I would chance a guess that most aircraft kits are primarily built by one person. While some projects are constructed by groups or teams of builders, the majority are single-builder completions. These lone builders still ask for help from others when it is needed. For example, some tasks require more than two hands. But when all is said and done and the time for inspection has arrived, usually one person will sign off on the build and take responsibility for the quality and completeness of the aircraft.

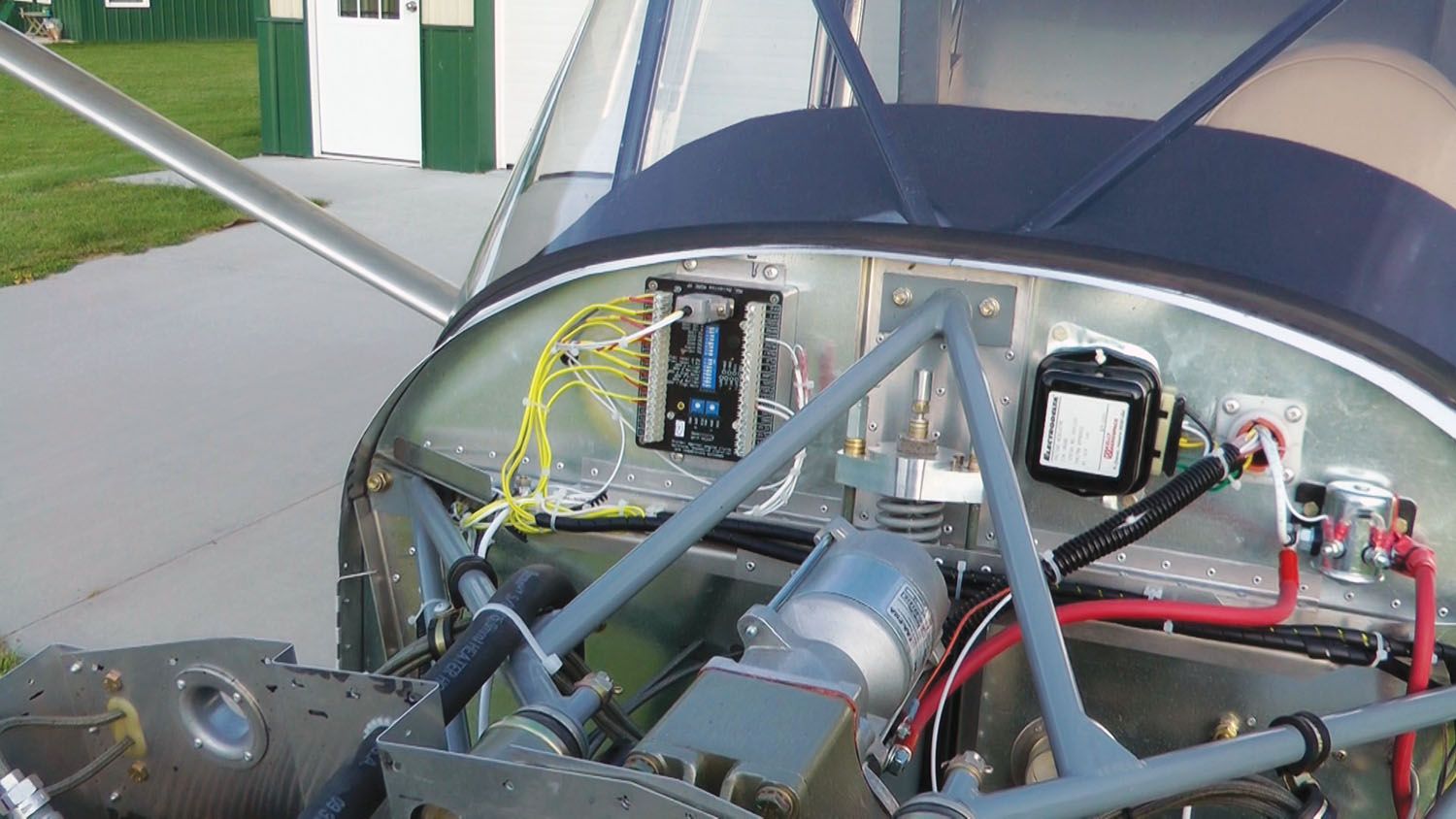

When your aircraft is ready for either an FAA inspection or its first flight, you are going to want a good second look at your work in order to reduce the chance of a problem in flight. Why? Even the best builder is only human! We all make mistakes that can range from simple forgetfulness (cotter pin missing) to misreading the plans (wrong bolt size). Considering the complex nature of an aircraft—moving parts, electrical wiring, plumbing for fuel and oil—the chance for construction errors is immense! If you welcome a second look at your project, then consider yourself a smart builder and pilot.

How do you find a good pair of second eyes to review your aircraft construction? The number one choice would be to find an EAA technical counselor. These are experienced volunteers designated by the Experimental Aircraft Association who are adept at this very task of building inspection. Check the website at www.eaa.org to determine if one is located near you. Another good option is to see if there is an EAA chapter club in your area. Usually one or more members of these chapters are experienced in Experimental aircraft building and can provide an excellent set of second eyes. It goes without saying that EAA is a great resource for meeting builders like yourself and getting help. But what do you do if, like me, there is no local chapter in your area that you can use?

While the next best choice is to find another aircraft builder, keep in mind that almost any set of second eyes can be better than nothing. But let’s increase our odds of quality. For example, you may have a friend who works on cars, boats or motorcycles as a hobby or profession. Although they may have never seen the inside of an aircraft, their experience with mechanical and electrical devices is perfect for the task at hand. Cars, boats, and motorcycles also fail for many of the same deficiencies that cause our homebuilts to fail. One shortcoming of using a non-aviation friend is that they may not be aware of specific aircraft procedures we use, like proper safety wire techniques on props, etc.

Ask your friend to start looking for obvious problems on your aircraft, like missing or loose rivets, bolts and cotter pins, binding or travel issues in any linkages and moving parts, sharp edges that might damage cables or humans, or wiring and electrical connections that are suspect. The routing of wires and cables must not allow chafing to occur. The list can go on and on, but these suggestions allow your inspector friend to focus on obvious safety issues. Let your friend know to not hold back on their critiques—you want to hear everything.

Usually, it is the simple, obvious things that get us into trouble. The missing nut, cotter pin, rivet or screw. Your eyes can scan the completed aircraft a dozen times and still not see a missing component. A second set of mechanically minded eyes will pick out the error immediately! I know this from experience. You will ask yourself, how did I ever miss that? As an example, a slightly binding moving linkage that you thought wasn’t that bad may make your inspector friend cringe from their point of view. Take lots of notes on your friend’s feedback and consider each comment that is made.

It makes sense to ask even another mechanically minded friend to repeat this exercise on another day to get a different perspective on your work. A third set of eyes continues to add value. You will approach your FAA inspection or first flight with great confidence knowing that obvious errors in your construction do not exist. The last thing you want to think about during your first flight is whether you forgot something that might ruin your day. The eyes have it! Plane and simple.