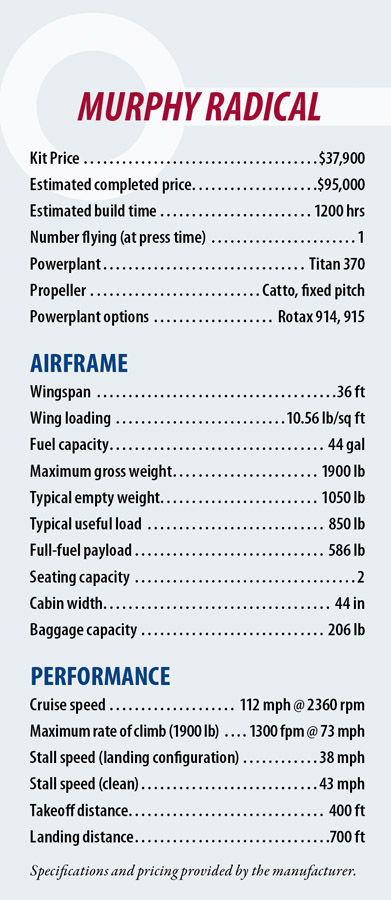

You know you are in for a fun flight when you see the airplane hung with bicycles on the wings! The latest design from Murphy Aircraft, a 35-year-old kit company from Chilliwack, British Columbia, is a fresh look at what it takes to design a machine that begs to go into the backcountry and let’s you enjoy it once you get there. The new Murphy Radical builds on previous designs from the company that brought you the Rebel and the Moose, giving pilots what they want in a package bigger than the typical LSA, but smaller than the moose-lifting Moose. The Radical was conceived to carry two people and their outdoor gear into places most light airplanes fear to tread, and it gives them the load-carrying capability to do it in style.

We recently had a chance to fly the prototype Radical at the company’s home field, and with only 31 hours on the clock, it appears to be living up to its promise. While development is still in the works and the interior was unfinished, we found the core competencies for the machine are being fulfilled quite nicely. With pleasant and unsurprising handling qualities, the airframe is both stable and responsive, leaping off the ground with two aboard and two-thirds fuel. The cavernous tail cone provides ample opportunity to load up gear, and the EFII (electronic fuel injection and ignition)-equipped IO-370 provides the power to lift it. Note, of course, that baggage should be carried in the forward part of the tail cone in flight—the rest of the space is to provide a place to sleep when safely on the ground! The engine drives a Craig Catto prop that seems to give a good balance of climb and cruise.

Carrying bikes outside is just a Canadian thing to do. They are smaller than the canoes many in the north country strap to their floats.

The airplane as we tested it carried 22 gallons on each side in wet wing tanks for a total fuel capacity of 44 gallons—plenty for getting way out into the hinterlands and back. The current version of the plane has a firewall brought over from a previous model and is about three inches narrower than Murphy would like. It will probably be widened in production models, giving a little wider cowl and eliminating a funny little depression on each side of the forward fuselage. The tail cone, from the aft doorposts back, is comprised of corner wraps fabricated from 0.20-inch aluminum, and sides, tops, and bottoms of thinner 0.016-inch sheet. The sides have a crease that adds a look of fabric from a distance but is actually there to add stiffness to the thin sheet.

The side panels of the tail cone have fore and aft creases to increase the stiffness of the thin aluminum sheet. They only look like fabric.

Construction

The Radical is primarily an aluminum airplane that sports fabric-covered control surfaces and fairly typical fiberglass wingtips and cowling. The tail surfaces are finished off with fabric on the balance arms, eliminating the need for fiberglass tips there. The small dorsal fin is also composite and requires simple trimming and no additional messy resin work. The landing gear is designed to absorb touchdown shock with tried and true bungees, and we found it to be well tuned to prevent bouncing rebounds on touchdown.

The oval rear window will likely be changed; it was convenient during the design phase. The prototype has exposed controls and plumbing, but this will be refined as production ramps up.

The aluminum is joined primarily with pulled rivets, making construction fast and easy. Parts are provided prepunched and preformed. Murphy has a very large and impressive hydraulic press that fills their two-story workspace and makes quick work of flat sheet metal that has to be formed into three-dimensional shapes. They do their own welding of steel structures and also produce their own wheels and brakes—a surprising result of a financial analysis that shows that in the quantities that they produce kits, they can save their customers money by building these parts rather than buying them.

