When looking at homebuilding magazines from the ’60s and ’70s, one factor that stands out is the engine selection: Most were using the small Continental engines, from the A65 to the O-200.

The main reason was availability. These engines were used by the thousands in the American lightplane industry after WW-II. As planes like Piper Cubs, Aeronca Champs and Luscombes were scrapped, their engines ended up available in the used market. Enter the “rag overhaul”: Buy an engine from the junkyard, wipe up the dirt and see if it will run.

The price was certainly right. In the plans for the Bowers Fly Baby, Pete Bowers wrote, “While the A65 is out of production, it is still plentiful on the secondhand market. Some with high time on them (500 hours or more since overhaul) can be had for $150–$300.”

I wish.

There are still a lot of the small Continental engines on the U.S. registry. Ten percent of the aircraft on the rolls mount the A65, A/C75, A80, C85, C90 or O-200 engine.

Still, only the latter is still being built. Everything else left the factory floors at least 50 years ago.

On paper, at least, the Rotax 912 looks like the perfect replacement. It’s light, it’s four-stroke and it even looks a lot like a traditional aircraft engine.

Before we pass the small-engine baton to the Rotax, there’s a fundamental question: Is it as reliable as the old traditional Continentals?

Fleet Size

How many of a given type of engine are installed on homebuilt aircraft?

It’s difficult to say. The FAA registry has spotty detail. The registry usually includes the specific engine type for aircraft mounting certified engines, but anything else is pretty random.

