Picking an engine is much like courtship. Builders flirt with an array of choices, each attractive in their own way. Some are practical, some feed a fantasy, and others are little more than a learning experience. With enough exploration we focus on our true desire, and eventually a choice is made. There is a honeymoon, full of unquestioned commitment, before settling into long-term reality. We accept occasional troubles as part of the bargain, and find ways to fix whatever went wrong. Most remain committed, for better or for worse, treating each inconvenience as an endearing trait. For others, a fresh start is the only reasonable answer. After all, life is short, and the world is full of engines.

Practical Selection

So how to set emotion aside, and make a practical choice? Start with the Big Three.

First, carefully consider the primary mission. Tumbling through space in a bundle of smoke and noise easily justifies a radical choice. A Pitts owner might willingly trade a wee bit of reliability for increased performance. In contrast, the mission of a family hauler places reliability above all else, with economy running a close second. The distances are large, the passengers are dear, and a dollar saved is an extra dollar for the college fund. There is no reason to shy from rapidly maturing technology, but the overall theme should probably be more Clydesdale than Thoroughbred, strong and sturdy.

Second, know your personal limitations. As the builder of an Experimental, you’ll be expected to install and maintain the engine at a professional level. Are you willing to do the technical research necessary to support the kind of engine you choose? Common engine models enjoy a huge support community, while one-offs (and many “packages”) can easily have you flying solo from the time you open the box. Be aware of the personal requirements, and think about how you’ll meet them. Don’t be afraid of a challenge, but don’t jump in too deep.

Last, be a skeptic. Hang around the Experimental/Amateur-Built (E/A-B) game long enough, and you’ll see lots of world-beaters on engine stands. Only a few go on to be long-term winners. The same reality check applies to engine accessories, propellers, and panel gadgets. There’s no need to develop a cynical streak. Simply measure the claims against fundamental physics. Compare performance to proven alternatives. Seek out current users and professional opinions. You’ll hear interesting stories, make new friends, and perhaps save a few dollars.

The Engine Ecosystem

No engine lives alone. Whatever you choose mu st be integrated into the airframe. For example, a change in engine shape may require the fabrication of a custom cowl. Water cooling will require heat exchangers, which often require their own enclosures and ducting, and creating them requires some knowledge of fluid dynamics. A non-standard engine may require the design of a new motor mount and choosing new locations for firewall penetrations.

Engine accessory choices also drive changes. For example, choosing electronic ignition means installing an electrical system capable of supporting it. Two EI’s usually require a dual independent electrical supply. Electronic fuel injection generally requires the same, plus a high-volume return line to the tank of origin, which means you’ll also need a duplex fuel selector valve and additional tank ports. Designing a good system can be tricky; year after year, fuel system error is among the top three causes of engine stoppage.

Going conventional? Maybe just a few horsepower tricks? Sorry Ace, there is no free lunch. Cooling requirement is proportional to power output. Power mostly benefits climb performance. The dark side of climb performance is low airspeed, which means less dynamic pressure to drive air through a cooling system. In consequence, many hot-rodded installations are severely limited. They make power, but it can’t be used effectively because the builder failed to make a serious commitment to the design and fabrication of an improved cooling system. It’s not a small thing. Roughly half the builder population has trouble cooling a stock installation effectively.

Make the propeller decision, fixed pitch or constant speed, early in the planning process. The choice has an effect on the engine configuration, as well as smaller issues like controls, governor location, and spinner mounting. Look hard at weight and balance too. Switching at a late date can be a real problem.

One last detail; vibratory fatigue of propellers is a very real risk. A blade failure will tear an airplane to pieces in the blink of an eye. Experience says the least risk is found in one-piece wood or wood/composite props, so if your engine is a torsional unknown, fixed pitch wood/wood core is the conservative choice. Choose ground-adjustable propellers carefully; a few brands have a history of throwing whole blades. Aluminum propellers of any kind should be researched for operating restrictions, and those restrictions should be observed. The laws of physics don’t vary for anyone.

Bottom line? Be realistic. Dream about what you want, but also think about what you need. No one will take away your Man Card if you decline to buy the latest cool toy. Remember, lightness improves climb, drag reduction is more effective than power increase, and stock engines last longer. Sometimes it is best to leave the whiz to the wizards, and spend the extra money flying new adventures in a simple, reliable airplane.

The Rules

Before proceeding to the 2017 Engine Buyer’s Guide, let us first address the rules. The Guide is limited to engines available now or in the near future, as more or less complete units marketed to the Experimental community. We’ve skipped engines marketed as “certified only,” and those deemed impractical or unavailable. Along the same lines, we can’t list every individual engine variation a manufacturer may offer. Don’t worry, if you want a particular feature, someone will find a way to supply it. Just pick up the phone and ask.

You’ll find engines logically sorted by configuration or family, then listed in alphabetical order. We’ll make no distinction between traditional “aircraft engines” and “alternative engines,” as the line has begun to blur, particularly in the world of diesels. Instead, we’ll carefully describe each powerplant as we go, and assume our readers are smart enough to know (for example) that a Volkswagen was originally supplied in a car.

The marketplace includes a wide variety of interesting small engines. Many don’t produce enough power to fly a typical E/A-B aircraft. We don’t have space to list them all anyway, so here we draw an arbitrary line at roughly 50 horsepower. Some listed manufacturers also sell smaller engines; call or check the web sites.

Prices and weights are supplied by the vendors. Some prices are MSRP, while others may be a street price. Quotes to us in euros or other currencies were converted to U.S. dollars using exchange rates in effect at time of writing. All prices are subject to change. As priced, engines are supplied fully assembled, unless marked as “kit.” We’ve tried to determine exactly what accessories are included at a given price and weight, but all the possible combinations make our brains spin like Sean D. Tucker in a tornado. Trust, but verify!

The Engine Guide is a source of basic information. It is not an endorsement. Here at KITPLANES, we have personal opinions like everyone else, but in the Guide we make no judgments. You are the aircraft builder, so please, do your homework!

And now, ladies and gentlemen…the Guide.

Flat Four-Stroke

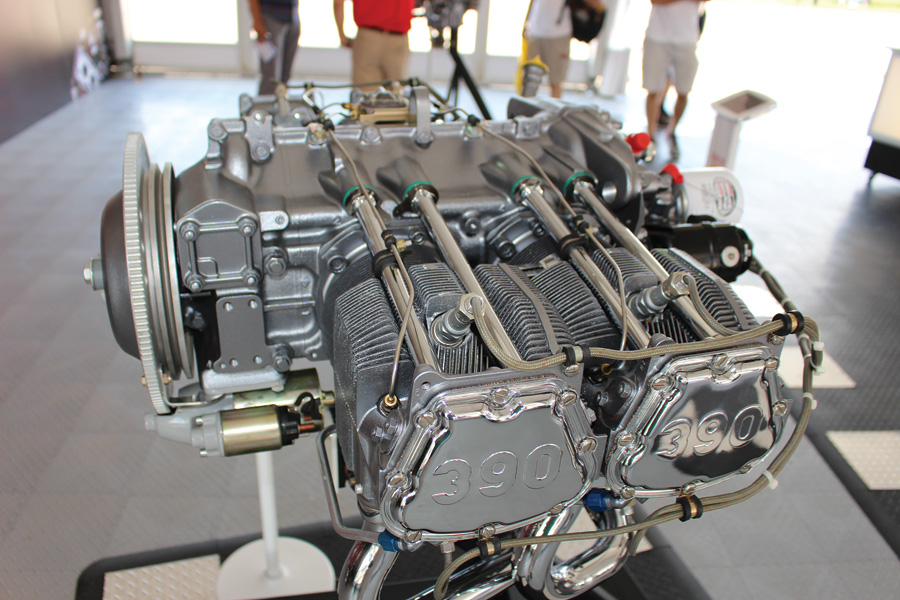

As we enter 2017, the #1 engine story has to be Continental’s consolidation. Continental Motors Group (CMG) purchased Engine Components International (ECI) and its companion business units in the spring of 2015. The purchase included the Titan brand, a popular source of Lycoming-like engines for the E/A-B market. ECI’s manufacture of PMA Continental replacement parts was ended, leaving the San Antonio facility to concentrate on the PMA Lycoming replacement parts market and the Titan E/A-B engine line. Then, in mid-August of 2016, Continental announced the consolidation of all production into its advanced manufacturing centers at Mobile, Alabama, and in southern Germany. Continental San Antonio would be closed.

Was CMG abandoning its Titan toehold in the E/A-B market, as some claimed? “Nothing could be further from reality,” said CMG’s Emmanuel Davidson. As he explained it, the company had invested very large sums in creating world-class production systems in the home plant at Mobile, and in its Technify plants in Germany. With additional component manufacturing capacity available in both locations, it simply didn’t make sense to upgrade the San Antonio facility too.