Overall, the airplane is traditionally constructed, using tried and true structural components and methods that can be easily learned by those just getting into aircraft construction. There is significant commonality between the various Murphy models, and this continues into the Radical. The advantage to the builder is that it is easier for the factory to keep parts in stock if replacements are needed.

Flying the Radical

Climbing into the Radical, the first thing you notice is the comfortably upholstered bucket seats. With padding and covers done by Oregon Aero, the fiberglass frames make for a nice cocoon in the cockpit. Mounted on standard sliding seat rails, they allow the pilot and passenger to fit perfectly between the rudder pedals and stick. Visibility over the nose was excellent (for a taildragger) with the standard tires, and with larger backcountry tires, only a little stretching was required to see where you were going on the ground.

Murphy Aircraft uses brakes manufactured in house—all components are machined and assembled at the factory.

The stick grip is at a comfortable height, and the flap handle is in easy reach on the overhead, just behind the windshield and right in the center, where either person can reach it. Fuel valves are located just over the pilot’s and passenger’s shoulders; you select the appropriate tank by turning it on or off. You could, of course, feed from both by leaving them both in the on position. The return fuel from the EFII system is plumbed to the right tank.

The panel on the prototype is simple: A large Garmin G3X screen is in front of the pilot, a com radio (with built-in intercom) is in the center, and the right-seat occupant has a G5 attitude/airspeed/altitude indicator in front of their nose to monitor what is going on. Over on the left is a circuit breaker panel with just a few switches underneath. Between the breakers and the G3X screen is a round gauge for monitoring the Titan 370’s EFII system.

Inspection windows allow you to check critical control connections before flight. This one is for the top rudder attach bolt.

Starting things up is simple: Pull the circuit breaker for the fuel pump (so it doesn’t run continuously before the EFIS boots up), and wait for the screen to complete its start-up. Crack the throttle (the only engine control, since the Radical has a fixed-pitch prop, and the EFII system handles the mixture), then push in the fuel pump breaker to watch fuel pressure come up. Once it is stabilized, hit the start button and watch as things crank up—just like a modern car. We didn’t do a hot start, but claims are that it should still start just like a car, with the electronics doing all the things a pilot’s busy hands used to manage.

Taxiing is simple and straightforward, with the Murphy-made tailwheel providing positive control until it breaks out to a swivel at 45 degrees deflection. The brakes (also custom made, along with the wheels, by Murphy) are effective and smooth. As noted, visibility over the nose is good, and we didn’t feel the need to S-turn to see what was ahead. Upon reaching the runup pad, we had to stretch to figure out what to do—there are no mags to check, the fuel was obviously already on, the mixture was automatic…so we checked the controls, pulled on two notches of flaps, and headed for the runway.

The panel on the prototype Radical is simple: The Garmin G3X Touch provides all that is needed for flight and standard engine monitoring, and the EFII display adds what is necessary to watch over the fuel injection and ignition.

Straightening out on runway heading, I added full throttle, and by the time the knob bumped the panel, the tail was coming up with just a little forward pressure. By the time we reached a level pitch, the airplane just levitated and began going up—like an elevator! Progress over the ground was overshadowed by progress in the climb, and I noted about 1700 fpm up, even after dumping the two notches of flaps. That’s what 180 hp does for a two-place airplane! Roll and yaw control were positive during the levitation climb, and we were soon pointed out of the pattern on a Chilliwack day with scattered light rain and ragged clouds at various levels. Oh yes, there was a little sun over that way, and in the other direction, some higher ceilings.

With a river in spring flood below, winding through the hills surrounding and cutting through the Chilliwack area, it was an engrossing sight—green and beautiful, and viewed through the large side windows of the quickly climbing Radical. My first impression of the airplane was that it was responsive. My second impression was the same. Maneuvering in the confines formed by the hills and clouds was simple and natural; it was if I had been flying a Radical all my life. Visibility into the turns was about what you’d expect for a high-wing airplane: a bit blind, but no worse than any plane without an overhead window. The good news is that adding such a window doesn’t seem like it would be a hard thing to do. On the plus side, the visibility out the side windows to the ground below was excellent—and airplanes like this are all about looking at what is below.

