For years, the motorcycle and automobile industries have enjoyed sizable advances in exterior running lights, but it wasn’t until relatively recently that similar technology has trickled down to aircraft lighting systems. Remember the days of approaching and maneuvering around a dark airfield in the blind because a short-lived incandescent landing light gave up the ghost? Today’s products may mitigate some of that risk.

There are lots of lighting products to choose from—too many to list in their entirety here. The market is thriving with cost-effective incandescent lights, along with LED replacement and retrofit options. There are also higher-end high-intensity discharge (HID) products. Still, one shouldn’t underestimate the overall installation cost and detailed planning that need to be considered as you ready your homebuilt aircraft for flight. As advanced as some lighting systems have become, they could require professional installation.

It’s also important to understand the lighting technologies that are available, and the benefits and drawbacks they represent for homebuilders. We’ll take a look at incandescent, LED, HID and other options to consider as you plan your lighting system.

Planning the Light Show

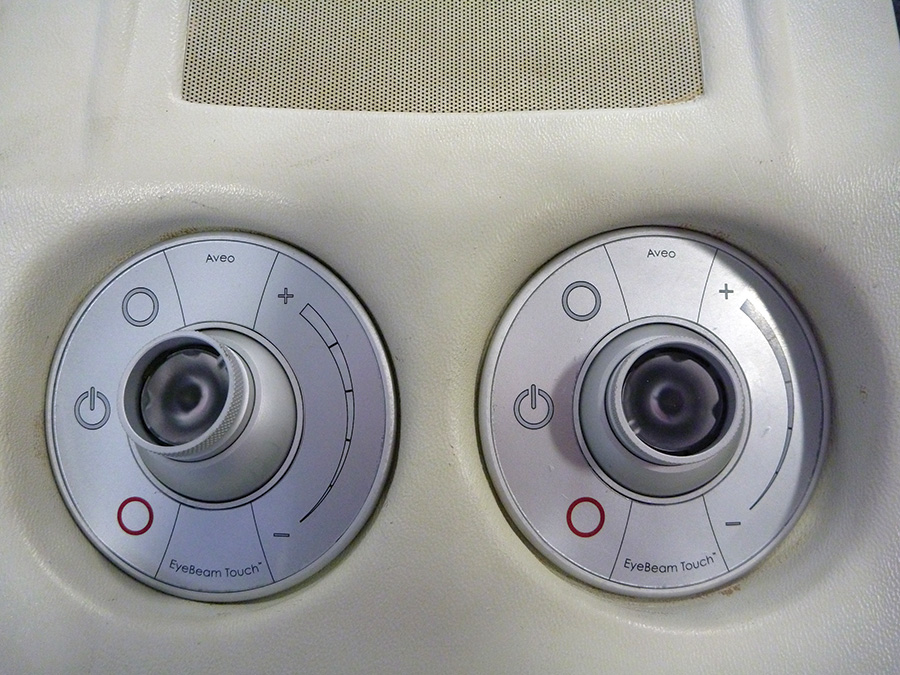

Aircraft lighting should be planned for in the early stages of the build. You probably don’t want to be tearing the airframe open at the later stages of the project to run wiring harnesses, power supplies and other hardware that tag along with lighting systems. You’ll also need to save room on the panel for appropriate switches. That may sound insignificant, but more than one builder has loaded up a small panel with avionics and circuit breakers and run out of room for lighting controls. You’ll also want to ensure that the lighting system won’t affect the integrity and performance of other critical systems, including AHARS and audio systems. Proper wiring, routing and installation technique is required.

The size of the lights—and their position on the airframe—must be a factor in planning an installation. As the sidebar (Page 48) explains, aircraft that fly at night are required to be equipped with FAA-approved lighting systems. The standards for certificated and Experimental aircraft are the same. FAA regulations specify the colors and brightness of exterior lighting for aircraft that will fly at night, and the lighting design choices that may be available within that range are abundant. Consider too that shielding may be an issue on some airframes. You’ll want to ensure the lights are visible and effective through proper positioning and mounting.

Also, think about the type of flying you’ll do and how you will use the lighting. As silly as it may seem, with incandescent bulbs the tendency sometimes is to use the lights sparingly—for fear of having to replace the bulb too soon. Halogen landing lights typically last only 100 hours, while Xenon strobe tubes may last 2000 hours in the aircraft environment.

Running with high-life LEDs could lead to you leaving the lights on all the time. I tend to think of LED lighting as always-on recognition systems—not just landing or taxi lights. For example, the Cirrus I fly has an LED landing light that I rarely turn off—day or night. I use it as a running light given its bright beam and promised long life. So even if you never venture out in the dark, investing in an appropriate lighting technology for your aircraft has benefits that might ultimately increase safety.

