As the editor of CONTACT! Magazine, a publication focused on alternative engines for homebuilts, I’m often asked what the most popular auto-engine conversion is. The answer is quick and simple, the Volkswagen. Sometimes that’s not the kind of detailed response expected, so the follow-up questions will usually lead me to count down the list of the most popular conversions, in descending order, with commentary on each, so I thought it might be fitting to recount it in print for this issue of KITPLANES.

| Company | Engine Category | Product | Details | HP Range | Contact |

| AeroConversions | VW-based | Engine, FWF | VW-based 4-cylinder, air-cooled | 80 | aeroconversions.com |

| Alturair | Rotary | Engine and PSRU | 1-rotor Wankel | 100 | alturdyne.com |

| Eggenfellner Aircraft | Subaru and Inline | Engine, PSRU, FWF | 6-cylinder Subaru and 4-cylinder Honda Fit | 100-200 | eggenfellneraircraft.com; vikingaircraftengines.com |

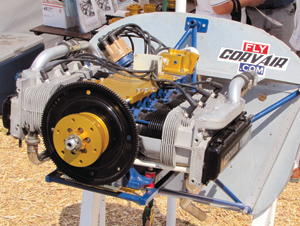

| FlyCorvair.com | Corvair | Engine, FWF | Corvair 6-cylinder | 100 | flycorvair.com |

| Geared Drives and PSRU for Subaru | Automotive V-8 and Subaru | Engine and PSRU | LS-Series GM V-8 and inline-4-cylinder conversions | 150-320 | geareddrives.com |

| Global Rotary Power | Rotary | Engine and PSRU | 1- to 3-rotor Wankel | 40-220 | rotaryengines.ca |

| Great Plains Aircraft Supply Co. | VW-based | Engine, FWF | VW-based 4-cylinder, air-cooled, 1600cc to 2180cc | 50-103 | greatplainsas.com |

| Hummel Engines | VW-based | Engine, FWF | VW-based 2- and 4-cylinder, air-cooled | 28-85 | hummelengines.com |

| Moteur Avance Mega, Inc. (Marcotte) | Subaru and Other | PSRU | glasairproject.com/marcotte | ||

| Powersport Aviation | Rotary | Engine and PSRU | 2-rotor Wankel | 215-250 | powersportaviation.com |

| RAM Performance | Subaru | Engine, PSRU, FWF | Subaru 4- and 6-cylinder engines | 115-300 | ramengines.com |

| Raven Redrives | Automotive-based inline | PSRU, FWF | 3- and 4-cylinder inline engines | 38-115 | raven-rotor.com |

| Revmaster Aviation | VW-based | Engine, FWF | VW-based 4-cylinder, air-cooled | 75-110 | revmasteraviation.com |

| Stratus 2000 | Subaru | Engine, PSRU, FWF | Subaru 4-cylinder engines | 105 | stratus2000.homestead.com |

| Valley Engineering | VW-based, other | Engine, PSRU, FWF | VW-based 4-cylinder air-cooled, plus converted V-twin engine | 40-100 | culverprops.com |

| Verner Light Aircraft Engines | Other | Engine, PSRU, FWF | Engines based on production cylinder assemblies with custom crankcases | 35-84 | flydiver.com |

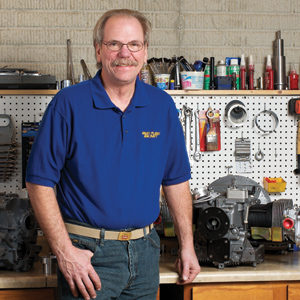

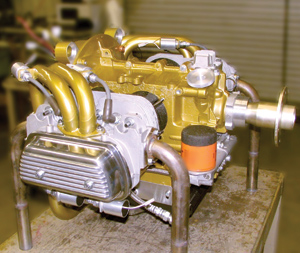

Volkswagen engines for aircraft have come a long way. Revmaster’s technically advanced powerplant is an industry leader.

Volkswagen

The VW engine has been a marginally successful auto conversion for nearly half a century. And why not? The horizontally opposed, air-cooled, direct-drive description sounds exactly like an aircraft engine. But notice I said marginally. That’s because it’s so simple and accessible that it gives the false impression that anyone can build one and fly it, and for the most part, that’s true. But the real problem is that in stock trim, as the engine was supplied in the automobile, the power-to-weight ratio is lacking. Still, with so many aftermarket auto parts suppliers out there, and with the "big bore" kits being readily available and pushing the engine well beyond the design limits, it was just too easy, and far too many backyard engine builders found out the hard way that with aviation, being conservative is often the best approach. The exploits of these innovators had left the VW with a bit of a black eye.

