I want to present a strategy and method to get a few more prospective airplane builders off the fence and into the workshop. This is targeted to those of us who may not be ready for the big financial and time commitment that is required for buying and building an aircraft kit. While there is no magic bullet for drastically reducing the cost of the completed aircraft kit, there are ways to ease into the project while never spending more than you can afford along the journey. And this can be done without a visit to the bank for a loan! Special feature: You can decide to completely bail (or take a pause) from the project as early in the process as you desire, with no kit or subkit to sell if things don’t work out. You decide the financial size of your commitment to building.

How does this work? It turns out that the secret to this process is found with kit manufacturers that allow you to purchase a complete kit—or purchase plans for the very same kit. Very few manufacturers allow you to do this. The plans they sell are designed to allow you to build the aircraft from “scratch,” meaning that enough detailed information is provided to allow the builder to take raw materials and create the very same parts that are included in the kits. This is called scratch building or plans building.

Why would a kit manufacturer sell just their plans and forgo a complete kit sale? While some money is made on the sale of the plans, they know not everyone is ready or financially able to purchase a complete kit. And there is a large population of scratch builders who evaluate aircraft by way of examining plans and would never buy a kit anyway. There is another less obvious reason, too. We’ll explore that in a moment.

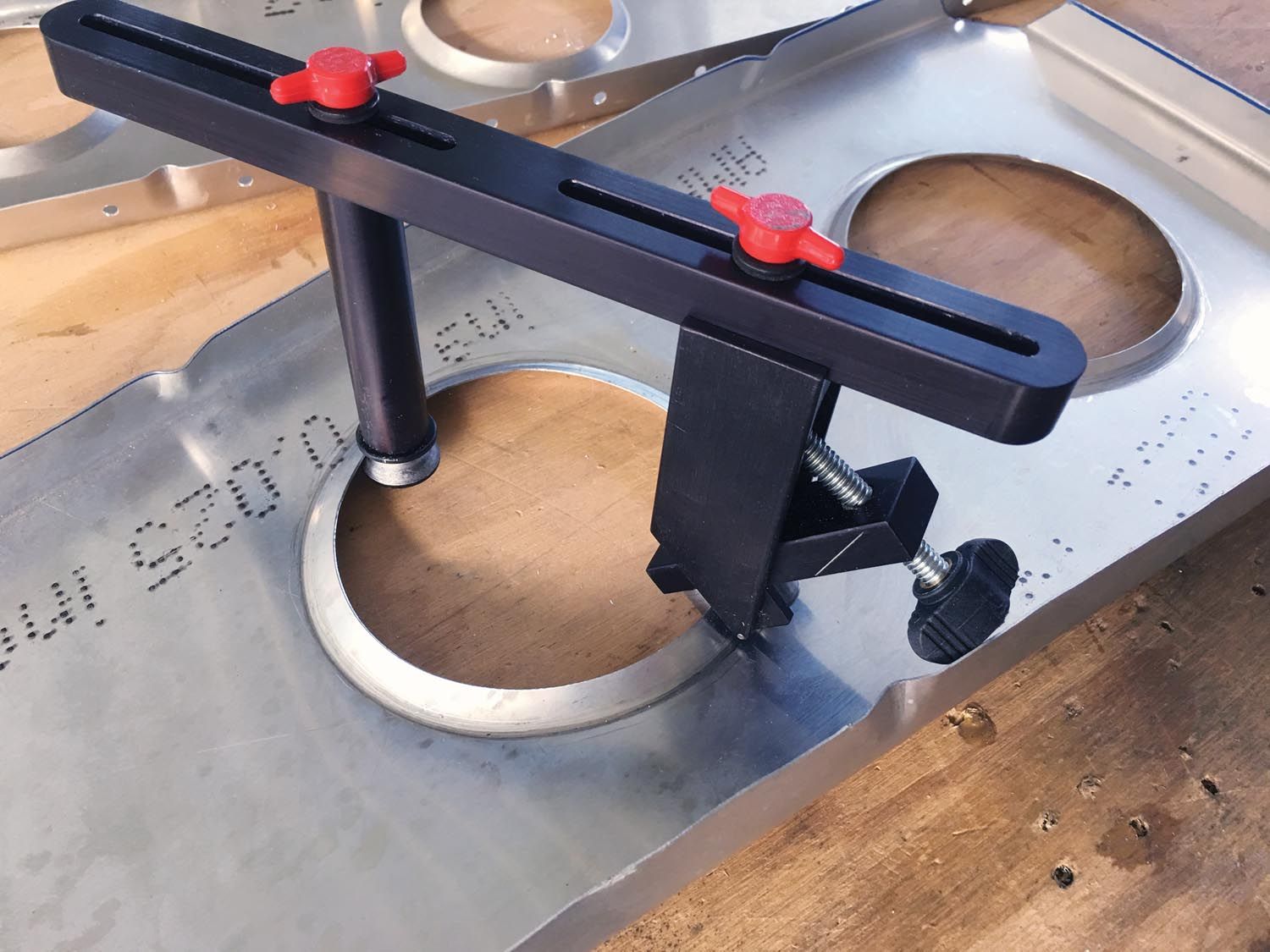

We need to make one more demand from the kit manufacturer that sells plans for their aircraft. They must also be willing to sell us any individual part from that kit so we can build the aircraft one part at a time. Why is this critical? Because scratch builders may not be able to make all the parts themselves. Some parts are complex and difficult to make (wing ribs as an example). Some parts may require welding, and we may not be good welders. Additionally, we may not have all the tools to build certain parts because of their size or complexity.

The beauty of choosing an aircraft kit from a manufacturer that provides plans and parts à la carte is that we can start today building our dream aircraft with just an investment in plans and limited materials for the first part. Move on to the next part when ready and one by one the aircraft will eventually be finished! At any time that you find a part is not within your technical ability to create (based on reasons we mentioned), make a note and purchase these parts at a later time.

Very few builders in this world can fabricate every part in the plans. Over the years, I have had the honor to meet many of them. How gifted they are in their abilities to assemble a flying aircraft from raw materials. But the rest of us—we can be successful by making the easier parts ourselves and purchasing the ones we dare not.

