Randy Schlitter, owner of RANS Designs, Inc., has been working on an all-metal utility airplane kit for going on three years now. Subscribers to his newsletters have tracked the progress of this plane since August 2016, and orders have been pouring in for several months now. It seems that people just can’t wait to get their hands on the new RANS S-21 Outbound. And why not? The S-21 promises to surpass the performance of the popular S-20 and take way less time to build. After taking a good look at and flight testing the RANS S-21 Outbound with the 180-hp Titan (Continental) engine, I can say that RANS has fulfilled both promises.

The RANS S-21 comes in two versions: trike and taildragger. It is not difficult to switch between gear configurations, but the main gear legs are different, with the trike legs being shorter. Over 90% of current S-21 orders are for the taildragger version.

I was taken aback recently when a group of RV owners began saying this is what the RV-15 should look like. Not that Dick VanGrunsven has even hinted at such a development, but they all seem to want a high-wing utility plane they can use to knock around the backcountry. It’s nice to be able to get from here to there at 180 knots, but if there ends up being a 1200-foot dirt strip, an RV-8 doesn’t look like the best choice for the trip. The point is that the utility plane is the hot ticket right now, and RANS seems to have come up with just the right plane at just the right time. And if the S-21 with a 100-hp Rotax is a good plane (it is), it is a better plane with 180 hp—a much better plane.

This S-21 with the big engine and big tires was a hit at Sun ‘n Fun 2019. Everyone wanted a demo ride in this popular new configuration of what is proving to be a very popular plane.

How Does It Fly?

In a sense you need to think of the S-21 as two airplanes—the version with the 100-hp Rotax and the big-engine version with the 180-hp Titan engine. To be sure, they share a common airframe, but an 80% increase in power changes things quite a bit.

My introduction to the S-21 was through the Rotax-powered version. It is a nice plane to fly with light controls and little need for more than light rudder inputs at the times you would expect to need them. For a plane with light controls, it was much more stable than I expected, making hands-off flying easy, at least in smooth air.

I flew the tailwheel version and found landings to be predictable with no tendency to bounce if the airspeed was not excessive. The gear legs are solid aluminum, so they don’t provide quite the cushion that Cub-style gear would, but they provide less bounce than most steel gear legs. Visibility over the nose was reasonable for me at a rather tall 6 feet 3 inches in the Outbound shod with 22-inch 8.50×6 tires, but forward visibility was seriously impaired with the larger 26-inch bush tires. Most people will have to spend more time looking out the side windows, especially with big tires. On the plus side, the seats do rise as they move forward. Unfortunately, as tire size increases forward visibility decreases. That is common to all tailwheel airplanes. Of course, there is the option of building a trike, which will solve the forward visibility problem but will limit tire choices.

The RANS S-21 Outbound in flight near Hays, Kansas, home of RANS Designs, Inc. This is about as close to the middle of the country as you can get.

The Rotax provided good power for takeoff at Hays, Kansas’ 2000-foot elevation. The one thing that impresses me with the Rotax is how smooth it is compared to many other engines. Achieving a 100-knot cruise speed was no challenge, which is about what you would expect for any Light Sport airplane. By the way, this is not with small tires and wheel pants. This is with 26-inch-tall bush tires unadorned by any fiberglass streamlining.

The S-21 with the Titan engine flew much the same as the lower-powered version, only better. The plane just feels better with the bigger engine, and naturally it climbs better and cruises faster if you don’t mind burning the extra fuel. What is so interesting is that the Titan S-21 seems to be all but immune to the effects of larger tires on cruise performance. With 26-inch bush tires and a high power setting, we managed a true airspeed of 136 knots. Amazing! Time and weather prevented a flight test at 8000 feet where one would expect to see the optimum cruise airspeed, but low-level performance suggests that RANS’ advertised numbers are achievable.

Stalls were devoid of drama, as they should be. At a somewhat forward loading at a bit less than gross, we saw a full-flaps, power-off stall at about 34 knots in my flight test. It is a real accomplishment by RANS to have designed a plane that can have such a low stall speed and then turn around and cruise just over 100 knots faster.