The AeroVee from Sonex. Extensive development meets low cost in a lightweight aero engine.

Throughout the decades, VW firewall-forward manufacturers have come and gone, but a few have persevered, learning from their mistakes and the mistakes of others. Through the efforts of these industry leaders, the VW has now matured into a highly refined alternative to expensive certified engines-when done right. Revmaster leads the pack with the most experience and the most technologically advanced engine, Great Plains following suit but also experimenting with a flywheel-end prop hub attachment. AeroConversions (AeroVee) was resurrected with the introduction of the Sonex (after a lengthy hiatus) and now offers a sufficient front bearing, and newcomer Hummel Engines offers an array of customizations and features with unparalleled attention to detail. The result is that anyone looking to purchase a reliable, turnkey 60- to 85-horsepower air-cooled engine need look no further.

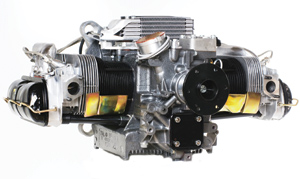

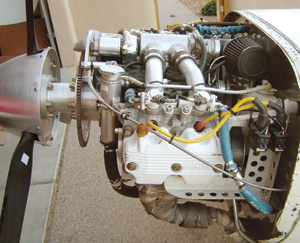

The four-cylinder, single-overhead-cam Subaru is a popular choice among homebuilders, but it requires a prop-speed reduction unit.

Subaru

Promising to pick up where the VW leaves off, the Subaru is the second most popular auto-engine conversion, with the EA-81 ushering in the Subaru revolution. Like the VW, it is horizontally opposed, but it’s also water cooled, providing close control of the internal component temperatures, and allowing for tighter tolerances and higher horsepower from the same displacement. The downside of this extra available horsepower is that it’s tapped at higher rpm, necessitating the installation of a propeller speed reduction unit (PSRU), which adds cost, weight and complexity. Couple this with the water cooling system, and the Subaru, like so many other conversions, is virtually out of reach for the do-it-yourself engine builder. At a minimum, most builders have to work with a PSRU manufacturer (or pioneer their own), and as with the VW, many manufacturers have come and gone since the Subaru gained popularity.

The little 1781cc EA-81 isn’t used as much as it once was, but the larger Subaru engines (both four and six cylinder, turbocharged and normally aspirated) are seeing much success in aircraft kits ranging from the RV series to the four-place Velocity.

Perhaps no one has brought more focus on the Subaru than Jan Eggenfellner of Eggenfellner Aircraft, Inc. His firewall-forward expresses intelligent engineering, bringing O-360 performance for two-thirds the price of a zero-time, used aircraft engine, but with the advantage of electronic ignition and electronic fuel injection.

Along with his successes, Eggenfellner has had his share of failures, causing one group of disgruntled engine owners to form its own support system. Many of the issues center on the PSRU, with the current engines running on Generation 3 of Eggenfellner’s gearbox; builders were expected to upgrade from previous generations at their own expense. Recently, Eggenfellner has shifted focus to a conversion of the Honda Fit inline-four-cylinder engine being marketed under the Viking brand name.

Stratus 2000 and RAM Performance offer the same price advantage as Eggenfellner engines, with the smaller 2.2- and 2.3-liter engines, and almost every firewall-forward manufacturer will sell its PSRU separately.

A newcomer to the Subaru arena is Bud Warren of Geared Drives. Known more for flying Corvette engines in four-place aircraft, Warren was challenged to adapt his PSRU methodology to a direct replacement for failed Eggenfellner PSRUs. He is not, however, currently offering a firewall-forward Subaru.

Maxwell Performance, a recent newcomer to the game, had to throw in the towel in mid-2010 due to legal issues stemming from the company’s takeover of the defunct NSI. Owners John and Gwen Maxwell made a great impression on the market, even going so far as to warrant NSI products. They were full of hope and promise, but never anticipated what was coming. The auto-engine conversion market needs more people like the Maxwells.

As with the Volkswagen and to some degree the Corvair, turnkey engine conversions (and PSRU manufacturers) have come and gone. Ross was perhaps one of the first to develop a geared PSRU for the Subaru; however, owner/developer Lou Ross passed away with no one to properly carry the torch. NSI failed miserably, both in design and marketing, giving birth to the now defunct Maxwell Performance.

Moteur Avance Mega, Inc. of Quebec, Canada, advertises 75- to 250-hp Subaru engines using the Marcotte PSRU that it also adapts to other engines. If you’ve ever been to the auto-engine workshops at Sun ‘n Fun, you’ve probably seen the Marcotte, offered by the late Ray Fiset.

