This one came in handy. If you’re like me, you make lots of mistakes and need to remove lots of rivets. The problem is punching out rivets on the airframe. You can’t use a vise to hold the backing tool or bar. One hand has to hold the backing tool. Then you need two more hands for the punch and hammer. Last count I only have two hands. Sweetie has been my helper, but today she was busy and as they say, “Necessity is the mother of invention.”

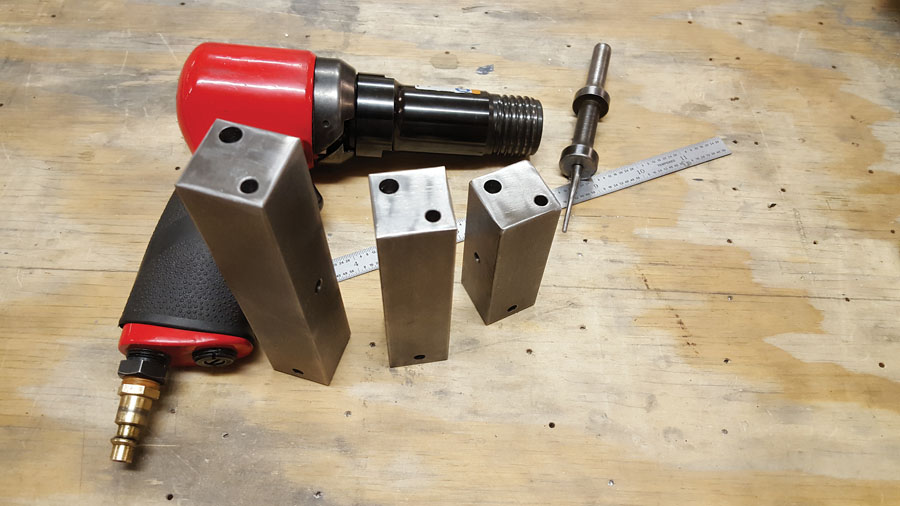

I made the backing bars in the photo some time ago. Notice the two holes in the ends. One is 3/16-inch for dies. The other is -inch to fit over bigger shop heads. The other holes are all 3/16-inch. They work great, but I still needed three hands.

So I took an old flush set and drilled a 3/16-inch hole in the end. I know you can buy a set with a hole, but this was faster.

Next, an old pin punch sacrificed its life. I cut off the business end and used a grinding wheel to take it down to 3/16-inch to fit the new set. To get it round, I chucked it in a drill and ran it at high speed while holding it against the grinding wheel. Once the size was close, I chucked it in the drill press and used various grits of emery cloth and sandpaper to finish and polish it.

It worked so well I also fabricated a 1/8-inch pin punch for #30 rivets.

Start by adjusting pressure down as low as possible. I usually start at 10 psi. Practice feathering the trigger to get one hit at a time. It works like a champ but may cause damage if you’re not careful. Use at your own risk.