As I do condition inspections and prebuy inspections, I come across all sorts of maintenance records. Some are good, others not so good. Actually, there aren’t many records that are required, but there are a number of things that should be in your logbooks, even if they aren’t legally required. Many of these items are just good to have for future reference and are also good to have when you decide to sell the plane to someone else. Our paramount concern, though, is safety, which goes hand-in-hand with good maintenance and proper records.

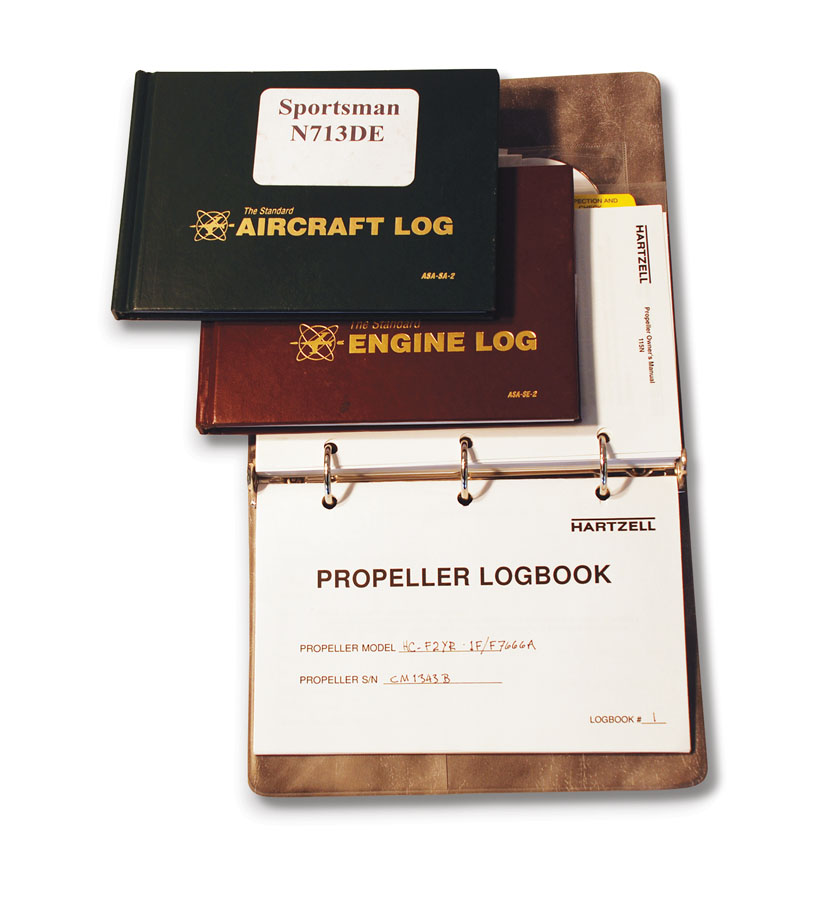

Every airplane should have three logbooks—airplane (airframe), engine, and propeller. In the case of the Hartzell propeller, the logbook is in the back of the owner’s manual. Engine and airplane logbooks are readily available from aviation vendors.

