KITPLANES Magazine, November 1998

Flying the Baby Belle*

Raising this Baby is pure fun.

Photos: Ken Armstrong and courtesy of Canadian Home Rotors, Inc.

*(Note: In 1999 name changed to Safari)

Looking for a rugged, nostalgic helicopter that uses a certified aircraft engine? The Baby Belle from Canadian Home Rotors, Inc. (CHRI) is a proven kit helicopter with 264 kits sold and more than 90 completed and flying. The company has also built fly-away helicopters for the overseas markets in China, Brazil and Italy. Pilots see the Baby Belle as a viable commercial helicopter for insecticide spraying, farm fertilizing, cattle and sheep mustering, commuting, surveying real estate or construction sites and flight training (in China). Of course, in North America, a homebuilt cannot be used for reward or hire, but it can be used for your own non-paid operations or a friend’s.

Modest Beginnings

An inventive, dedicated craftsman has developed a rugged aerial workhorse that he claims beats the competition in durability. The similarity to the certified Bell 47 is not only skin deep; the Baby Belle boasts beefy components, extended reliability between overhauls and the ability to operate in the weather extremes of North America.

Murray Sweet, president of CHRI, is a modest, hard-working millwright with lots of homebuilding experience. His first helicopter was a Commuter II, and his expertise was so widely recognized that other Commuter II builders were constantly soliciting his advice. When the Commuter company folded, Sweet bought the basic Helicom/Commuter II helicopter distribution rights and kept making improvements that eventually evolved over two decades into the Baby Belle. My first flight in this series of helicopters was in 1992. Since then, the aircraft has evolved with even more durable components that require less inspection and maintenance.

Component Evolution

Some improvements include using titanium as a weight-saving feature for both the main and tail rotor spindles and shafts, and 2 cubic feet of under-seat storage has been added to swallow the additional payload that customers crave.

To improve utility, a cargo hook with a 200-pound capacity is optional and “bear paws” for the heels of the skids are available for landing in deep snow or soft terrain. The main rotor gears were widened to 2 inches for cooler, quieter operation, and their TBO increased to a proven 1000 hours. Also, the bearings have been upgraded for longer life, and the yoke was redesigned to include self-alignment for easier dynamic balancing.

Tail rotor pedal and collective forces have been neutralized, and the stainless steel tail rotor blades are now rivetless for improved airflow. The aluminum engine cooling fan has been replaced with a stainless steel version. By mounting it directly to the clutch drum, the overall system weight has actually been reduced while improving component life. A proprietary oil cooler with a built-in thermostat and pressure relief valve allows extreme temperature operations, and chip detectors on the main and tail rotor transmissions add a measure of safety and confidence

The company prototype has logged more than 1100 hours of flight time as the company continues an aggressive program of accumulating flight time ahead of their customers to increase confidence and TBO times. This level of testing and proven reliability has allowed the company to increase periodic inspections to once every 200 hours.

The cabin seats are now sloped for additional comfort, and an upholsterer will produce contoured leather, vinyl or cloth seats to exacting customer specifications. Other popular options include a night lighting kit, ground wheels and an engine primer

The Baby Belle uses readily available certified engines to ensure reliability, but a builder could always invest the large amount of time and energy to design and create an automotive conversion in the large area available under the transmission. Or how about a turbine? As a rule of thumb, a helicopter is able to lift about 10 pounds of weight for every horsepower the engine can deliver to the transmission.

Because the center of gravity is always within a couple of inches of the rotor shaft located directly above the engine, the builder can experiment with a broad selection of engine weights and power outputsbeing careful not to exceed the transmission limit currently set at 160 hp. Using a derated engine has additional benefits other than improved reliability and high-altitude capabilities, because a derated engine can easily provide more power for cruise, increasing speed.

In the 150-hp aircraft I flew, the vertical lift capability was approximately 550-600 pounds of payload, although the legal limit would be approximately 530 pounds. The 160-hp version of the same engine would add insignificantly to the basic helicopter weight but would be capable of carrying heavier loads on hot or windless days or from higher-altitude helipads.

