Building an aircraft typically requires a good metal-cutting band saw. Some aircraft kits claim that this shop tool is not required. The reality is that there will be some need for cutting and trimming brackets, tubes, and a variety of other parts before the aircraft is finished. Unless you are plans building, it’s hard to justify this expensive tool as it may not be frequently used in your project. How can one get the best bang for the buck when shopping for band saws?

Comparing an electric hand drill with a drill press, portable tools require taking the tool to the part needing work. Table-based tools require the part to be carried to the tool. The same is true with band saws. Portable band saws can be carried to the part for cutting, while table-based saws require moving the part to the saw table. Both portable and table-based tools have their unique advantages. Most of us would never give up either the hand drill or drill press—both styles come in handy for different kinds of jobs. The same principle is true for band saw tools.

Building contractors have used variable-speed portable band saws for many years. Their durability, reliability (at least with name brands), and portability allow heavy-duty cutting capability to be taken directly to the job where it is needed. Replacement blades and parts are readily available at competitive prices. If we could only convert these workhorses to a table-based saw—that would be ideal!

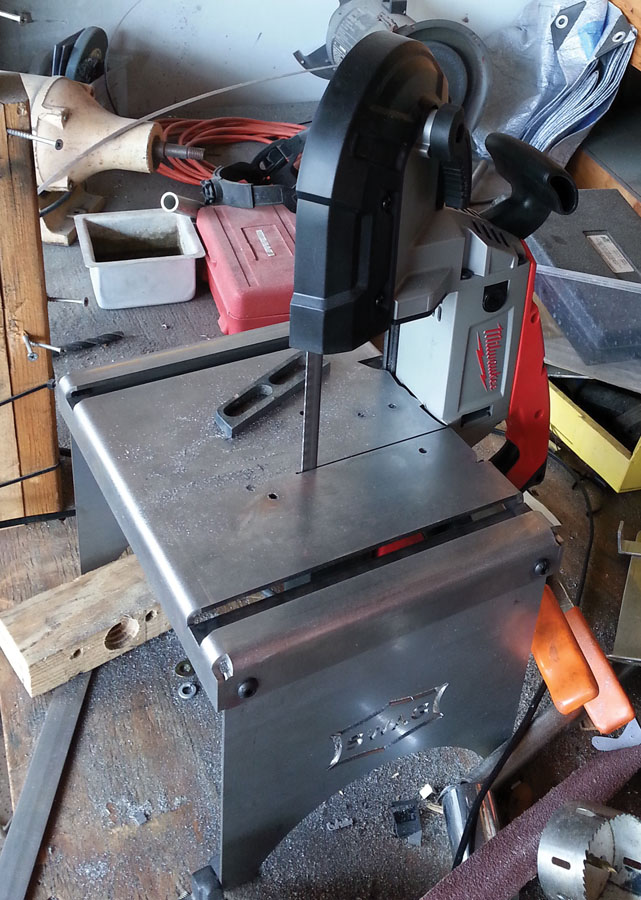

It turns out there are companies that do in fact make a conversion kit for this purpose. One prominent vendor is SWAG. They manufacture a simple table designed to accommodate the popular Milwaukee portable band saw (and other brands, including Harbor Freight). Using two screws for attachment, the saw now stands vertical within the table for a new role as a high-quality table band saw. There is even an optional miter fence attachment for straight and angled cuts. While the price of around $100 may seem high for a simple metal table, this might encourage some builders to fashion their own table from scratch materials using the same clever idea.

What I like most about this band saw conversion is that it gives new use to the portable saw that I already own. It can be attached and removed from the table in less than a minute, so the conversion is far from a permanent loss of portability. Compared to commercially available table saws, this is by far the lightest and smallest size of any, which means it is easy to lend to a friend and carry in a trunk or back seat for travel.

Now you can have a second table saw at the hangar shop without investing in an expensive dedicated model. If you are in the market for a band saw and want maximum versatility without a lot of expense, consider the portable band saw table conversion!

![]()

As the founder of HomebuiltHELP.com, Jon Croke has produced instructional videos for Experimental aircraft builders for over 10 years. He has built (and helped others build) over a dozen kit aircraft of all makes and models. Jon is a private pilot and currently owns and flies a Zenith Cruzer.