Legally Required Records

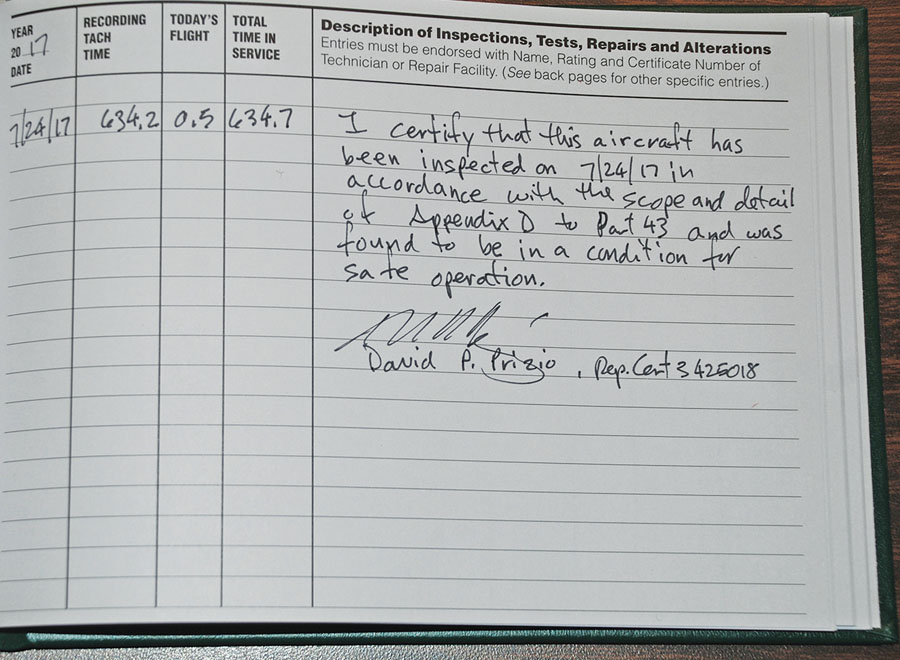

Your airplane logbook should have as its first entry the initial condition inspection performed by the builder. In the past there has been some confusion about who needs to make this entry since the builder does not have the repairman certificate at this point, but the FAA has made it clear that this entry should be made by the builder. It should say, “I certify that this aircraft has been inspected on (date) in accordance with the scope and detail of Appendix D to Part 43 and was found to be in a condition for safe operation.” This should be followed by the builder’s name and signature, and his or her pilot certificate number and type.

The next entry should have been made by the DAR or FAA representative who issued the airworthiness certificate. It should look something like this: “I find that the aircraft, Nxxxxx, meets the requirements for the certificate requested. I have issued a Special Airworthiness Certificate and Operating Limitations for the purpose of an Experimental/Amateur-Built aircraft on this date, (date), with an expiration date of Unlimited.” That should be followed by the inspector’s name, signature, type of authorization (DAR), and number.

Other entries that may precede the airworthiness certificate would be such things as the transponder certification and the pitot/static system certification if such things are required. I recommend both of these for all planes. The transponder certification is required if you will be operating in Class B, C, or D airspace, with a few exceptions. The pitot/static certification is only required for IFR flight. The expiration of the ELT batteries must also be logged according to 14 CFR 91.207.

Part of each oil change should include cutting open and examining the oil filter. If any significant amount of deleterious material is found, it should be noted in the engine logbook. Each engine manufacturer has a standard for the amount and types of material that can be found in an oil filter and still be acceptable for flight. For Lycoming engines see SB 480 F, which is available online.

After the airworthiness certificate endorsement, the next required entry will most likely be the one required by the operating limitations at the completion of Phase I flight testing, unless a yearly condition inspection comes due before the completion of Phase I. If a condition inspection comes due during Phase I, it would be logged in the standard way.

According to the latest version of the Experimental/Amateur-Built operating limitations, this is the required endorsement at the end of Phase I, which should be made by the builder: “I certify that the prescribed flight test has been completed, and the aircraft is controllable throughout its normal range of speeds and throughout all maneuvers to be executed, has no hazardous operating characteristics or design features, and is safe for operation.” However, the exact wording from the airplane’s operating limitations should be used, whatever it may be.

This is a sample taken from recently issued operating limitations for an Experimental/Amateur-Built airplane. Item 20 gives the language that is to appear in the aircraft logbook at the conclusion of Phase I flight testing. It also includes the aerobatic endorsement language required listing each tested maneuver. If your operating limitations have different wording for these items, be sure to use the language contained in your operating limitations.

If the airplane is to be used for aerobatic flight, this endorsement should also appear, or a similar one that is an exact copy of the words in the operating limitations: “I certify that the following aerobatic maneuvers have been test flown, and that the aircraft is controllable throughout the maneuvers’ normal range of speeds. The flight-tested aerobatic maneuvers and speeds are _________ at _________ , _________ at _________ , __________ at _________ , and __________ at _________ .”

If the Phase I sign-off is not in the logbook, the plane is still in Phase I and subject to the Phase I operating limitations that are much more restrictive than Phase II restrictions. Similarly, if the aerobatic endorsement does not appear in the logbook, then no aerobatic maneuvers are allowed to be flown until they have been tested and logged. Sadly, it is quite common to find logbooks that do not contain either of these required endorsements.

Assuming we have made it this far without any glaring omissions in record keeping, the next endorsement should be for the condition inspection due after one year of service. This endorsement should be the same as the first one, plus it should include the time in service since new. Every year after that, there should be a record of another condition inspection signed by the holder of the repairman certificate or an A&P mechanic.

If there has been a major modification at any time, there should be an endorsement placing the airplane back in Phase I for testing, and at the completion of that testing another endorsement indicating the successful completion of that testing. The required language is in the operating limitations and should be used as it appears there. That about wraps up the legally required maintenance records for an Experimental/Amateur-Built airplane.