So, what does it mean for home-builders? At press time some details remained undecided, but the big picture was clear. The U.S. and German plants will each produce the components for which they are best suited, in OEM Continental, Continental Diesel, and PMA Lycoming versions. Complete Titan engines will come to life on a new flexible production line at Fairhope, Alabama, directly across Mobile Bay from CMG’s traditional Brookley Field base. The Fairhope airport (Callahan, KCQF) already hosts CMG’s Continental Motors Services MRO, as well as its U.S. center for aviation diesels; building Titans in the new North Building will be a logical extension.

All Titan-branded engines for E/A-B applications will be built to order using PMA certified components, with the exception of customer choices (a crank-triggered electronic ignition, for example), which may not be available in the certified market. CMG expects to pursue full certification for complete Titan engines, starting with the IO-370.

In another announcement, CMG disclosed a new master distributor agreement with Aviall, a division of Boeing. The stated focus of the new agreement is faster delivery, by keeping all of CMG’s popular OEM Continental and PMA Lycoming replacement parts on hand at the 40 Aviall locations around the world. For homebuilders, it means any direct sale of Titan-associated parts has ended. As very few E/A-B owners will qualify for an Aviall distributor account, the new agreement means those who do their own maintenance must purchase their PMA Lycoming/Titan parts through one of Aviall’s sub-distributors, typically aircraft parts retailers and engine shops. Independent engine shops that formerly purchased direct will also buy through Aviall.

There are plenty of choices in the Titan lineup, and prices are strongly competitive. Every displacement from 320 to 540 is available carbureted, or with constant flow fuel injection in three different brands. Simple speed-density electronic injection is also available. CMG-produced Bendix-style magnetos are standard, while most popular electronic ignitions are available. Weight conscious builders can select a magnesium updraft sump, and (with EI) a magnesium accessory case with a built-in oil filter adapter. Roller lifters will be available shortly. Everything will get 3-angle valve seats and sodium-filled exhaust valves. Counterweighted cranks (technically speaking, crankshafts with pendulum absorbers) are standard on all E/A-B-market engines of 370 displacement and up. A purchaser may select paint colors in any combination. Prices include a 3-hour dyno run for break-in, and preservation for storage. The warranty is homebuilder-friendly: up to one year on the shelf, followed by two years in service, with a maximum of three years total.

RV-10 and Rocket builders will particularly welcome Titan’s O-540 and IO-540 six-cylinder. Past choices were a single Lycoming version via the Van’s program, or a rebuild. The Titan six cylinder is built with all new PMA parts, in both carb and fuel injected versions, and may be optioned as desired. Pricing is very aggressive.

CMG is reporting some progress toward making its diesel engines available to the E/A-B market. The key concern is installation quality, so the company is taking a cautious path, working on beta installations with a few selected builders. The ultimate goal seems to be development of firewall forward packages much like the conversion kits for certified airframes, but details are sketchy. The first public announcement of an E/A-B beta “in the wild” was at AirVenture 2016: a CD-230 air-cooled flat four in a Van’s RV-10, which should be flying by the time this issue reaches your mailbox. The next beta will probably be a CD-155 in an RV-7 or RV-8. The water-cooled CD-155 is already available in the Glasair Sportsman, via the factory Two-Weeks-To-Taxi program.

With all the talk about Lycoming clones and European diesels, it’s easy to forget the traditional Continental offerings. Frankly, none of them has been selling in large numbers within the E/A-B market, one of several reasons for the Titan acquisition. Most O-200s and IO-240s go to Light Sport OEMs; homebuilders who need an O-200 tend toward an overhauled unit. In years past, the best E/A-B buyers for new six-cylinder Continentals have been Lancair Legacy builders. However, in July of 2016, Lancair placed the tooling and rights to the Legacy and previous models on the open market, so for now, all bets are off.

Things seem to be quiet at Lycoming. The primary outlet for a non-certified genuine Lycoming is Van’s Aircraft, through a kit program that permits one engine per airframe serial number. Those engines are largely configured to match Van’s firewall-forward kits and engine mounts, the front-governor IO-390 for the RV-14 being an example. A few other airframe kit OEMs have a similar arrangement, although nothing like the volume of the Van’s channel. The only remaining sales path is through Lycoming’s own “Thunderbolt” custom shop, as conventional outlets in the GA marketplace don’t handle the non-certified models.

Kit program engines come with Slick magnetos and a Marvel carb or Precision constant-flow injection. In theory, other ignition and fuel systems can be ordered via the Thunderbolt channel, but at press time, no one seemed willing to offer details about anything at Thunderbolt, technical or pricing, despite repeated calls and letters. We don’t know why. The prices in the tabular listing are from the Van’s program.

Katie Bell, Lycoming director of marketing and communications, did respond with an email stating the factory had adopted the ion nitriding process for crankshafts. Used commercially in WW-II Germany, and generally accepted in industry since the 1970s, ion (or plasma) nitriding replaces a gas nitriding process, speeds production, and is eco-friendly. The switch was FAA-approved in 2014. Bell also mentioned a proprietary anti-wear coating for flat tappets, and the opening of an automated piston production line, but offered no technical details.

Competition is good, and going into 2017, a resurgent Superior Air Parts appears to be positioned as a serious player. Their strategy is well-focused: concentrate on the core PMA parts business, develop a clean-sheet diesel for an uncrowded market segment, and sell a limited lineup of high-value avgas engines targeted at the volume center of the market.

At this writing, the Gemini opposed-piston twin-crank diesel has reportedly met its initial targets, and progressed to endurance testing, which includes harmonic analysis, cooling analysis, and piston ring studies. Initial plans anticipate a wood/composite fixed-pitch propeller for the 100-hp version, and a constant speed for the 125-hp. A Gemini 100 is expected to fly early in 2017. Based on its light weight, Superior also envisions marine and industrial markets for the Gemini, and should that effort be successful, it will leverage the aviation version with increased production volume and long-term development.

Lycoming-pattern engines are offered in four models from 160 to 215 hp. They’re built from Superior’s certified PMA components, which are marketed as better than the originals they were designed to replace. The list of improvements is extensive; we recommend a visit to the Superior web site for more detail than space permits in the Guide. XP engine buyers may select flat tappets or roller tappets, then choose Precision or Airflow Performance fuel injection, all at the same standard price. Although not listed here, a carb is also available. Superior’s own optimized updraft sump is standard, but with FI their popular horizontal “cold air” may be ordered at extra cost. Most XP engine combinations are approved for 91UL auto fuel, except the 8.9 CR, 215-hp IO-400.

Alone among the majors, Superior offers complete engine kits for assembly by selected independent shops. Buyers who prefer factory assembly may simply place an order, or visit the plant and watch Superior technicians assemble their engine, or visit the plant and assemble the engine themselves under the direction of a Superior technician. Warranty is 24 months or 1000 hours, with up to 12 months between the date of delivery and first flight.

The ubiquitous Rotax 9-Series 4-stroke just seems to get better and better. Over 50,000 9-series engines have been produced since the 912 was introduced in 1990, with product improvements every year, some major, and some quite subtle. Right now the 912 and 914 hold an estimated 80% of the LSA market, not surprising when horsepower, weight, reliability, purchase price, and support costs are considered as a package.

The big news will be the release of the new 915iS/iSC sometime in the second half of 2017. Although the fuel injected, turbocharged, and intercooled 915 has the same 83 cubic inch displacement as the other 9-Series engines, it is expected to maintain 135 hp all the way up to 15,000 feet. In fact, at roughly 8000 feet and higher, the little 915iS will produce more power than a typical 360 cubic inch normally aspirated engine. The only catch appears to be price; the current estimate is in excess of $35,000. Stay tuned; official prices have not yet been announced.

Two-strokes put Rotax on the map, but today only one model remains, the trusty 582UL. The popular C-gearbox has been dropped, so now all 582s come with an E-box and a standard electric starter. Unfortunately, the more expensive box bumped the standard price upward a bit…such is progress.

Andy Higgs and Kevin Eldredge are still swinging for the fence with their Advanced Component Engineering (ACE) high-performance cylinders, pistons, rods, and cranks for Lycoming cases. Although pricey, they arguably present the latest thinking in air-cooled piston engine design. Higgs is also developing a new series of heavy fuel engines, which are certainly worth watching. Eldredge recently accepted a position at Lancair and cannot devote full attention to building ACE engines. For now, assembly is farmed out to a respected custom shop.

