Part 1 of our Engine Buyer’s Guide focused on traditional engines (see KITPLANES® April 2012). In this issue we’ll review another builder option: auto engines for aircraft. The alternative-engine community is in a constant state of flux, with players coming and going so frequently it’s hard to keep up with them. As the editor of CONTACT! Magazine, a nonprofit publication dedicated to Experimental aviation, especially alternative engines, I travel to most of the airshows around the nation each year and see new companies pop up, many of which seem promising, only to watch them disappear just as quickly.

For this article, I contacted alternative-engine vendors and asked them questions, including what’s new, what trends they see, and what they project for the coming year. The majority expressed concerns for general aviation, with its ever-increasing costs, the potential loss of 100LL fuel, airport and FBO closures, and the economy. Others were optimistic in that with all of these issues affecting the bottom lines of their potential customers, the appeal of affordable alternatives to traditional powerplants seems to be on the rise.

And so, in alphabetical order, here is the state of alternative engines for Experimental aircraft. If I’ve inadvertently overlooked someone, please let us know by writing to [email protected].

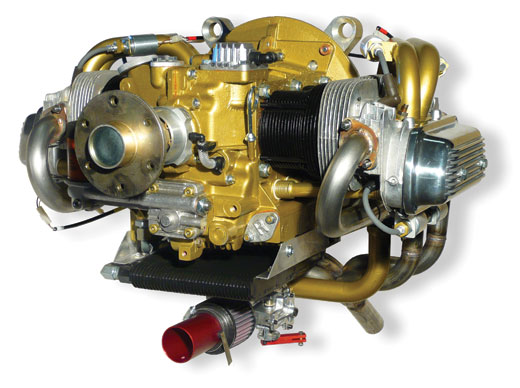

AeroConversions

Volkswagen conversion company AeroConversions recently introduced the AeroInjector, a lighter and more compact version of the AeroCarb. In addition to reducing the size and netting a weight reduction of 9 ounces, the guillotine-type slide carburetor has its operation reversed from push-to-open to push-to-close, so the use of a reversing throttle quadrant is required. Those familiar with John Monnett’s Sonex line of aircraft aren’t strangers to the 2180cc AeroVee Volkswagen engine conversion kit, as it’s the recommended engine.

AeroVee

In recent years, AeroVee has had a crankshaft upgrade that increases the amount of material used in the fit of the prop hub but also eliminates the use of the drive gear for the distributor.

Although the AeroVee is a kit engine, the company will preassemble the prop hub to the crankshaft at an additional cost. The kit comes complete with everything needed to run it, including the AeroInjector carb, but excluding the optional exhaust system. The option of using Nikasil-plated billet-aluminum cylinders to save 9 pounds is a tempting upgrade.

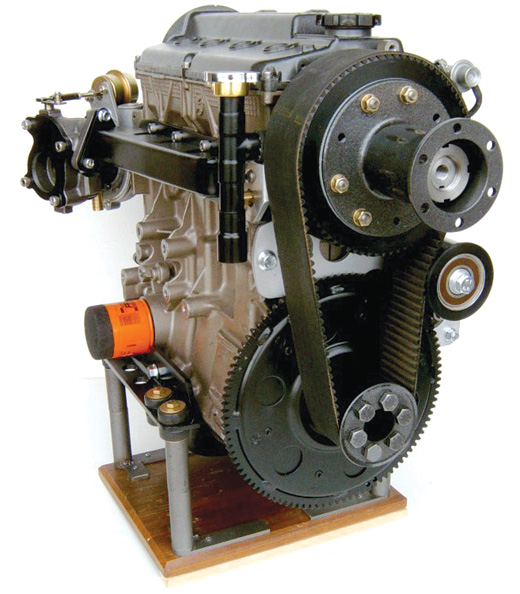

Autoflight

The choices of reduction drives for homebuilders just got bigger thanks to New Zealand’s Autoflight, which released a range of them for Subaru engines; they are also adaptable to just about any other auto engine. The gear-driven propeller speed reduction unit (PSRU) uses a helical-cut and carburized gear set, which is internally supported by double angular contact, high-load bearings; it is internally lubricated with its own oil supply.