Recommended Maintenance Records

I started a condition inspection on a 19-year old airplane once that had 18 condition inspection sign-offs in its logbook and nothing else. I was unable to complete the inspection because of some serious problems with the engine. While this is legal, sort of, it is a long way from best practices.

Good records add value to an airplane, making it easy for a potential buyer to see that the plane was well maintained by a conscientious owner. Good records also make it much easier to see what important tasks were completed during the life of the airplane. Who can remember when they last changed a battery or replaced a tire? How can you keep current on oil changes if you don’t have a record of it somewhere? With that in mind let’s look at each logbook—airframe, engine, and propeller—and see what things should be recorded in them.

Airplane Logbook

Every Experimental/Amateur-Built airplane must at least have an airplane logbook in which to record yearly condition inspections. This is also where any major modifications or airframe repairs would be noted, with entry and exit of Phase I flight testing noted as required. This is the absolute legal minimum maintenance record.

In addition to that, this is where compliance with any service bulletins should be made. Though this is not a legal requirement, it is certainly a good practice. If these have not been addressed and recorded in the logbook, any potential buyer will ask why and expect something to be done about it. You should comply with service bulletins for your own safety and keep a record of it for the sake of maintaining the value of your plane. Unfortunately, many airplane owners are rather lax in this regard, but when it comes time to sell your plane, most potential buyers are usually not.

Some other things that are nice to have in the airplane logbook, but are certainly not required, are things like paint colors with reference numbers and the fabric system you used to cover your plane, if applicable. This information is very nice to have down the road when touchup or repairs are necessary. You may elect to record this information somewhere else, but my theory is that the airplane logbook is the least likely record to get lost, so I put it there.

Engine Logbook

The engine logbook is the place to record oil changes and compression test results from the condition inspection. It is also the place to record any other maintenance or repairs performed on the engine. It should begin with the engine make, model, and serial number. If you have a factory-new engine or a zero-time engine rebuilt by the manufacturer, your time in service for the engine will begin at zero hours. If your engine is used or had a field overhaul, you should get a logbook from the previous owner of the engine with a record of the time in service and any work that was done to it.

Usually a detailed description of field overhaul work will be listed separately. These records and any yellow tags should be kept with the engine logbook for future reference. Any future buyer of your plane will be very interested in seeing these records. Without them you just have another used engine. To be honest, an engine logbook is not legally required, but it is surely a good idea.

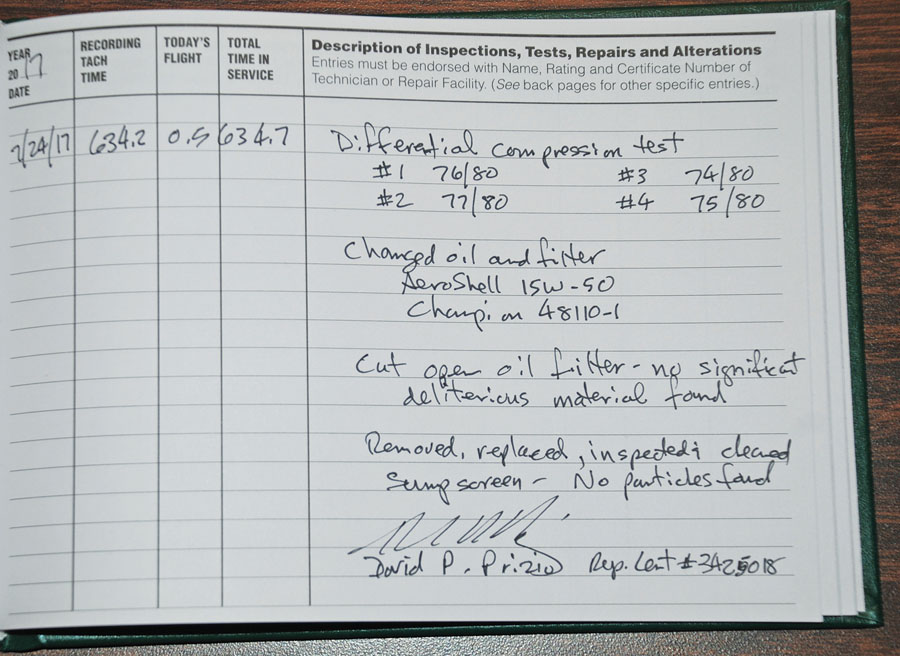

Here is a sample logbook entry for the engine work performed during a yearly condition inspection, including differential compression test and oil change.