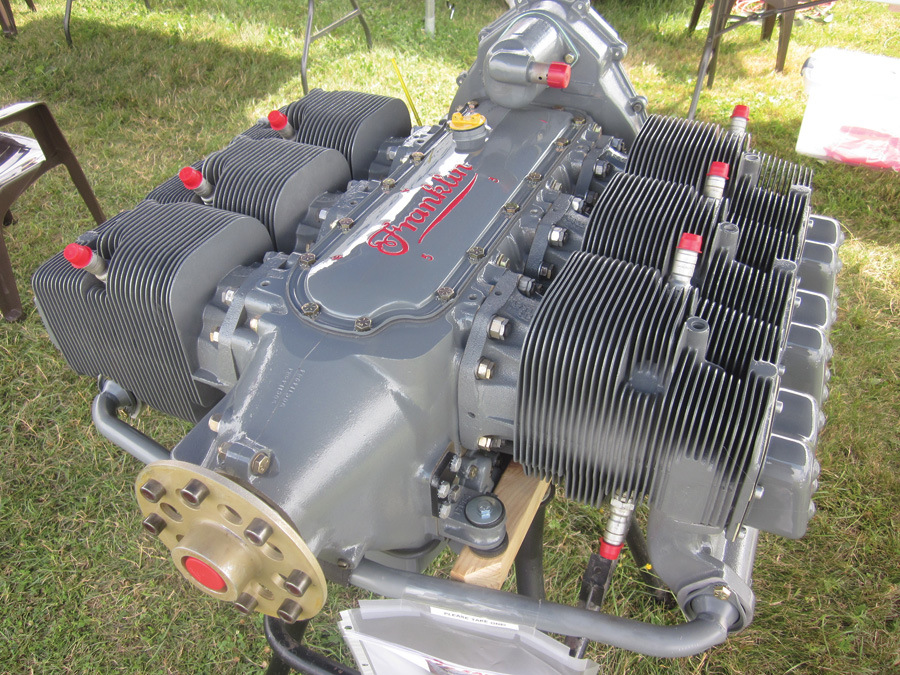

At deadline, Kelly Bartlett of Franklin Aerospace had just returned from Poland with news of an agreement that makes his company the sole U.S. importer/dealer of new Franklin parts. Bartlett also told us the Polish certificate holder, Franklin SP.Z, has steadily increased production, allowing the addition of “a multitude” of new parts to the Franklin Aerospace catalog. We’re sure a stable parts supply will be welcomed by Franklin owners.

Bartlett offers two engines, the 4A-235 four cylinder and the 6A-350 six cylinder. The E/A-B version of the 4A comes with Electroair electronic ignition and a Rotec TBI. A certified version, the 4A B-4, gets a Franklin SP.Z-designed direct fuel injection system. The 6A will remain available in the original 220-hp carbureted version, with 10.5-to-1 compression and Slick mags. A 6A with an 8.5 CR and fuel injection is expected to be certified at 200 hp, which will allow the use of lower octane fuels. Warranty is two years or 500 hours for the certified versions and one year for E/A-B models.

When we reported last year, Jabiru operators in Australia were in the odd position of warning passengers, in writing, that the Jabiru engine “had suffered a high number of failures.” Not surprisingly, many in the industry objected to the action, and questioned both motive and method.

As it turned out, the Australian Civil Aviation Safety Authority (CASA) had mandated the blanket warning before detailed investigation had established a specific cause, and thus could not (at that time) mandate a hardware-specific correction. The best quote comes from CASA’s own document, “Jabiru Engine Reliability Analysis Report“), released in June of 2016: “…the decision to impose operational limitations was taken as a precautionary measure, without the benefit of complete, comprehensive, and determinative data.” In the end, the problem was narrowed to a small group of Series 2 engines with 3/8-inch studs, used more than 500 hours in flight training, and not maintained per the manufacturer’s instructions. Let’s all hope this one has been put to rest.

Going forward, the big news is the arrival of two entirely new Jabiru engines, the 2210 four cylinder and the 3310 six. Unlike prior Jabirus manufactured by the now-defunct CAMit Aero Engines, the new crankcase, cylinder barrels, and heads are cast, not machined. The cylinders have nickel/silicon carbide bores, which are both wear resistant and highly corrosion resistant. There are a number of other changes too, and a price reduction of about $1,000. The new engines have been under development about four years, and meet both ASTM and JAR standards. The 2210 should be available around the first of the year, with the 3310 to follow in April.

Belgian engine manufacturer ULPower is growing fast, with dealerships in about 15 locations worldwide. Here in the U.S., importer Robert Helms tells us the key has been the development of more firewall-forward kits. Given an existing dynafocal engine mount, the usual path is an adapter so the stock mount structure can remain; typically the ULPower engines are lighter and need to be moved forward anyway. It’s a particularly handy approach to the Van’s RV series and similar, as the landing gear sockets are part of the existing mount. Ray Lawrence at Kaolin Aviation is doing much of the kit development; his own RV-4 sports a 200-hp UL520iS, which replaced a vintage O-320. The switch added 40 hp and lopped off roughly 40 pounds. Lawrence also has mounts and cowls available for the RV-6, RV-7, and RV-9.

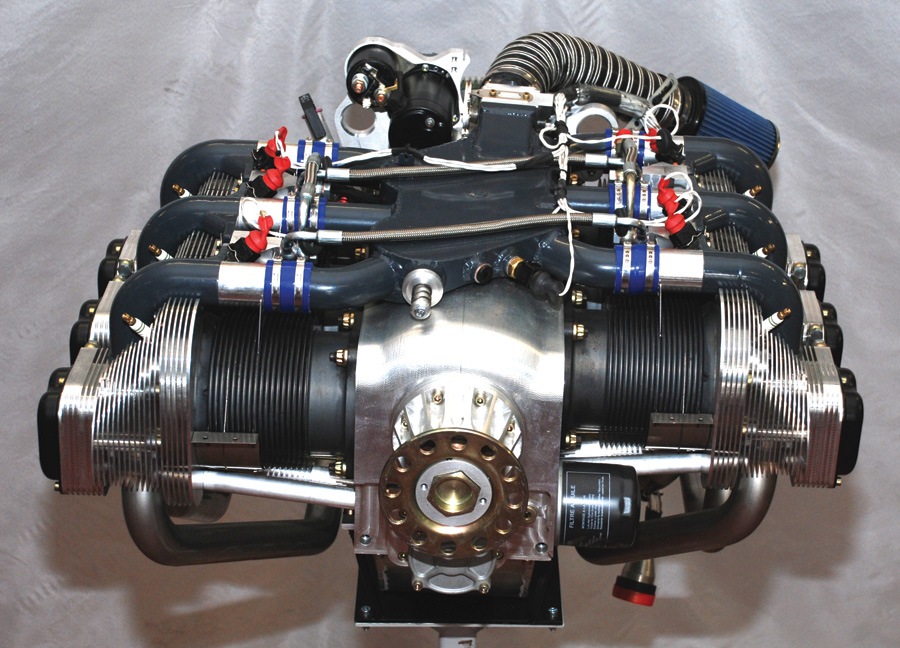

ULPower offers eight models ranging from 97 to 200 hp, all direct drive, air cooled, with fully integrated electronic ignition and multi-port fuel injection. A single ECU is standard. An optional second ECU makes the system fully redundant. Builders will need to incorporate an appropriate airframe electrical system, a return flow fuel system, and possibly a header tank. Inverted oiling is available, as is an Airmaster controllable-pitch prop.

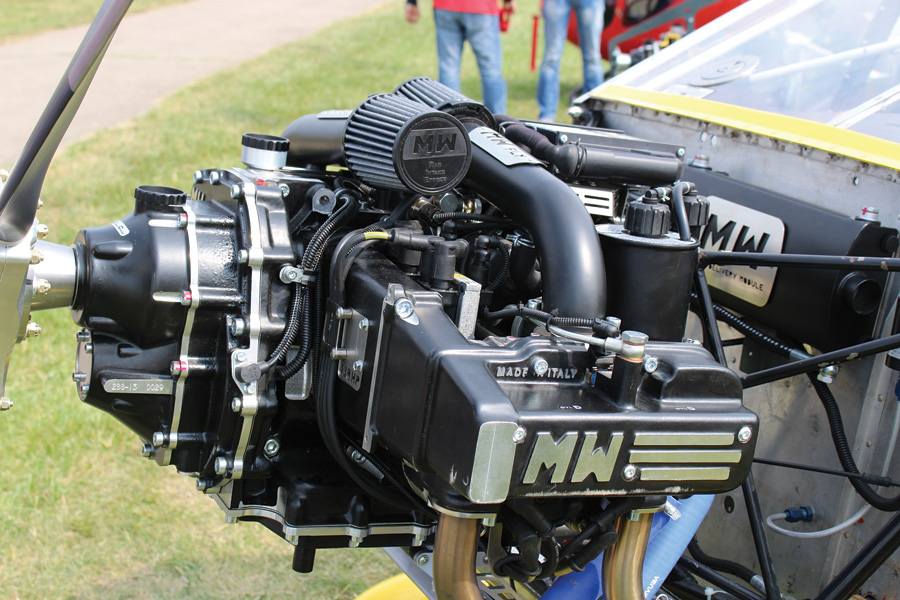

Italian made MW Fly has had a somewhat slower start, with a half dozen now flying in North America. The engines are available in two displacements, with direct drive or one of two reduction ratios. The ratios allow increased rpm for more horsepower, while swinging larger-diameter propellers. MW Fly engines are technically advanced: water cooled, fuel injection, with dual FADEC with data export, and an automatic compression release for low-rpm vibration control. Given a bit of inertia, we’ll probably see more of them in the air.