Autoflight

Three ratios are available, 2.21:1, 2.47:1 and 2.94:1, and five variants of the gearbox are possible with the long-nose option or standard length. The EA drive is designed to fit the Subaru EA81 and EA82 series engines. The EJ drive fits the Subaru EJ single-cam series of engines. In each series, the propeller centerline can be mounted offset down or up in relation to the crankshaft centerline. Another variant is a universal drive that can be mounted to a wide range of motors via an adapter plate.

At last count, more than 70 units are in use worldwide, many of which have surpassed the 1000-hour mark. Designer Neil Hintz trained as a fitter and turner (machinist). He developed the componentry for Sub4 Aeromotive, Ltd., of Hamilton, New Zealand, specializing in Subaru conversions. Hintz also manufactures and distributes the popular Dominator gyroplane.

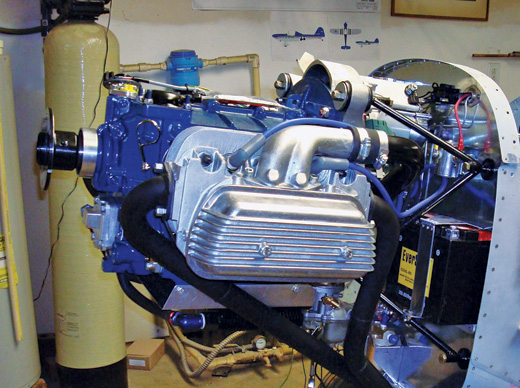

DeltaHawk Engines, Inc.

The cost of diesel is unlikely to ever be cheaper than auto fuel, so the demand from builders who want diesel engines for homebuilt aircraft has waned, at least in the United States. Now 100LL is the only leaded gasoline produced in the world, and outside the U.S. it can be extremely difficult to find. The U.S. military failed to meet the 2010 deadline of having one fuel for all of its vehicles (diesel- or kerosene-type fuels), but that doesn’t diminish the appealing aspects of using it, all of which have been incorporated into the DeltaHawk.

DeltaHawk

Every aspect of this all-aluminum, turbocharged, supercharged, direct-drive two-stroke, V-4 engine says aviation. It can be mounted with the crankshaft below the pistons or flipped over with the crank at the top of the engine—whatever it takes to get the prop station where the airframe designer intended; it can even be mounted vertically for helicopter applications. The engine’s smooth running from overlapping power pulses from each cylinder firing at every revolution is on par with what one would expect from a V-8 engine. For these reasons and more, John McGinnis designed his double box-tail Synergy using the DeltaHawk, and hopefully the revolutionary aircraft will be flying soon, powered by this proprietary-design engine.

EPI Inc., Expertise + Integrity = Performance

Specializing in the design and development of larger (V-8 and above) piston engine conversions and redrives, as well as components and subsystems for aircraft, automotive, marine and industrial applications, EPI also has a substantial archive of technical writings by company founder Jack Kane.

What’s new for EPI is an updated web site making the navigation of Kane’s countless educational writings easy to find. The company not only offers products and service to those wishing to convert an automobile engine for aviation, it offers a free education.

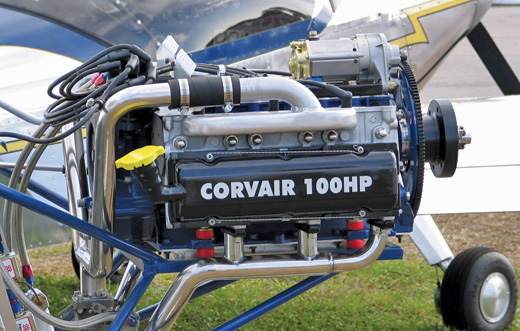

FlyCorvair.com

William Wynne is the go-to guy for all things Corvair-engine related. His book (build manual) is an indispensable tool for anyone attempting to convert the 1960s air-cooled, horizontally opposed, direct-drive, six-cylinder automobile engine for aviation. At last count there were more than 150 Experimental aircraft flying with an engine built from this manual, many of which use Wynne’s parts.

