As supply-chain problems continue to make it hard to find the products you seek, it is worth noting that not all manufacturers have the same problems at the same time. For example, some AeroShell greases have been hard (even impossible) to find lately, but Mobil and NYCO greases have been more readily available. The NYCO brand may be unfamiliar to many aircraft owners, but Hartzell is now using and recommends NYCO GN 3058 grease for its constant-speed propellers. Hartzell’s adaptation of the NYCO grease is a pretty solid endorsement for this line of products and offers owners and maintenance shops an alternative to the unicorn-like AeroShell products. (As of February 2022, Aircraft Spruce has many AeroShell greases listed as on “indefinite backorder.”) More on the Hartzell recommendations in a moment.

It seems our supply-chain issues are unlikely to get a lot better over a short period of time, so it’s worth reviewing the nature of grease and consider where there may be alternatives to the stated or recommended brands. Let’s see what greases are out there and what different component manufacturers recommend. There are almost always substitutes available for your preferred grease that will meet the manufacturer’s specifications. Many recommendations were made with the “most common” grease in mind, but it’s an ever-changing world, so it’s useful to understand which components must use a specific grease and which can be used with substitutes.

Wheel Bearings

Unless your plane is permanently mounted on straight floats, you will have wheel bearings to maintain. If your plane lives on wheels, you will need a general-purpose grease such as AeroShell 5 or 6, which can often be substituted with NYCO GN 05 and GN 15, respectively. AeroShell 22 is a good synthetic grease that will match or exceed the performance of AeroShell 5 and work over a wider temperature range; its equivalent in the NYCO line is GN 22. Mobil 28 is another good choice if you prefer synthetic grease, but it is slightly more expensive and not as widely available.

As always, refer to the manufacturer’s recommendations. Matco, for example, recommends a wide range of greases for the wheel bearings in its assemblies, including AeroShell 22, Mobil 28 and Mobil SHC-100; it notes that other greases meeting MIL-G-81322 spec are acceptable. (An important exception is when the wheels are part of an amphibious float system when BG Products’ 605 grease is called for.)

Tailwheels

Tailwheels should be greased annually or every 100 hours. To grease a tailwheel, first make sure the grease fitting is clean. Any dirt or debris on the fitting can end up on the bearing surfaces and cause damage. If possible, cover the grease fitting with a protective plastic cap. Attach the grease gun to the clean fitting and pump in a few squirts of grease. Keep an eye on the grease seal to be sure you do not push it out of place with too much grease. As soon as you notice any movement, stop pumping. Be sure to use a grease that is recommended by the tailwheel manufacturer. Some tailwheels use sealed wheel bearings, so they obviously do not need to be greased, but the pivot joint will still need servicing.

Propellers

Typically, constant-speed propellers are serviced once a year at the time of the condition inspection. If you fly more than 100 hours per year, you should consider servicing the prop every 100 hours. Hartzell has clarified its lubrication recommendations over the years. Older versions of the Hartzell Propeller Owner’s Manual (Number 115) said to remove the trailing-edge grease fittings on each blade and pump grease into the leading-edge fittings until grease squirted out of the trailing-edge holes. Some mechanics overdid it. In the current version of the manual (Number 115N), Hartzell says to pump not more than one ounce of grease, about five squirts, and call it good. Excess grease can get into places where it doesn’t belong, leading to the removal and teardown of the prop in question.

As mentioned at the start, the original recommendation by Hartzell was to use AeroShell 5 or 6, but the company has changed over to NYCO GN 3058 on the production line and within its overhaul network. (We checked stock as this story was being readied—in February of 2022—and Aircraft Spruce, for example, had the NYCO grease in stock in cartridges, a 1-kilogram can and even a 35-pound pail.)

But there’s a catch. Hartzell doesn’t want you to mix greases—the exception is that AeroShell 5 and 6 are similar enough that they can be mixed in the hub. But replacing AeroShell with NYCO in situ is not allowed. Period. So if your Hartzell was built or overhauled before the changeover to NYCO, you likely have AeroShell in it, and you’ll need to find a few squirts of that grease every annual until the prop is overhauled and converted to NYCO.

