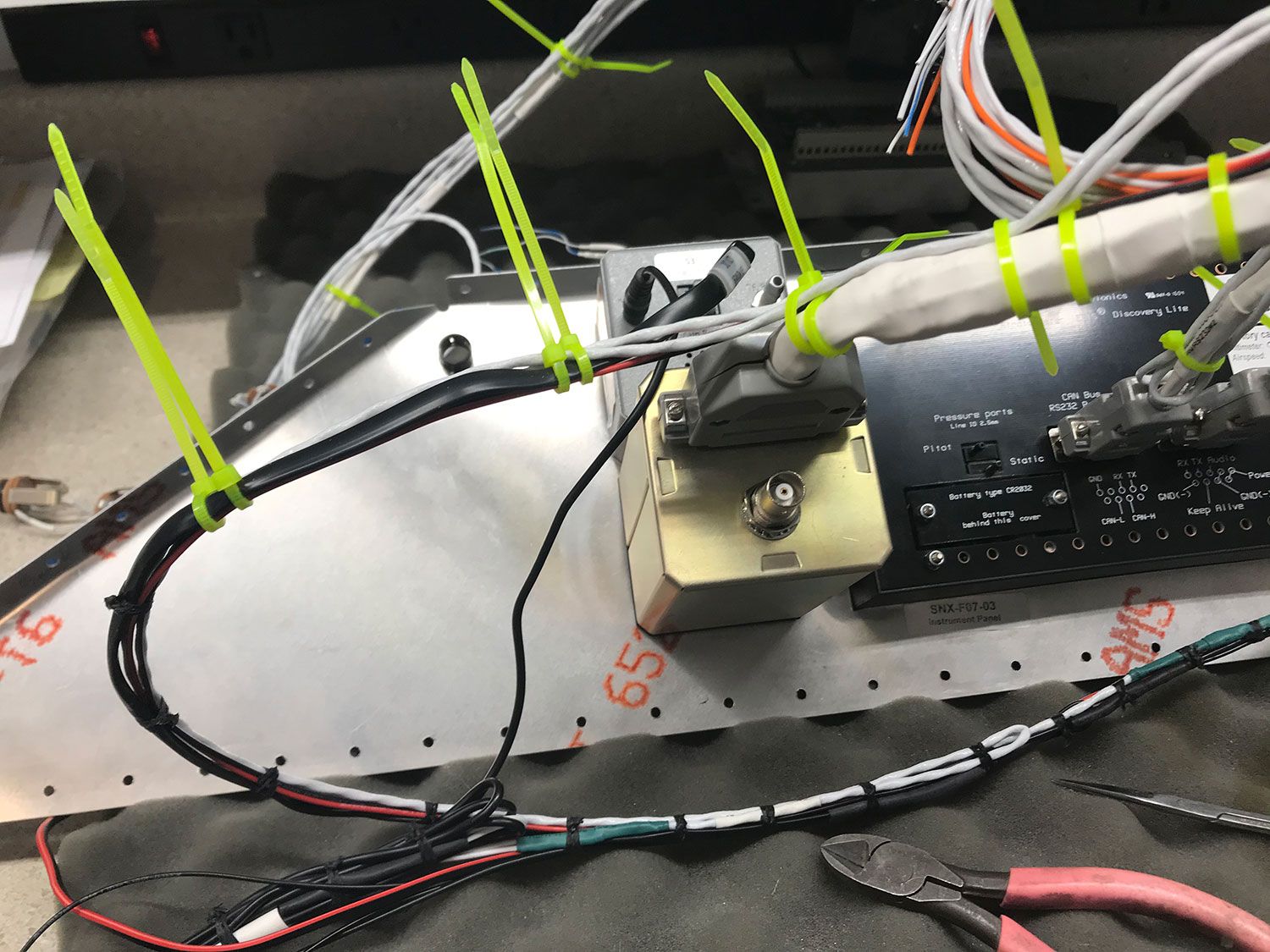

So here is the back of the Xenos panel – a single EFIS box, a radio, and an electronic variometer for soaring. We chose MGL equipment for this airplane, with pre-made harnesses for each box that interconnect with CAN bus cables and a couple of serial and audio lines. Power layout is dirt simple, with half of the switches for the engine ignition and starter. The biggest bundle of wires is, as usual, for the headset jacks.

I took these pictures in the middle of cleaning up the finished harness, which in my shop means replacing the temporary, cheap wire ties I use for layout with nice waxed lacing cord. Especially in an airplane like this where future wiring work will be done laying underneath the panel, I like the smooth nature of lacing rather than the razor-sharp ends of tie-wraps just waiting to scratch your hands.

I also like building panels on the bench, complete with nothing but pigtail wiring that goes elsewhere in the ship. In this case, that’s just a few wires to the engine data box and remote magnetometer, plus power and ignition running to the firewall. It’s a clean, simple way to build an airplane – just the way good engineering practice dictates.

“in anything at all, perfection is finally attained not when there is no longer anything to add, but when there is no longer anything to take away….” Antoine de Saint-Exupery