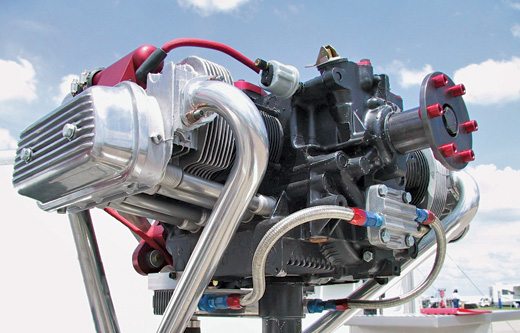

Corvair

One of his newest offerings, still in the testing stage at this writing, is a high-volume oil pump for those who have opted to also install one of the two “approved” and optional prop hub support bearings. Along with this new oil pump, it’s recommended that Corvair builders install the robust distributor Wynne offers, as it also drives the oil pump, and the extra load from the increased oil flow needs to be addressed.

At the beginning of 2012, Wynne started an interactive blog where anyone, manual owner or not, can post questions and comments that he will address, in addition to writing about topics of interest. The blog is independent from his web site.

Great Plains Aircraft Supply Company

Great Plains Aircraft Supply Company celebrates its 30th anniversary this year, headed by founder Steve Bennett. The company has grown to serve almost every facet of VW-powered flight, from half-engines (where the four-cylinder engine is cut down to two cylinders) to the elusive Type 4, the largest horizontally opposed (air-cooled boxer) engine produced for VWs.

Great Plains Aircraft Supply

With products including a small belt drive for higher revving, and the company’s newest offering, adapting the engine so that the propeller can be attached to the flywheel end, Great Plains seems to have the market covered.

What’s new is a complete FWF package for its flywheel-drive engines. The motor mount and exhaust were designed to fit Bruce King’s new BK1.3 all-aluminum, single-place, VW-powered homebuilt. The kit includes a bed-frame style engine mount, laser-cut flywheel side mount bracket, 35-amp three-phase alternator and mounting kit, prop hub, flywheel, starter with mounting kit, exhaust system complete with shrouds for carburetor and cabin heat, intake manifold and carburetor. The kit will fit any of the company’s VW-based engines, from 1600cc through 2300cc.

HaasPowerAir

With several hundred hours logged on Ben Haas’s Zenith STOL 801, he is prepared to offer firewall-forward versions of his all-aluminum, small-block V-8 Ford engine and belt-driven PSRU. In addition, HaasPowerAir can provide the Experimental aircraft builder with a wide array of custom parts. From motor mounts to starter adapters to bushings, Haas can fabricate it all. He is targeting the RV-10, Murphy Moose, Lancair, Velocity and any other Experimental aircraft needing a powerful, lightweight and affordable powerplant in the 200- to 400-hp range.

HaasPowerAir

Hummel Engines

Of the four Volkswagen conversion companies detailed in this guide, Scott Casler of Hummel Engines is the newcomer. With two-cylinder engines using a cut or uncut case (a VW is a four-cylinder horizontally opposed engine whose case can literally be cut in half, or the whole case may be used with an opposing pair of cylinders and pistons situated in the front of the case), and power outputs ranging from 28 to 45 hp, or full four-cylinder engines with power output as high as 85 hp from 2400cc, Casler offers an engine (or kit) for just about every application, from Part 103 legal ultralights to Light Sport Aircraft; he uses the Great Plains Force One front bearing and prop hub.

Hummel

Hummel Engines has the capability to perform the machining operations required for VW conversions, maintenance and upgrades, including the creation of its own billet-aluminum cylinders with Nikasil plating, capable of saving up to 2.5 pounds per cylinder over the stock cast-iron alternative. The cylinders are available in 92mm and extended-length 94mm sizes, ideal for long-stroke conversions, and can be purchased for an engine you already have. These cylinders are also easily adapted to the six-cylinder Corvair engine.