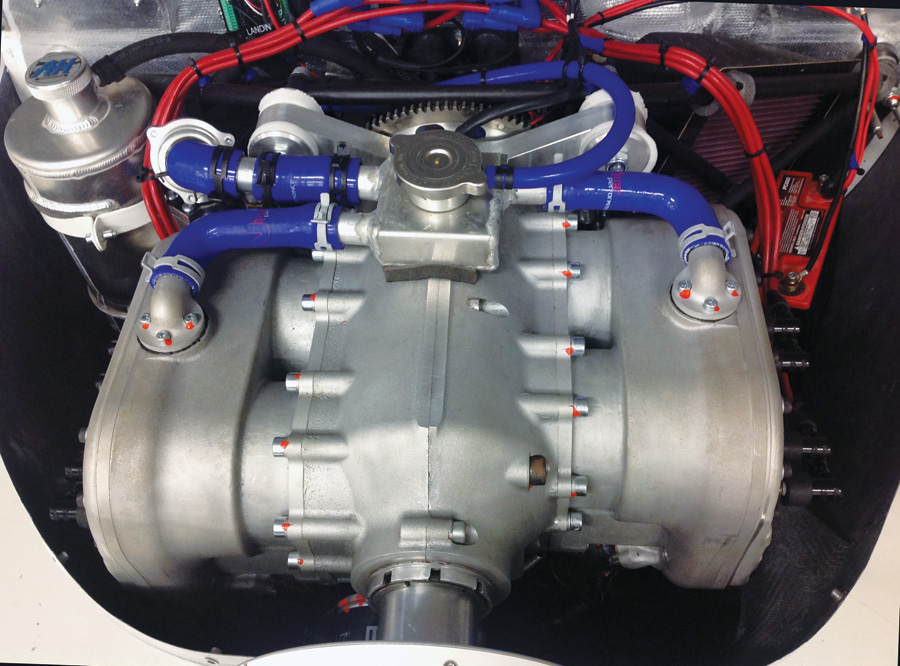

Another Belgian entry, D-Motor, builds a truly different engine: a short-stroke, liquid-cooled, valve-in-block flathead, with Nikisil cylinders and fuel injection, in both four and six cylinders. Although we often associate flatheads with lawnmowers and early Fords, it’s a sensible arrangement for a low-rpm, direct-drive aircraft engine. The key virtues are simplicity, which is good for reliability, a small width dimension, resulting in low frontal area, and less weight, which is always welcome.

There are also subtle details that make the D-Motor attractive. The fuel injection uses a pressure regulating pump, so the airframe does not need a recirculating fuel system. D-Motor mounting points are dimensionally the same as Jabiru, CAMit, and ULPower, so engine mounts are relatively easy to obtain. The US importer delivers every D-Motor with a complete installation kit, and the price even includes shipping to anywhere in the continental USA.

Let’s talk about a pair of twins. The 60-hp HKS 700E remains in production, through the joint efforts of Jerry Olenik of Green Sky Adventures and Chris Hatin of Quicksilver Aircraft Northeast. Together they are the sole worldwide distributors of the engine for HKS of Japan, interesting because Olenik reports fully 2/3 of their sales are outside North America. The 700E is a sweetheart: a four-stroke, four-valve-per-cylinder opposed twin with dual CDI ignition. Oiling is dry sump, with an oil tank and both scavenge and pressure pumps. The stated 121-pound weight includes the exhaust system, oil tank, and oil cooler, so the whole installation weighs about the same as an installed two-stroke with the same power.

Pete Plumb of Pegasus Power continues his effort at bringing the DP-1 twin to market, despite supplier delays. Cranks are in production, and he already has cases and other parts. The DP-1 is (in theory) exactly half a Continental O-200. However, the crankshaft, connecting rods, and pistons are fresh new designs. The DP-1 is a kit engine for the DIY homebuilder, who brings a donor O-200 to the party or buys new parts (accessory case, cylinders, pushrods, etc.) as desired. Plumb has been running a test mule on a stand for quite some time, so confidence is high. Stay tuned, and look for a production-based DP-100 sometime in the spring.

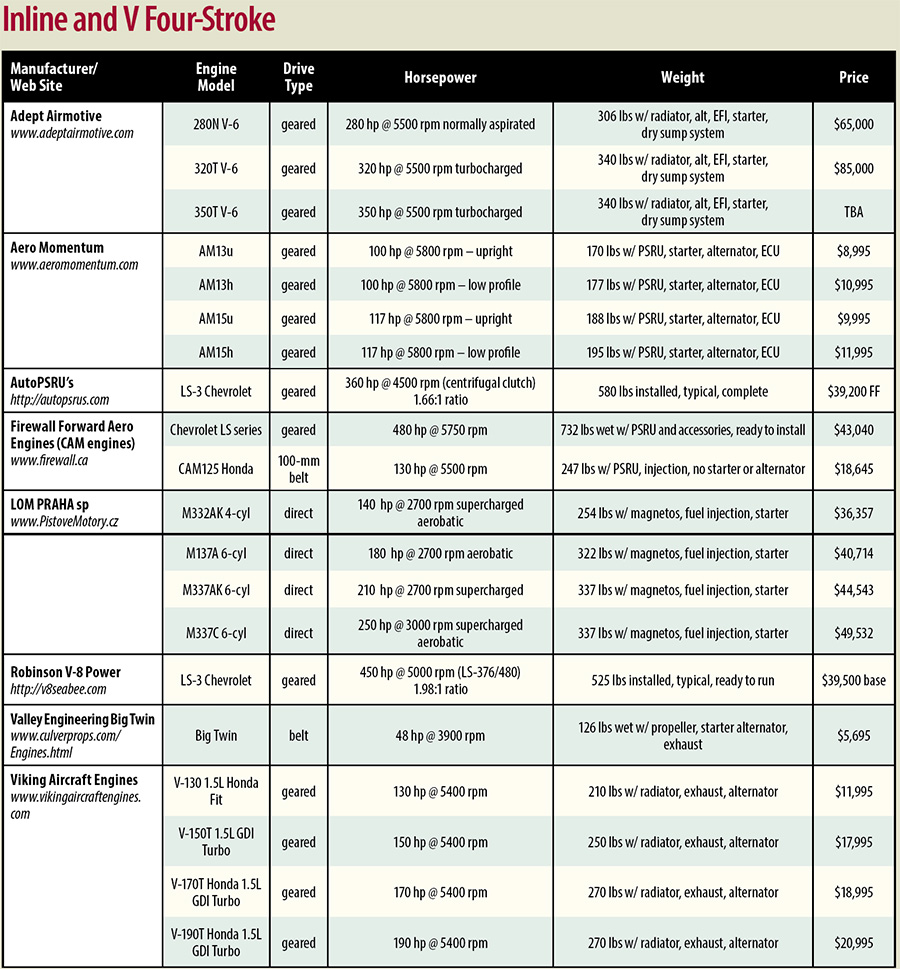

Inline and V Engines

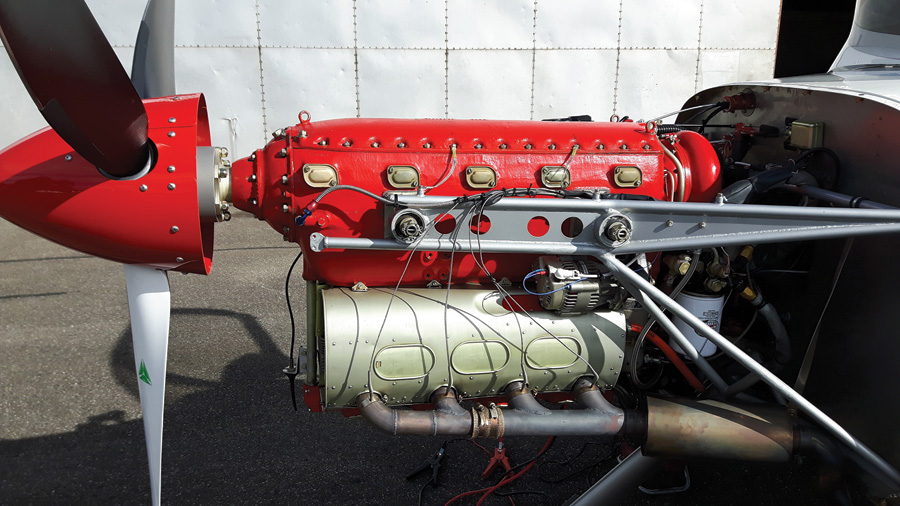

LOM PRAHA inline engines have a long history in Europe. Four models are currently in production, a supercharged 4-cyl and three 6-cyl versions. All are air cooled, fuel injected, and run on mogas or avgas. Interested purchasers should contact the home office in the Czech Republic.

