It looks like an airplane, it wins NASA airplane efficiency contests, and it’s a sweet-flying machine. But it’s not an airplane—it’s a self-launching glider. And even if your medical has been revoked or denied—something that would disqualify you from flying as a Sport Pilot under Light Sport Aircraft rules—you can still cruise at 147 knots. Do I have your attention yet?

The aircraft from Pipistrel is called the Virus, and it is carbon fiber, high wing, with full-span flaperons, optional speed brakes (spoilers, if you will) and an 80-horsepower Rotax 912 up front. The Virus comes with either a 40-foot wingspan or a 36-foot span, but the 100-hp Rotax 912S is optional only on the short-wing (SW) version. The SW fuselage looks the same, but has more internal structure for the higher speeds.

Look at those sleek lines, stem to stern. Add an 11.3:1 high-aspect-ratio wing, and high efficiency must be the result.

Big brother Sinus has a 49-foot (15 meter) wingspan, along with the 80-hp Rotax. All can be either nosewheel or tailwheel and can be factory-built or Experimental/Amateur-Built as either a standard airplane or a glider. Cruise speeds range from 115 knots for the 80-hp Sinus to 147 knots for the Virus SW with the 912S.

What’s in a Name?

The Pipistrel comes from Slovenia (next to Italy at the northern end of the Adriatic Sea), where Ivo Boscarol and Bojan Sajovic were building radio-control airplanes in the 1980s and branched out into trikes. One story is that the name Virus came about because the plane was so much fun to fly that pilots became “infected” with enthusiasm. The other story is that the Sinus (pronounced SEE-nus) came first and, in the European tradition, “sinus” is the Latin language translation of sine, as in sine wave. Having recognized the linguistic faux pas, they decided the next aircraft would be the Virus.

But what about Pipistrel? Company founder Ivo Boscarol started flying ultralights at a time when such activities were frowned upon in the former Yugoslavia. To avoid detection by the authorities, the pilots would fly in the evenings after the hangars had closed for the day. That, combined with the shape of the powered hang gliders, prompted locals to call them bats. Boscarol adopted the name Pipistrel because it’s similar to the Italian word for bat.

All of the Pipistrels are composite aircraft. The skins are fiberglass wet layups over foam cores, but there is Kevlar around the cockpit area. Bulkheads and interior reinforcements are prepreg, and the fiberglass pieces are beautifully made. Some 35 Pipistrels are flying in the U.S., the company says, about 15 of them kitbuilts.

Stylish seats and big doors. The speed-brake handle points straight down in the fully deployed position.

The Virus SW carries a lot, relatively speaking. The gross weight is the standard LSA 1320 pounds. Empty weight is advertised as 636 pounds, less than half of gross. Passenger weight is limited to 396 pounds (slightly over the LSA standard of 190 pounds per passenger), and that leaves 132 pounds for baggage and extra avionics on the panel as long as center-of-gravity limits are respected.

Lights, Camera, Regulations

Let’s look at the legalities of who can fly motorgliders. Because they are, in fact, a type of glider, you need a glider license with a self-launching endorsement. (The other two endorsements are aero tow and ground launch.) If you already have airplane and glider licenses, the self-launch endorsement is basically a thorough checkout with three power-on and three power-off landings. Otherwise, you’ll need a real glider license, with the written exam, but you can get your glider training in the motorglider. That’s at most a small obstacle.

As for the medical, a glider pilot can self-certify, regardless of any previous medical certificate history. If you’re not fit to fly, you’re not fit to fly, but a glider pilot has more regulatory freedom than a Sport Pilot. Unlike a Sport Pilot, a glider pilot can fly at night, IFR and above 10,000 feet, all without a medical—as long as he’s fit. So what license do you get? Fly as a Sport Pilot and be restricted to LSA motorgliders and Sport Pilot limitations, or fly as a regular glider pilot with none of those restrictions.

The factory-built Virus is a Light Sport glider, which means that it has a 120-knot limitation that regular gliders don’t have, along with the maintenance limitations. But it does benefit from lower certification costs. Many may prefer to build it as an Experimental/Amateur-Built and enjoy the freedoms that designation confers.

All Aboard!

I took a break from AirVenture last year and drove north to Brennand Airport in Neenah, Wisconsin, for a demo flight. The Virus SW was unavailable, so we flew the 40-foot-wingspan model. Both the Experimental/Amateur-Built and SLSA airframes are identical.

Before getting started, it’s wise to consult the aircraft manual. The one for the Virus is well-written, and you could hardly tell that it is for a non-U.S. airplane. A noticeable difference is that there are no checklists explicitly spelled out. Still, it compares favorably with the recommended guide for transition training, the FAA’s Glider Flying Handbook.