Geared Drives

Bud Warren and his daughter and “right hand,” Phyllis Ridings, were killed in a plane crash on May 7, 2011. This was just after they introduced their 200Z zero-offset retrofit PSRU aimed at Eggenfellner Subaru customers who were dissatisfied with the Gen X PSRU. The 200Z occupies a footprint slightly smaller than the Eggenfellner Gen X and requires no changes in thrust line, cowl or propeller. Any type of prop can be used, including the electric constant-speed unit offered with the Eggenfellner engine/PSRU, in addition to traditional certified hydraulic props.

One person who was a strong supporter of Warren’s efforts has taken over the web site and chat group, and is working with the family to fill outstanding orders and offer support. It remains to be seen whether the company can be salvaged.

Moteur Avance Mega, Inc. (Marcotte)

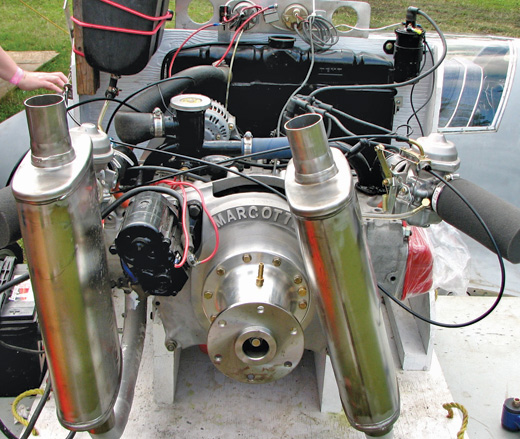

Founder Guy Marcotte’s planetary PSRU is intended to work with almost any auto engine via a custom adapter plate or proprietary 3555-T6 cast-aluminum bell housing. Marcotte provides bell housings for all Subaru and Mazda rotary engines, as well as Chevrolet, Ford and Chrysler V-8 bolt patterns.

Marcotte

The gears inside the Marcotte are machined from alloy steel and then hardened to 62 Rockwell C. The aluminum gear casing is machined from 6061 billet, and it houses all Timken bearings. Viton oil seals are used to resist the tortures of heat. The internals are lubricated by their own supply of synthetic oil splash, eliminating the worry about potential failure from external oil lines and hoses. Torsional resonance issues are reduced by a multi-pin elastomer bushing assembly that isolates the crankshaft from the redrive.

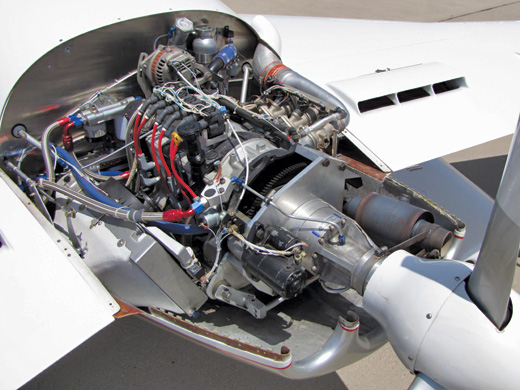

RAM Performance

Founder Ron Carr’s Subaru conversions are built in-house using proprietary parts including lightweight forged pistons, stainless-steel valves, bronze guides, and a one-coil-per-plug electronic ignition that’s cockpit adjustable and doesn’t require a computer. Starting with cleaned, inspected castings and forgings, each part is then machined to new tolerances. Rotating assemblies are balanced; heads are ported and bench-flowed and assembled to exacting tolerances.

Firewall-forward packages are custom-built, one at a time, but much of the production work is done in lots of 10 to keep overhead low. As a complete package the company offers an engine and redrive combo (2.2:1 ratio) and electronic engine controller, and this can also include a stainless-steel exhaust system with optional muffler, 4130 (chrome-moly) engine mount, aluminum radiator, twin fuel pumps and filters.

To keep the costs manageable, the company doesn’t exhibit at fly-ins or tradeshows. Instead, it concentrates on engine building and on offering machine shop facilities that can handle every operation necessary to remanufacture engines to new specifications.