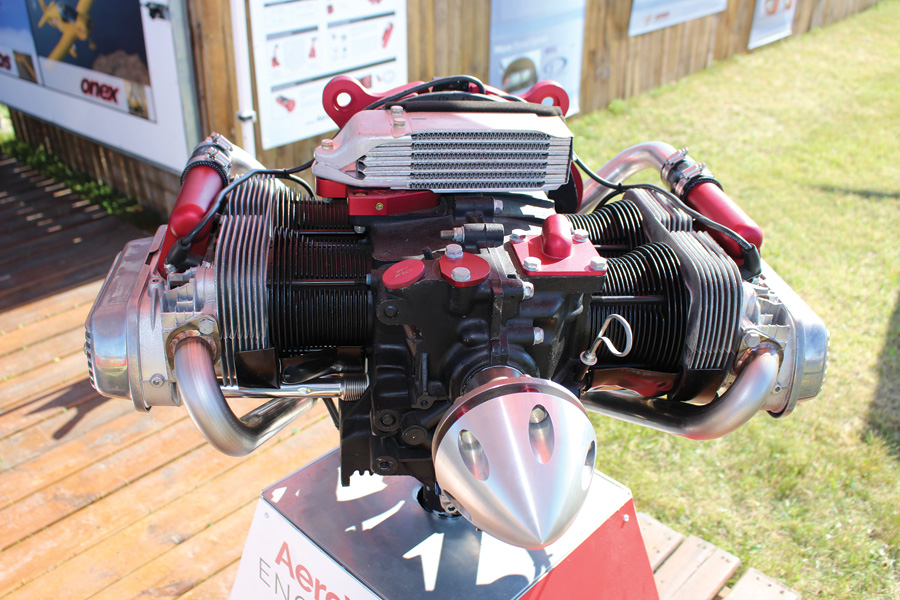

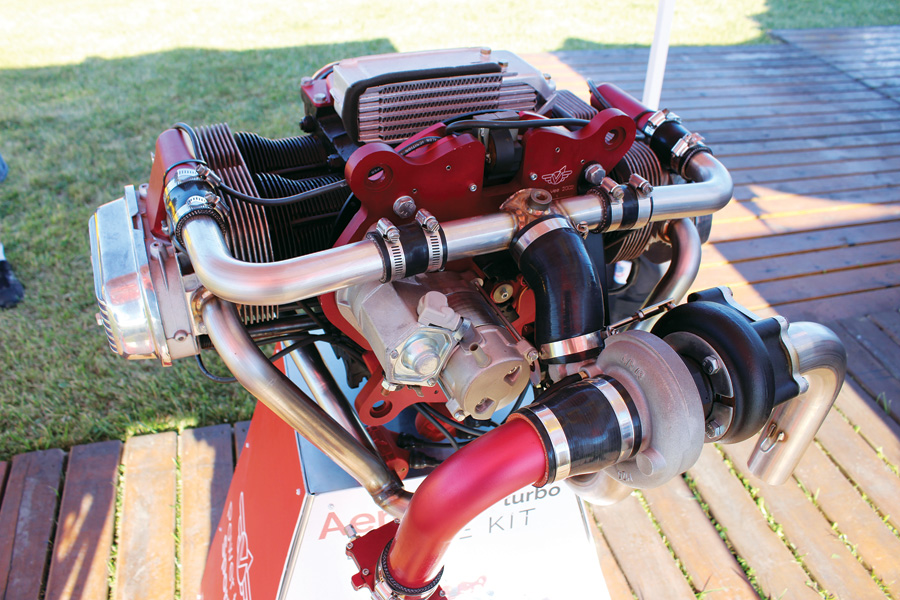

South Africa’s Adept Airmotive is poised to make a splash in 2017. The core engine is a clean-sheet 120-degree short-stroke gasoline V-6, with two chain-driven overhead camshafts per cylinder bank, and four valves per cylinder. Valve gear is typical of high-performance motorcycle practice, with the cam lobe acting directly on the valve, via bucket and shim lash adjustment. Sequential electronic fuel injection, individual coil-on-plug ignition, and dry sump oiling were incorporated from the start of design. Rated rpm is 5500; an integral spur gear reduction unit with a cush drive results in a conventional 2700 prop rpm.

The first Adept V-6 in the U.S. is a 320T, going on a four-place pressurized Lancair ES. It is expected to fly in April. A Legacy owner has committed to a 350T, and at this writing, the company was looking for an RV-10 owner interested in a 280N.

Robinson V-8 Power is best known for re-powering Seabee amphibians with LS-1 and LS-3 Chevy V-8s, but Seabees are a favorite, not a limit. They flew their own family Seabee well over 2000 hours on the first V-8, then upgraded to the newer LS-3 package flown by customers, and started clocking hours again.

The reduction units use a Morse HiVo chain and sprockets, properly sized for the application and oil lubed with a spray bar. The nose case is available in three lengths, from short to very long (for the Seabee, of course), with a choice of 1.7:1 or 2:1 ratios. The engines are purchased new from GM. A stock ECU is mapped with an export code for leaded fuel; there are no O2 sensors. The system works with any standard hydraulic CS prop.

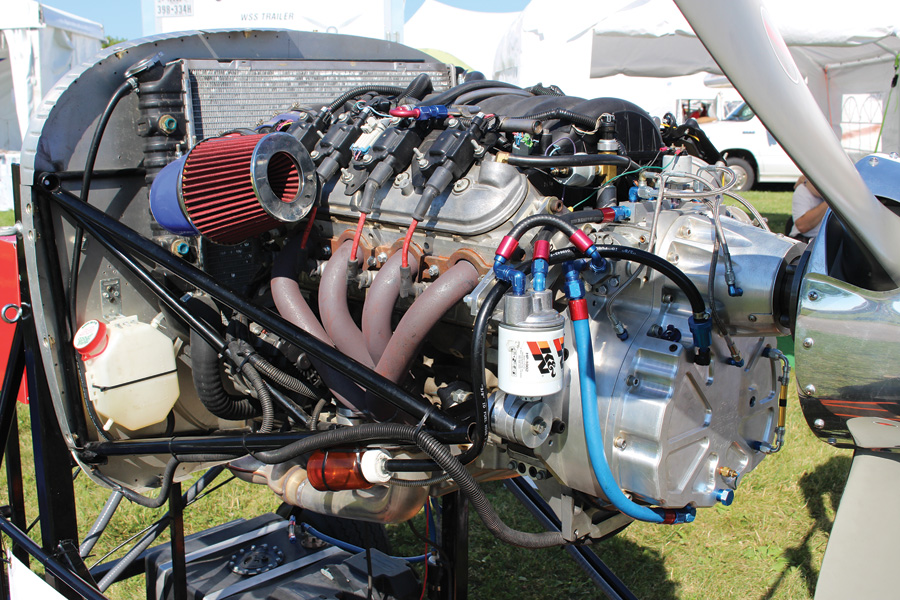

AutoPSRU’s is best known for a signature feature designed by the late Bud Warren, a centrifugal clutch that decouples the engine from the spur gear reduction box at idle. Owner Stuart Davis has upgraded the clutch, the cases, and other items. AutoPSRU’s also supplies a crate motor and a reprogrammed GM ECU.

Firewall Forward Aero Engines offers both Chevy V-8 and 4-cyl Honda packages. The Camdrive 500 PSRU for the V-8s uses three helical gears to transmit power, inside a fully machined billet case. The hydraulic prop governor is on a separate mount plate and is driven with a cog belt. Internal oiling is via pressure pump and spray nozzles.

The CAM100 Honda Civic package has been available for more than 20 years. The PSRU uses a 100-mm cog belt on well-supported sprockets. We’ve listed the normally-aspirated version here, but it can be ordered with a turbo for 125 hp.

You find Aero Momentum in Florida, offering very nice Suzuki-based 1300 and 1500cc packages in upright or low-profile versions. The low-profile engines are unusual, being based on blocks with a 70-degree slant, which were never sold in the US. Owner Mark Kettering buys components in Asia and builds complete new engines at the Florida facility using OEM and aftermarket Suzuki parts. The geared PSRU is coupled to the flywheel with a German-made Guibo torsional coupler. Fuel injection and ignition are handled by a Bosch ECU. The engines come complete with an exhaust system, an engine-mounted radiator, and an ND-style alternator.

Viking Aircraft Engines continues to offer an engine package based on the Honda Fit, but recently announced Civic-based packages with more power. They’re late model 1.5L GDI (gasoline direct injection) engines, and with a turbo, owner Jan Eggenfellner claims as much as 190 hp. Unlike previous Vikings, both Fit and Civic are now supplied with the block in an upright configuration. A 40-amp alternator is standard.

Budget-minded fliers with long memories consider Gene Smith to be a legend. His lightweight Valley Engineering redrive for VWs allowed turning props with significant diameter, and to demonstrate the performance gain, he designed his own airplanes. Today, the Smith family’s Big Twin continues the tradition, swinging a prop about six feet long, and producing lots of usable thrust at a very affordable price. How affordable? Look closely at the tabular listing. The Culver prop, another Smith family product, is included with the engine.