For example, I have tried making metal wing ribs and was successful—once. The subsequent ribs I created (the aircraft needed a few of them) would not match the original in proper dimensions. They were either too big or too small in one direction. All ribs must be very close in size (check the plans) or else your finished wing is going to have problems. You quickly learn as a scratch builder that technique and precision are not always related skills but both are required.

There are many parts a novice can make (those with simple bends for example), and there will be many more parts a greater experienced builder can make. We all bring different levels of skill/talent to the workbench and will yield different results. Ultimately, no one will know which parts were factory built versus handcrafted on your completed plane.

Who Ya Gonna Call?

Which aircraft kit companies sell plans and individual components? Two come to mind that I have dealt with: Zenith Aircraft and Sonex. Visit their websites and familiarize yourself with their aircraft models and then check to see if plans are available for the model you like. Purchase the plans and enjoy several days reading them. What can you learn from the plans? Everything! You’ll see what types of materials, tools, dimensions, etc., will be required.

Pick a simple part anywhere from those plans. Some are as simple as a straight cut from a flat sheet of aluminum. Order a quantity of material from your local supplier and create the part. Congratulations! You have started the aircraft building journey with minimal financial investment and still have the option of getting out of the project at any time. Label and record your part as completed and move to the next one. Your aircraft is nothing more than the total collection of all the parts on the plans. (Some assembly of those parts is required, too!)

You can now see that aircraft companies that sell plans also sell a lot of parts to scratch builders. It makes good business sense and helps a lot of builders who might not otherwise be able to participate in aircraft building. My experience with Zenith Aircraft was that their individual parts were priced in a manner that their sum total cost (if you bought all of them) was very close to the full kit price. In other words, there was no penalty for individual part purchases other than the obvious shipping costs.

If you are on the fence regarding committing to the dream of building your own aircraft, look at those companies selling plans and parts. Pick an aircraft model that looks good to you and then order up the plans. It is just one part at a time. If you don’t have the tools or expertise to create a part, make a note to order one when your funds are available. Save money and ship those parts together. You can get started today on your dream. Plane and simple!

Great article. There is something very exciting about unrolling those plans for the first time, making the first small material order, and then fabricating that first part.

I think kit manufacturers can almost guarantee additional part and sub-kit sales as reality strikes the scratch builder and they move into the hybrid model.