Real World Solutions

It’s hard to consider a Mazda rotary engine conversion without thinking of Tracy Crook, who has been a staple in the engine workshop area at Sun ‘n Fun for a long time, sharing knowledge about converting the 13B, 20B and the Renesis engines for Experimental aircraft. Having proven the 13B and the Renesis engine on his RV-4, Crook recently brought his newly hatched RV-8 to life, powered by the three-rotor Mazda Cosmo 20B engine.

Mazda

Although Crook doesn’t offer a FWF package, his PSRU has been adapted to more than just the Mazda rotary. But for the rotary, Real World Solutions offers two versions of its planetary-gear redrives, the RD-1B with a 2.17:1 drive ratio, suitable for use in most auto-conversion applications (including the Mazda 13B) and the RD-1C with its 2.85:1 drive, designed for the higher-revving Renesis engine that has a 9000 rpm redline where it makes 232 hp.

Real World also sells and supports the EC2 ignition controller and EC3 electronic fuel injection (EFI) and ignition controller combo, both of which were developed for aircraft and are available for many engines, including the two- and three-rotor Mazda rotary, four- and six-cylinder Subaru boxers, inline-four, V-6 and V-8 Chevrolet and Ford offerings, as well as two-cylinder BMW motorcycle engines.

An engine-monitoring system that ties in with the EC2 and EC3 is also available. This is in addition to offering the parts needed to overhaul a Mazda rotary engine, regardless of its pedigree, and options for enhancing engine performance.

Raven Rotorcraft & ReDrives Inc.

Now in its 17th year of providing Geo/Suzuki engine packages, Raven’s Jeron Smith also provides reduction drive kits along with a book, Converting the Geo/Suzuki 3-Cylinder Auto Engine for Homebuilt Aircraft, for DIY types. Raven is also a source for rebuildable engine cores.

The highly modified 1000ULXX three-cylinder, direct-drive engine package is the “energetic toddler” that weighs 112 pounds but cranks out 60 hp. It offers four-stroke performance for less cost than the mainstream two-stroke, at the same weight, and does so at about half the fuel consumption while taking up less space.

The bigger brother, Raven’s new 1300SVX 90 hp (115 hp with the turbo upgrade) four-cylinder engine, now packaged in the latest upright configuration, is the engine of choice for trikes, powered parachutes, gyroplanes and other sport aircraft. Engine kits and complete running engine packages are available at a fraction of the cost of the equivalent Rotax 912, 912S or 914 turbo. It’s the chosen powerplant for Raven’s new STOL cargo aircraft, now in development at its skunk works in New Mexico. “Look for a couple of newcomers to our family of engines during 2012,” Smith said.

Raven

Revmaster, LLC

The new Revmaster R-2300 (2331cc) engine maintains Revmaster’s proprietary systems and parts, including its latest head design, the RM-049, which features thick cooling fins, hemispherical combustion chambers, improved access to the lower spark plugs and a host of other features, most of which are intended to handle the heat from making 85 hp—extreme for a VW conversion. The R-2300 maintains the earlier R-2200 engine’s maximum 82 hp, but does it at 2950 rpm continuous and offers 85 hp for takeoff at 3350 rpm.

Revmaster

The additional power ultimately comes from a 94mm bore plus increasing the stroke to 84mm, but that’s an oversimplification. “We’ve put a lot of energy into this redesign,” says Joe Horvath, president and founder of Revmaster. “On paper it looks like just a few minor modifications, but we’re really closer to a complete rework of the internals; crank specification, connecting rods, pistons and cylinders are all new.” The longer stroke results in greater displacement, longer connecting rods yield reduced vibration and improved torque, the lower cruise rpm allows for the use of longer props, and the higher peak horsepower can be felt in shorter takeoffs and steeper climbs.

