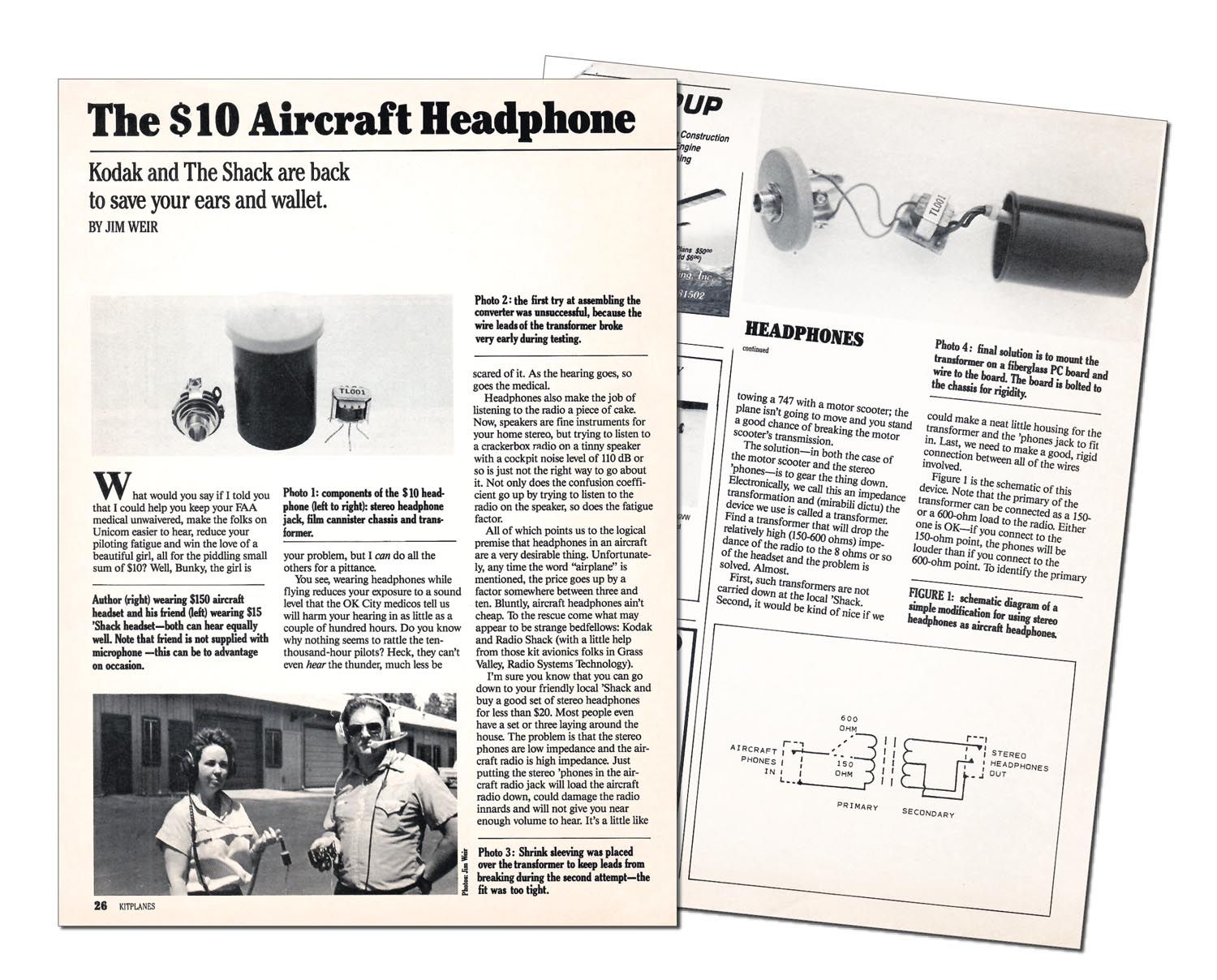

It was 1985 when this 42-year-old kid wrote an article for an upstart magazine aimed at the homebuilt aircraft market. Appearing in the October issue of KITPLANES® was an article on how to make an aircraft headphone using Radio Shack headphones and a film canister. Please note that both Radio Shack and film canisters no longer exist. Actually, KITPLANES® was a spinoff of the old Private Pilot magazine for which I started writing in October 1977. That makes me a thorn in the side of the editorial department for 46 years.

