The dark interior of a hangar comes into focus as an announcer says, “Building Time Theater presents, ‘The Usual Suspect, Part Two: The Missing Power.’”

It’s a bright, warm morning. The first in months for a landscape that has finally kicked off a grey blanket of snow. Two men become silhouettes against the morning’s diffused light as they push a heavy hangar door open. The grinding of its metal rollers on a metal rail overlap the sound of a Continental 65 laboring against the drag of a Piper Cub. A third silhouette joins them.

“Mornin’ Cliff. Mornin’ Joe.”

“Mornin’, Clarence. We got donuts and the coffee’s percolating,” replies the tallest silhouette.

The men watch the Cub climb into the sun and then walk to a workbench where they pour black coffee into stained mugs commemorating EAA’s 1972 Fly-in.

“Goin’ flyin’, Clarence?” asks Joe, stirring creamer into his mug.

“Planned to. Spent the winter makin’ improvements to the plane but I can’t get it to make power this morning. Need you to look at the carburetor for me.”

“Why the carb?” asks Cliff, licking powdered sugar from his fingertips and lips.

“Gotta be the carb. It’s the only thing I didn’t touch forward of the firewall this winter. Had the engine apart to replace the bearings, had the intake manifold and cylinder head ports matched— even put a new prop on. Wait till you see it—hand carved beauty. Engine’s better ‘en it was last fall. Carb’s the only thing ain’t been touched.”

Cliff lights a cigarette, completing his breakfast of sugar, caffeine, and nicotine. “We’ll take a look. Can you bring it over?”

“Can. It runs well, just no power.” Clarence’s silhouette slips through the open hangar door.

Soon, the sound of an engine draws near. Its exhaust is smooth and steady. “Doesn’t sound right to me,” says Cliff.

“Sounds fine to me,” replies Joe.

“Engine sounds fine. Story doesn’t add up. He said he didn’t touch the carburetor. It would be unusual for it to need adjustment unless he has squirrels with opposable thumbs and access to tools winterin’ in his hangar.” They contemplate that statement. Cliff puts a powdered-sugar donut hole in his mouth.

The scene fades to black as the announcer closes with these cautionary words, “Since the invention of the internal combustion engine, the systems—all the bits of the engine, the propeller, the fuel system, the wiring harness—have made carburetors their scapegoat. It’s tough for an average Joe to not suspect the carburetor when power goes missing. Wise mechanics know, however, a carburetor usually needs the fleshy hands of an accomplice to cripple an engine.”

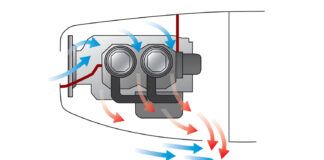

If you tuned in to Building Time Theater last month, you’ll remember we discussed how carburetors are simple machines that facilitate the mixing of fuel (supplied by the fuel system) and air (drawn in by the intake stroke of the engine) into a combustible aerosol, and they can neither cause nor correct the bad behavior of a single cylinder. When an engine performs poorly overall, however, it is difficult to keep from suspecting the carburetor and its mysterious network of passages and adjusting screws. Other causes of poor engine performance—failing fuel pump, plugged fuel vent, air leak, plugged fuel line, dirty fuel filter, dirty air cleaner, slipped mixture or throttle cable, and so forth—often frame the carburetor for the poor performance, causing an average Joe to probe the carburetor with screwdrivers. We’d all like to turn a carburetor’s screw 90-degrees to restore an engine’s compression or repair its broken magneto but, in the history of engines, that has never been accomplished. What’s more, two common carburetor failures—debris in a fuel passage and sinking/stuck floats—can’t be fixed by turning adjusting screws.

When a propulsion system receives maintenance or alterations, as Clarence’s did, and the engine’s performance is degraded in the process, the most likely cause is something that was touched on purpose or something that was touched incidentally. For instance, if intake tubes near spark plug wires are replaced, it is more likely an intake tube isn’t sealed or a spark plug wire was bumped free than it is the carburetor went out of adjustment.

My ears perked up from two of Clarence’s declarations; he replaced the prop and the engine’s bearings. If I were Cliff and Joe, after a brief run-up to check the engine’s reaction to the throttle and cockpit mixture control, I’d cast suspicion on the new prop. I’d put the old prop back on to see if the power is restored. If that failed to restore power, I’d confirm the marks on the cam timing gear were aligned correctly with the drive gear when he reassembled the engine. One tooth off and the valves will open and close out of time with the pistons. The engine may run and sound fine but it will lack power.

Carburetor adjustments should only be made for good cause. There is no need to touch the idle screw unless the idle is too high or too low. If the engine doesn’t exhibit signs of being too rich or lean, no mixture adjustment is needed. When you do confront a carburetor with a screwdriver, note the original settings so you can restore them if your efforts fail or make things worse. Make small adjustments, one at a time. Common sense dictates a carburetor should not require significant adjustments if it had been functioning fine.

Carburetors become less mysterious when you understand what they can and can’t do. Before casting an accusatory glance at a carburetor, remember it cannot cause individual cylinders to misbehave and adjustments impact all of the cylinders, not only one that may be misfiring, running hot, or fouling its plug. That knowledge will speed you toward a correct diagnosis and repair and get you back in the air, building time.

Being in the two wheeled industry I have been found most problems to be what I call finger problems , those created by fiddling owners .

I always teach apprentices to check the basics first , is there fuel and is it getting to the combustion chamber and are all carburettor settings standard , is there spark and is it’s timing correct , is there compression and is the cam timing correct . If these are all in place then the engine should run .

But , I have seen perfectly healthy engines getting a complete rebuild when the original.problem.was a dodgy spark plug , all because the basics weren’t checked .