The key to making this engine’s power is Revmaster’s proprietary four-main-bearing, 4340 forged steel crankshaft (boasting nitrided journals), which runs on huge (as compared to a stock VW) 60mm center main bearings. Thrust is handled by the custom-installed 55mm No. 3 thrust bearing at the prop end of the crank, formerly found at the other end. Fully utilizing its robust, proprietary No. 4 main bearing, the Revmaster crank has built-in oil-controlled variable-pitch propeller capability, unique in this horsepower range. Props other than wood, including composites (such as Warp Drive and Ivo), are usable on any Revmaster engine.

Revmaster has been working away on its next offering, a 3000cc, purpose-built aircraft engine loosely based on the VW, but sharing only cam bearings and a few dimensions so that it’s compatible with the VW Beetle. Most of the castings and forgings are proprietary to Revmaster. The company is looking forward to servicing the LSA and SLSA market with this air-cooled, lightweight engine once it has ASTM certification and is in full production.

Robinson V-8 Powered Aircraft

Brian Robinson has been instrumental in breathing new life into the orphaned Republic Seabee for nearly a decade by replacing the marginal (stock) 500-cubic-inch, 215-hp Franklin engine with a 400+ hp, all-aluminum, Chevrolet Corvette LS series V-8. Installing the V-8 conversion with Robinson’s proprietary PSRU, though not inexpensive, is substantially more affordable than the alternatives, and the additional power is easily worth the cost.

Picking up where he leaves off with the Seabee, Robinson has developed two additional PSRU lengths (with the original Seabee length being extended more than one could use in a tractor configuration), allowing for installations in a variety of airframes, especially when you consider that they can be built with either 1.7:1 or 2:1 gear ratios.

Based on standard Morse Hi VO chain and sprockets, the PSRU is sized and installed per the technical publication, and the chain is lubricated with engine oil via a pressurized spray bar. The design is loosely patterned off of the existing Franklin engine extension, with changes as required to maintain the existing thrust line and propeller position. All thrust loads (forward and reverse) are carried by the rear reduction unit thrust bearing.

Engines are sold only as complete systems. Reduction drives are not sold separately.

Take Off GmbH

The BMW motorcycle engine is gaining popularity in the trike and European ultralight markets thanks to Take Off. Whether used as a pusher in the Merlin weight-shift trike or mounted under the cowl of a Breezer or BX-2 Cherry, the opposed two-cylinder, four-stroke, air-cooled boxer engines represent an interesting alternative in the 90- to 115-hp range.

A complete, ready-to-run powerplant based on the R1100, R1150 or R1200 BMW motorcycle engine is available to the European market, but for a number of reasons not in North America. The company does supply everything else that’s needed for the conversion. It’s then up to the end user to find the core engine to work with. One reliable supplier of stock boxer engines is Beemerboneyard of Morristown, New Jersey (www.beemerboneyard.com), but there are others around the country.

A variety of lightweight reduction gearboxes are offered, with ratios from 2.8:1 to 3.5:1, which may be mounted in either above or below orientations (as related to the crankshaft centerline) providing designers with more options to match the thrust line to its optimal position. Custom wiring harnesses including a single wide connector for all required engine sensors simplify panel installations. A proprietary one-piece, dry centrifugal clutch engages the prop at engine speeds of more than 2000 rpm, and helps protect the engine from damage in the event of a low-power prop strike by transmitting power from the crankshaft to the redrive through a flexible coupling. This same coupling is in place to damp torsional vibrations, a killer of many engine systems.

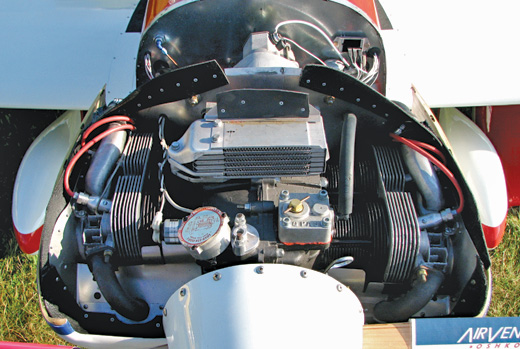

Stratus 2000

Stratus has been plugging away at producing engines and all of the associated accessories since 1992. Mykal Templeman, the second owner of the company, manages to continue support of his 175 or so flying customers, but otherwise has little to share in the way of new developments. If you are considering a belt-driven Subaru conversion, Stratus might be a good place to start.

