I’m kind of loose with my engineering and teaching. I don’t have a lot of hard-and-fast rules. One of them is that any time I have a calculation that I’m going to do more than twice, or that takes more than one or two steps, it gets reduced to a spreadsheet. I cannot calculate (you should pardon the expression) how much time it has saved me to do a voltage divider or a wire temperature estimation to have done the work (sometimes an hour or so on the spreadsheet) that saves literally lots of hours in the field.

That and spreadsheets allow me to print out charts that I use in the machine shop and post them near the machine on which they are used. 4-40 clearance hole? Easy —#31 drill at 0.120 inch, and if I want to tap the sheet behind it then a #43 at 0.089 will do just fine.

This month let me take you through a few of the spreadsheets posted at my college website. You can download a zip file. It contains a few dozen spreadsheets, some of them incomprehensible unless you are familiar with the subject, but you are certainly free to use them if you can figure them out.

I’m going to take from them what I think is the most usable information and try to explain them so that you can use them.

1. First of all is machscrw.xls. Here you will find all machine screws from #0 through inch, everything from threads per inch (both NC and NF), clearance drills, tap drills, head sizes for round, flat, and fillister heads, hex nut sizes, and washer outside diameter, inside diameter, and thickness.

a. I’ve got this chart on the wall behind my drill press in a frame to keep the cutting oil and metal shavings from destroying it from time to time.

b. As the note at the bottom says, in “soft” aluminum (say, 5052H32 or the like) cut yourself some slack and make the drill bit a size or two larger. I regularly go to #42 (0.093) for 4-40 with no ill effects.

You may find altitude.xls useful to figure out whether or not you are operating in “standard atmosphere.”

2. Second is altitude.xls. You may find this useful to figure out whether or not you are operating in what is called the “standard atmosphere.” Temperatures or pressures may be different from what you are currently testing your airplane in, and it may explain some differences in the data that you are recording.

a. Lots of data with reference to sea level (0 msl). However, here we introduce the convention of “E to the power.” This may take some thought if you’ve never seen it before. Let’s take, for example, the density of air at sea level. It says that it is 76.5E-3 pounds per cubic foot. E-3 means that the numbers in front of it are multiplied by 10-3, which we remember from high school algebra as divided by 1000. So, the actual value of the density is 0.0765 pounds per cubic foot.

b. Get this convention down now, because it is going to be used a whole bunch in future articles.

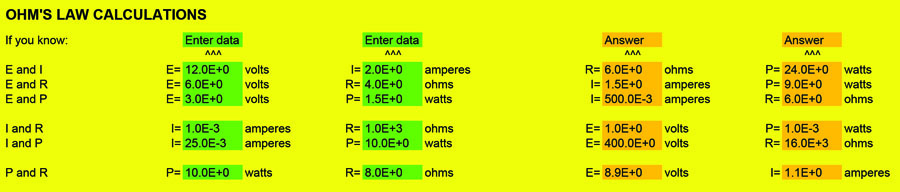

3. You may find ohmslaw.xls useful if you have to convert from power to resistors to current to voltage on a regular basis.

a. Here we introduce a whole new concept. You fill in the data in the green boxes and the answers come up in the orange boxes.

b. Example—you have a 150-watt landing light on a 12-volt aircraft. How much current does it draw? You know E (electromotive force, or volts = 12 volts) and watts (power = 150 watts), so you have to either use a fuse or circuit-breaker for a current of (I) = 12.5 amperes (“amps”) (plus whatever overcurrent or safety factor you wish). Me? That’s a 15-amp breaker.

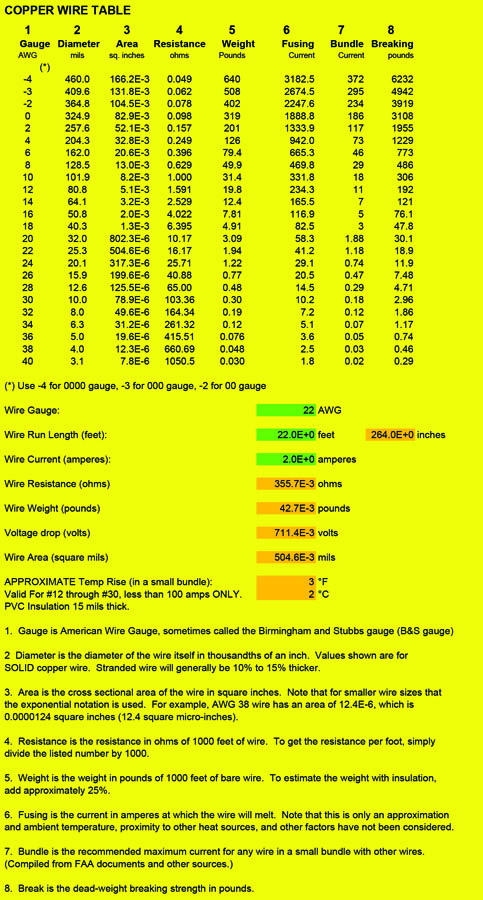

Not many wire tables give fusing current, bundle current, or breaking strength, but wirecalc.xls does.

4. Here is the granddaddy of them all, and I have this copied into my engineering binder that I carry with me nearly all the time. wirecalc.xls is the ultimate wire table reference and calculator. Ten years ago it was a neat spreadsheet; today they’d probably call it an “app.” Sigh.

a. Yes, it is a wire table. It is the most complete wire table I’ve ever seen. Not many wire tables give fusing current, bundle current, or breaking strength.

b. Fusing current is the current at which the wire will melt.

c. Bundle current is the current recommended for a wire in a bundle of wires that may or may not be run to the maximum current of each wire. It is extremely conservative and may be derated (in my personal experience) by a factor of 2:1 without any problems. This is my personal opinion; your mileage may vary.

Coming up? If you will recall in the last three articles, I’ve taken you through the mill on voltage regulators. I’d like to then take you through a “theory reduced to practice” on a lamp dimmer using all the techniques that I’ve used in these articles.

Then I’d like to take you through the “anatomy of an ADS-B installation” that I’ve done in the RST Engineering C-182 heavy that you might want to consider prior to 2020. From there? Who knows; certainly not I.

Until then…stay tuned…

![]()

Jim Weiris the chief avioniker at RST Engineering. He answers avionics questions in the Internet newsgroup www.pilotsofamerica.com-Maintenance. His technical advisor, Cyndi Weir, got her Masters degree in English and Journalism and keeps Jim on the straight and narrow. Check out their web site at www.rstengineering.com/kitplanes for previous articles and supplements.