The walk-around inspection is pretty conventional for an aircraft, but there are a few extras, one being inspection of the speed brakes. The manual explains how to inspect the speed brakes in both the extended and retracted position, but the preflight section of the manual doesn’t tell you to go around the airplane twice so you can check them in each position.

Climbing in is easy enough: You stand with your backside against the door, slide your best part in first (as one customer gracefully put it), then pivot around, pulling the stick back to slide under your inboard knee. The shoulder straps are permanently attached to the lap belts. The rudder pedals are easily adjustable by pulling on a knob that lets them slide toward you, unless you push them away. Legroom is good.

The ELT antenna, the bump for the ballistic ‘chute and fully deployed speed brakes.

Visibility forward is OK in the tricycle gear configuration, but the instrument panel is tall. In the tailwheel version, forward visibility is like looking down the side of a locomotive.

One difference from standard airplane instrumentation is the presence of a variometer—a sensitive vertical speed indicator calibrated in knots, not feet per minute, to make it easier to calculate glide ratios. One knot is 6076 feet per hour, or close to 100 fpm.

Unfeather That Prop

The Pipistrels start much like other Rotax-equipped airplanes, and have a choke. The engine was warm, so we didn’t need it, but we were careful to turn on the fuel valves for each of the 13-gallon, long-range wing tanks that are standard on the U.S. aircraft. Those valves are clamps in the clear plastic fuel lines above the aft portion of each side door. A push on the starter button got the engine going, but one quirk was that it needed a shot of power to get the rpm high enough that centrifugal force would cause the prop to unfeather.

The rudder pedals are chrome-plated welded tubing, and the brakes are smaller tubes above and on the inside of the rudder pedals. The trick to avoiding inadvertent braking on takeoff is to move your feet to the outside of the rudder pedals. A little power got us going, and taxiing was easy.

To keep the big, efficient wing from lifting prematurely, parking and taxiing are done with the speed brakes fully open and the flaps at a -5° reflex setting. The speed-brake handle is in the ceiling, and the short flap handle is between the seats. Both are a bit clumsy, but tolerable because the forces in flight are low.

Runup was conventional with dual ignition and engine gauges. The only different part of the pre-takeoff routine was to remember to add flaps—either 9° or a full 18°—and to retract the speed brakes again, each with its own handle.

Acceleration down the runway soon got us flying, but it is easy to overrotate. Dave White, great fun and a skilled demo pilot and CFIG (Glider), guarded the stick to prevent us from dragging the tail.

Best rate of climb speed (Vy) is 70 knots, which is also the maximum flap-extension speed. Reflex flaps are available at any speed. We did a cruise climb at 85, and didn’t try for the advertised 1500 fpm, but we were soon up to 4500 feet for the handling qualities evaluation.

The door-latch mechanism. Note that the window comes all the way down, which is better for sightseeing.

Virus Needs No Cure

As a powered plane, the Virus is well behaved. Stalls were benign, controllability was good in all regimes, and the roll rate was brisk. The ailerons were heavier than the very light elevator—a combination that often results in poor handling—and the rudder was light. Somehow, though, the combination worked in the Virus without problems, just as in “real” gliders. Because the Virus is so clean, has so much power, and is saddled with the LSA 120-knot Vne, it’s easy to exceed that when leveling off from climb. It was similarly easy to exceed the seemingly low flap speeds during the various handling qualities evaluations, somewhat like it would be with a clean fiberglass sailplane.

There were minor handling quirks, more of passing interest than of significance. One is that the Virus is heavily damped in yaw, so much so that on a rudder doublet (pulse the rudder one way, and then the other), the Virus did not ever return to center. Instead, it stopped while enough displaced from the original heading that it started a turn in that direction, as if you were steering with the rudder.

Another quirk was that at 53 knots, the pitch response was asymmetric. Slowing 10 knots and releasing the wheel below the 53-knot trim speed, the oscillation damped in two cycles. Pushing to 63 from 53, the airspeed went from 63 to 48, back to 63, and repeated this before I recovered. The stick forces for the displacement were very light, maybe only a pound or two, the norm for sailplanes. Because significant stick displacement was required, the low force gradient was certainly tolerable. These light pitch forces also require attention during the landing flare and, as noted, during the takeoff rotation.

One other interesting observation was during slow Dutch rolls. While the maneuvers generally worked well, any quick movement of the ailerons would give yaw coupling and spoil the maneuver. Practice would be the cure for this minor annoyance.