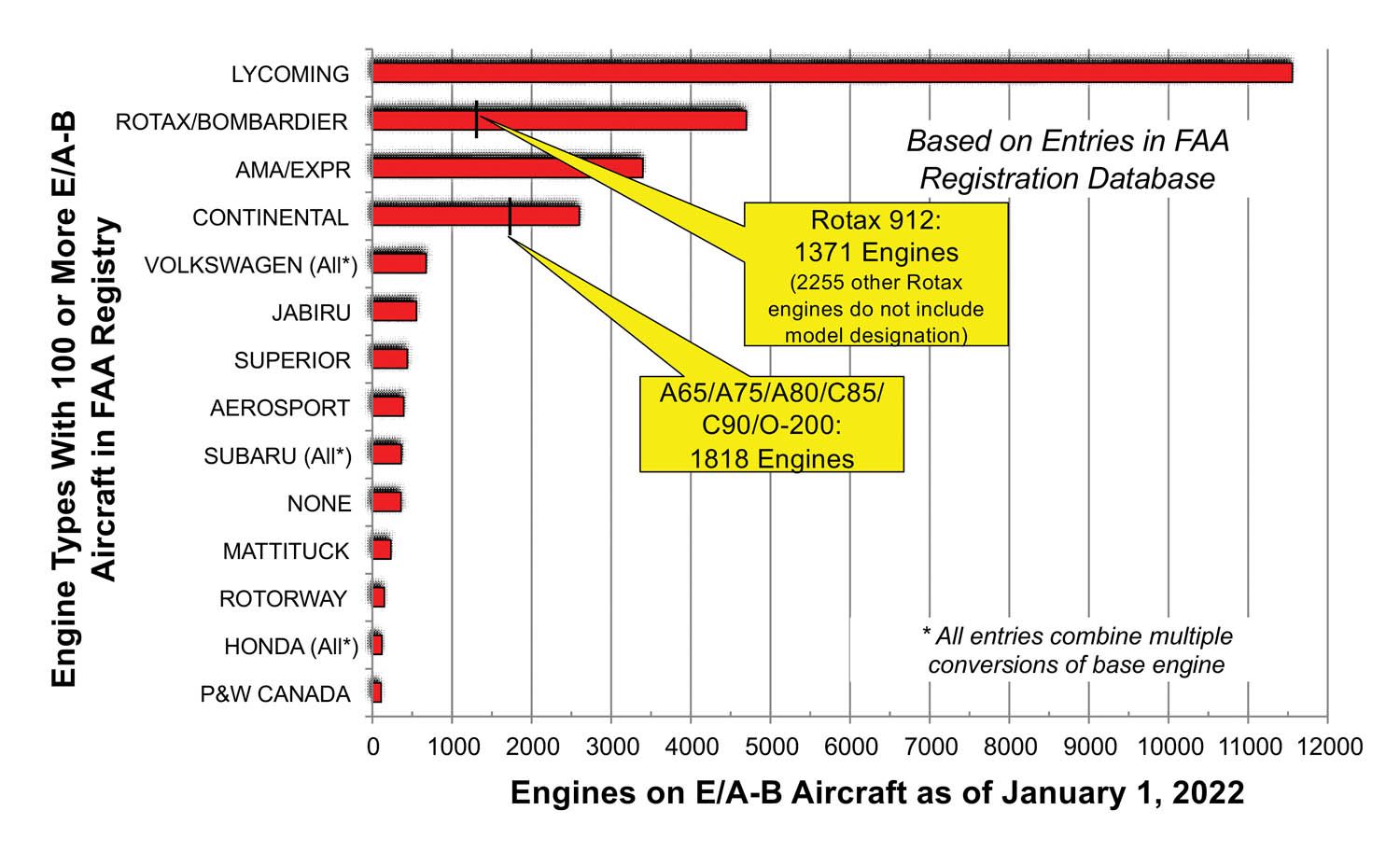

Figure 1 shows the number of engines installed in E/A-B aircraft. Of no surprise is that Lycoming leads the list. That’s about 40% of all homebuilt aircraft—not really surprising with Lycomings gracing the noses of thousands of RVs.

The surprise is No. 2: Rotax. Between “Rotax” and “Bombardier” listings, Rotax engines power about 17% of the homebuilt fleet.

Our problem is that out of the 4700 Rotax-powered E/A-Bs in the registry, almost half (2250) don’t specify an engine model. Some of those are undoubtedly Rotax 912s, but there are a lot of Rotax engine models. There’s no way to tell. About 1300 E/A-B registrations do specify models of the Rotax 912—but certainly additional examples lurk in the model-not-listed category.

Of the cases where a Rotax-powered aircraft does have its engine model included, over half are Rotax 912s. So there are likely to be another thousand 912s in the homebuilt fleet.

Number three on the list throws our statistics for a tizzy: One of every eight homebuilts has the engine listed as “AMA/EXPR.” For whatever reason, the builder decided not to list the engine make or model. These could be just about any engine type, including Rotax 912s, Continental O-200s, or any number of auto conversions.

Continental comes in at No. 4, with almost 2600 installations on E/A-B aircraft. About 1800 of them are the “small” Continentals, A65s through O-200s.

Picking the Accidents

Normally, when I compare homebuilt aircraft types, the basic factor is the number of accidents that were triggered by a loss of engine power for any reason. These account for nearly a third of all homebuilt accidents.

However, when comparing engines, this is rather unfair. It includes cases where problems occurred with the aircraft fuel system or even the instances where the pilots ran out of gas.

Instead, let’s look at the instances where the loss of power was due to a mechanical failure of the engine. This includes both cases where the engine spontaneously quit, as well as the incidents where the builder’s or maintainer’s errors led to the failure.