As with most auto conversions, any negative reputation that Subaru may have earned throughout the past two decades is a result of the conversion, whether from a turnkey provider or a backyard mechanic. The engine itself is well-engineered and robust to say the least, and for the most part the PSRU is the hurdle.

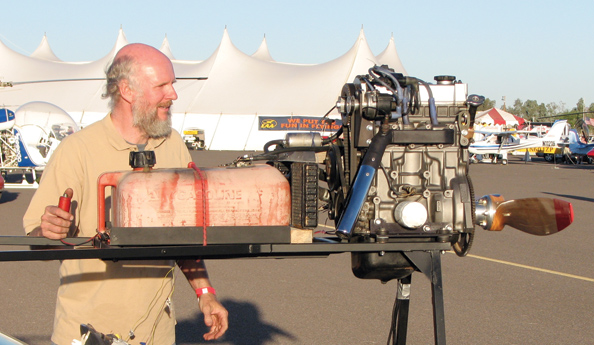

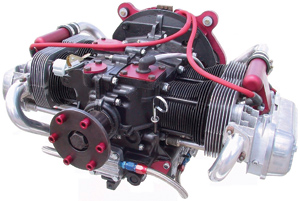

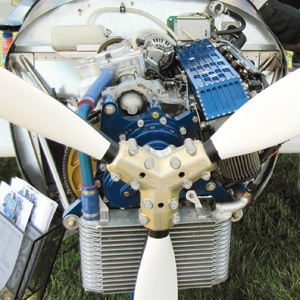

Mazda’s evolution of the rotary (Wankel) engine has brought it to a high state of development. This is a three-rotor example.

Mazda Rotary

Like the VW and the Subaru, the current success of the Mazda Wankel rotary engine came via a difficult path, and while I’m hesitant to say it’s as refined as the top two contenders, its successes can’t be ignored. Not many have tried to offer a turnkey Mazda conversion, though there have been several one-off Wankel engines that have tried, or are still trying.

When one sees a successful Mazda rotary auto conversion at a fly-in, odds are good that it is using a PSRU from Tracy Crook of Real World Solutions (RWS). Crook designed, manufactures and supports an engine-control system that offers redundant electronic ignition and electronic fuel injection not only for the Mazda rotary but for virtually any four- or six-cylinder auto conversion. This eases the installation of the ignition and induction systems, though many have been successful adapting the system that came from the automobile, using other aftermarket offerings or even converting to a set of carburetors.

Although Mazda rotary engine guru Dave Atkins of AtkinsRotary.com doesn’t sell a PSRU, he does work closely with the Experimental aviation community, providing engines and accessories. As a homebuilder, Atkins has flown his rotary-powered RV-6 from his home in Puyallup, Washington, to AirVenture Oshkosh (and back) every year for more than 20 years. With more and more rotary-engine enthusiasts following his and Crook’s lead, amassing logged hours, I’m confident the engine will reach a state of refinement that will rival any certified engine, while offering a better power-to-weight ratio, a longer TBO, and a much lower overall installation and operating cost.

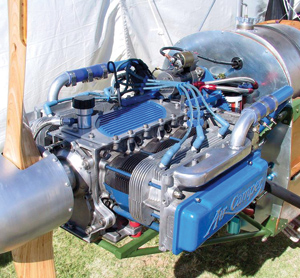

The 100-hp Corvair engine is popular because it’s simple, inexpensive to buy and maintain, and because the fleet hours are sufficient to support a thorough understanding of the type.

Corvair

No one can deny the fact that the Corvair conversion has come into its own. A 100- or optional 120-hp, horizontally opposed, silky smooth, air-cooled six-cylinder engine successfully bridges the gap between the VW and the rotary, and does it without the added weight and complexity of a PSRU or water cooling. Although technologically advanced from the WW-II-era certified engines it replaces, it’s still crude compared to modern automobile offerings, but that’s part of its allure. Simple in design, the hydraulically actuated pushrod engine is not overwhelmingly complex for the novice engine builder. But the simplicity has also given some the confidence to go into the firewall-forward business only to fail from lack of experience, leaving those who paid deposits out in the cold. Buyer beware! Research the company before you plunk down a hefty deposit.

I would say that the Corvair engine conversion would not be in the "sweet spot" it currently occupies today without the tireless effort of William Wynne of FlyCorvair.com. With nearly two decades of Corvair conversion research and development, including building and flying his own Corvair-powered aircraft, Wynne’s experience and dedication is unparalleled. Although he offers a firewall-forward engine, the Corvair is primarily a do-it-yourself project, with Wynne offering a comprehensive illustrated manual (including phone and email support) and all of the specialty parts one would need. Actual engine parts such as pistons, rings, rods and bearings are readily available from several vendors serving the large automobile market.