Other Applications

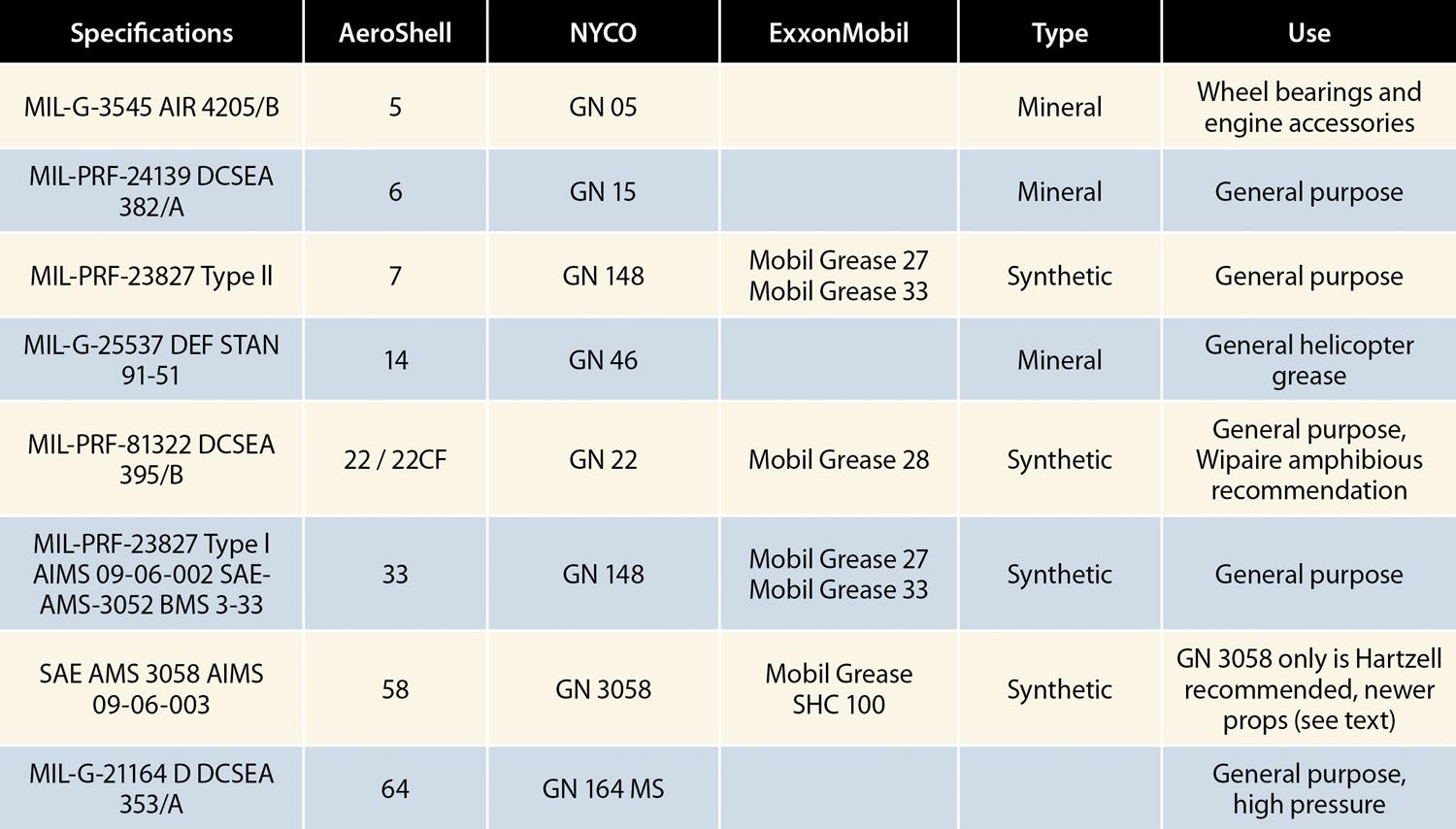

What grease you should use for any particular application will depend on the conditions under which it will operate. For example, AeroShell 5 and 22 are particularly good in hot environments, whereas 7, 22 and 33 are the best in extremely cold situations. AeroShell 5 and 22 are best in wet conditions among the AeroShell choices. AeroShell 14 is widely used by helicopter mechanics for its superior anti-fretting properties. With the information available on the internet, it is pretty easy to do some detailed research if you have a special need. Refer to the table on this page to determine the best substitutions for greases that are currently hard to find.

Some Takeaways

Use a grease that is approved by the maker of the part you are greasing. The people who make your parts know best what works well for their products. In just about every case, that will mean using an aviation grease. Follow the lubricating procedures recommended in the manufacturer’s service literature. There are right and wrong ways to do most things. Do not mix greases, especially do not mix mineral and synthetic greases. If you want to use a different grease, thoroughly clean the part before applying a new type of grease. Mixing greases can lead to corrosion and other negative consequences. Nobody wants that.

Great article. Even for a mechanic. Good clarification on greases as well as the information on prop hubs.