Young pilots flying fast military aircraft need ejection seats to fling them away quickly if problems occur. But us old guys flying slow homebuilts sometimes need ejection seats, too. Aging is a slow foe; things feel OK forever, but suddenly you realize it’s caught up and you’re hollering, “Mayday!”

Take my case. For 25 years, I’ve been lifting myself vertically out of the open cockpit of my Fly Baby with a combination of arm and leg leverage. But knee problems took one leg out of the mix, and made the first few inches of lift difficult. I had to brace myself on one of the rudder pedals with my good leg, and I didn’t like the extra wear and tear on a control system.

What I needed was an ejection seat. Not a youngster’s rocket-equipped Martin-Baker to fling me over the hangar roof, but a much slower one that would boost me those first critical inches. And, hopefully, it would be usable more than once.

Examining the Options

To my surprise, I found there already was a lightweight General Aviation ejection system. Competitive sailplanes tend to gather within thermals and stand a greater chance of midairs. Following resulting structural failures, G forces can pin the pilots in the seats of their gliders. DG Flugzeugbau’s NOAH emergency-assist device uses an airbag to force the pilot out of a sailplane cockpit.

But NOAH wouldn’t work for me. It’s a one-shot emergency system, and the $3,500 price was a third of the value of my airplane.

What to use, then? I looked at scissor-lift tables, with an eye toward adapting the lift portion to the Fly Baby cockpit. All of them were too big and too heavy. Inspiration finally struck: What about those lift chairs for the older folks? Could I adapt that lift mechanism for the airplane?

Up She Rises

The Uplift seat is sold as an assist to senior citizens. Use as an aircraft ejection seat is probably not approved by the manufacturer.

I stopped by a local medical-supply store, hoping to examine some of the mechanisms used by the seats for those with limited mobility. Instead, the manager showed me the Uplift Technologies Power Seat. The Uplift is a single, self-contained package that is designed to be placed atop any type of chair, plugs into a wall outlet, and lifts and lowers the occupant about 8 inches. It’s designed to be portable, so the weight is low enough to allow a senior citizen to carry it around.

It was a perfect solution, with no need to disassemble and attempt to modify the mechanism. But I was concerned about the length. Would it fit in the available space without interfering with the control stick?

I confessed my potential use, and my concern about length, to the store manager. “Is your plane at the airport just down the road?” he asked. “Take it down and see if it’ll fit!”

With the seat fully raised, the inside of the mounting surface can easily be accessed. The label on the panel was partially scraped away to access the screws to permit inspection of the motor.

The Fly Baby has an extremely basic seat interface, just a flat, framed area in the cockpit floor. The Uplift’s flat bottom lay atop it without a problem, and the length and width were perfect.

I couldn’t resist. I ran an extension cord to the cockpit, plugged in the seat, and hopped in. A flick of the lever, and the seat rose smoothly, letting me easily grab the cockpit sides to push the rest of the way out. Back to the store, plastic on the counter, and $150 put me in possession of the seat.

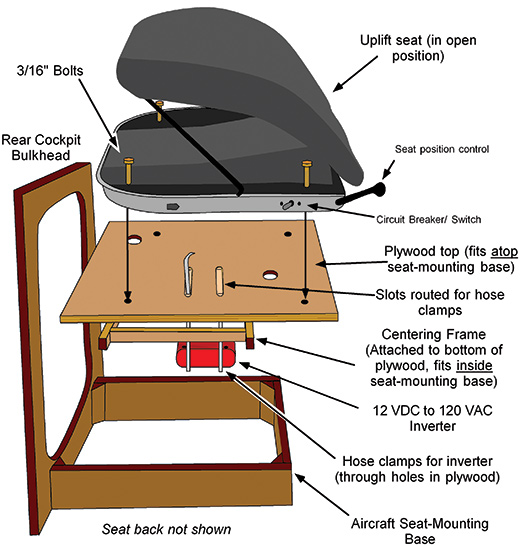

An exploded view of the seat assembly. The seat back is attached to the plywood base using a piece of piano hinge. The piezo warning buzzer (not shown) can be mounted anywhere on the bottom of the plywood. Note the holes in the plywood to pass the power cable for the seat and the 12-volt power from the switch.

Power Issues

The power cord was a problem, of course. My initial hope was that I could replace the motor with a 12-volt DC unit. Accessing the motor was easily achieved, but finding a 12-volt unit that would fit the same mounting holes and carried the same gear on its shaft would be problematic.

The combination circuit breaker/switch and the Molex power connector were installed on the right side of the seat’s base. The plywood mounting base is also visible.

My fallback was an automotive inverter. Many companies sell units that plug into a car’s cigarette-lighter port and supply wall-plug power to electrical gizmos. Some of these can be purchased for $20 or less.

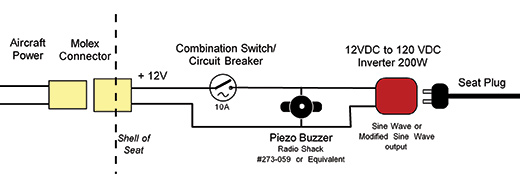

How big an inverter? The Uplift seat is rated at 120 volts and 0.6 amps, or about 72 watts. Considering inefficiencies of the inverter, a 200-watt inverter seemed the minimum size. Fortunately, it only runs a few seconds per flight.