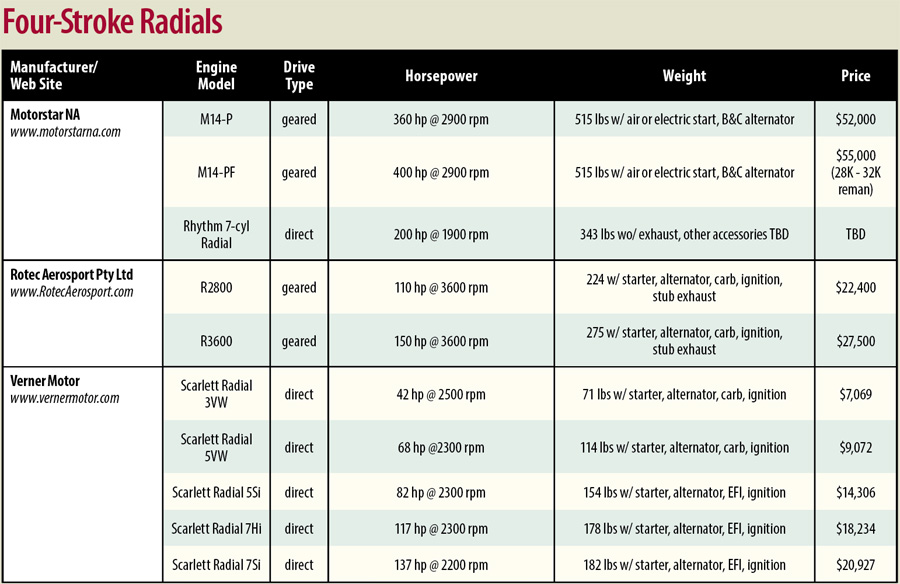

Four-Stroke Radials

Need a big radial? There are several sources for overhauled M14s, but Motorstar NA can supply a new Romanian-made M14P, having recently built some for a military contract. Motorstar’s “Rhythm” 7-cylinder is not yet in production.

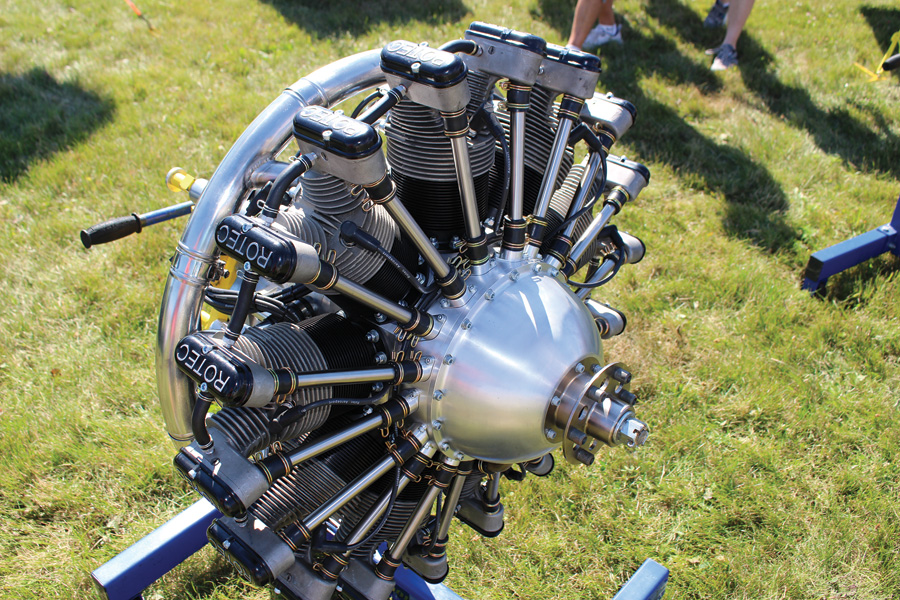

Currently the most popular radials in sport aviation are the Rotec Aerosport R2800 and R3600. The seven-cylinder R2800 is roughly 32 inches in diameter; the nine-cylinder R3600 is about 33.5 inches. Both are carbureted, with dual ignition. Planetary gearing allows large-diameter propellers for great low speed thrust. Most applications to date have been vintage themed with fixed-pitch props, but at least one R3600 is flying on a Van’s RV-8, with a constant speed from GT Propellers of Italy.

Rotec engines are sold factory direct. The factory will arrange shipping from Oz to anywhere. Delivery to most USA destinations is currently in the $1,500 to $2,000 range; call or email for a quote to your destination. Standard warranty is three years maximum, with not more than two years in the crate, plus one more or 200 hours from first start.

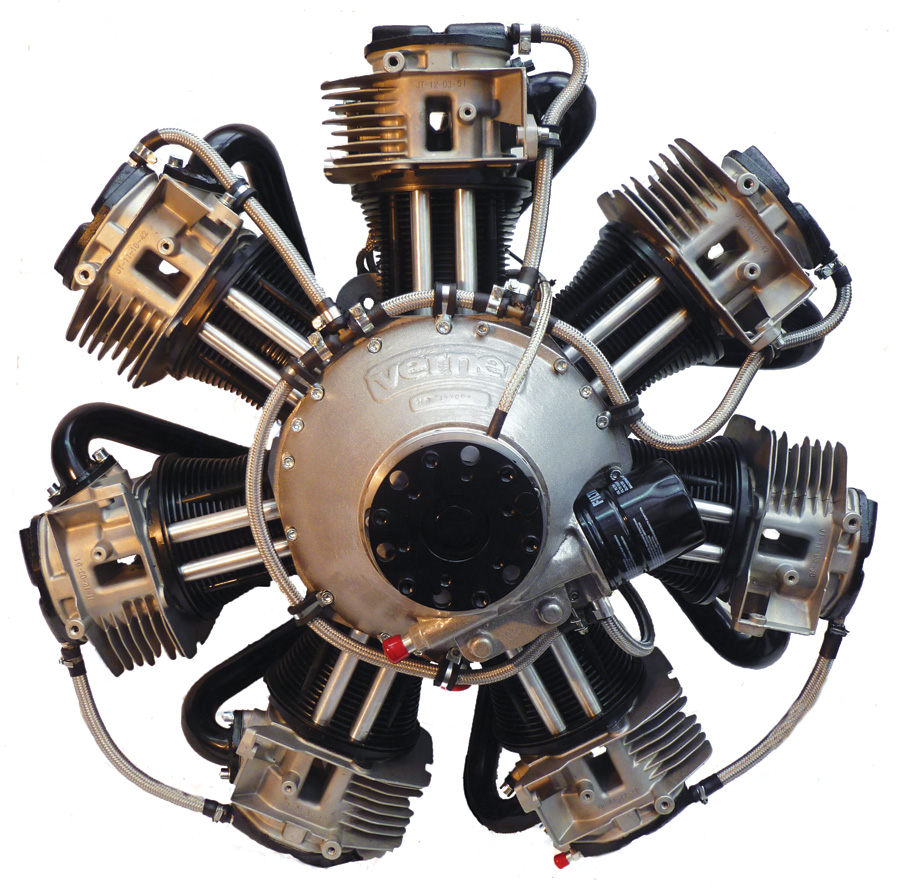

Verner Motor builds radials too, in five different models, with 3, 5, or 7 cylinders. So far, the most popular model is the seven-cylinder 7Hi, at 117 hp for takeoff, and 97 hp at 2000 continuous rpm. Kamil Verner’s designs substitute displacement for rpm; they are direct drive, not geared. A comparison with the Rotec R2800 illustrates the point. The 7Hi’s 4466cc swept volume is about 1.6 times larger than the Rotec’s 2800cc, but the geared R2800 spins its crank 1.57 times faster at full power. The 7Hi’s torque at the prop hub is 268 foot-pounds at 2300 and 254 foot-pounds at 2000, while the R2800’s hub torque at 2400 prop rpm is 240 foot-pounds after gearbox multiplication…remarkably close.

The 137-hp Verner 7Si is a 7Hi stroked to 102mm, which boosts displacement to a bit over 5 liters. Its 32-inch diameter is the same as an R3600. The five cylinder 5Si shares the 7Si’s 95mm x 102mm bore and stroke. The 5VW and 3VW are short-stroke engines of 28 inches in diameter, designed for low weight. The 7Si, 7Hi, and 5Si are standard with electronic fuel injection, while the smaller 5VW and 3VW use a Walbro carb. There are now three Verner dealers in the USA, and one in Canada, so don’t be surprised if radials start sprouting like daffodils.

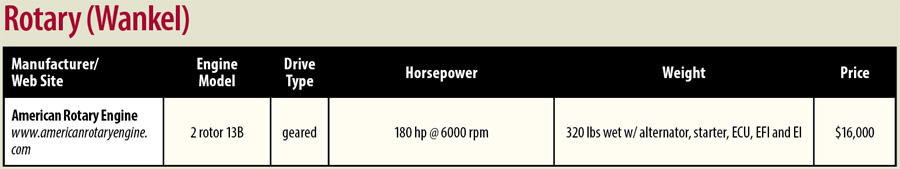

Rotary (Wankel)

The Guide’s only remaining survivor in the once-popular rotary segment is American Rotary Engine. A sister company under the same roof (Atkins Rotary) owns what is claimed to be the world’s largest storehouse of Mazda rotary parts, which is why owner Dave Atkins says American Rotary is not going away anytime soon. Aviation engines are built to order and equipped with the well regarded Powersport PSRU, one of the very few to undergo detailed torsional vibration analysis.