LED: Replacing the Standard

If you’ve played the cat-and-mouse game of frequent landing-light-bulb replacement, you’re probably familiar with the GE 4509 PAR36. It’s pretty much been the industry standard for both certified and Experimental aircraft landing lights. Trouble is, the lamp hasn’t quite earned its reputation as “old reliable.” (By the way, that mysterious PAR nomenclature stands for the parabolic aluminized reflector design, and the 36 represents the lamp’s diameter, expressed in increments of one-eighth inch; thus, the PAR36 is 4.5 inches in diameter.)

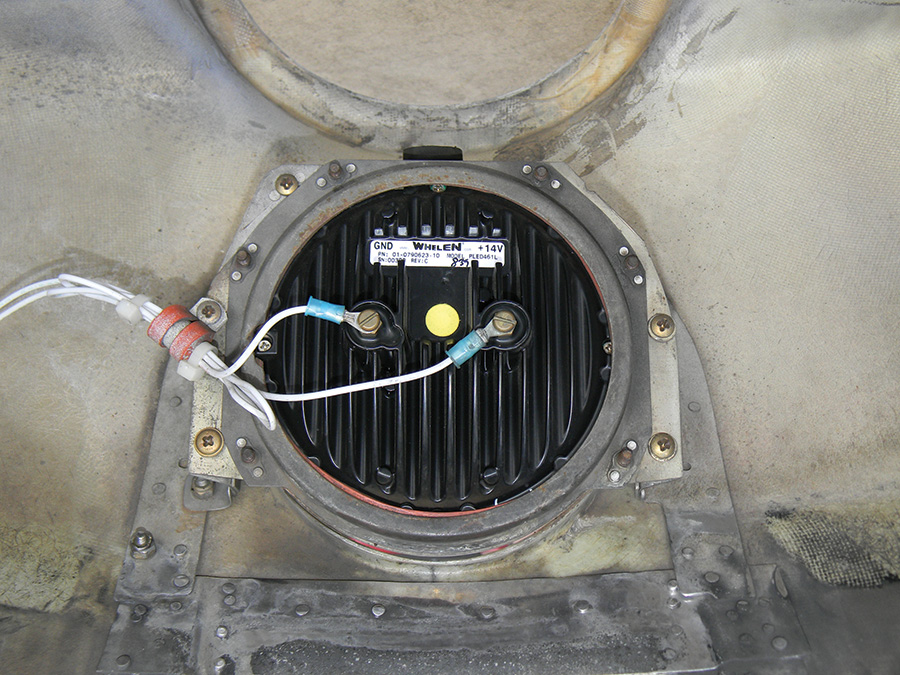

Whelen Engineering offers the Parmetheus line of PAR36 landing and taxi light incandescent replacements. These are GE plug-and-play, drop-in replacements, meaning they’ll use the existing wiring and mount. It often takes longer to open the cowling to access the lamp than it does to swap one out. The Parmetheus lights have a polycarbonate, replaceable hard-coated outer lens.

LED technology affords some benefits over traditional incandescents. When integrated into a well-designed lighting system with adequate heat sinking and solid-state mounting, LED-based lighting products will easily last more than 50,000 hours of continuous operation, and their lifespan is not reduced by power cycles.

Lighting systems such as those offered by AeroLEDs are designed to keep the LED junction temperatures well below their maximum rated values to ensure that the manufacturer’s rated life projections are achieved. And AeroLED says all of the LEDs in its assemblies are hard-mounted to avoid stress failures.

LEDs have proven efficiency not available in incandescent bulbs. For instance, the LEDs used in AeroLEDs lighting products have high lumen efficiency ratings, and as a result, they typically use less than a third the power of halogen bulbs. Of importance here is the significant reduction in the electrical load on the airplane’s battery and alternator system. Think about what happens in the real world with a typical halogen bulb. With the power back on final approach, low engine rpm reduces alternator output, causing the lamp to produce less than its rated light output at full voltage. LED lights usually maintain full light output, even at lower battery voltages.

LEDs come in all shapes and sizes, making them easy to mount in the leading edge during the build process.

Further, the primary driver of halogen bulb filament and Xenon tube lead failures is airframe vibration. The LEDs are solid-state mounted devices that can tolerate high levels of shock and vibration without failing. LED lights are designed to tolerate this high-vibration environment indefinitely.

AeroLEDs says its Sunspot PAR36 light produces 962 lumens inside a 20° cone, as compared to the 873 lumens produced by a GE4509 bulb, while consuming just 32 watts of power. Check that against the GE4509 consuming 100 watts. The narrow beam Sunspot PAR36 has a slightly wider beam pattern than the GE4509; the center of the GE4509 beam is about 100,000 candela, while the Sunspot is 30,000 candela. AeroLEDs offers the Sunspot 36, 46 and 64 series lamps for the PAR36, 46 and 64 replacements.

The Aveo Caprica is a three-in-one navigation, position and strobe light packaged in an aerodynamic footprint.