Comparing the S-20 and S-21

Stacking the S-21 Outbound up against its sibling, the S-20 Raven, is inevitable. The S-20 is all fabric covered unless you opt for the metal-wing option, in which case it becomes a sort of hybrid half S-20 and half S-21. The fabric S-20 is lighter than the S-21 and a bit draggier, thus a little slower in cruise. It will also take longer to build, about twice as long for the fabric-wing version. Those differences are moderated with the metal-wing option, although not completely.

This Outbound is equipped with a single-screen Garmin G3X and VFR navigation. You could go up or down from this as your budget and desires dictate. Note the autopilot. These are now almost standard equipment in these planes due to their very reasonable cost.

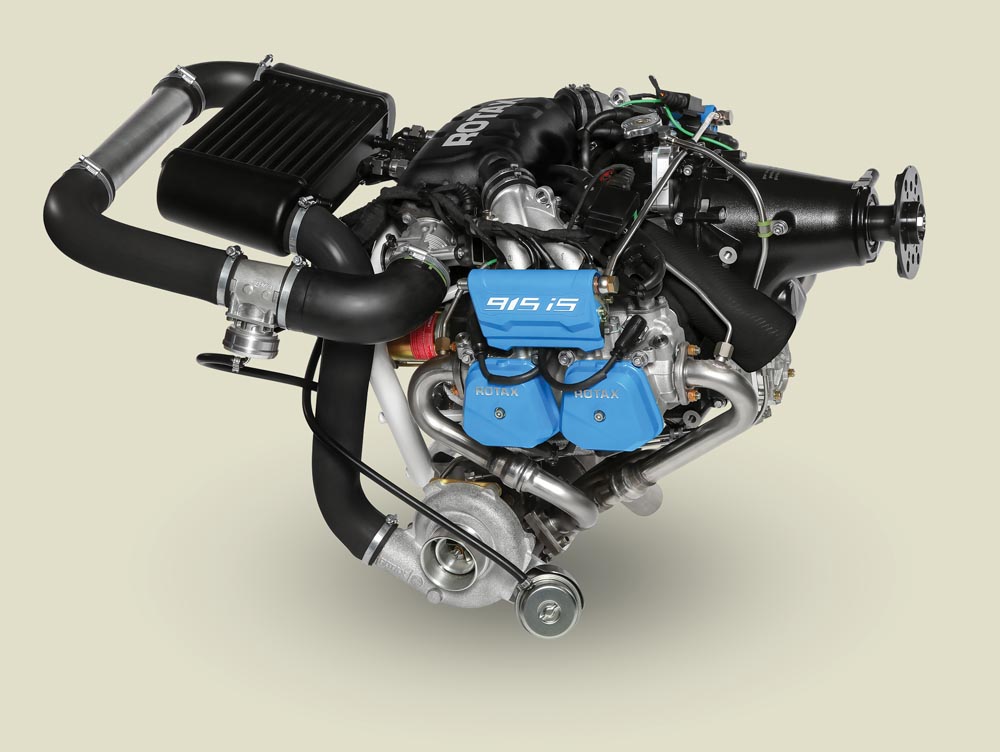

Engine Considerations

Both engine options are available in S-LSA versions of the S-21, which are available from RANS as complete airplanes ready to fly away. Thus, both options can be incorporated into Experimental/Amateur-Built airplanes that can be flown by sport pilots. Unfortunately, with the current restrictive maximum gross weight of 1320 pounds for Light Sport-compliant airplanes, the Titan version effectively becomes a single-place airplane. We expect to see an increase in the gross weight limit for Light Sport airplanes in the not-too-distant future, but that day has not yet arrived.

For those builders who are not limited by the Light Sport rules, a gross weight of 1800 pounds is available for the Titan S-21. With a useful load of around 800 pounds, there is plenty of room for fuel, baggage, and a couple of good-sized people.