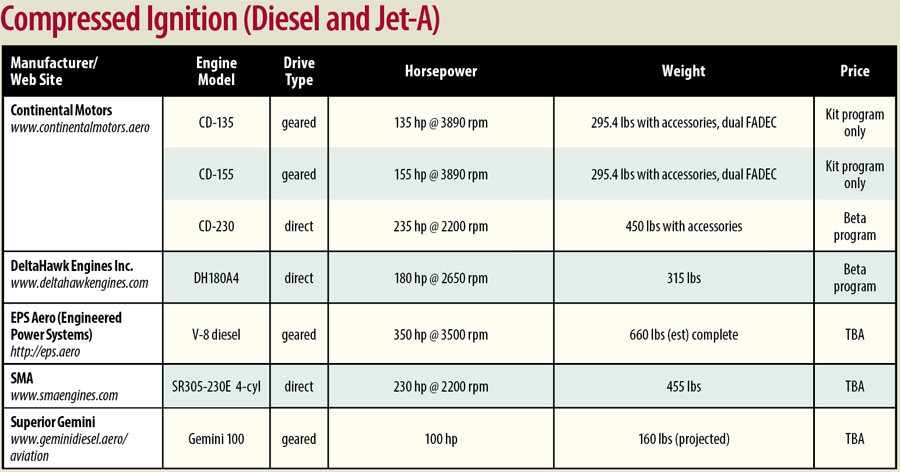

Compression Ignition, Diesel, and Jet-A

We’ve already told you about diesels from two broad-spectrum suppliers, Continental Motors Group and Superior Air Parts. Continental holds the lead in this rapidly developing segment, but more players are gaining speed. Top of the list appears to be Engineered Propulsion Systems (EPS), with their 8-cylinder, 4.3L four-stroke. EPS has been flying test engines since 2014, and expects to complete a full FAA certification program by the end of the year. The engine is technically advanced in many ways, so we expect this one to be “kit program only” for some time.

Deltahawk Engines received a significant investment boost in 2015, and it looks like they may soon have some engines flying on an Experimental. Yes, we said “engines,” plural; the application is Velocity’s V-Twin pusher, previously flown with a pair of 320 Lycomings. DeltaHawk’s first demo airplane was a Velocity, flown way back in 2003. In recent years, overall market confidence has slipped due to lack of deliveries, but with new owners, confidence is again high.

The DeltaHawk is a V-4, water-cooled two stroke. As a dry-sump engine, it can be configured upright or inverted. The V-4 is also relatively simple as compared to the other market entries (for example, fuel injection is via old-school mechanical injection pump), so release directly to homebuilders should not be a problem.

Last, we have French engine maker SMA with its SR305-230E four stroke. As a 230-hp air-cooled flat four, the SR305 seems like it would be a natural for the E/A-B market, yet following an abortive attempt to repower Cessna Skylanes, the SMA folks have been quiet. At this time, they’re still talking about kit program sales, but have no beta airframe applications to show us. We suspect the right builder could make a deal.

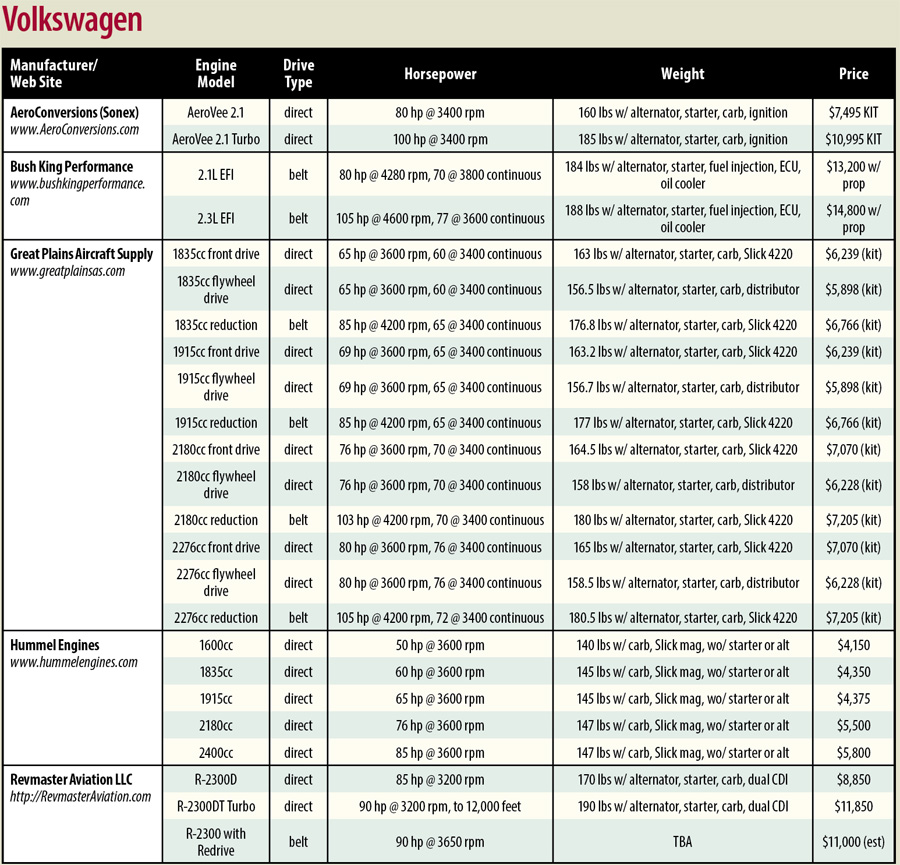

VW-Based

All hail the humble Beetle motor! Eighty years after the creation of the People’s Car, VW-derived flat-fours are still a popular choice with budget flyers. Mr. Porsche would have been proud.

The Elder Grand Wizards of All Things VW are unquestionably Joe Horvath and Ralph Maloof of Revmaster Aviation. Horvath founded Revmaster in 1959 to rebuild VWs for the auto market. Around 1965 he called on Maloof, then a manufacturer of small VW-powered hovercraft. Maloof, an aeronautical engineer, was paying $330 for new VW industrial engines; Horvath’s re-mans were $220, so he placed an order. By 1969 they were partners.

The R-2300 is a purpose-built engine for the aviation side of Revmaster, available in naturally aspirated and turbo versions. Key features are Revmaster’s own 049 cylinder heads, a billet crank, dual CDI ignition with 2 plugs per cylinder, and dual alternators to keep them firing. Maloof’s latest engineering project is a redrive unit for the R-2300.

Another long-term source for flying VWs is Great Plains Aviation Supply. GPAS is all about choice. In addition to “conventional” VWs driving the prop with a well-supported hub at the accessory end of the crank, they also offer VWs with prop hubs at the flywheel end, and reduction drives as well. All GPAS engines are kits; in return for some careful work, a builder saves money and learns a lot about the engine he/she will fly.

Bush King Performance offers the most extensive “all-in-one” package in this market category. As the name suggests, Bush King engines are focused on STOL performance, so a redrive unit is standard in order to swing a large prop diameter. Both the 2.1L and 2.3L engines are equipped with electronic fuel injection, typically a pricey option elsewhere. Last, Bush King packages include a matched propeller. The current favorite is a P-Prop from South Africa, built with a eucalyptus saligna wood core and a glass/carbon sheath.

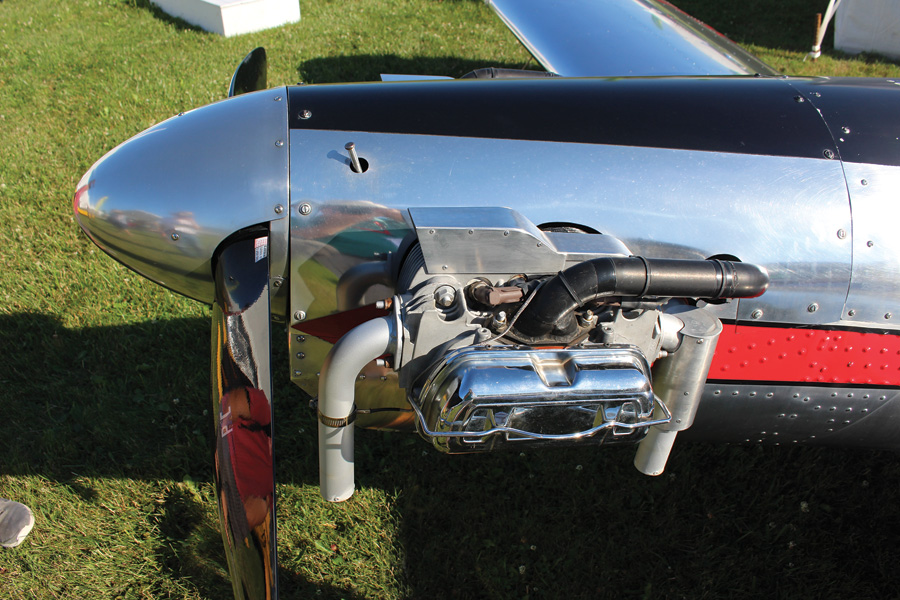

Aero Conversions is the engine shop side of Sonex Aircraft. They offer two versions of their 2180cc AeroVee, naturally aspirated or turbocharged. The AeroVee is also a kit engine, requiring owner assembly. Dual ignition is standard. The AeroVee crank and prop hub are a bit different; the hub is shrunk onto a straight section of the crank nose, which runs in a standard case, rather than being mounted on a tapered crank nose with hub support from an additional bearing housing. Although most components are off-the-shelf aftermarket VW, AeroConversion-sourced parts are well-finished billet aluminum, anodized red.