Finally, it was time to shut off the engine and try soaring in the day’s marginal conditions. The drill is to pull the power back to idle for at least a minute until the cylinder head/water temperatures are below 200° F. Then the radio and transponder are turned off to protect them from electrical transients. The two ignition switches are turned off, and then you watch the propeller auto-feather and stop. Next, the radio and transponder are turned back on, along with the ignition switches, so that the engine is ready for an immediate restart if necessary.

With a glider wing, flight down into the white arc feels normal. Having the GPS positioned top dead center in the panel works well for VFR flying.

Even with the relatively short (by glider standards) 40-foot wing, we were able to thermal the Virus. The variometer sounded, and as we thermalled with full flaps, we occasionally got what White referred to as a whistle, but which to me sounded more like the steel squeal of subway wheels. Stalls and handling qualities were good as we thermalled at slow speeds—sometimes under 40 knots—and the stick forces were conventional for a glider. The overhead windows weren’t much help in reading the clouds, but they were better than nothing.

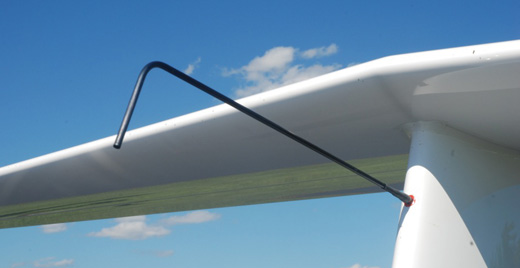

The speed brakes. Lots of drag and lots of reduction in lift, just what you want if the airframe has little drag and abundant lift.

Project Runway

After maintaining altitude and some occasional slow climbs, it was time for landings. Recommended final approach speed is 55 knots as we landed on the 2450-foot long runway with its attention-getting 20-foot width. Trees at one end and along the side of the runway provided an additional, natural boost to one’s attention and adrenaline.

The landing procedure was simple: Slow to deploy full flaps, release the uplatch on the speed-brake handle, and pull the speed brakes open just past halfway till the handle wants to jump out of your hand. The speed brakes are Schempp-Hirth style (a German sailplane manufacturer) and extend only from the top of the wing. One tiresome characteristic of this type of speed brake is its tendency to abruptly pop open, but the Pipistrel speed brakes were much less obnoxious than on, say, the Grob 102 sailplane.

The total-energy probe. If you pull up (slow down), this probe detects that airspeed is being traded for altitude and will subtract the trade-off to give a truer, compensated vertical speed.

With trees at the end of the runway, the recommended drill is to fly a steep approach and to not aim for the very end of the runway. Modulating the speed brakes between half and full gave excellent glide-path control, and on very short final, we went to half speed brakes for a manageable sink rate in the flare. My reason for never landing on the centerline was the forward view obscuration caused by the tall instrument panel, but that is an excuse. White said everybody does it.

The baggage compartment can carry enough to be useful as long as c.g. limits are respected.

Once down on the runway, good practice is to extend full speed brakes and to raise the flaps to the reflex position, both of these to dissuade the wing from further flight. (This is antithetical to the retractable gear standard of don’t touch anything until you’re off the runway.) In addition, the book says to hold the nosewheel off until 25 knots. I overcontrolled my landings, particularly laterally, which may have been a result of the adverse aileron yaw I experienced in the Dutch rolls. For power-off landings with the prop feathered, just remember not to fly a long, shallow approach and expose the flight path to sinking air. It was easy to coast to the desired runway turnoff and around the corner.

The 100-hp Rotax engine drives an auto-feathering prop.

Finishing Up

Three hours after the flight evaluation concluded, I returned and paid for three more landings to complete my glider, self-launch endorsement. The winds were calm, the air was clear, and it was a glorious late afternoon for flying over the beautiful green countryside of the upper Midwest.

On the first takeoff, we did a simulated engine failure at 400 feet and came back for a landing after a 180° turn. Piece of cake. Then came two power-off landings, which took longer than normal circuits because of the need to cool the engine before shutdown. On the first one, I coasted down the runway and around the corner of the first turnoff for taxi back. On the second, it was down to the second turnoff to park the plane. Easy.

If the day comes when, for whatever reason, I can still manage to fly safely though I don’t have an FAA medical, the Virus will get my serious consideration. Call me Batman.

For more information visit www.pipistrel-usa.com.

I would like information about the kit. Price. What is in the kit are plans available thank you. Robert thompson. 19075702409. Robertthompson202222@ iCloud.com. Box 35 kaktovik Alaska. 99747

You mentioned Challenger 2 being registered as motor glider. can you provide some details? this isnt the first time ive seen mention, and I’d like to try that myself.

buy a risen 250 knots top speed 3000 ky range