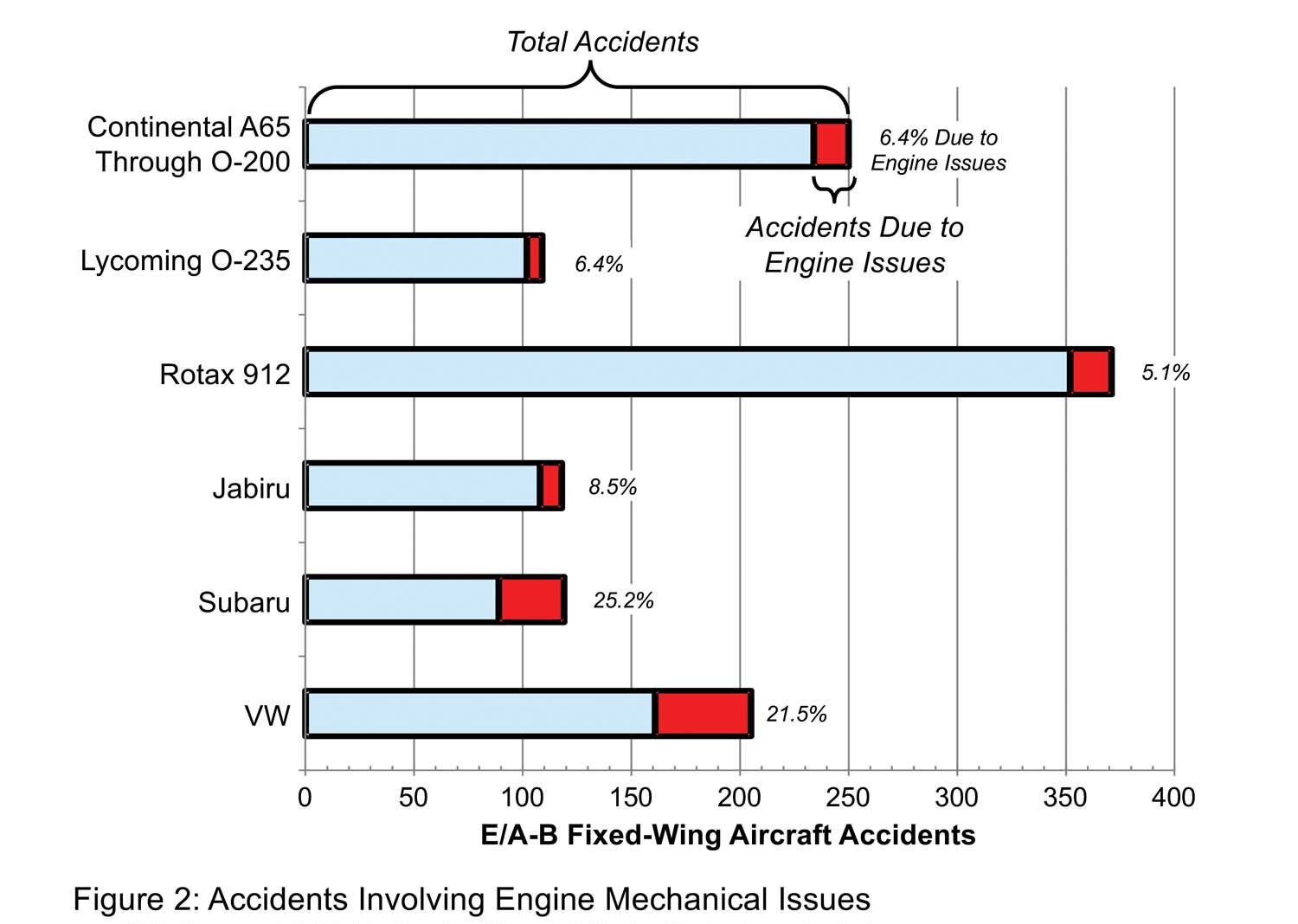

Figure 2 shows the results. The full length of the bars shows the total number of accidents that occurred to E/A-B aircraft with that type of engine. The red “tip” shows the number of accidents that were due to mechanical failure of the engine. The percentage at the end of the bars shows the ratio of accidents due to the engines.

The Rotax 912 has the lowest rate of all engines examined.

Breakdown Breakdown

Now, wait a minute. The 912 is (partially) liquid cooled and requires a radiator. It has a reduction drive and electronic ignition. All three are often problems on auto engine conversions. How do they stack up on the Rotax 912?