In that time, I’ve done a few things that I think bear repeating, albeit in a rather abbreviated format. I’ll give you a synopsis of the article along with the magazine issue if you want to do library research. In no particular order…

October 1985

As I mentioned above, making a regular set of a stereo headphones into an aircraft headphone can still be done using a transformer from Best Buy and an aspirin bottle with a plastic top. Good for the kids and good for you since the headphone isn’t a headset and doesn’t have a microphone with which to interrupt you. You can still make it for $10 if you shop around.

October 1997

My editors knew they had a bull goose loony on their hands when I wrote this one. I proposed using a commercial plastic connector most often used in washing machines and low-end electronic test equipment as an aircraft connector. Believe it or not, after 26 years it is still available from the same vendors with the same part number(s) as back then, and they are still just as reliable.

Molex 03-06-xxxx series connectors are currently available for reasonable prices from Mouser, DigiKey and Newark. They still work exactly the same way as they did back in 1997. I did find a new use for the metal pins that I hadn’t considered back then. They work just fine as input/output pins on a PC board without the plastic shell connector.

I did raise a question way back then that nobody has as yet been able to answer. A male connector shell is called a plug and a female is called a jack. Why the female is a jack and not a jill is an unanswered question to this day.

We also found out that the nylon connector shells could be color coded (jack and jill) using nothing more than Rit fabric dye (the powdered stuff) and a warm- to hot-water dye bath using a surplus-store slow cooker (Crockpot) on low power overnight and on high power if you were willing to babysit it for a couple of hours. Convention was the male plug was black and the female jill was red. The trick was to do the red dye bath first, and if you messed up and used the wrong color, black over red worked. Not the other way around.