Research unveiled an issue when using an inverter to operate an appliance with a motor. The cheap inverters produce a square wave, fine with most electronics (which convert it back to DC anyway) but motors can’t use it. Units producing a sine wave are a bit less common and more expensive.

I found a 200-watt inverter with a “modified sine wave” output for about $45. A quick test with a battery showed the power was acceptable to the seat.

The seat has a flat bottom that will easily adapt to most structures. The oval hole is the carrying handle.

Assembly

The initial plan was to place the Uplift directly atop the existing seat-mounting frame, adding just a few brackets to keep the seat in place. After a bit of consideration, I reluctantly abandoned that approach. The frame would have concentrated the weight into narrow portions of the seat base, and I was concerned the plastic would eventually crack.

Instead, I used a piece of half-inch plywood, like the stock seat. A wood frame on the underside of the plywood fit inside the seat-mounting frame to hold the unit in place.

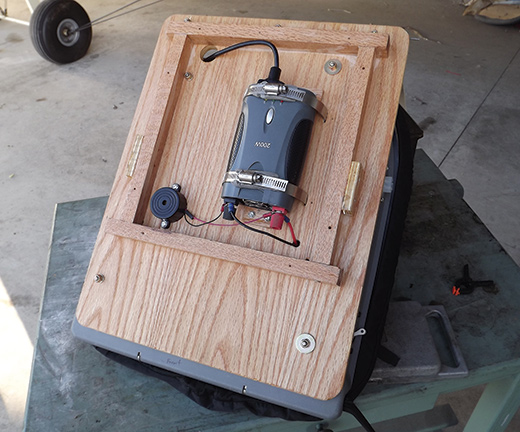

The inverter had a flat mounting surface with small feet. I installed it upside down (e.g., an inverted inverter) below the plywood, held in place by stainless-steel hose clamps (with padding) through holes in the plywood panel. The top of the plywood was shallowly routed out so that the clamps sit flush with the surface. The surfaces were curved and smoothed with chisels and sandpaper to avoid stress points on the hose clamps.

The bottom of the seat-mounting base, with the 12 VDC to 120 VAC inverter and the power-on warning buzzer. Hose clamps hold the inverter in place, with small wooden blocks to keep the inverter from shifting under the padded clamps.

With the seat in the full-rise position, access to the inside of the plastic exterior shell was easy. A Molex connector was installed on the outside of the shell for power, as was a combination switch/circuit breaker. A bit of bench testing showed about a 4-amp draw, so I used a 10-amp breaker left over from a recent electrical-system rebuild.

A small computer label-maker was used to generate drill templates. This label marks the holes for the combination switch/circuit breaker.

Electrical Cautions

Testing showed that the inverter drew about half an amp even when not running the seat, so I didn’t want to leave it running all the time. Plus, I suspected it might induce a lot of garbage in the aircraft’s electrical system, and I did not want to have the avionics exposed to it. There’s probably little risk, but I didn’t feel like betting that my $45 inverter wouldn’t blow out a $2,000 transponder.

For a reminder to turn off the power, I added a piezo buzzer from Radio Shack. Connected to the inverter’s output, it beeps loudly whenever the inverter is powered on.

An electrical schematic of the seat assembly.

My recent electrical system rebuild included an avionics Master switch, so I make sure to have it “Off” before turning on the inverter. Had I planned the seat during the rebuild, I would have used a DPDT switch for the avionics Master to ensure the seat could not be powered on unless the avionics Master was off. I could install a small relay to perform the same function, but I’m content with handling it via the checklist for now.

The seat in position in the aircraft. The plywood seat back is temporary.

Testing

The seat works. Turn on the aircraft Master switch, verify the avionics Master is off, and flip on the seat-power switch and hear the beeper. Pull the seat lever up, and the 8 inches of rise makes it easier to clamber out of the cockpit.

The seat runs a bit slower on the inverter than it does on wall-plug power, something research had mentioned. It takes about 25 seconds for full rise. It’s a subtle motion, not really apparent other than my adjusting position in the cockpit as the sides drop away. One friend said, “You looked like you had a bad case of gas.”

Currently, I’m working on comfort issues. The stock 3-inch-thick astronaut-foam cushion put me up too high, so I reshaped it with an electric carving knife. I’m currently experimenting with thinner sections of foam to strike a good balance between height and comfort. Also, the current back is just a piece of straight plywood and is definitely too uncomfortable to be retained.

The Bottom Line

The bottom line was surprisingly reasonable. Cost? Less than $250, including the seat, inverter, buzzer, connectors and associated wood.

Weight? The seat-lift mechanism itself weighs 12 pounds, and the inverter was less than a pound, plus a pound or two for the wood and other bits. But my old seat was surprisingly heavy, and the net weight gain was only 9 pounds. The simple operation of the seat, including its dirt-simple flat-bottom interface, would probably make it suitable for any number of other homebuilts.

Eventually, a fancy new store-bought knee is probably in my future. Hopefully, my “Moron-Baker” ejection seat will let me keep flying until then.

The seat-lift mechanism in action.