Titan Aircraft

Although primarily an airframe manufacturer, Titan Aircraft provides engines for its T-51 scale Mustang, also available to those not building a Mustang. With three different small-displacement V engines, Titan offers a range of power options. Starting with the 2.5L Suzuki, this 24-valve V-6 makes 165 hp at 6500 rpm. Next up is the slightly larger 2.7L Suzuki 24-valve V-6, producing 183 hp at 6000 rpm. Both engines have impressive specifications including low power-to-weight ratios and a compact installed size.

Titan Merlin

Then there’s the monster 60°, V-6, 3.5L, four-stroke, liquid-cooled Honda engine. With all-aluminum construction, single overhead cams, four valves per cylinder, VTEC variable valve timing (duration and lift) and

electronic multi-port fuel injection, it produces 245 hp at 5750 rpm and 242 foot-pounds of torque at 4500 rpm. The power-to-weight ratio is amazing enough, but when you consider that Titan is conducting tests with a supercharger installed, amazing may be too low-key a descriptor. Installed in a T-51 test bed, the airplane will climb at 3000 fpm with 34 inches of manifold pressure, and at 8000 feet it will cruise at 215 mph with 30 inches of pressure. Autoflight of Waikato, New Zealand, makes the reduction unit.

Valley Engineering, LLC

Not known as much for VW engines as for its “Big Twin,” Valley Engineering, owned by Gene and Larry Smith, offers great deals in small engines. The four-stroke, 990cc, V-twin engine that produces 40 hp at 3600 rpm begins life as a Generac industrial engine, which Valley Engineering modifies by using a custom intake manifold, Weber carburetor and a belt-driven PSRU. The weight of the fan-cooled engine package (excluding oil, but including prop) with the 1.98:1 PSRU, 20-amp alternator, electric starter, oil cooler and filter, is 120 pounds. Although the engine is specified as 40 hp, 32 hp is the continuous rating. The direct-drive version weighs 105 pounds and is more suited for Part 103 legal ultralights.

As for the VW engine offerings, the company starts with parts from Great Plains and then provides a custom-designed engine/PSRU/prop package made for your project, which is flown in the company’s test aircraft during the break-in process. Customers are welcome to visit the Rolla, Missouri, facility for a demo flight, after which they’ll unbolt the engine, load it in your vehicle, and you’ll be on your way with a complete FWF installation ready to mount on your aircraft.

Valley Engineering sells complete engines of various horsepower ratings, and will provide a PSRU for your engine. In addition to engines and redrives, the company offers a complete line of wood props in standard and custom configurations under the moniker Culver Props.

Verner Light Aircraft Engines

The Verner VM133 MK (1329cc/85.13 cubic inch, air-cooled, opposed twin) engine was designed and developed to bring affordable four-stroke reliability and economy within reach for owners and operators of ultralight and Experimental/Amateur-Built aircraft. Since 1995 Verner engines have been installed and tested successfully in a number of kit aircraft including the Kitfox, Avid and RANS.

The traditional design of the engine employs well-proven concepts, allowing the cost of production to be relatively low. This approach to the design and construction is reflected in the affordable purchase price. Despite its low cost, the Verner VM133 MK engine incorporates many technologically advanced features including overhead cams, four valves per cylinder, dual spark plugs and a geared reduction drive with torsional vibration damper. The price includes a stainless-steel exhaust system, air filter, oil tank, oil cooler (with hoses), electric starter, dual CHT gauge with thermocouples and more.

Each engine is tested and fine-tuned at the factory during a 2.5-hour run time, eliminating the need for additional break-in procedures. All engines are covered with a six-month warranty, which unfortunately begins on the delivery date.

The engine’s maximum power of 84 hp is reached at 5500 rpm and is good for a 5-minute climb. Continuous power of 70 hp requires only 4200 rpm, which is not a lot higher than many direct-drive auto conversions.