HID Technology

Before the growth in LED lighting, HID lamps were a popular lighting mod. Unfortunately, the high prices prohibited widespread retrofitting, but that’s changing. Even though the HID’s market isn’t as large as the LED’s, LoPresti Speed Merchants has made a run at the market with the Boom Beam. LoPresti says the Boom Beam HID lighting system (which sells for just shy of $1,000) can improve lighting by more than 500%. The Boom Beam is available in various boom widths, including a 54° taxi lamp beam, a 17° intermediate width and a 9° width landing light.

HID lamps are arguably more efficient than traditional filament-type bulbs, producing five times the light on less current, nearly one-third in many cases. Further, because they have no mechanical filament to fail prematurely in high heat and vibration environments, HID lamps last longer than filament bulbs, easily reaching several thousand hours of continuous use.

XeVision offers HID plug-and-play conversion kits for incandescent lamps. These may be worth looking at for some kits because they’re offered in various oval- and rectangular-shaped designs—making them a viable option for wingtip and wing leading-edge mounting.

HID lights may have a distinct advantage over LEDs when the primary use is for landing or taxi lights, because the luminosity, which is the ability of the light to project a narrow, powerful beam, is something that remains difficult to achieve with LEDs. The owner of a newly installed LED landing and taxi-light system may rave about the lamps’ brightness but find the beam too narrow during taxi. Still, the LED drop-in option is certainly less expensive than a full HID system retrofit.

Can You See Me Now?

There are numerous offerings in aircraft lighting, at various price points. The more popular brands for LEDs include Whelen and AeroLEDs and offer the widest variety of choices (Whelen also sells incandescent options), including the drop-in replacements mentioned. But there are other brands worth looking at. For instance, the Aircraft Spruce catalog offers a $529 product called the Electronic Landing Light, a German-made unit that’s advertised as having a blinding, attention-getting red flasher that will leave you seeing spots.

For an inexpensive option, the folks at CRAZEDpilot offer a $39, low-current-draw wig-wag strobe system that the company says is easy to install and geared for a variety of applications. The company claims its LED strobe light can be seen for over a mile—in daylight. Each strobe lamp measures 3.75x1x1.75 inches, and the complete system weighs only 3 ounces.

Aircraft Spruce also sells drop-in LED lamps for $33 to upgrade existing incandescent position or recognition lights. These fit standard S.C. Bayonet Indexed Base Sockets and are available with replacement clear plastic lenses. These lamps are non-PMA, however.

Kuntzleman Electronics targets the Experimental, ultralight and LSA markets with a variety of LED systems, including the Streamline combo. This aluminum machined combination assembly is fitted with red, green and white LED position lights. Kuntzleman offers a similar unit that adds an LED strobe that’s combined with a special LED driver circuit in the controller, which allows you to adjust the synchronized strobes to flash any one of seven patterns. There is also an FAA-approved LED tail beacon, which the company says has a flash rate of 60 per minute and will not produce EMI or RFI interference.

Kuntzleman targets Van’s RV applications as well, offering two special packages of its strobe and position light systems to builders of RV-7, -8, -9 and -10 models or any other kit that has similarly mounted wing lights. Kuntzleman says the wing-light configuration on these RV models—the white, rear-facing LED on the regular combo head—is problematic because it can’t be seen from the rear and requires a white position or taillight. It offers two retrofit kits, complete with either two- or three-strobe driver modules.

Aveo Engineering sells the Aurora series AveoFlash LSA, which is popular on Light Sport Aircraft applications but is equally at home on Experimentals and ultralights. It’s light—weighing 83 grams—and built with an aerodynamic shape and minimal footprint. Aveo says these lights are unbreakable and offers a lifetime warranty against LED burnout. The system comes standard with synchronization, making it an all-in-one solution for position, navigation and strobe light. It’s available with multiple mounting adapters for composite fairings.

If you want to go the incandescent route, Aeroflash Signal offers a variety of nav/strobe, nav/strobe/position and other position lights, including lightweight kits for remote-mounted units. The Aeroflash web site also has a section for FAQs that may help in system planning and purchase decision-making.

Putting It All Together

I spoke with one builder who’s knee-deep in a Lancair Evolution turboprop project, and he offered an interesting perspective on lighting his speedster. “If I’m hauling along at 300-something knots in busy airspace, I want other traffic to see me before I see them,” he said. “The bright LEDs I’m installing on this airplane could be my best defense against swapping paint with other aircraft.”

If you are undecided about which type of lights to install on your project, it’s a good idea to do some research at trade-show gatherings, if you’re able. There, you can judge quality and price and get a demonstration of a system’s light-beam width and throw. Some companies offer side-by-side comparisons with their competitors’ products. Many lighting manufacturers can offer satisfactory results, and it’s reasonable to expect that this growing field will continue to evolve with new products at a variety of prices.