The “shark gills” are part of the development process as Murphy determines the necessary cooling air inlet and outlet requirements. The final configuration is still being determined.

Once we gained some altitude, I did a pitch pull to about ten knots below trim speed, and it took only about one full cycle for the airplane to settle back close to trim speed—very stable. A yaw doublet was similarly quickly damped; the airplane wants to stay where you put it. Very little opposite aileron was required to hold the airplane in the turn, again speaking for the stability of the machine. Pitch and roll were well harmonized. For a given pull or push in either axis, you got about the same response rate—a nice thing that contributes to the natural feeling of flight.

The current air inlet to the fuel injection servo is 3D printed. This allows Murphy to make easy modifications during development.

Next up: slow flight. We pulled back on the power to approach speed, then back a little more. The airplane mushed a little at about 50 mph (indicated, not calibrated), and the break was more of a slight complaint than a true break. Pulling on two notches of flaps while in slow flight allowed us to drop the speed about 5 mph. Another notch gained us another 3, and with all the flaps in, it slowed to about 37 mph before it paid off with a little more noticeable break. The airplane was very well behaved throughout.

One of the things that Murphy is still working on is engine cooling—a common problem with a brand-new design, especially with airplanes designed to fly low and slow with a 180-hp Lycoming. There simply aren’t that many air molecules flowing through the cowling at typical slow speeds to keep the powerplant happy. On our flights, we were able to keep the CHTs in the low 400s or below, sometimes with a little power reduction, other times simply by lowering the nose a little. So far, the factory has been working with inlet and outlet areas for the cowl, and the vents on the sides of the lower cowl are a result of experimenting with outlet options. For our flights, we were able to keep oil temperatures within normal limits without a problem.

The tail cone has a reinforced floor for rolling out a sleeping bag and using the airplane as a camper. CG considerations will rule out using it for much baggage in flight.

Another area they are exploring is to uncover the source of the CHT issues. Tyler Penner, general manager of Murphy, told us that they had tried adjusting the mixture knob that is part of the EFII system and had seen no changes in fuel flow or temperatures, hinting that there might be something they don’t yet understand about the system. We are confident that this is something they will solve, as it has been solved by other manufacturers with similar projects.

The bungee landing gear did a good job of absorbing shock and, coupled with Tundra tires, makes landing a breeze.

Returning to the airport, it was once again obvious that the Radical simply flies like an airplane—it was easy to descend and hold pattern altitude, and easy to slow down to flap speed on downwind. We dropped two notches abeam the numbers and another on base, then simply pulled power back and slipped a little to control glide path to a soft wheel landing on the first try—then had to add power to get to the first turnoff. Yup, this airplane wants to land as short as it takes off. The good visibility over the nose is partly attributable to a fairly low deck angle on the ground with the standard tires. This also means that it is hard to fully stall the airplane for a three-point landing. Although our second landing touched all three wheels at about the same time, it is doubtful that is was stalled at the time. A third landing was slightly tail first about the time the wing paid off. With these results, we expected that adding Tundra tires would effectively lengthen the main gear and allow a higher nose attitude at touchdown, giving a nice three-point. (There was also some discussion of lengthening the gear itself, a change that has not been ruled out by the company.)

We got our chance to find out the next day, as when we arrived for a morning photo shoot, the airplane had been magically transformed onto tundra tires! They weren’t the 31 inchers most people think of when imagining balloon wheels these days. These were 22-inch Goodyears—not extreme, but something that Murphy had on hand. They were more than adequate to raise the nose a bit and give a Cadillac ride on touchdown. We didn’t see much of a loss of airspeed, which was the reason for the smaller wheels. You could always go huge if your goal was touching down on really rough terrain, but these were perfectly adequate for operating off reasonably suitable places to land—prepared or unprepared.

Overall, this is a backcountry airplane that will go where you want it to, when you want it to get there, in a predictable fashion, and without a lot of drama.

About Those Bike Racks

When was the last time you landed at a remote airport or strip and wanted to go someplace on the ground when you got there? There’s no courtesy car at most of the mountain strips I have visited, so why not take along some bikes? Sounds like a plan—until you remember the hassle of taking them apart to get the components to fit behind the seats in most airplanes. And then there’s the whole greasy chain thing that always ends up making a mess on your hands. So how about taking them along on the outside of the airplane?