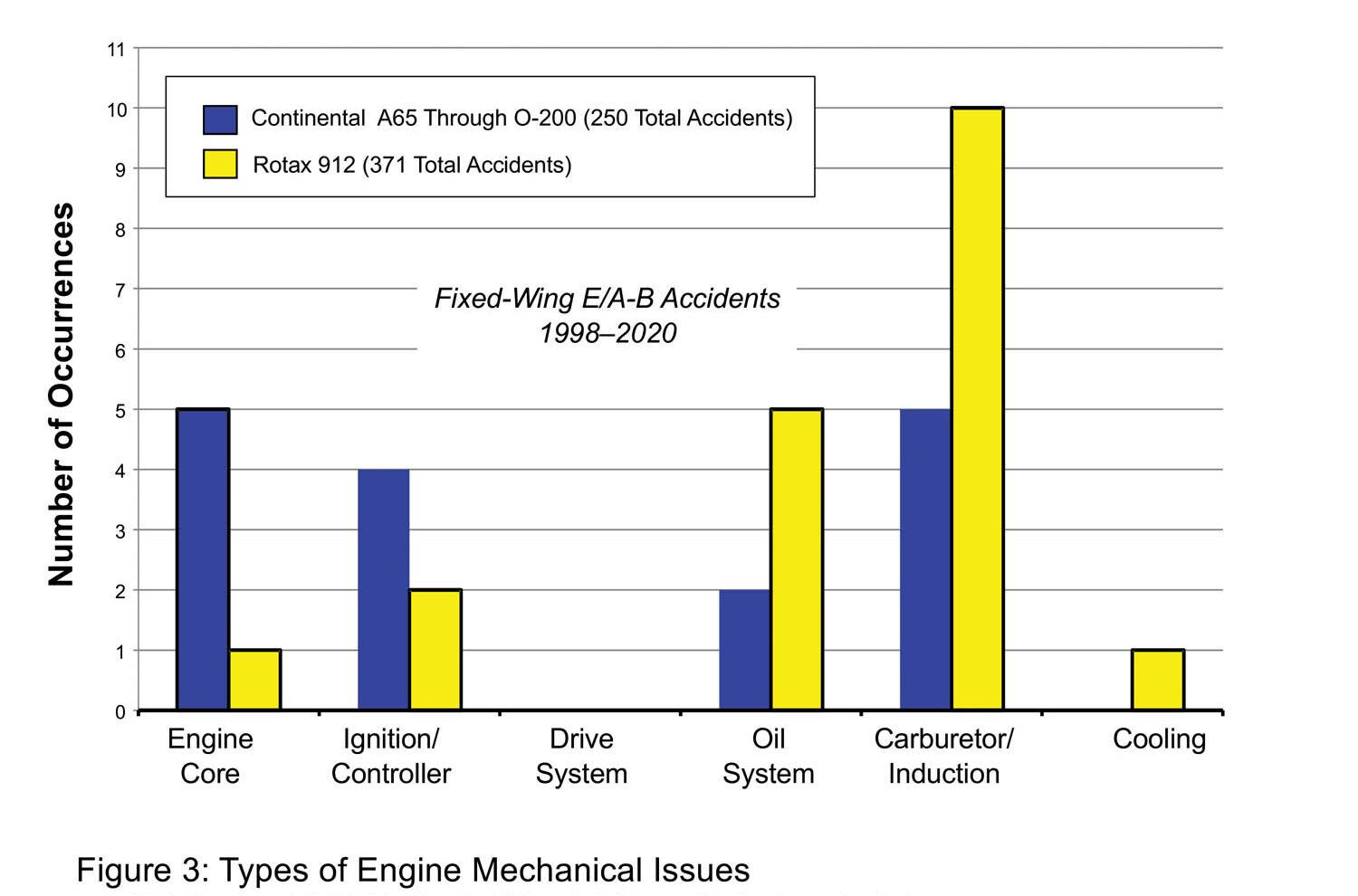

Figure 3 compares the number of engine issues in a variety of categories. Note that this is not the percentage—it is the actual number of cases in my database that involved each system. It totals 16 for the Continentals and 19 for the Rotax 912s. With these small sample sizes, percentages can vary too much. Let’s look at raw numbers, instead.

Cooling, ignition and gearbox issues? No E/A-B Rotax 912 accidents at all attributed to the reduction drive, only one to the cooling system, and the Rotax electronic ignition saw half the number of problems of the conventional magnetos used on (most of) the small Continentals.

Only one of the 371 accidents involving fixed-wing E/A-B aircraft with Rotax 912s involved a failure in the core engine. That was a failed valve pushrod seal that had been removed and reused by the aircraft owner. The 912 saw no failures of the major components such as connecting rods or valves over the 23-year period examined.

Figure 3 shows us that if we have to pick at the Rotax 912, there are two categories to examine: issues with the oil system and problems with the carburetor or induction system.

Remember, though, that there are 50% more Rotax 912 accidents than our small Continental set. And the sample size, as I mentioned, is low. There were two small Continental-powered homebuilt accidents attributed to the oil system, for instance, versus just five for the Rotax set. The difference isn’t that significant.

And I’m not seeing any recurring failures. For the five oil system cases, two were failures of oil lines (one was builder error), one was trash in the oil tank (probably also builder error), a Kitfox owner installed the wrong oil filter and the final one is a “dual entry” for the reused pushrod seal (its failure led to a loss of oil).

For the carburetor/induction cases, other than three involving improperly secured carburetors or controls, there weren’t any common causes. In addition to those three, another couple of cases were directly related to maintenance issues.