As you can see from the performance table, the Titan engine makes some big improvements in the performance of the Outbound. Remember, these performance numbers are with 8.50×6 tires with no wheel pants. Larger 26-inch bush tires will add to the empty weight and decrease cruise by a few knots.

The S-21 Outbound kit with the Titan engine laid out on the floor for the National Kit Evaluation Team (NKET). The S-21 kit is approved for majority amateur-built status by the FAA. If you don’t get carried away with commercial assistance, you should have no problem meeting the 51% amateur-built requirement.

What’s in the Box?

The RANS S-21 kit is very complete, except for electrical and avionics. There are two packages for the firewall forward installation (FWF), one for the Rotax 912 ULS and one for the Titan XIO-340. Both packages include engine mount, cowl, prop, spinner, engine-related electrical except for wire and terminals, and related hardware. The battery, all electrical except for FWF items, lights, avionics, instruments, and paint are not included.

Both engine packages as priced here include a fixed-pitch or ground-adjustable prop. A constant-speed prop would add considerably to the cost. Neither engine is equipped for a hydraulic constant-speed propeller, so an electric constant-speed prop would be your only option. Remember, the Titan engine does not have a prop governor drive in its accessory case.

Common options include such items as headrests, internal corrosion protection, pitot/static system, passenger seat elevator trim, dual-caliper brakes, big tires, and various fairings.

Cost for a Complete Airplane

The cost for a completed airplane is going to vary based on engine selected, options included, and avionics. A day/VFR taildragger with the Rotax 912 ULS engine using all new parts and an inexpensive VFR-only panel could be built for around $80,000, if you painted it yourself. If you can find a good used Rotax engine, you might cut several thousand dollars off that number.

That same Rotax-powered plane with lights, an IFR panel, and a professional paint job would likely come in somewhere around $100-110,000. Step it up to a deluxe version with the Titan engine and a dual-screen Garmin G3X panel, and don’t be surprised if you start getting close to $150,000. The plain fact is that the days of building a complete plane for something like $60,000 are long gone. Most people should plan to spend at least $90,000 and not be shocked when they have trouble holding to that number. This doesn’t just apply to the RANS S-21. It is a pretty good general rule for any two-seat kitbuilt airplane.

S-21 Outbound Specifications

| Rotax 912 ULS | Titan XIO-340 | |

|---|---|---|

| Engine power/rpm | 100 hp@ 5800 rpm | 180 hp @ 2700 rpm |

| Gross weight | 1320 lb | 1320 or 1800 lb |

| Wing loading | 9.36 lbs/sq ft | 12.77 lbs/sq ft |

| Empty weight | 820 lb | 985 lb |

| Useful load | 500 lb | 815 lb |

| Wingspan | 28 ft | 28 ft |

| Wing area | 141 sq ft | 141 sq ft |

| Length | 22.41 ft | 22.41 ft |

| Cabin width | 46.5 in | 46.5 in |

| Baggage | 24 cubic ft/80 lb | 24 cubic ft/120 lb |

| Fuel | 43.5 gal/261 lb | 43.5 gal/261 lb or 45 gal w/optional larger header tank. |

When gross weight is limited to the Light Sport maximum of 1320 pounds, the Titan version of the S-21 effectively becomes a single-place airplane.

S-21 Outbound Performance

| Rotax 912 ULS | Titan XIO-340 | |

|---|---|---|

| Cruise speed 75% power | 104 kt | 135 kt |

| Rate of climb | 850 ft/min | 1500 ft/min |

| Landing roll | 325 ft | 375 ft |

| Takeoff roll | 325 ft | 380 ft |

| Service ceiling | 12,500 ft | 14,000 ft |

| Stall speed clean | 40 kt | 43 kt |

| Stall speed with flaps | 33 kt | 35 kt |

With 180 hp, the Titan XIO-340 offers much better performance than the 100-hp Rotax 912 ULS, but it’s also more expensive.