If you are the one changing the oil, whether or not you hold a repairman certificate or A&P, you should make the logbook entry. The person performing the compression test should be the one who makes that entry. The important thing is to be sure engine work is tracked in the logbook and maintained on a regular basis. As someone who performs prebuy inspections from time to time, I always look at the logbooks to see what maintenance was performed and when. If these records are incomplete or missing, my evaluation of the plane will always be downgraded by this oversight.

I also recommend recording the key dates in an engine’s life such as date received, date of first operation, and date of first flight. These can be important if there are warranty issues later.

A fuel flow test should be performed before the first flight and the results recorded in the airplane logbook. A full description of the fuel system test is contained in FAA Advisory Circular 90-89B.

Propeller Logbook

Based on my recent experience, I almost feel like beginning this section with a question. Did you know that you are supposed to have and maintain a propeller logbook, even for a fixed-pitch propeller? Well, you are. This is not a regulation for an experimental, but it is a good idea. You can keep maintenance records in any number of more or less organized forms, but a prop logbook is the best and most widely accepted way. The prop should be inspected annually and receive any required maintenance, which should be noted in the logbook.

Wood props should be retorqued twice a year as the weather changes, and this should be logged. Even fixed metal props should be checked for corrosion, nicks and other damage at least yearly and have that inspection recorded. Also, any damage should be noted and repaired by the owner if appropriate or by a prop shop if it is more serious. Constant-speed props need to be inspected as per the manufacturer’s operating manual, which often includes a prop logbook. Don’t forget to note the type of grease you use, so you don’t accidentally mix grease types at a later service.

This is an example of the logbook entry to be made at the conclusion of a yearly condition inspection. The entry includes work performed, date, time in service, signature and name of person doing work and their certificate number, in this case a repairman certificate.

Logbook Entries

The essential elements of a logbook entry are: date work completed, time in service of aircraft, description of work done, name and signature of person performing work, and certificate number. The date the work was completed seems obvious enough. Just remember that if the date the condition inspection was completed goes beyond the expiration date of the previous condition inspection, you should not do any flying, even test flying, until after the condition inspection entry has been made and signed.

Time in service can be a little vague. If you have a recording tachometer, that is the time you should use for time in service. However, there are other options. You can use the flight time record from your EFIS if it is so equipped, or you can use the time off a Hobbs meter. The important thing is to be consistent since each of these options will yield a different time in service.

The description of the work can be brief, but it should contain all pertinent information. For example, an oil and filter change entry might look like this: “Changed oil and filter. AeroShell 15W-50, Champion 48110-1. Cut open filter; no significant debris found.” If you removed, examined, and cleaned the sump screen you could add that comment.

A differential compression test should be performed at least yearly and the results entered in the engine logbook. This is a requirement for certificated aircraft, but it is only a recommendation for experimentals.

The entry for a differential compression test, which should be done at least yearly on a warm engine, might look like this: “Differential compression test: #1-78/80, #2-77/80, #3 76/80, #4-78/80.” My preference is to be brief and only mention key items or problems and not list routine inspections that did not result in additional maintenance or repairs, but you can include as much or as little detail as you like.

Conclusion

Required maintenance record keeping will be listed in the operating limitations for your plane. As with all matters concerning an experimental airplane, be sure to look there first for any specific requirements and restrictions on what you can and cannot do. The specific language to be used for condition inspection signoffs and major modification signoffs will be found there.

Aside from the legal requirements, logbooks will help maintain the value of your plane by showing a pattern of regular maintenance. They may also be useful in case of a warranty claim on an engine or propeller. But the most important thing may be that they will instill in you the routine of doing regular maintenance, which will in turn keep your plane safe and running well. What could be more important than that?

![]()

Dave Prizio has been plying the skies of the L.A. basin and beyond since 1973. Born into a family of builders, it was only natural that he would make his living as a contractor and spend his leisure time building airplanes. He has so far completed three—a GlaStar, a Glasair Sportsman, and a Texas Sport Cub—and is helping a friend build an RV-8. When he isn’t building something, he shares his love of aviation with others by flying Young Eagles or volunteering as an EAA Technical Counselor. He is also an A&P mechanic, Designated Airworthiness Representative (DAR), and a member of the EAA Homebuilt Aircraft Council.