The company advises that there are electronic ignitions available for the Lycomings to increase power slightly, and Slick produces a certified magneto with an integral electronic ignition. One mountain-based Colorado builder is replacing the Lycoming O-320 with a 180-hp Lycoming O-360 to ensure adequate power. Theoretically, this engine would be able to lift two 200-pound pilots easily, 130 pounds of fuel and about 300 pounds of whatever else at sea level. Other light sport helicopters often can’t lift two full-size people over obstacles when the tanks are fullnever mind carrying some fish or game back home to the freezer

For owners looking for the ultimate in high-altitude performance, CHRI recommends the turbocharged versions of the 320-cubic-inch Lycoming. It’s interesting to note that the Baby Belle series of helicopters have never had an engine failure. Compare that to the competition!

Many helicopter builders of competing products have had problems with manufacturers when it comes to tracking, balancing or even obtaining a checkout in their newly built helicopters. CHRI thinks customer safety and training are paramount and provide this assistance at no charge. The company even provides free instruction for checkouts in your new helicopter. CHRI sells no products or upgrades until they have been flight-tested at least 100 hours and have proven trouble-free.

An Army of Converts

Sweet has invested a great deal of money and 19 years of research and development to bring the Baby Belle to this level. He has surrounded himself with other keen helicopter builders who are knowledgeable in rotary wing operations. Don’t expect a major marketing team with slick sales gimmicks when visiting Ear Falls to tour the plant. Instead, you will find down-to-earth fling-wing aficionados who will talk helicopters with you beyond the last rays of the setting sun. One can’t help but like these fellows for answering complex or probing questions with complete candor.

One of Sweet’s stalwarts, Larry, is a slim, tobacco-chewing Texan who has logged hundreds of hours herding sheep on his massive spread. Larry sold his previous helicopter with its slipping belts and high-cost replacement parts in search of a stronger helicopter with durable components. He invested in a Baby Belle with the 160-hp Lycoming and lifted four men off the ground with only 27 inches of manifold pressure on his first flight! I saw the picture.

Another convert is Skip Tyler of Glencove, New York, who bought a used Commuter with 100 hours on the airframe. He flew this early version for 250 hours over four years and found it totally trouble-free. As a matter of fact, he only needed to grease and oil the machine. CHRI still supports those older Helicom and Commuter helicopters, and as a result they are enjoying a resurgence in the marketplace in terms of usage and increasing resale value. Plus, all Baby Belle parts can be retrofitted to the Commuter II, allowing them to enjoy a lengthy service life.

Is It a Bell 47 in Disguise?

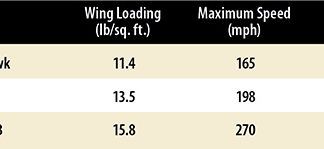

While I could go into a lengthy description of the Baby Belle and its construction, it would be easier to say it looks very much like a Bell 47 series helicopter because it is similarly built. The most apparent difference is the variation in canopies or bubbles that owners choose to install. Some use the bubbles from the Bell 47 G and others fabricate more streamlined enclosures to provide higher cruising speeds.

CHRI Baby Belle

(name changed in 1999 to Safari)

| Prices: Standard kit $41,000 Quick-build kit $45,548 VHS Video $30 Information pack $20 Specifications: Rotor diameter 25 ft. Tail rotor diameter 4 ft. Length 29.8 ft. Height 8 ft. Seats two, side-by-side Weights and loading: Maximum gross weight 1450 lb. Empty weight 920 lb. Useful load 530 lb. Fuel capacity 28 gal. | Engine: 160-hp, four-cylinder Lycoming O-320. Performance: Maximum speed 100 mph Cruise speed 85 mph Range 200 s.m. Rate of climb, sea level 1000 fpm Service ceiling 10,000 ft. Hover (in ground effect) 7000 ft. Hover (out of ground effect) 2000 ft. Manufacturer: Canadian Home Rotors, Inc., P.O. Box 370, No. 4 Roy St., Ear Falls, Ontario, Canada, P0V 1T0; phone/fax 807/222-2474 |

FOR MORE INFORMATION, contact Canadian Home Rotors, Inc., P.O. Box 370,

No. 4 Roy St., Ear Falls, Ontario, Canada, P0V 1T0; phone/fax 807/222-2474; e-mail [email protected]; http://www.acehelicopter.com/