Building the S-21 Outbound

If you are serious about building an S-21, you should visit the RANS website. There they have current prices for the kits and options for all of their current models, including the S-21. On the first day of Sun ‘n Fun 2019, they had a backlog of about 150 orders, which is likely more now. They are quoting delivery dates nine months into the future. Interestingly, out of that 150 orders, only about five or six are for trikes, and most builders plan to go with the 180-hp Titan engine option.

Mating the aft structure to the cage is a critical step. Alignment must be precise to make sure the plane flies well. Once everything is aligned, it is a simple matter to drill through the tabs on the steel cage into the aluminum skins.

The construction process is greatly simplified compared to the fabric-covered S-20 or just about any other two-place utility airplane. The entire plane is match-hole drilled for rapid installation requiring no drilling or deburring in most cases. A build time of 500-700 hours seems realistic when you consider how easy it is to build the wings. The big time-saver is the ingenious design of the wings with an extruded aluminum nose section that eliminates all nose ribs and nose skin fitting. Combined with a trailing edge extrusion that eliminates cove ribs and skins, the design goes together very quickly with just preformed ribs and flat skins. A technician at RANS built the first set of two wings in only 50 hours. You may not quite match that performance, but you will be hard pressed to find another similar set of wings that will go together more quickly.

The unique extruded aluminum leading edge makes riveting the wing skins a snap. This one innovation saves hundreds of hours of build time with the S-21.

One place where you will need to do some drilling is the mating of the aft section to the steel cage. It is very important to get this exactly straight, so these parts must be carefully fitted together and drilled from the inside through tabs in the cage. This is not a difficult process, but it must be done precisely to make the plane fly straight.

There is also some fitting of the fiberglass cowl to the fuselage. For most builders, this seems to be the least favorite part of the process, but it is unavoidable. It shouldn’t be a problem to find someone in your EAA chapter to help you with this if you have no fiberglass experience. Every RV builder has to fit the fiberglass cowl to their metal airplane, so the expertise should be around if you ask.

Big flaps that will go down to 40 degrees make steep approaches into short fields possible. The plane can also be slipped with full flaps, providing an even steeper approach angle. Flaps are controlled with Teleflex cables, similar to the steering cables used on many outboard motorboats. This greatly simplifies construction.

A small but important point is that the strut vibration problems that appeared on the very first S-21s and metal-wing S-20s have been solved. There is no longer any need to install a strip of anti-skid tape on the bottom of each strut.

Something that RANS does differently than most kit makers is to have all of their assembly instructions online. There is no printed book to carry around unless you download the PDF file and print it. This allows RANS to instantly update everyone’s assembly instructions. Builders can print out sections as they see the need, but much of the work can be done by referring to a laptop screen. This is the age we live in.

Telephone technical support is available from RANS, but many builders can get a solution to their problems or questions by posting on the RANS Clan forum (www.ransclan.com). Fellow builders can often respond more quickly in the evening or on weekends than the factory. Builder support groups such as this are vitally important to builders, especially first-time builders.

The important thing about buying a kit such as the RANS S-21 that is easy to build and well supported is that you are much more likely to finish it in a reasonable amount of time. This may be hard for a first-time builder to understand, but it can be a real problem if a kit is too hard to build for whatever reason. This should not be the case with the S-21.

S-21 Outbound Kit Pricing

- Complete airframe kit—tricycle gear $34,580

- Complete airframe kit—taildragger $32,685

- Titan XIO-340 engine and installation kit $44,155

- Rotax 912 ULS engine and installation kit $29,327

- Crating for foreign shipment $700

- Shipping $2,000 (varies)

- 26-inch Bush tires $3,000

- Other popular options—see order form $2,874

Truly fabulous. I can’t get the same depth from the Rans site, but I’m sure they’re improving, or on FB or YouTube. Thank you. You have helped a prospective buyer a lot.

Respectfuliy,

John Good

Rans S21 will it take floats.

What about the Yamaha Aircraft Engine? Can it work with this Airframe?