Here’s a short little tip for making your composite work a little more efficient.

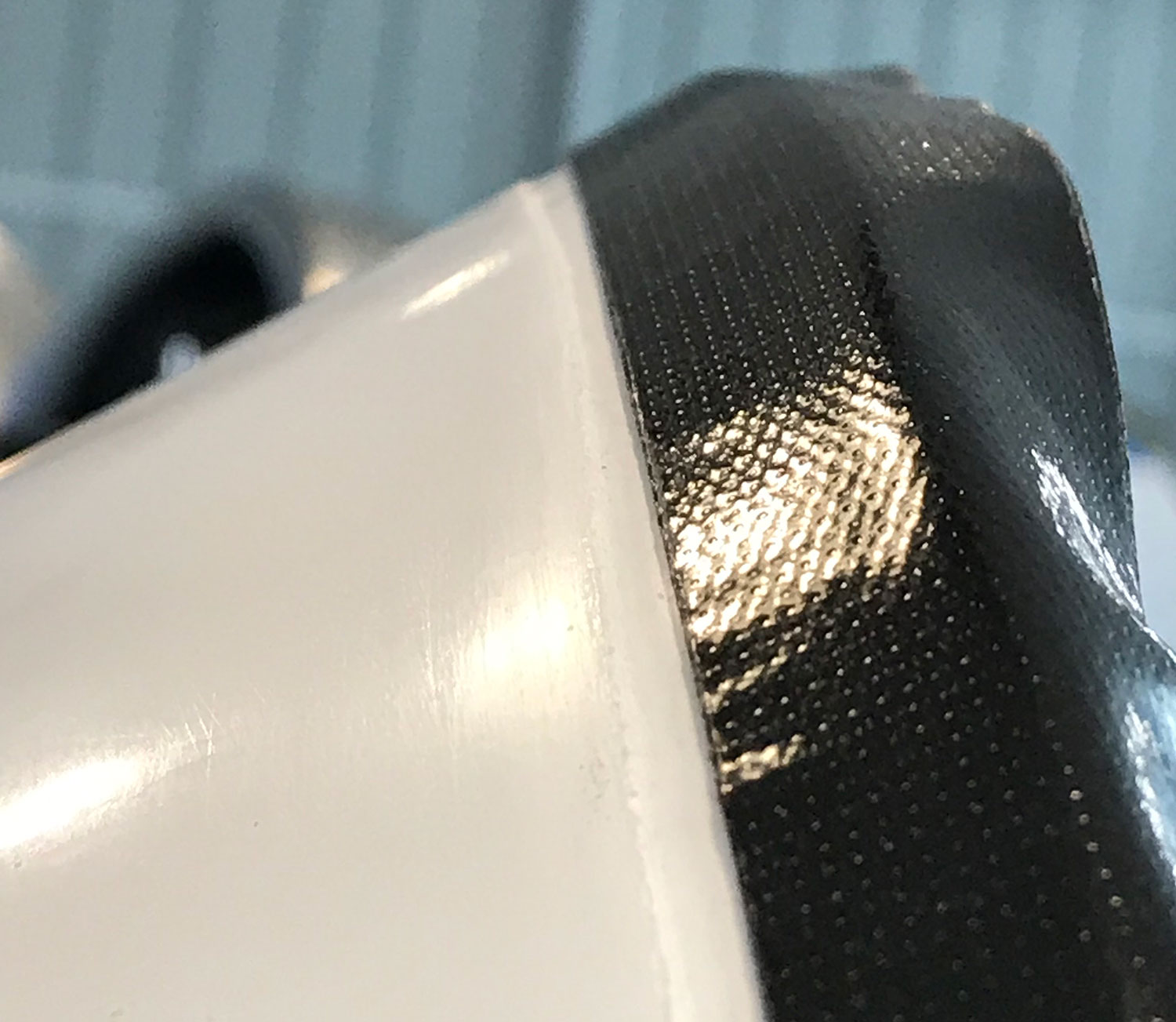

How many times have you started a work session by mixing up some resin, adding flox or micro, and then slathering it on your project to fill depressions, holes, or other blemishes? The next step, of course, was to stand around waiting for it to cure. Sure, you could have gone on to do other things, but like most of us, you probably left the fiberglass work until the very end of your airplane build (I am excusing those who are building all-glass airplanes – they already know all these tricks, and are proud not to have to deal with all of that aluminum dust…) – so you don’t have a lot else to work on while waiting for the goop to harden.

Well this is what I do. Start the work session by doing all of the sanding and shaping from the previous epoxy mixing session. Then, before you quit, put on more goop (because you found you still had some depressions or pinholes to fill). Go to bed, but set your alarm clock for an hour before usual. When you get up, you’ll have more hardened epoxy to work with – sand and shape that, and apply more (because you know you have to), then go about your daily activities. When you next appear in the shop, you have more hardened epoxy – lather, rinse, repeat.

You get your glass work done much quicker this way – but you might show up at work with sanding dust all over your face, so be prepared for the funny looks.