This was the challenge that Murphy GM Tyler Penner threw out to his team—and it was not hard for them to respond. Hard points were built into the main and rear spars for simple racks that allow the bikes to be slung under the wing, inverted. Safety straps keep the bikes from becoming ordnance. But how well do they ride along? Far better than I would have imagined, given the potential drag from all those flying wires (otherwise known as wheel spokes). In fact, on our second flight, we took the bikes along—and noticed no perceptible increase in drag at the speeds the plane likes to fly. Turning base, with three notches of flaps out, I pulled the power back as I did when the plane was “clean” (sans bikes), and it came down about the same as before—not steeper, as I would have imagined with extra drag.

The Radical’s signature bike racks are removable and hold the bike firmly by the frame. The wheels and tires are held by Velcro straps to keep them from turning. The bikes ride very well, with no motion or vibration.

I was also concerned about the bikes flopping around in their mounts, especially with a little sideslip, but they were rock solid and stable. Yup, this looks like a great way to haul bikes to a backcountry strip or just an airport a little ways outside of town. No, you wouldn’t do this on your speedy cross-country cruiser, but for a plane in this speed range, it seems to do just fine. And it looks so “Radical!”

Murphy is Waking Up

Murphy Aircraft, founded in 1985, is now 32 years young and has the feeling of freshness that only comes with youth and new energy. Founded by Daryl Murphy, the company has produced a number of popular designs, from a simple two-place biplane to the monster Murphy Moose. They have sold several thousand kits in that time, and many of those kits have become flying aircraft.

But the past few years have been a bit quiet, with the company actually being advertised for sale at one time. Daryl was looking to retire, but like most kit company founders, was reluctant to let the marque go. With good designs and a loyal customer base, Murphy (the company) was just waiting for fresh blood, and it came along in the form of Tyler Penner, a longtime company employee who is also Daryl’s nephew (see sidebar).

The company’s new Radical is a prime example of youthful inspiration in today’s world. With plenty of power and lifting capability, it’s a machine that can get into tight places and carry enough gear to enjoy those places once you’ve landed. It’s the stuff of TV commercials aimed at the youth who enjoy extreme sports—but it’s also an outstanding flying machine for people of all ages who strongly desire to visit the most magnificent, out-of-the-way places on earth.

A Work in Progress

We flew the new Radical with about 31 hours on the clock. It was well behaved, pleasant, and capable. But there are changes in the works by the factory to make it even better before the first kits reach customers (and several are already on order).

At the top of the list right now is to figure out the best cooling configuration for the IO-370 Titan engine. We noted high cylinder head temperatures, and the factory has been busy opening up the cooling to see if that will make a difference. The cooling “gills” on the lower cowling are evidence of this effort, and as we flew the airplane, they had pretty much decided that airflow was not the issue. They were busy looking at the timing and fuel injection provided by the EFII system to see if something requires tuning in that department. We’re sure that by the time you read this, they’ll have this nailed down. There is plenty of experience with these engines and systems, and the vendors are excellent at solving these kinds of issues.

The airplane as we flew it probably had the shortest landing gear of any Murphy plane, and even with the small bush wheels, it felt like a little more nose up attitude on the ground would be helpful. The airplane was easy to land, but three-point landings were not full stall, so raising the main gear a little bit will increase the ability to drop into short fields at even slower speeds.

Don’t be confused about pictures of that huge tail cone; it’s not all usable cargo space for flight! The CG would get pretty radical if you tried to shove heavy items all the way back there, so they will have a cargo net and tie downs to keep things closer to the back of the seats. However, that is all useable space when it comes to using the airplane as a camper at some remote strip, so feel free to stretch out in the aluminum cocoon if you don’t like waking up in a wet tent.

Conclusion: Get Radical!

The new offering from Murphy is honest, simple, and lots of fun—exactly what it was designed to be. We look forward to seeing the changes they have on their list before finalizing the design, but we saw nothing that should prevent it from being a well-mannered airplane with solid capabilities and trouble-free systems. It should make getting out into the backcountry and off the beaten path easy—and going where there are no roads is one thing that airplanes are all about.