Like the VW, the Corvair has a long history powering homebuilt aircraft, and it wasn’t long before those who pushed the limits began breaking cranks from propeller loads. The fix is to install an additional crankshaft main bearing (dubbed the "fifth bearing") close to the crank, housed in an oil-fed adapter plate. Wynne developed the prototype that includes relocation of the thrust bearing from the rear of the engine to the front, nearest the prop. Although it was designed for R&D and potential mass production, it has been successfully flying for nearly 500 hours. The recipient of the prototype is happy with it. Two others have followed Wynne’s lead and are presently offering a fifth bearing with his blessings.

The GEO/Suzuki inline engine is popular with builders of WW-I replicas because of its form factor and weight.

Geo/Suzuki

Three- and four-cylinder, water-cooled, inline engines from the junkyard have been used successfully, albeit quietly, for several years now. These little gems are seemingly bulletproof, inexpensive to obtain and maintain, and are very light, especially compared to the power they can make. While more popular with trikes and powered parachutes (in the pusher configuration), we are seeing more and more of them at airshows and fly-ins in smaller Light Sport Aircraft types such as the Avid or Kitfox. At the bigger shows, you’ll find these engines in the ultralight areas, as they are an excellent replacement for the more expensive Rotax.

Although several companies offer an adaptation of their PSRU for the Geo/Suzuki, not many have put in the R&D time for the total package like Jeron Smith of Raven Rotorcraft and Redrives. With several versions of the company’s PSRU designed to work in chorus with the engine model they’re coupled with, it’s hard to find a greater selection of engines ranging from 38 to 115 hp. A few of Raven’s engines are also capable of being installed on their sides for space considerations. The newest offering is a three-cylinder, direct-drive, hand-prop version aimed directly at the Part 103-legal ultralight market, intended to power a 103-legal gyroplane.

The Honda Fit four-cylinder engine is being marketed under the Viking brand name.

And Many More…

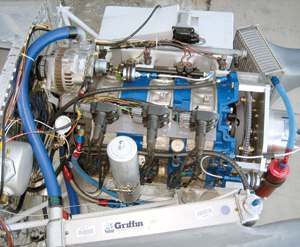

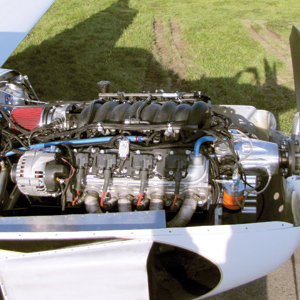

While these five engines have gained substantial popularity over all others, there are several more that deserve an honorable mention, beginning with Belted Airpower. For nearly two decades, Jess Meyers has offered his rugged belted PSRU, but recently efforts have been turned to complete firewall-forward kits for the RV-6, -7 and -9 series. Belted Airpower’s PSRU is compatible with the Chevrolet 4.3 liter V-6 and the Chevy 350 V-8.

Slowly getting a foothold over the competition is Geared Drives, offering an all-aluminum Corvette firewall-forward conversion for the RV-10 and any other application requiring the power of the O-540 at a lower price and with power to spare. If space is a consideration, Geared Drives has also pioneered the use of the Chevy EcotecLSJ, four-cylinder supercharged all-aluminumengine good for 150 to 245 hp. The key to the company’s success is the brainchild of proprietor Bud Warren: a centrifugal clutch (resolving potential torsional harmonics) and a PSRU that allows for a standard prop governor and certified constant-speed props.

The evergreen General Motors V-8 engine remains a top choice for aircraft that need 300 hp or more.

In addition to spearheading the use of the industrial V-twin in light aircraft, dubbed the Big Twin, Valley Engineering (aka Culver Props) has quietly offered a VW-based belted PSRU for many years, recommending the Great Plains engine. The company is now packaging an engine of its own coupled with its PSRU.

The Mini Merlin, marketed by Titan Aircraft to give its Titan T-51 (P-51 replica) the engine (and the sound) it deserves, is a modified 2.5-liter V-6 Suzuki, producing 165 hp at 6500 rpm, 162 foot-pounds of torque at 4000 rpm. An upgrade is available from a 2.7 version, netting 183 hp at 6000 rpm and 180 foot-pounds of torque at 4000 rpm.

All in all, the state of affairs in the automobile conversion arena is better than ever. A proven engine of just about any size and horsepower rating can be obtained. Support for the engine, either turnkey or home-brewed, is certainly available, especially with the various online groups. But none of these is truly for the faint of heart. It takes a hard-core experimenter to nurse the successful installation and operation of an auto conversion, and unless you are in it for the fun of Experimental aviation, sticking to the plans and installing the certified engine specified is the answer.