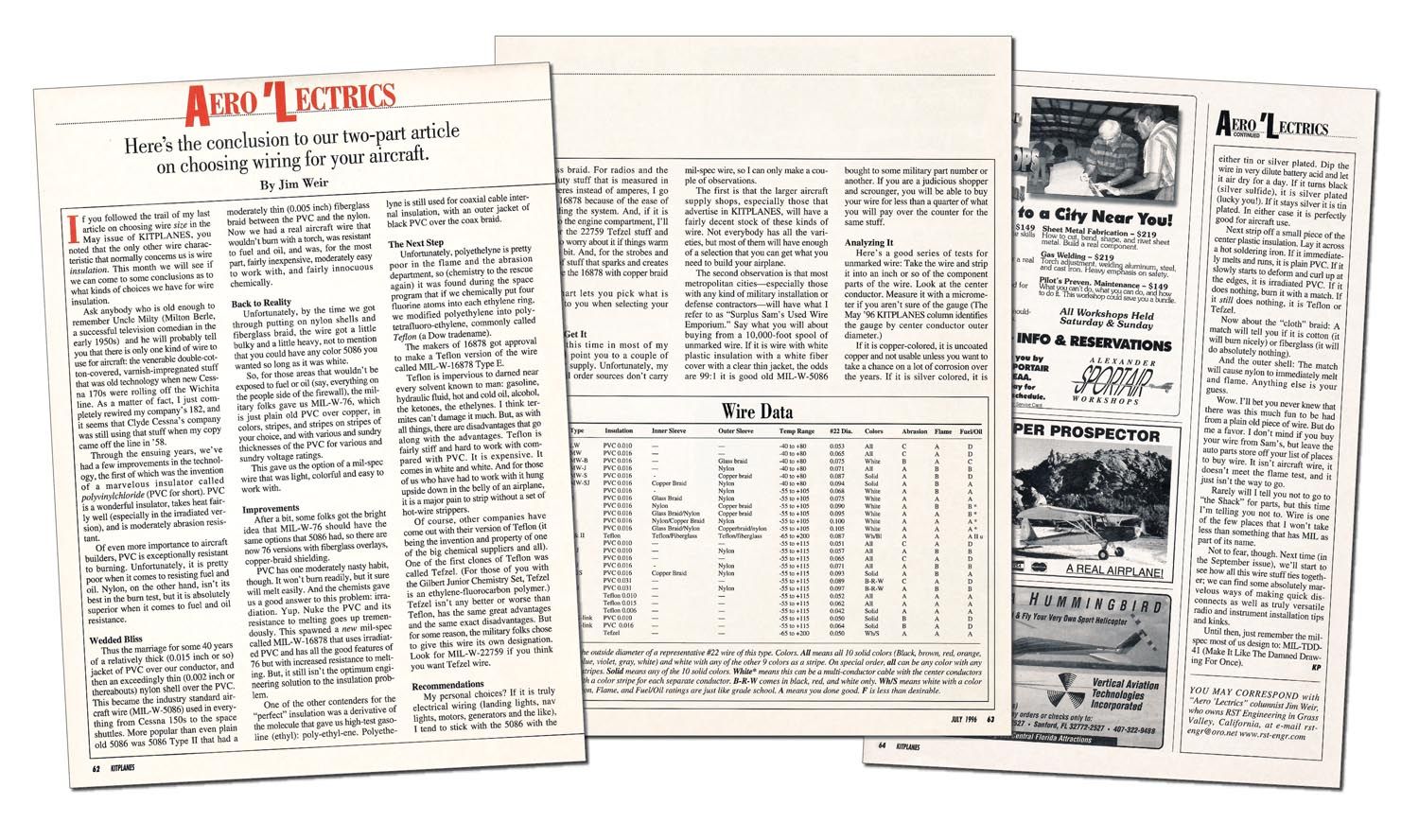

July 1996

My first real tweak of the establishment nose came when I proposed that we start using PVC (polyvinyl chloride) wire for other than engine compartment wiring. “Oh my god—PVC burns, giving off toxic fumes!”

Two quick answers to this one: Yes, regular PVC burns quite nicely, thank you (witness the recent train accident in East Palestine, Ohio), but chemists came up with a way of irradiating PVC and the military gave it the designation MIL-W-16878 and approved it for use in everything from tanks to generals’ staff cars. MIL-W-16878 will melt, but not burn. I have personally completely rewired a 1946 C-120, a 1952 C-170, a 1964 C-172 and a 1958 C-182 using 16878 PVC. The 120 is still flying. The 170 nosed over in Alaska, totaled. The 172 hit a bridge in a forced landing, totaled. And last time I looked, the 182 is in a hangar about half a mile from where I am sitting. No fires, no wire problems.

Two, if you’ve got a fire under your instrument panel, you’ve got a lot more to worry about than melting wires. This issue also introduced us to one of the most important mil-specs that I use to this day when sending a prototype to an outside shop for fabrication: MIL-TDD-41 (Make It Like The Damned Drawing For Once).

February 2023

I just couldn’t leave without mentioning one of the current crop—we took carborundum, the stuff that you make grinding wheels out of. Some research engineer went all the way back to Madame Curie’s lab and found that as an experiment one of the scientists took this newfangled stuff called “electricity” and put it across a lump of carborundum. It glowed a dull and dim white. So noted in an obscure technical notebook and put on a dusty shelf, never again (until last year) to see the light of day.

Funny thing about science and a quotation from Wernher von Braun: “Research is what I am doing when I don’t know what I am doing.” Somehow, in this crazy world of patents, cross-patents, trade secrets and all the rest of the legal stuff, somebody at Cree Lighting in North Carolina and New York came across this notebook experiment and decided to make a super-pure carborundum (silicon carbide) and put current through it. Brilliant white light with not a lot of current was the result. True engineers are never satisfied with something this great, so they went to the chemists of the company and said, “Take this pure carborundum and start putting other impurities into it.” Now, given all the research we’ve done with gallium arsenide LEDs and other LED mixtures, it didn’t take the chemists much time to find the right impurities, and the amount of impurities, to put into the pure carborundum to make most of the colors of the rainbow.

Then along I come to tweak the noses of the powers that be again. I say that “the rules say that the top of the vertical fin can have a rotating beacon that is either red or white. And the rules also say that the aft navigation light has to be white.”

Well, let’s see now: If the powers that be said that Cessna could have flashing navigation lights (red and green on the wingtips and white on the aft structure) then certainly if we make a circle pattern of these new high-brightness LEDs in our rotating beacon, brighter than any aft nav light ever thought of being, then certainly we should be able to have a rapidly rotating anti-collision light be a part of the aft nav light system.

Which brings us up to speed as to where we are today. Thanks for reading and until next month…stay tuned…