The People’s Engine guy in this group is probably Scott Casler of Hummel Engines. Casler’s focus is simplicity. Although he is happy to build something more complex, the typical Hummel engine is magneto-fired, and has no starter or alternator. The result is an inexpensive, very light VW suitable for simple, fun airplanes without electrical systems. Hummel also builds lots of half-VWs, twin-cylinder engines from 28 to 45 hp. All engines are delivered fully assembled after a test run.

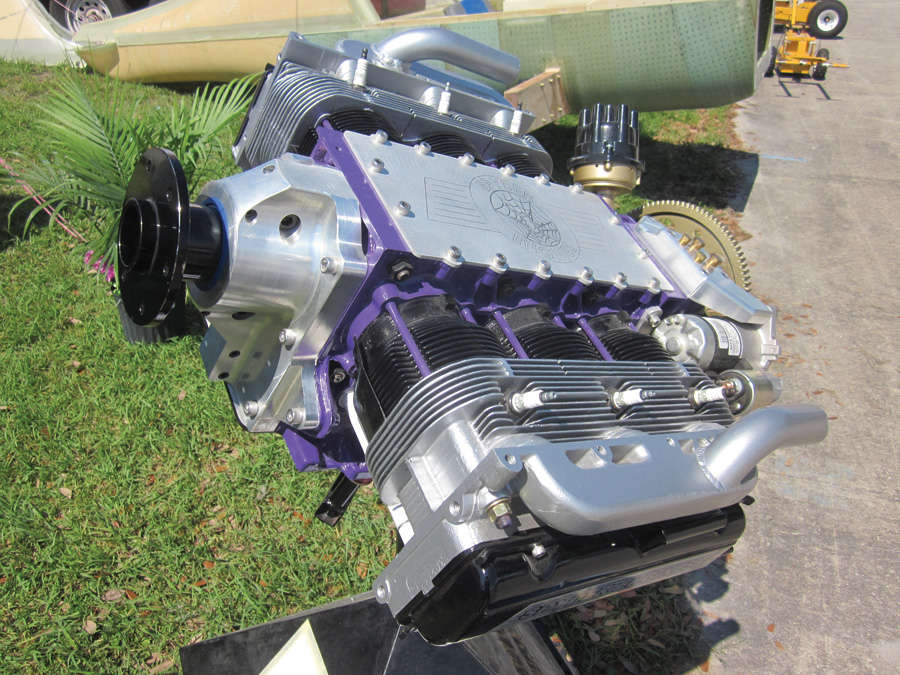

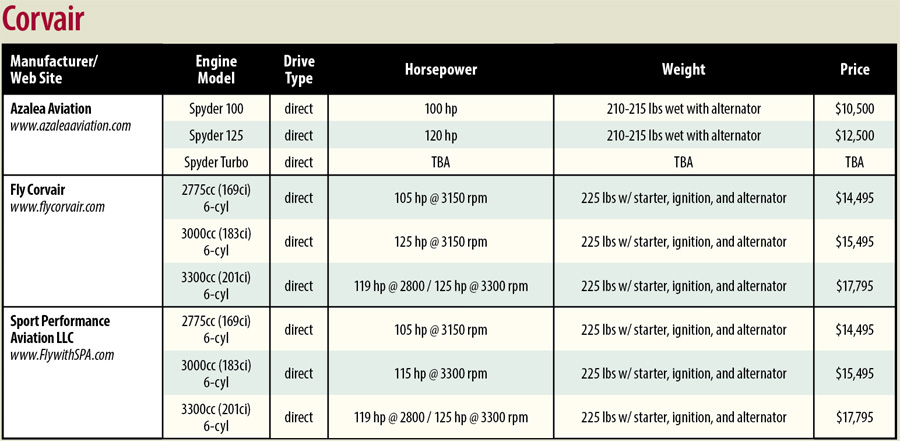

Corvair

Ask a question about flying GM’s iconic 6-cylinder, and sooner or later you’ll be directed to William Wynne of Fly Corvair. Nobody has written more, spoken more, or taught more about Corvair conversions than Wynne. He will build a complete engine to order, deliver a complete engine kit, or supply parts and teach you how to build your own. Wynne, like the guy in the beer commercial, is also an interesting fellow. Don’t believe it? Visit www.flycorvair.com and start reading!

Sharp-eyed readers will note that Dan Weseman’s Sport Performance Aviation and Fly Corvair have identical listings in the tabular data. It’s not a misprint, but rather a collaboration between long-time friends. Both manufacture parts; some are Wynne developments, and others are Weseman’s. Both told me it really doesn’t matter where you place your order; you’ll get exactly the same Corvair engine, and calling either phone will get help when you need it. Listed prices are for assembled engines, but they can also be purchased as complete kits for $2,000 less.

Azalea Aviation builds very attractive Corvairs to order. Owner Bill Clapp developed his own approach to the Corvair “5th bearing” hub support, which certainly appears to be robust. The latest development is a turbocharged version. The goal is not more power at sea level, but rather turbo-normalizing at altitude. Clapp reports he has maintained 36 inches of manifold pressure at 10,500 feet with the current test turbo. The end goal is a power package suitable for fast cruise in Azalea’s Saberwing composite 2-place.

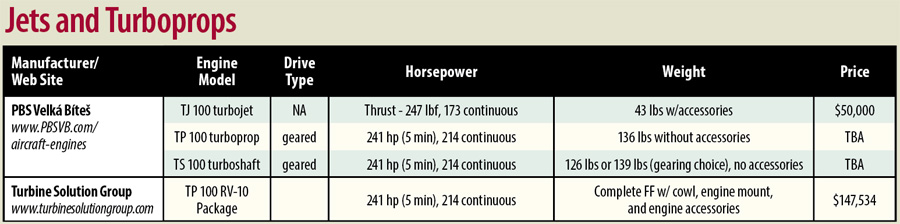

Jets and Turboprops

The Czech Republic’s PBS appears to be the sole provider of small jets and turbines for sport aviation. The TJ100 is familiar to most EAAers; it’s the little kerosene torch that powers the SubSonex personal jet. The TJ100 also powers at least one self-launched sailplane. We’re not aware of anyone using the TS100 turboshaft, but it’s only a matter of time before someone puts one in a kit helicopter. The PBS TP100 turboprop is available as a complete firewall forward package for the Van’s RV-10. Contact Turbine Solutions Group in Deland, Florida, for more information, or read Amy Laboda’s flight review [“Turbine-Powered RV-10“] in the June 2015 issue. PBS has established an office in Atlanta, Georgia, for direct inquires.

Two-Stroke Engines

While Rotax has pared its two-stroke line down to one engine, Germany’s Hirth continues to offer a full line. Here we’ve listed nine models suitable for typical homebuilts, from 50 to 110 hp. Take a close look at the hp and rpm tables. You’ll find most engines come in two versions, with one ported to move maximum torque to a lower rpm than the other. Although doing so reduces maximum power, it increases cruise fuel efficiency and reduces noise.

All engines have dual CDI ignition. Readers might be surprised to learn that every Hirth in the Guide can be ordered with optional electronic fuel injection. The listed prices do not include a belt reduction or gearbox. However, the U.S. importer, Recreational Power Engineering, maintains an excellent web site that clearly detail options and prices on each engine’s data page.

Compact Radial Engines is a producer of small engines for PPGs and PPCs, but they also build a pair of larger engines suitable for sport aircraft, a 60-hp twin and an 85-hp triple. Comparison shoppers will find prices to be attractive; these engines are sold complete with an exhaust system, a gearbox with a centrifugal clutch, and an electric starter. Gearheads will want to visit the web site just to look at the 3- and 4-cylinder two-stroke radials.

Our last entry is Simonini Racing, a builder of high-output two-strokes from Italy. The Victor 1 Plus is a water-cooled single with belt reduction. Water cooling may aid reliability, but does add the weight of a radiator. The Victor 2 series are water-cooled twins with gearboxes; with gearbox included, they appear to be 10 to 15 pounds lighter than engines of similar output.

We hope you enjoyed the 2017 Engine Buyer’s Guide. If we’ve made an error or missed any obvious sources of propulsion (within the stated limits), send an email please, and we’ll endeavor to do better next time. Until then, fly safe!