Other Power Failure Causes

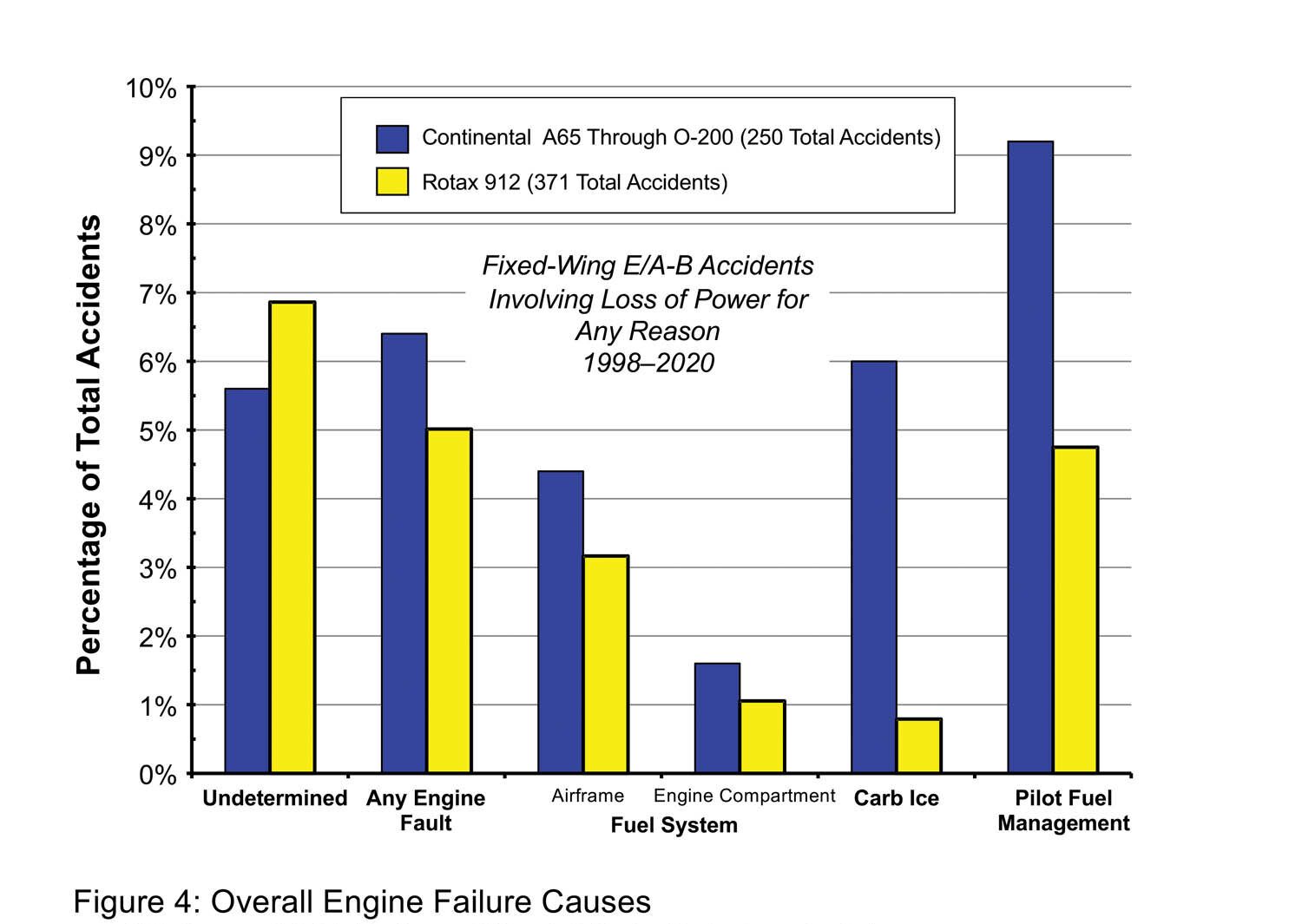

In 26 of 371 fixed-wing E/A-B accidents on aircraft carrying a Rotax 912, the aircraft lost engine power but the NTSB was unable to determine why. That’s about 7% of all the 912-powered accidents. It’s a little higher than the small Continentals—14 out of 250, or 5.6%, versus 26 out of 371 for the Rotaxes.

Why? Likely it’s probably just due to the NTSB investigator’s familiarity with the small Continentals. They may be more experienced at figuring out failures of those well-known engines.

