Throttle-body injection (TBI) systems aren’t new, but Rotec Industries of Australia has spiffed up the technology while bringing its system in at a surprisingly modest price. What you get is something less expensive than a carburetor and yet better than a carburetor because it makes an end run around icing and other issues that owners of carbureted aircraft are familiar with.

The System-It’s Simple

Throttle-body injection systems aren’t fuel-injection systems in the conventional sense because the fuel isn’t shot into the intake system under high pressure. With the Rotec TBI, an ordinary low-pressure (2 to 6 psi) electric fuel pump is recommended for safe operation, but the system will work fine under gravity-feed fuel pressures of as low as 0.5 psi. Mechanical fuel-injection systems such as the Bendix/Precision require 20- to 40-psi inlet pressure to operate properly.

Nor is Rotec’s TBI quite like a carburetor, because instead of the fuel being drawn into the engine through a single jet, fuel is drawn out of a bunch of very small jets aligned along the length of a single metering tube that spans the width of the throttle-body throat. This is where a TBI is more like a carburetor than conventional fuel injection; insertion of the fuel takes place in the throttle-body throat, not further along in the intake tract.

Engine power is controlled by air volume, and in the Rotec TBI airflow is controlled by a slide that the operator moves back and forth across the throttle-body throat. At full power, the slide is fully retracted, allowing maximum airflow and exposing all of the holes in the fuel-metering tube. At idle, the slide is extended, closing off the throat opening and reducing the number of metering-tube holes that are exposed to airflow. Fuel mixture is controlled by rotating the metering tube through 90 of rotational travel via a control arm thats connected to a simple push-pull control.

Because the TBI system requires only a slight negative pressure to start fuel flow from the metering-tube holes, there is no venturi in the throat such as is required for carburetors to develop sufficient negative pressure to draw fuel out of the main jet. For this reason, the TBI airflow throat is less restricted and has greater flow capacity than a comparable carburetor. This characteristic in combination with better fuel atomization results in slightly more power and lower fuel consumption than with a common carburetor.

Looks Like an Ellison

Yes, it does. Here’s why. In 2000, brothers Matthew and Paul Chernikeeff built their first seven-cylinder 110-horsepower R-2800 radial engine under the Rotec banner. In 2005, they finished work on their second engine-the nine-cylinder 150-hp R-3600 radial. As they got more feedback from operators and looked for ways to strengthen their product line, they realized that while the Bing altitude-compensating carburetors they were using were adequate, they and their customers weren’t totally satisfied.

We tested an Ellison and found it to be perfect. It was easy to start up, ran smooth at all settings, and made more power for the same manifold pressure settings. We were very impressed, says Paul Chernikeeff.

The Rotec designers thought they could build a TBI-based system-also called a variable venturi system-that was less expensive than the Ellison by using modern computer-controlled machining processes to produce high quality components from aluminum billet. Ellison components are sand-cast aluminum.

In the end, the brothers were right. Rotec’s TBI units are reasonably priced and look good enough to be displayed on a living room coffee table.

What’s Your Power?

The Rotec TBI is built in four sizes. The TBI-40-S has a standard spigot-style mount for installation on Jabiru, Rotec and Rotax engines. The TBI-40-2 has an aviation flange (size 3) for smaller engines such as the Lycoming O-235 (108 to 115 hp). The TBI-40-3 has an aviation flange for engines such as the Lycoming O-320 (150 to 160 hp), while the TBI-48-4/5 is for engines such as the O-360 (180 hp) and above.

All models cost the same, $765, and the price includes the required fuel-pressure regulator and air-freight shipping.

Installation

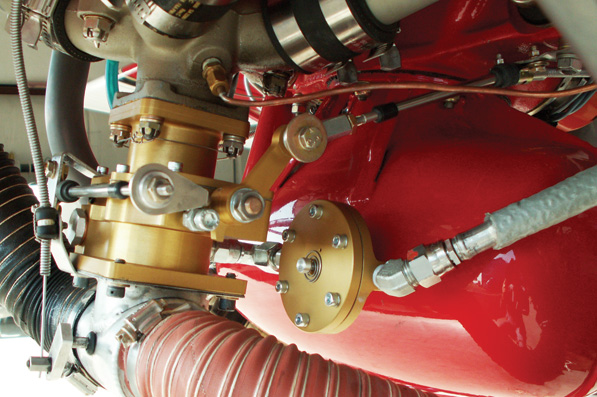

There’s nothing difficult about installing a Rotec TBI, but there are a few caveats. After the throttle body is connected to the engine, the fuel regulator must be installed nearby. Fuel flows through the regulator to the throttle body.

It’s usually possible to connect the regulator directly to the throttle body using a common fitting, but it’s not always the best option. In any case, the regulator must be installed no more than 6 inches from the throttle body and always at the same level or slightly higher-never lower-than the throttle body.

Because the Rotec TBI does not have an accelerator pump, the engine must be primed before cold starts by locally manufacturing and installing a linkage to depress the diaphragm override button on the pressure regulator, or by using a generic plunger-type instrument panel-mounted engine primer. Usually a simple 90 two-arm bell crank and a cockpit pull-type cable are all thats required.

After the installation is done there are a few adjustments required before the installation is truly synched for the engine. Idle fuel flows through a separate jet, and that mixture is fine-tuned by adjusting a needle valve. The other main adjustment is to set the slide throttle stop to tune the full-throttle airflow for best results.

It was pretty straightforward. I hooked it up, started it up and it’s been running ever since, says Nick Coleman. Coleman replaced the Bendix PS-5C on his Lycoming O-320 with a Rotec TBI-40-3. The Rotec TBI installation instructions and updates posted on the web site state, The unit does not have an accelerator pump, so rapid use of the throttle should be avoided. When asked how the lack of a pump affects engine performance during aerobatic flying, Coleman said that he learned to set his idle mixture slightly to the rich side of the range to compensate.

The Customers Like It

Mike Custard owns Advanced Aviation in Bend, Oregon. He removed the carburetor from a specially built O-200 to install the Rotec TBI on his Kitfox Series 7 SuperSport. I wasn’t happy with the EGT splits using the carburetor, he said. I felt like I had two cylinders with the correct mixtures and two that were too rich. He tried various tacks to correct the mixture problems. When unsuccessful, he started looking for another solution and read about Rotecs TBI. I thought I would give it a try and Im very pleased.

Custard has collected data that shows the benefits. Typical cruise-power EGT splits average more than 200 F for the carburetor. The Rotec TBI yielded splits of 80 to 100 at the same power settings.

Lynn Mattson of Grass Lake, Michigan, has the Rotec TBI on the Jabiru 2200 that powers his Kitfox IV. I fly it lean of peak [EGT], he said. Yesterday I was flying along at 80, burning 2.7 gallons per hour. Thats a big improvement over the basic, fixed carburetion that is standard on the Jabiru and Rotax powerplants.

So whats not to like? The Rotec TBI is compact, has few moving parts, can be purchased new for the price of a carburetor overhaul and by all reports does an excellent job of metering fuel. Not only that, Rotec has developed a reputation for bending over backward to provide excellent customer service. Sounds like a good combination.

For more information, visit www.rotecaerosport.com/tbi.

how can I contact the Rotec TBI company.

Roger: we’ve corrected the links for Rotec in the article.