Viking Aircraft Engine

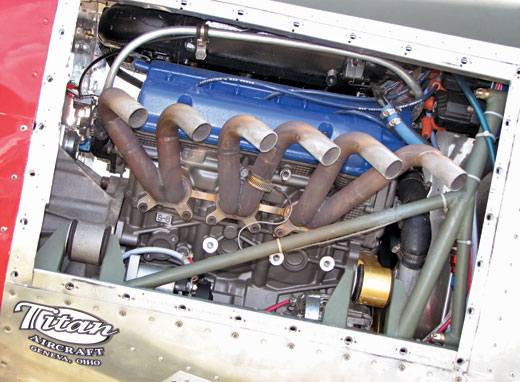

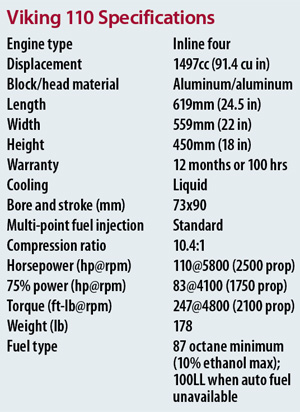

Introduced in the last year is the Viking 110, based on the all-aluminum Honda 1.5-liter engine. Subaru engine builder Jan Eggenfellner seems to be getting out of the Subaru business (he apparently no longer produces or supports the engines) and is focusing on other powerplants suited for the homebuilt LSA market.

He starts with low mileage (0 to 15,000) engines imported from Japan, but this time it’s the inline four-cylinder Honda Fit long block. Known as JDM (developed for the Japanese domestic market), these engines were pulled from otherwise good cars that failed Japanese emissions. They are the same engines designed for the U.S. market and are capable of going in excess of 100,000 miles (in an automobile) before even needing new spark plugs.

With plenty of CNC’d anodized aluminum parts adapted to the long block, Eggenfellner converts the engine to lie on its side to complete the low profile. He then adds a proprietary redrive consisting of helical-cut gears that drive the prop at a ratio of 2.33:1. The gears and ball bearings are lubricated by the unit’s static supply of gear oil, and a sight glass is provided for fluid level verification. A flexible drive coupling separates the PSRU from the engine to mitigate nasty harmonics.

The Viking 110 comes assembled and test run, and is shipped complete with a fully muffled exhaust, intake filter, engine mount, oil cooler and fuel pumps, and other goodies.

Viking

Conclusion and Caveats

It bears repeating that every buyer should research a purchase thoroughly before plunking down a hefty deposit. Just because you see it listed here, that doesn’t necessarily give it a green light. This is a guide, intended to introduce you to what is available.

Read the brochures closely. (See the Guest Editorial on Page 2 for more on how to examine manufacturer specifications.) Investigate every claim before signing a check for a new engine, and make sure the alternative engine you are considering is not only right for your airframe, but that you are up for the rigors of installation. A good place to start understanding the nuances of installing an alternative engine is with the collection of books called Alternative Engines. There are three volumes, available from CONTACT! Magazine.

Want to Know More?

Every major aviation event has some alternative-engine presence, whether via vendors or those who fly in with an auto-conversion aircraft. Consider visiting a few shows before you make a decision. Talk with people who have flown with the engine you are considering. Spend time with the vendors asking questions and listening to the answers. Ask for a list of customers who are flying an aircraft with the engine.

If possible, get some stick time in an aircraft with the engine, preferably in the same make and model of the project you want to build.

For the past nine years CONTACT! Magazine has hosted an alternative-engine fly-in, and in 2011 merged with the Golden West Regional Fly-in in Marysville, California. This event is a day of alternative-engine forums along with show-and-tell on the ramp. The Golden West event will be held June 8, 9 and 10, but the CONTACT! portion is on Saturday, June 9. If you fly in with an alternative-engine-powered aircraft, the entry fee will be waived. Details are at www.contactmagazine.com.

For more on installation of auto-conversion engines and special considerations, see the June 2012 issue of KITPLANES®.