The small Continentals have about five times the rate of carburetor-ice-related accidents. Some 912s are fuel-injected, but in the other models, the carburetors are snugged up to the warm crankcase. Continental’s updraft system isolates the carburetor from engine heat, making them more reliant on separate heating of the incoming air.

Curiously, aircraft powered by the small Continentals suffer power failures due to pilot mismanagement of the fuel twice as often as those carrying Rotax 912s. I’ve no good explanation for this. It’s possible, as a more-modern engine, aircraft carrying Rotax 912s might be more likely to include automated fuel monitoring systems. These could be giving pilots more insight into the actual fuel state of the aircraft.

The Bottom Line

For years, folks have complained that traditional aircraft engines need to be replaced by powerplants using modern technology.

As far as the small Continentals are concerned—well, the replacement is here. Data shows the Rotax 912 has better reliability than the traditional workhorses.

However, our “Continental” category suffered by lumping a number of different models together. Looking just at the O-200, the Rotax 912 and the O-200 have nearly identical statistics.

The downside? Cost. I’d love to replace the C85 on my Fly Baby with a 912, but the four-stroke Rotaxes start at about twice what my airplane is worth. For that matter, so do the brand-new O-200s.

When you think about it, though, that’s the way it was in the early homebuilding days, too. Few, if anyone, bought a brand-new C85 to bolt onto the front of a Stits Playboy. Those wanting engine reliability at a budget opted for good used engines.

It’s not an impossible option for those interested in Rotax 912s. Used engines are available. It may be a hard way to look at it, but the more Special and Experimental Light Sport Aircraft that are added to the registry, the more used Rotax 912s will eventually wind up for sale.

The nice thing is, the engines have been around for quite a while. There are a lot of online resources for troubleshooting, including dedicated factory support.

Continental vs. Rotax 912? If we include only the O-200, the two competitors are neck and neck. Maybe the baton hasn’t been passed, but both engines are marvelous options.

Photos and illustrations: Ron Wanttaja.

I’m very surprised that the direct drive UL Power engines are not listef

Not enough of them to be statistically significant. I’ve recently updated my homebuilt accident database from that used in the article. It has accidents for 402 Rotax 912-powered aircraft and 250 accidents involving the small Continentals. But there are only 12 accidents for homebuilts with UL Power accidents. It’s not fair to compare such a small data set to bigger ones. For instance, one accident more or less for the Rotax 912 set would affect its percentage by 0.25%, while one more accident to a UL Power would be almost a 10% change.

Irrespective of sample size, I have compared the Rotax 912 against many of the alternate engines out there, including UL Power, Jabiru, and various auto engines. The 912 still comes out on top.

Excellent article. I love how you analyze and then explain the stats in a realistic way.

Thanks for your long-time contributions to aviation safety, Ron.

Thanks!

FWIS, as a young aspiring homebuilder, I’m planning to go with a 912is or possibly a UL power engine (once more data is available).

Xlnt piece of informative writing and info from an Author with few equals if any. Ron, the statistics you’ve presented shows extensive research on your part. Well done on your part. I think another far lighter, but equally powerful engine to consider that I’ve seen on You Tube successfully flown and fitted, has been your Harley Davidson non Sportster bare engine powerplants using a belt reduction drive. We’re talking an engine whether it’s the Evo/Evolution engine, Twin Cam etc., that you’ll easily see selling used for $800-$1000+, possibly less on eBay and other similar websites. Your Harley engine also has its starter plus alternator fully integral with its overall design. The cash you have left over will easily cover your belt reduction hardware, plus your stand alone off the frame carburetion/fuel injection and ignition kits, to include tuning and performance parts that’ll have your Harley motor netting you reliable horsepower easily in excess of your cubic inch displacement, along with your V Twin cylinders enjoying far superior aligned airflow better than what they ever had mounted in the Harley motorcycle frame. Grant it, your Rotaxes, Lycomings and Continentals are essentially plug and play, but only by you forking out a far greater cash outlay and weight penalty incumbent with 2 extra cylinder heads, pistons, crank throws and con rods. Your money saved can also go towards your avionics, construction materials, etc.

This is a VERY excellent article, done with a truly sophisticated, scientific, facts-and-numbers approach — radically different from most of the utterly subjective writing in this field. This is a truly meaningful and substantial contribution to aviation safety literature, and to the E/A-B and broader LSA communities. Thank you